-

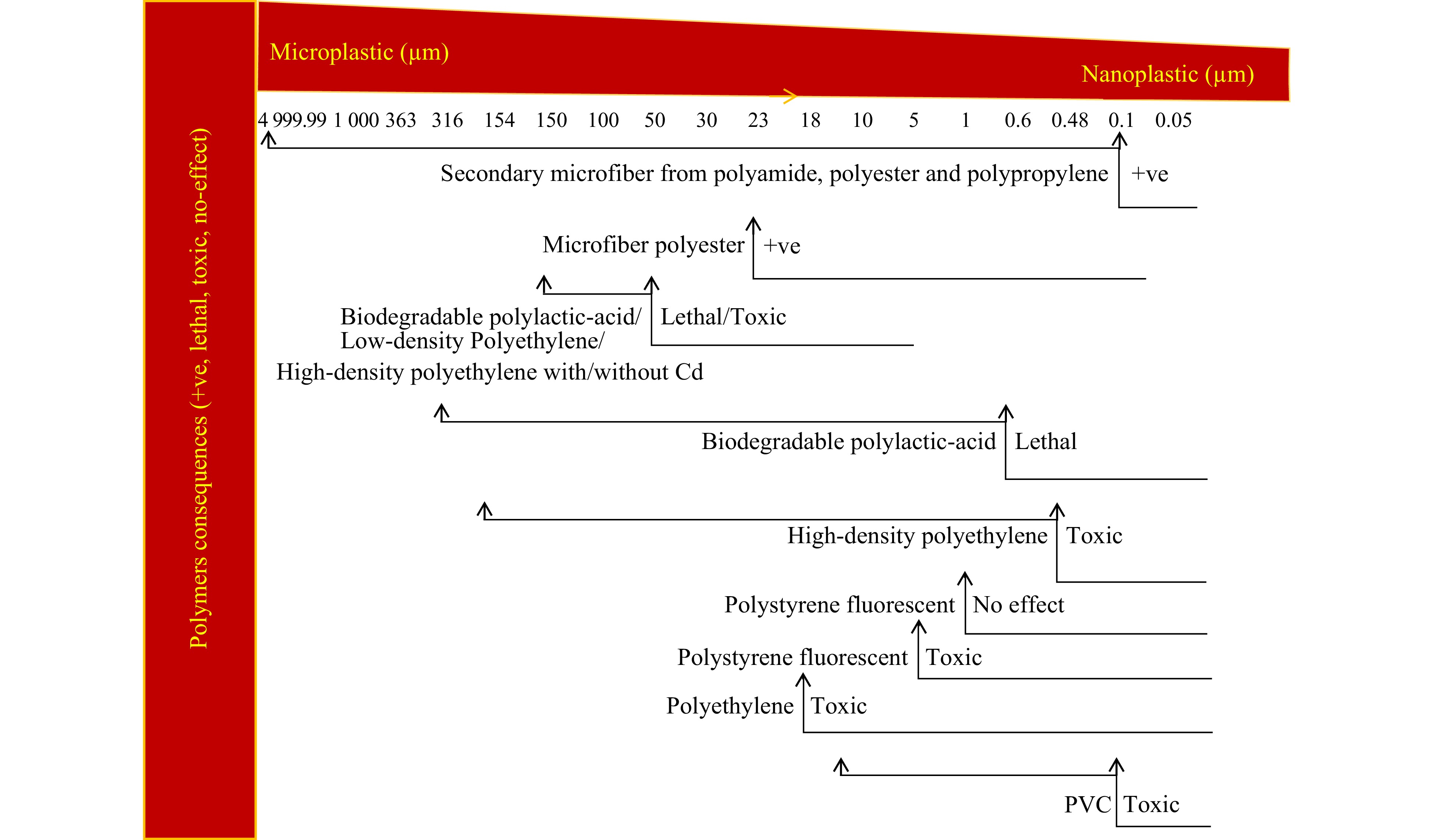

Figure 1.

Conceptual model of various effects of microplastic on crops. Positive (+ve) effect related to microfibers in onion and carrot[14,24], lethal effect linked to biodegradeable plastic in wheat, ryegrass and maize[8,25,26], toxic effect related to low-density polyethylene in wheat[8], high-density polyethylene in ryegrass[25], polystyrene fluorescent in broad bean[27], PVC, polyethylene in lettuce[12,16,26], and no effect associated to polystyrene fluorescent in wheat[28].

-

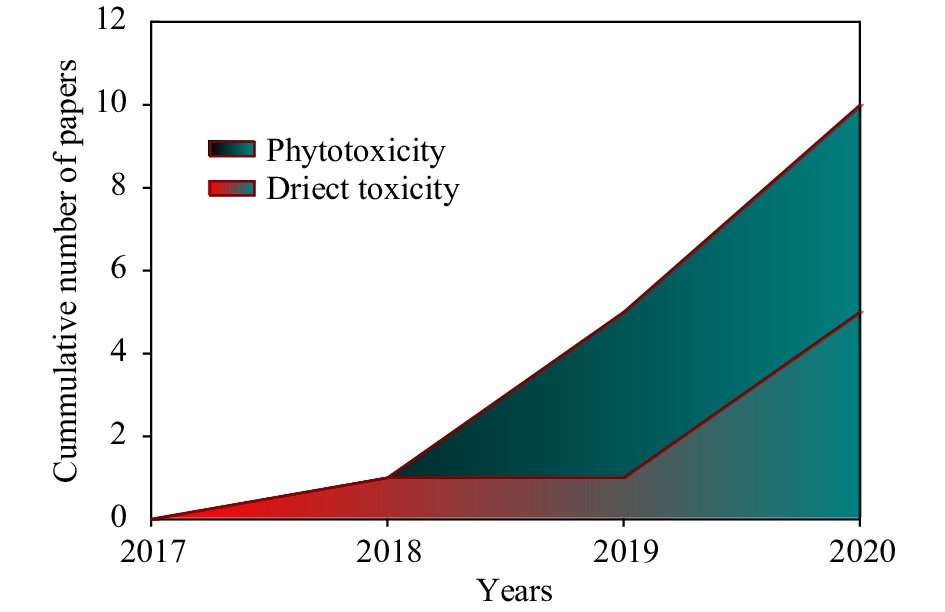

Figure 2.

Cumulative publications numbers on microplastic consequences and direct toxicity for food crops.

-

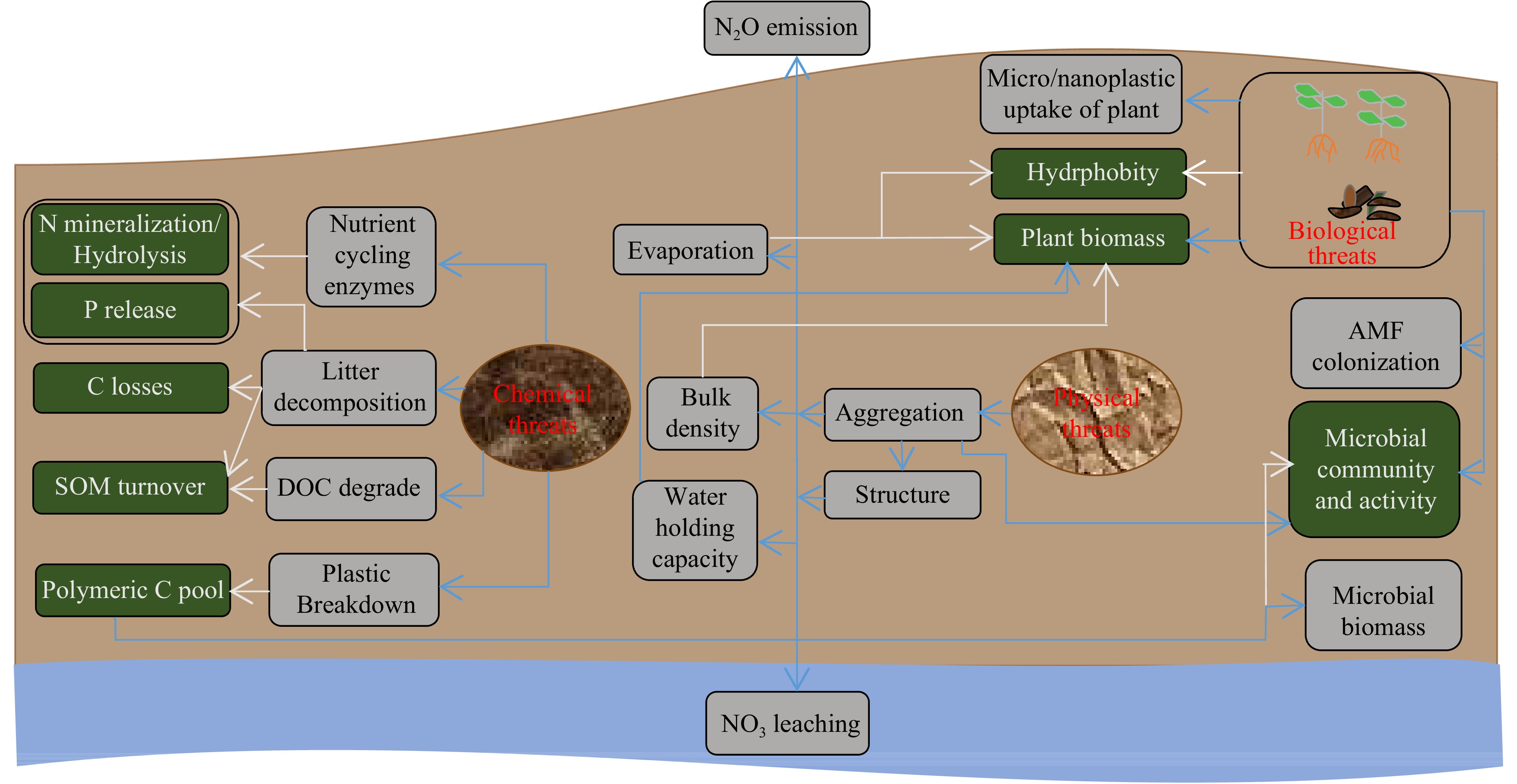

Figure 3.

Diagram disclosing various mechanisms through which microplastic can affect ecosystem functions and plant performance. Blue arrows show observed effects in previous studies while white arrows show conceptual mechanisms.

-

Additives Polymers Reference Irgafos 168 (tris (2,4-ditert-butylphenyl) phosphite) Polyethylene and

Polypropylene[19] Diisoheptylphthalate, Benzyl butyl phthalate, Di butyl phthalate, dipentyl phthalate, di-(2-ethylhexyl) adipate, di-octyladipate, diethyl phthalates, diisobutylphthalate, Tris (2 chloroethyl) phosphate, dicyclohexyl phthalate, butyl benzyl phthalate, diheptyl adipate, and heptyl adipate Polyvinylchloride [20,21] Irganox 1010 (tetrakismethylene-(3,5-di-t-butyl-4- hydroxyhydrocinnamate) methane)Linear low-density polyethylene and

High-density polyethylene[20] Table 1.

Examples of additives released from different polymers.

-

Crops Polymers Observed effect directions

(+, –) for crop growthExpected category Tolerant Sensitive Onion Polystyrene, polyethylene terephthalate, polyamide, microfiber polyester + √ Carrot Microfibers: polyester, polyamide, polypropylene + * * Wheat Low-density polyethylene, biodegradable polylactic-acid – √ Maize Polyethylene, biodegradable polylactic-acid – √ Ryegrass Biodegradable polylactic-acid – √ Broad bean Polystyrene fluorescent – √ Lettuce Polyethylene – √ * unclear. Table 2.

Hypothesized classification of different crops based on their observed responses to polymers (Fig. 1).

Figures

(3)

Tables

(2)