-

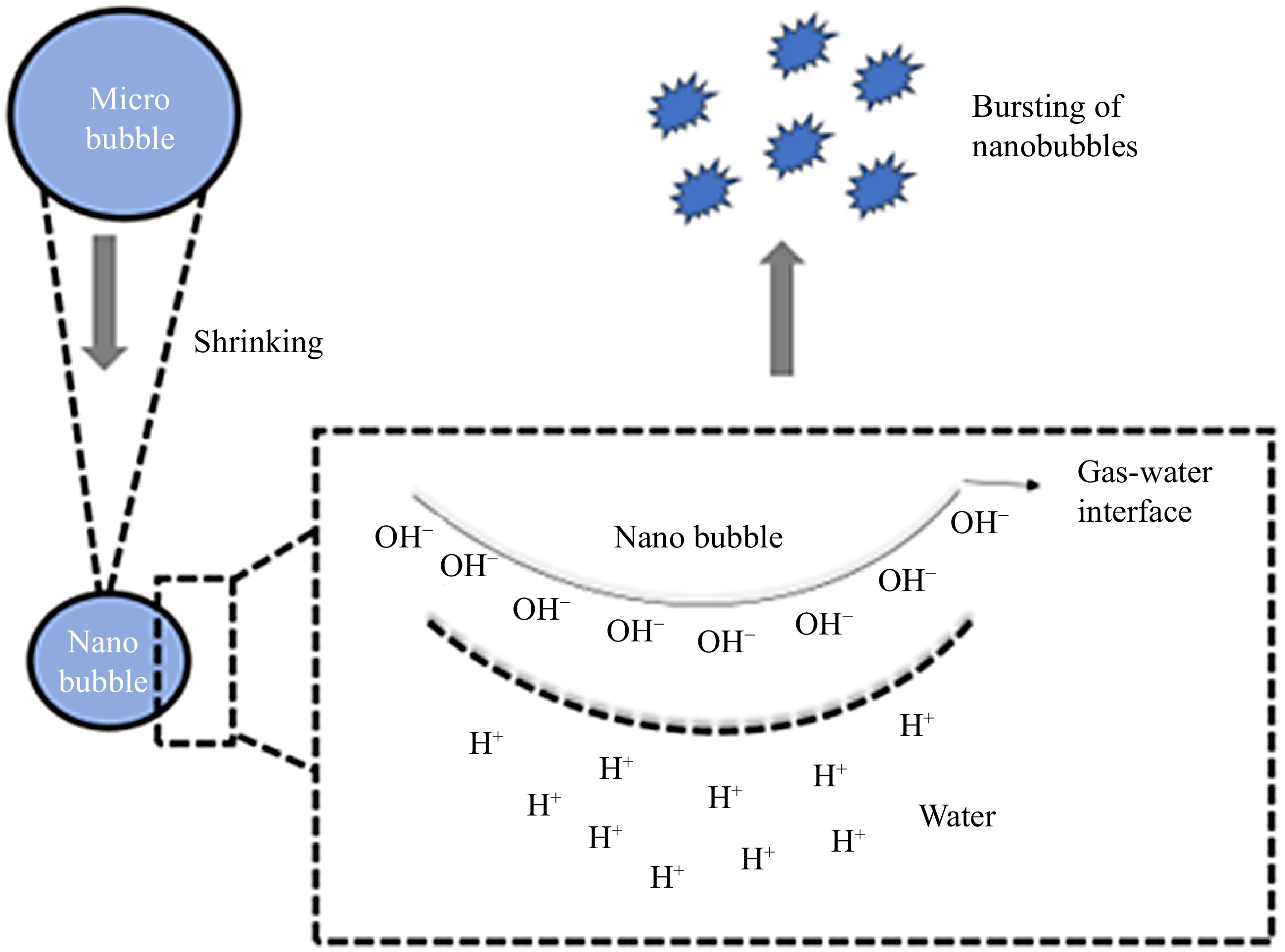

Figure 1.

Conversion of microbubbles to nanobubbles formation with a high negative charge.

-

Figure 2.

Methods of nanobubble generation.

-

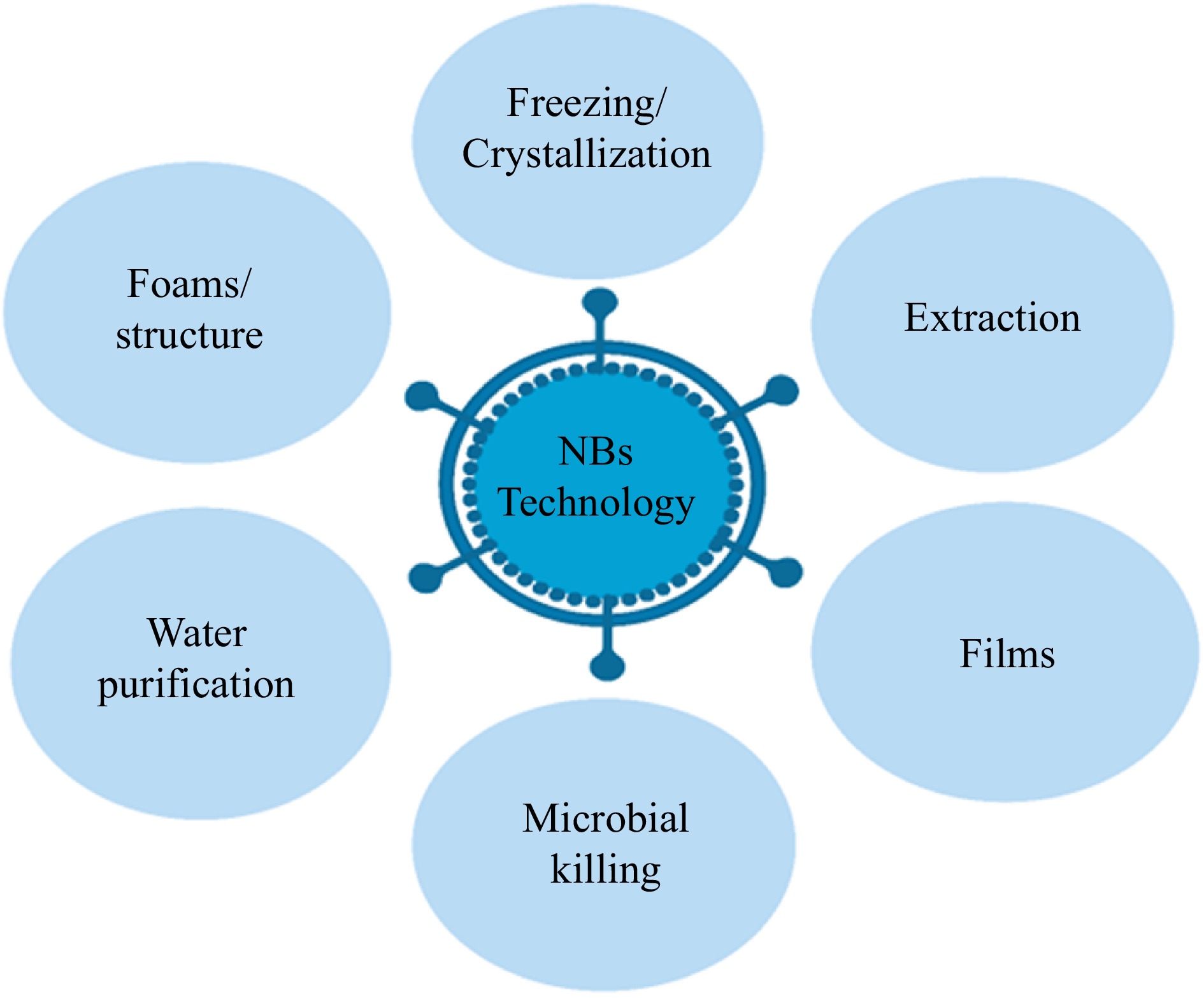

Figure 3.

Application of nanobubble technology in food and beverages.

-

Figure 4.

Mechanism of nanobubbles action in different applications.

-

Sample NBs method

(alone or coupled)Process mechanism Process parameters Process efficiency References Camellia oleifera shells Coupled with ultra-sonication Nano jet formation Rhamnolipid concentration (5 CMC), time (16 min) Efficient green method for extraction [16] Carya cathayensis Sarg (Walnut shells) Coupled with ionic

liquid solutionIonic liquid Nano jets formation Ionic liquid concentration (1 M), time (9 min), temperature (30 °C) Showed better extraction of phenolic compounds than ethanolic [12] Mustard Alone Air and O2 NBs generated through nano bubble aerator Cavitation time (30 min), pump speed (3,600 rpm) Weight increased by 35% [13] Tomato Coupled with micro

bubble technologyAir NBs injection method Air NBs concentration

(15 and 25 mg/L)Improved tomato yield and enhanced vitamin C and lycopene content [77] Cucumber Coupled with micro

bubble technologyAir NBs injection Air NBs concentration

(15 and 25 mg/L)Improved cucumber yield [77] Maize Coupled with micro

bubble oxygenation

technologyGas liquid mixing O2 NBs concentration

(10, 20, and 30 mg/L)Yield increased up to 11.7% [78] Sugarcane Coupled with micro

bubble water technologyPasteurization MNBs water (1:0 and 1:4) Increased soil fertility and yield increased up to 17.6% [79] Barley Coupled with low-concentration H2O2 NBs Water stimulated the expression of genes involved in cell division and cell wall thinning NBs generation time

(60 min)Germination rate increased up to 25% [80] Camellia oleifera shells Coupled with ultra-sonication Green extraction methods crucial for efficient and safe extraction Tween 80 and rhamnolipid NBs concentration (5 CMC), time 16 min) Increased total phenolic and flavonoid content [58] Carrots and fava beans Alone Compression and decompression method NBs generator pressure (414 KPa), time (90 min), flow (0.4 L/m) Increased seed germination rate [9] Chinese cabbage Couple with micro

bubble technologyOstwald ripening Electrolyzed solution

(50 mg/L) and NBs

solution (50 ppm), pH 4.0Enhanced microbial cleaning [81] Instant coffee Coupled with spray

freeze dryingStable NBs foams Pressure (588.39 KPa),

flow rate (6 mL/min)Outstanding foam stability and unbroken foam surface [18] Apple Juice concentrate Alone CO2 NBs influence

on juice on viscosityNBs pressure (300 Kpa), time (5, 13, 26 min), temperature (23 °C) Significant reduction in viscosity [82] Ice cream Coupled with micro

bubble technologyEffect of CO2 NBs on physicochemical properties NBs concentration (2,000 ppm), temperature

(5 °C), time (1 min)Enhanced the sensory and physicochemical prope [83] Milk Coupled with spray

dryingNano bubbles helped

to produce milk via

non-aggregationAir NBs flow rate

(0.3 L/min)Enhanced process efficiency and reduced viscosity [84] Apple Coupled with micro

bubble technologyOzone MNBs for removing pesticide residue MNBs pressure (0.5 MPa) Improved residual removal efficiency [85] Eggs (without

shells and boiled)Coupled with micro

bubble technologyFood seasoning N/A Improved liquid seasoning permeation [86] Protein (hydrophobin) Alone Supporting in protein purification Purity improved by 2.8 times [68] Table 1.

Nanobubble applications in food products.

Figures

(4)

Tables

(1)