-

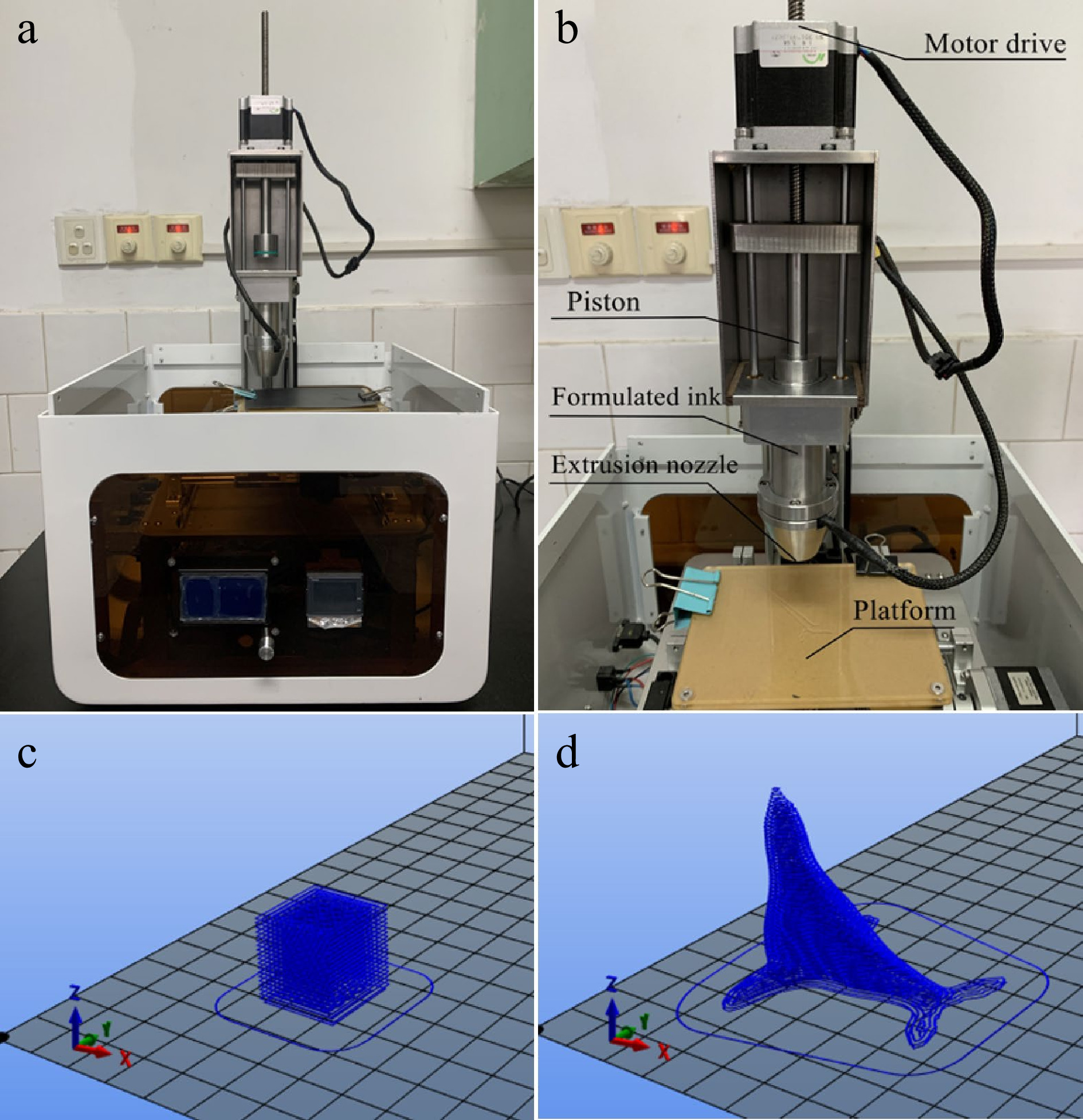

Figure 1.

(a) 3D printer appearance, (b) main parts, (c, d) the virtual model used during printing experiments.

-

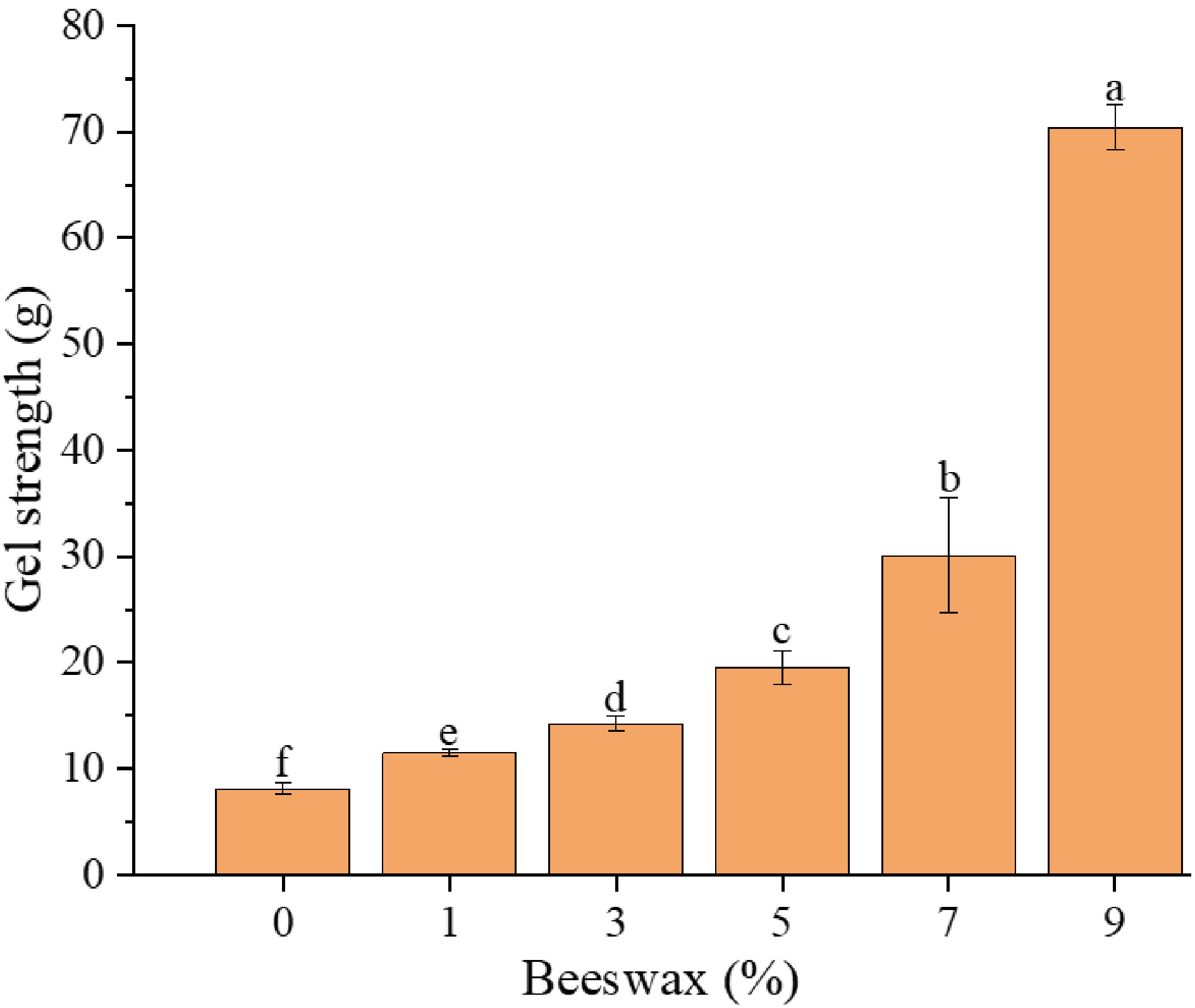

Figure 2.

Gel strength of 3D printed compound products at six beeswax levels (0, 1%, 3%, 5%, 7%, 9%, w/w). a−f: values with different lowercase letters indicated significant difference (p < 0.05).

-

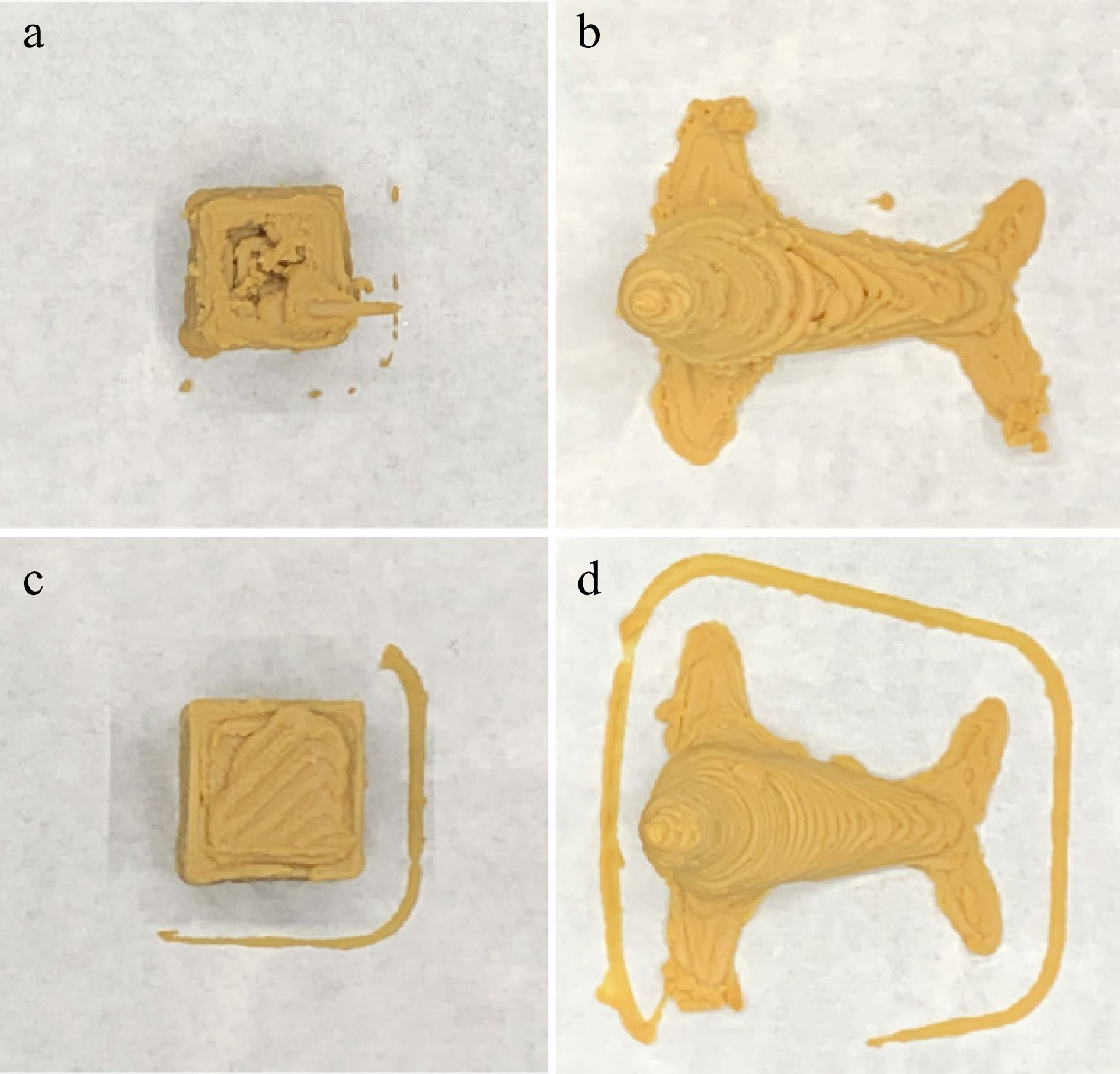

Figure 3.

Printing quality of 3D printed compound products at two beeswax level (a, b: 0; c, d: 3%, w/w).

-

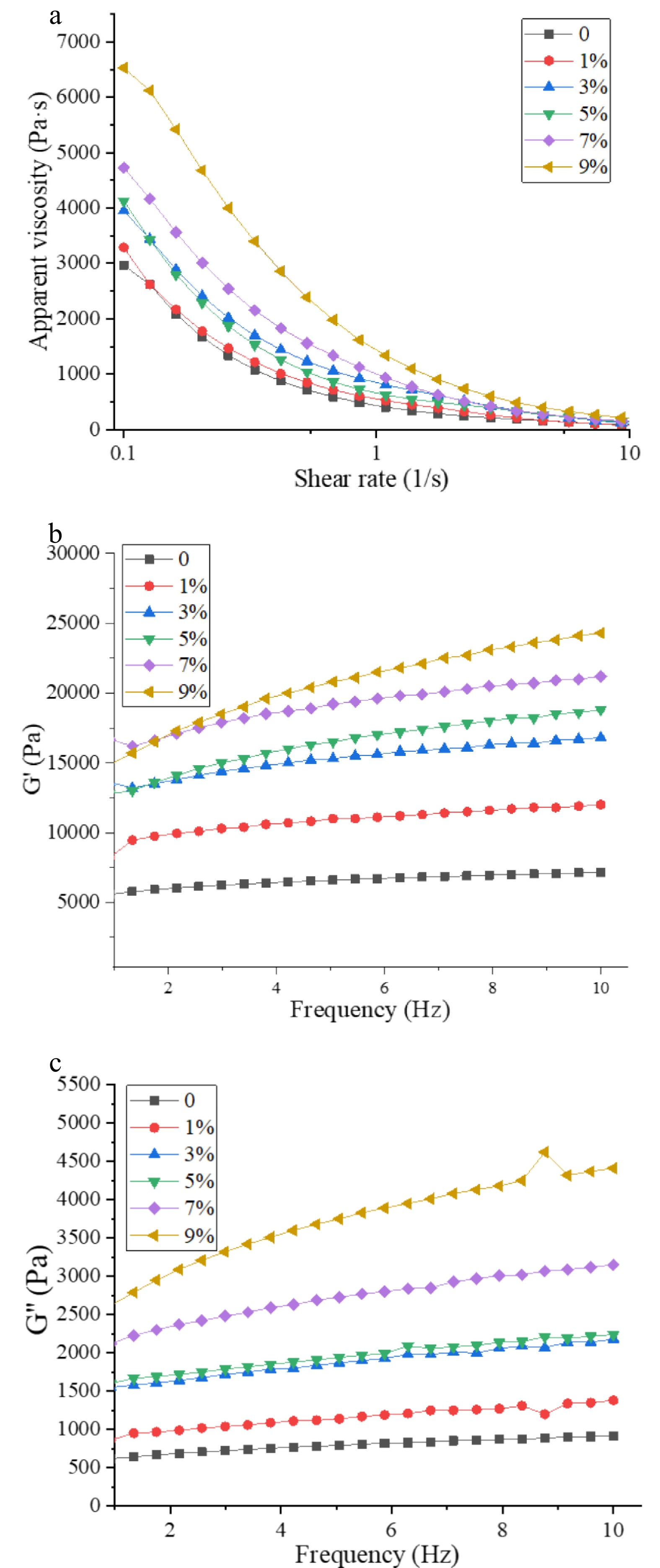

Figure 4.

Rheological behavior (a: apparent viscosity; b: G', c: G'') of inks at six beeswax levels (0, 1%, 3%, 5%, 7%, 9%, w/w).

-

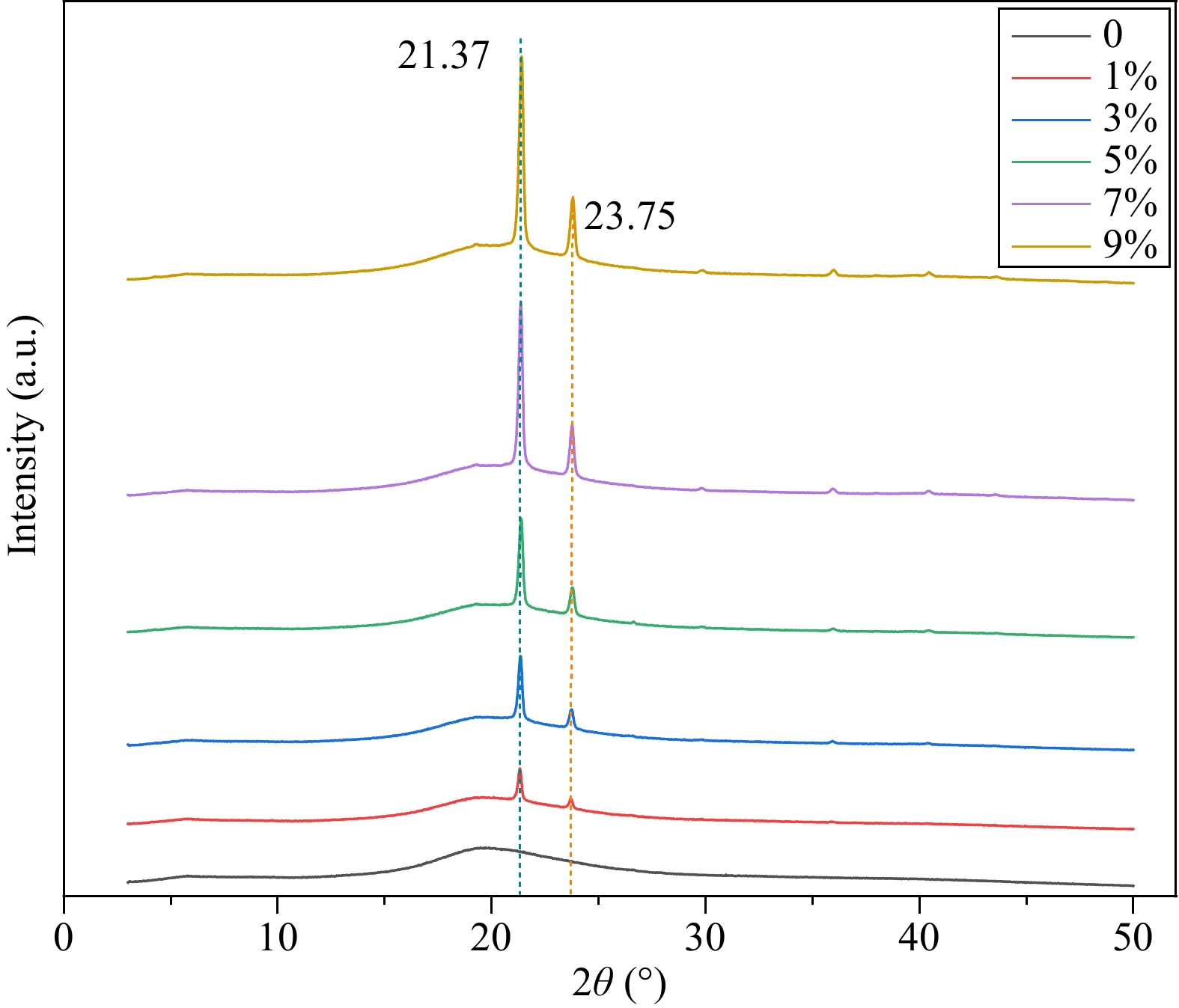

Figure 5.

X-ray diffractograms of inks at six beeswax levels (0, 1%, 3%, 5%, 7%, 9%, w/w).

-

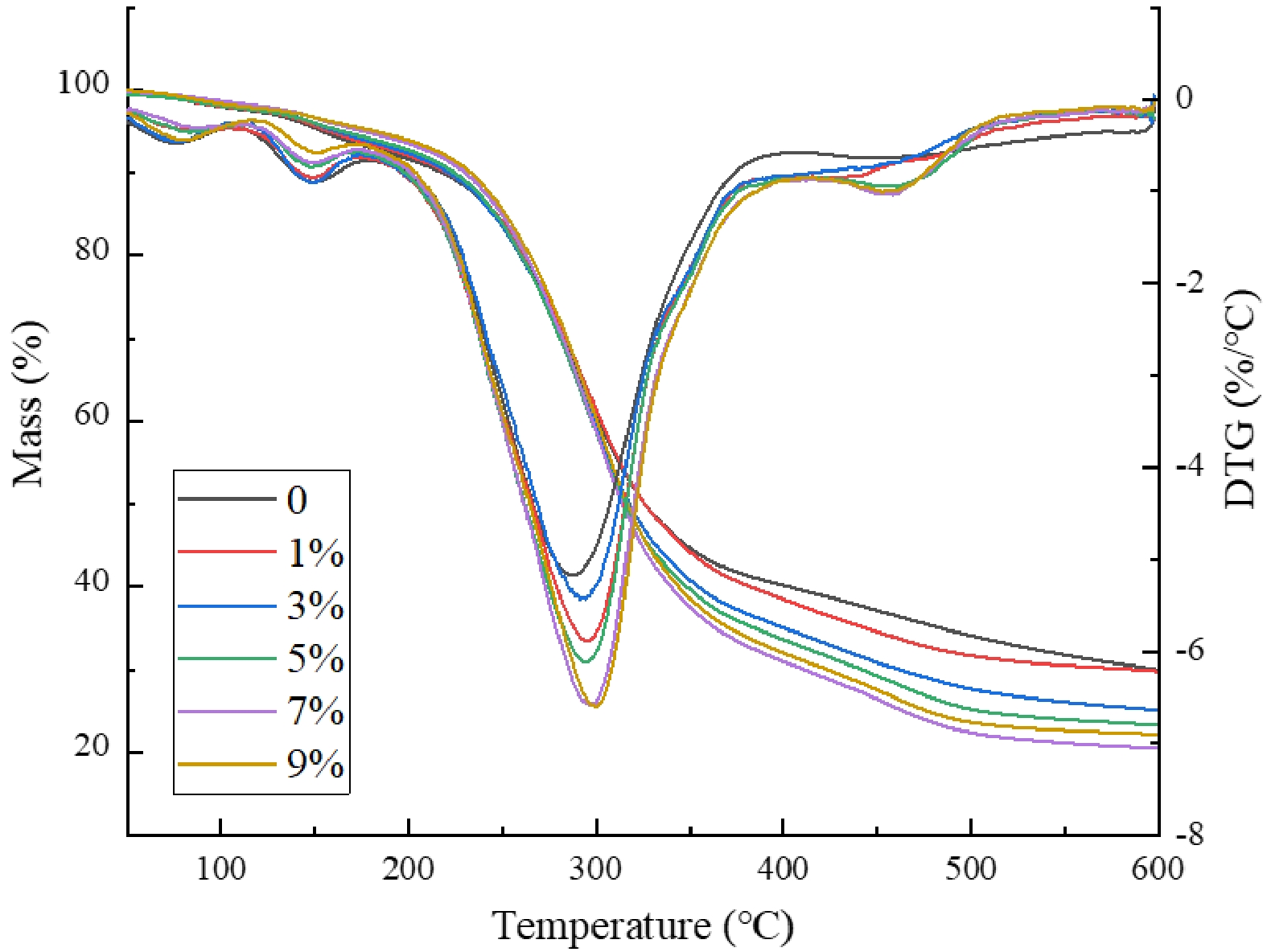

Figure 6.

TGA results of the thermal decomposition and its derivative (DTG) of inks at six beeswax levels (0, 1%, 3%, 5%, 7%, 9%, w/w).

-

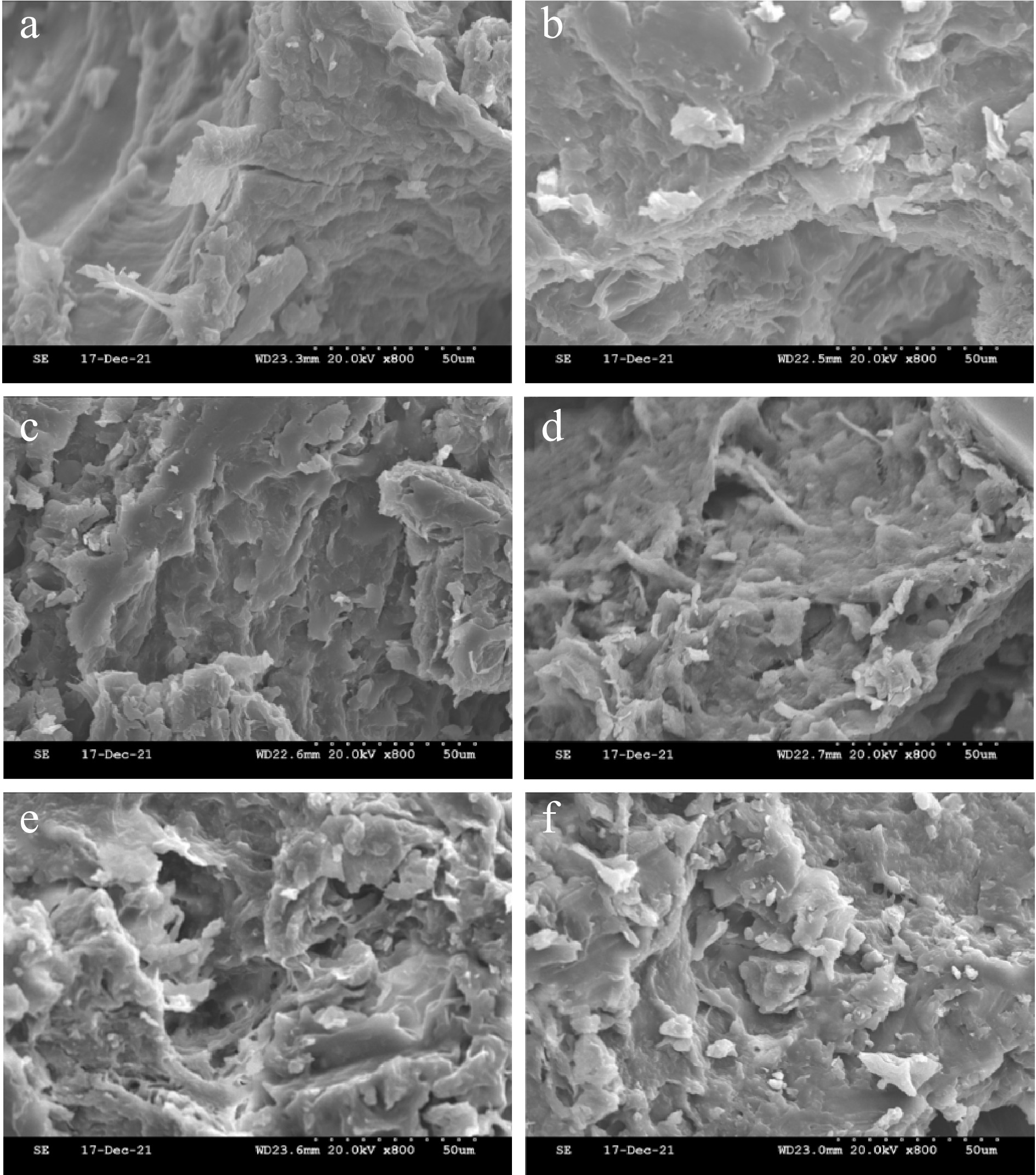

Figure 7.

SEM images of inks at 800x magnification with six beeswax levels (a−f: 0, 1%, 3%, 5%, 7%, 9%, w/w)

-

Beeswax

(%, w/w)Actual height after

30 min (mm)Accuracy

(%)0 17.45 ± 0.32b 87.25 ± 2.60b 1 19.32 ± 0.11d 96.60 ± 1.15d 3 19.67 ± 0.09d 98.35 ± 1.60d 5 18.59 ± 0.26c 92.95 ± 3.10c 7 16.26 ± 0.47a 81.30 ± 4.40a 9 NI NI Different lowercase letters in the same column indicated significant differences (p < 0.05). NI, no information. Table 1.

Accuracy of the 3D printed compound products at six beeswax levels (0, 1%, 3%, 5%, 7%, 9%, w/w). The model set height was 20 mm.

Figures

(7)

Tables

(1)