-

Figure 1.

The chemical formula of AQ.

-

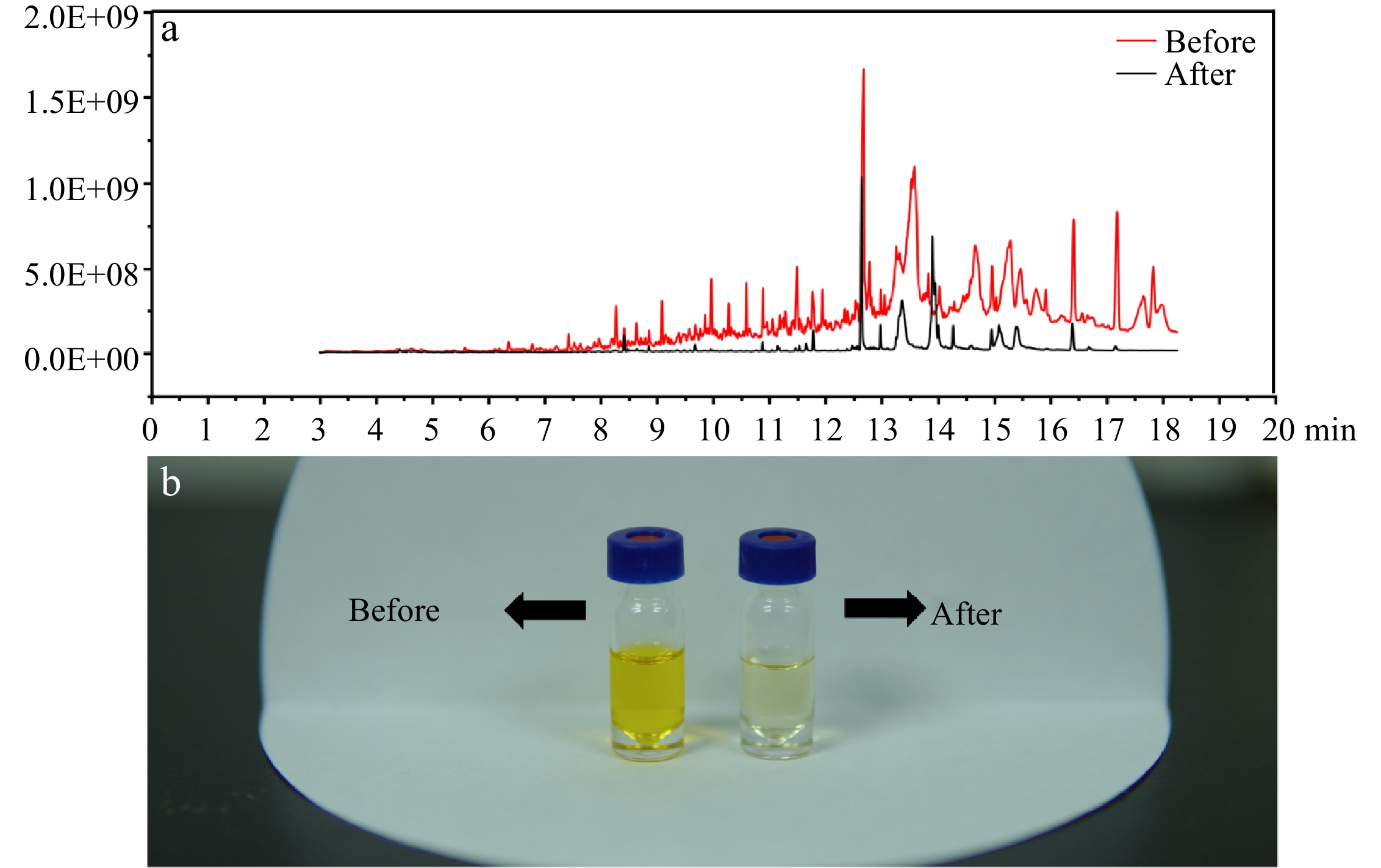

Figure 2.

(a) Full scan spectrum of the sample before and after the purification. (b) The purification effect of the improved method.

-

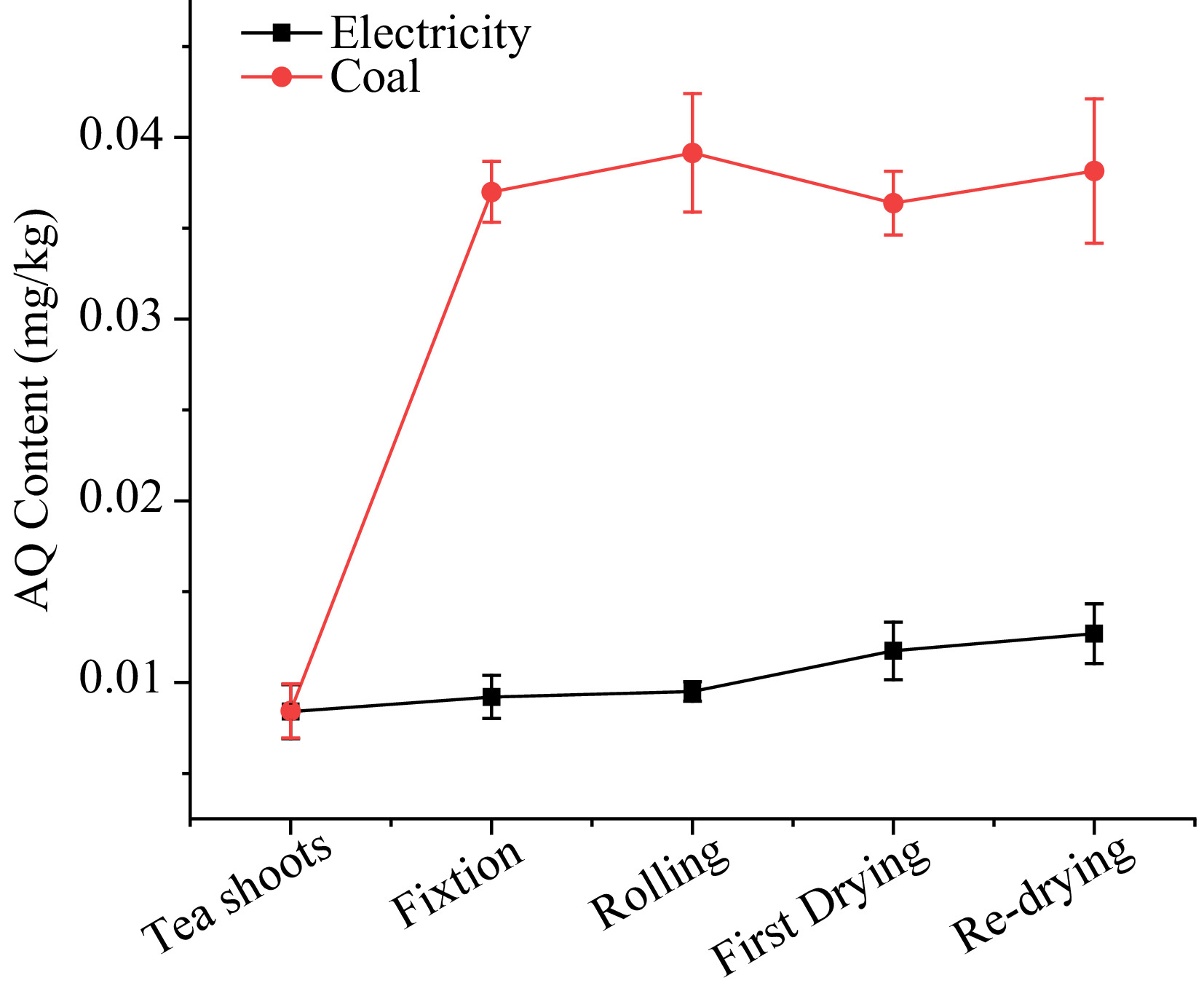

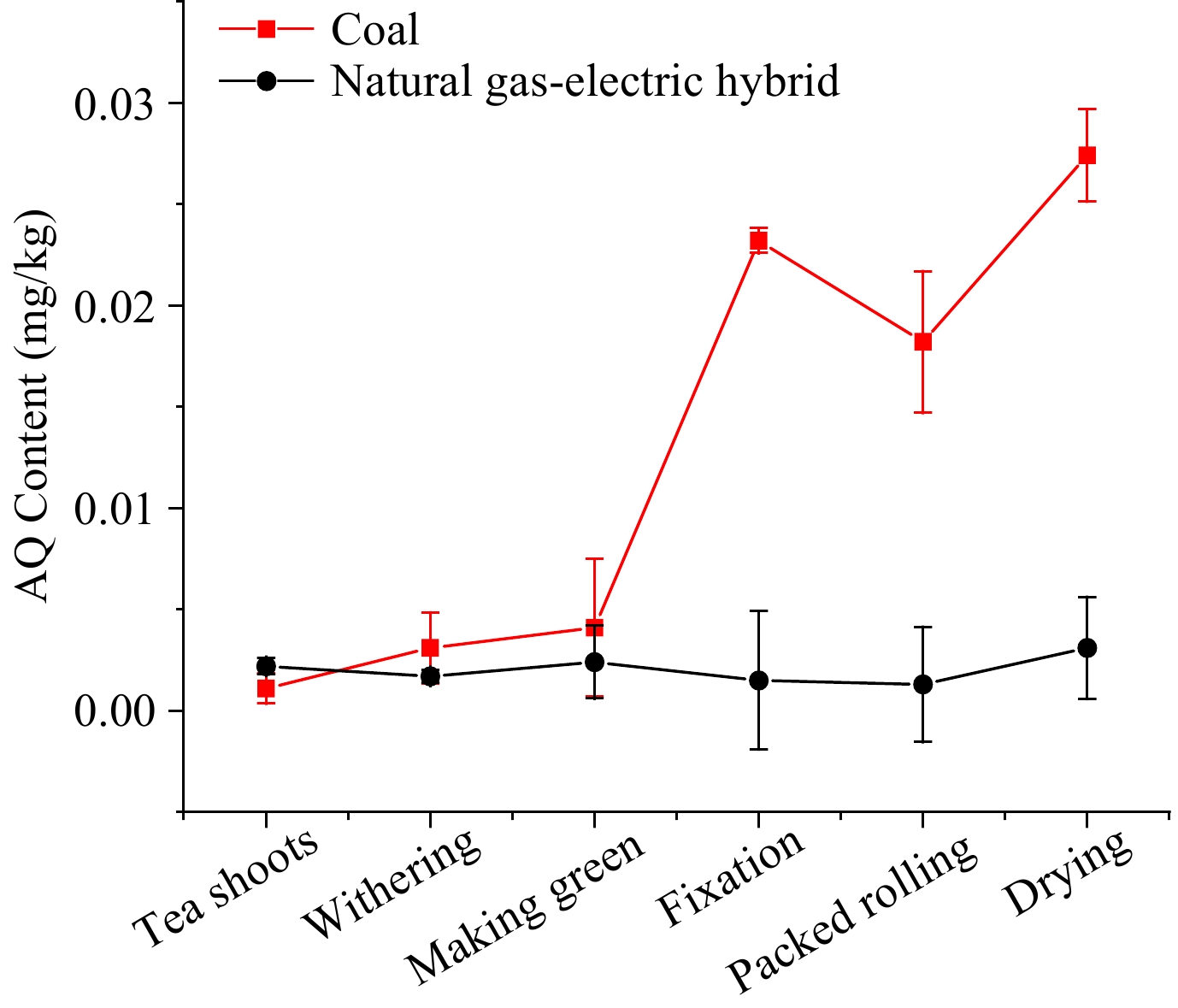

Figure 3.

The AQ level during green tea processing with electricity and coal as heat sources.

-

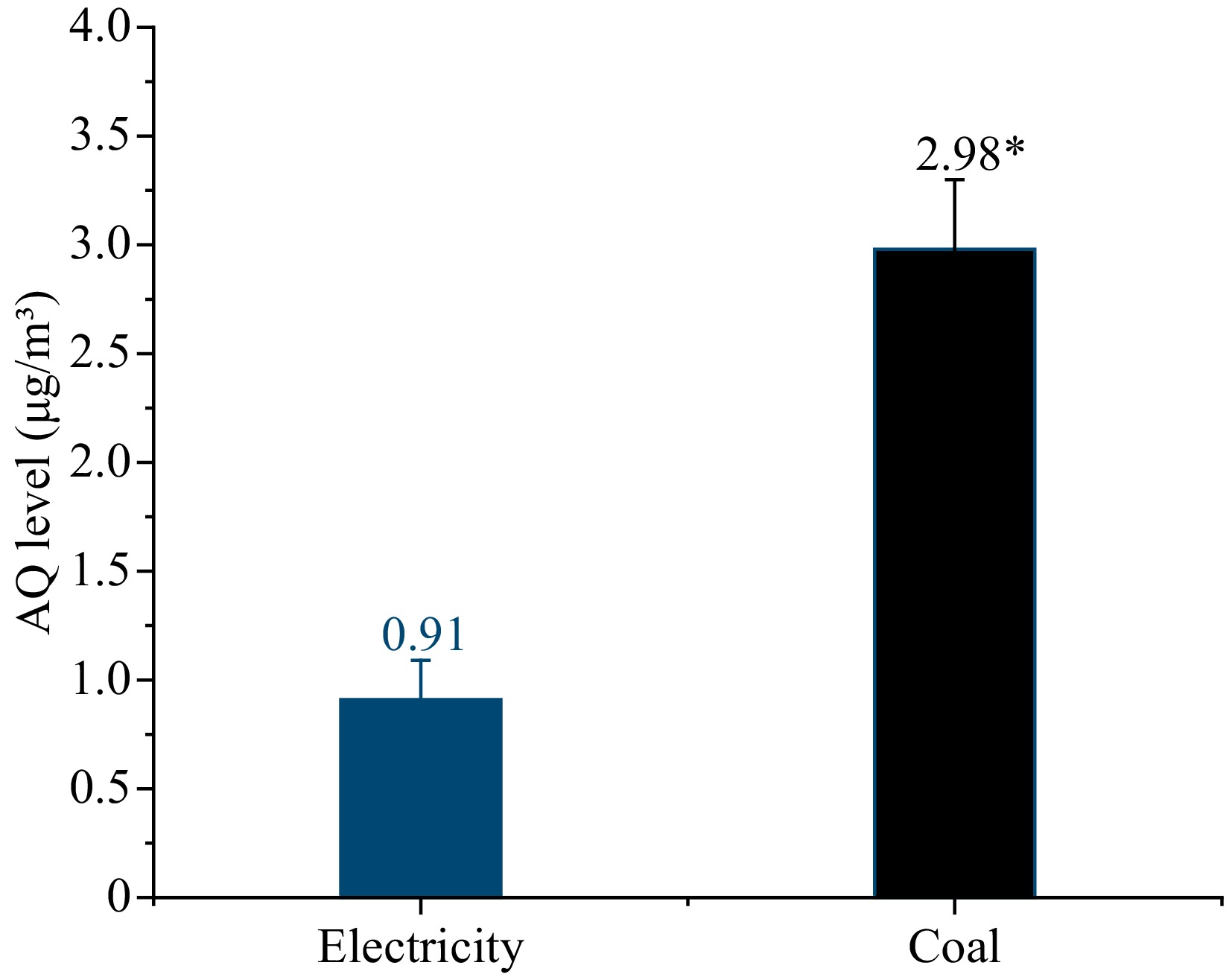

Figure 4.

The levels of AQ in the environment with electricity and coal as heat source. * Indicates significant differences in AQ levels in the samples (p < 0.05).

-

Figure 5.

The AQ level during oolong tea processing with natural gas-electric blend and coal as heat source.

-

Martrix Fortified level

(mg/kg)Recovery

(%, SD)RSD

n = 5LOQ

(mg/kg)r2 (range g/L) ME (%) Tea shoots 0.005 125.7 ± 8.6 6.9 0.005 0.999 (5−200) 10.9 0.01 96.5 ± 5.7 5.9 0.02 87.4 ± 6.4 7.3 Dry tea 0.005 77.8 ± 9.7 12.5 0.005 0.998 (5−200) 9.0 0.02 113.0 ± 3.2 3.6 0.005 107.6 ± 1.4 1.5 Air sample 0.5a 117.06 ± 9.4 10.8 0.5a 0.999 (0.5−8) 196.1 1.5 78.47 ± 4.0 5.1 3.0 105.07 ± 14.8 14.1 a: µg/m3 Table 1.

Validated parameters of AQ in spiked samples.

-

Total samples

analyzedNumber of detective

samplesRates of

detection (%)Number of samples

exceeded MRLRates of

exceedance (%)Min

(mg/kg)Max

(mg/kg)Electricity 20 10 50.0 1 5.0 ND 0.020 Coal 20 17 85.0 7 35.0 ND 0.064 Table 2.

The occurrence for AQ in tea products with different heat sources.

-

Equipment Compound TR (min) Parent ion (m/z) Daughter ion (m/z) Collision energy Vairan 450GC-300MS 9,10-anthraquinone 13.02 208 152 22 180 10 D8-anthraquinone 12.99 216 160 20 188 10 Agilent 8890GC-7000DMS 9,10-anthraquinone 12.15 208 152 30 180 10 D8-anthraquinone 12.19 216 160 30 188 10 Table 3.

MRM conditions of 9,10-anthraquinone and D8-anthraquinone.

Figures

(5)

Tables

(3)