-

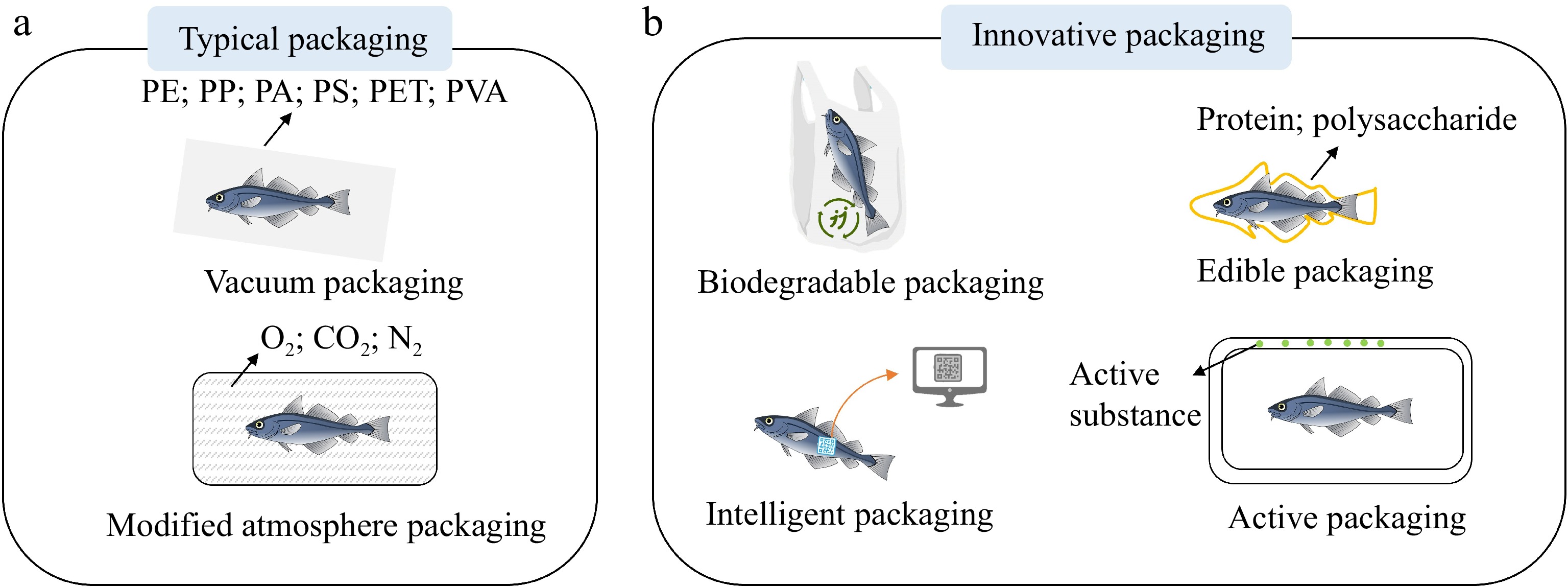

Figure 1.

(a) Typical packaging materials and methods and (b) innovative packaging materials and methods for prepared aquatic products (PE: Polyethylene; PP: polypropylene; PA: polyamide; PS: polystyrene; PET: polyethylene terephthalate; PVA: polyvinyl alcohol).

-

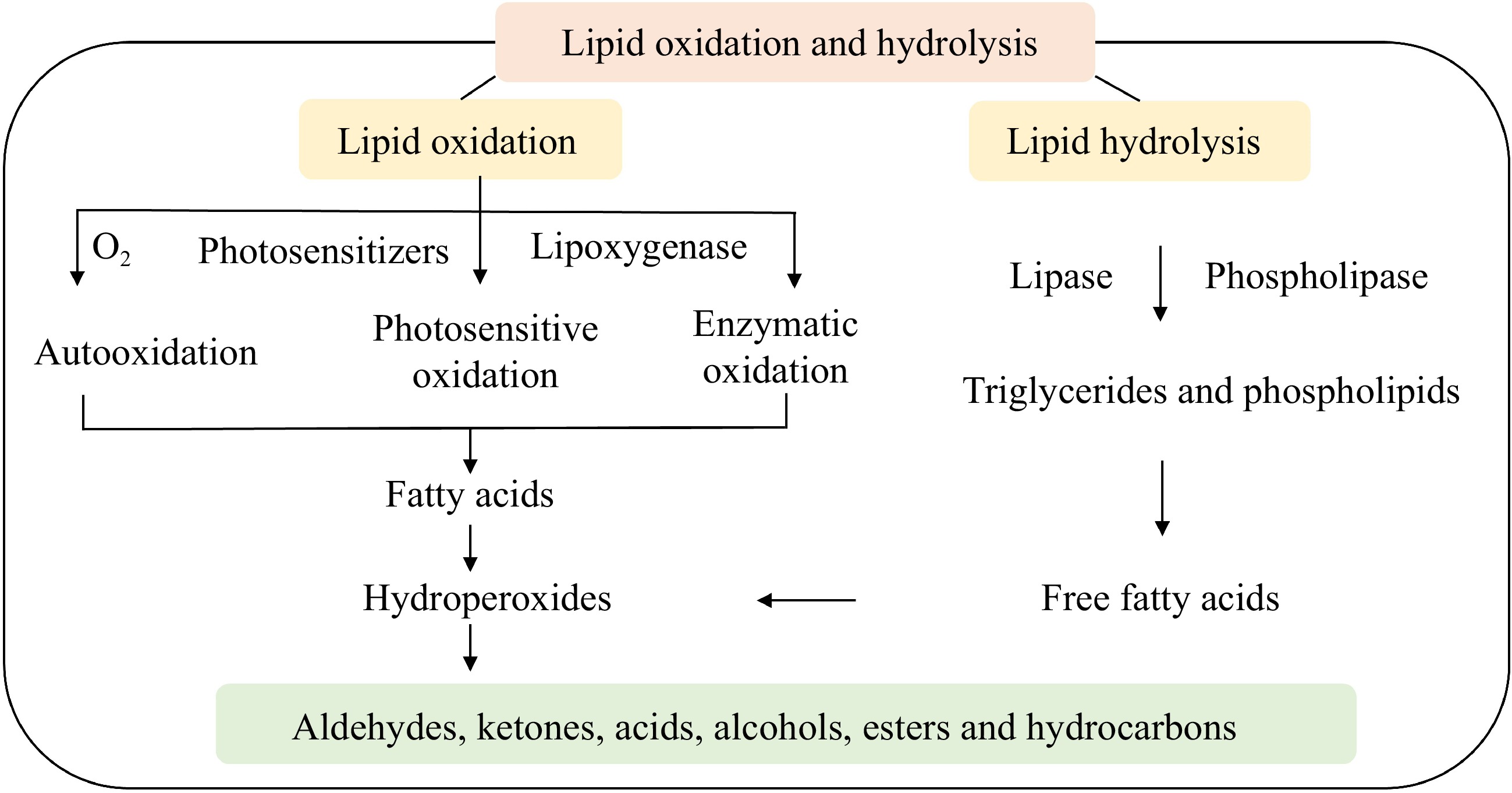

Figure 2.

Mechanism of flavor change in prepared aquatic products under lipid oxidation and hydrolysis.

-

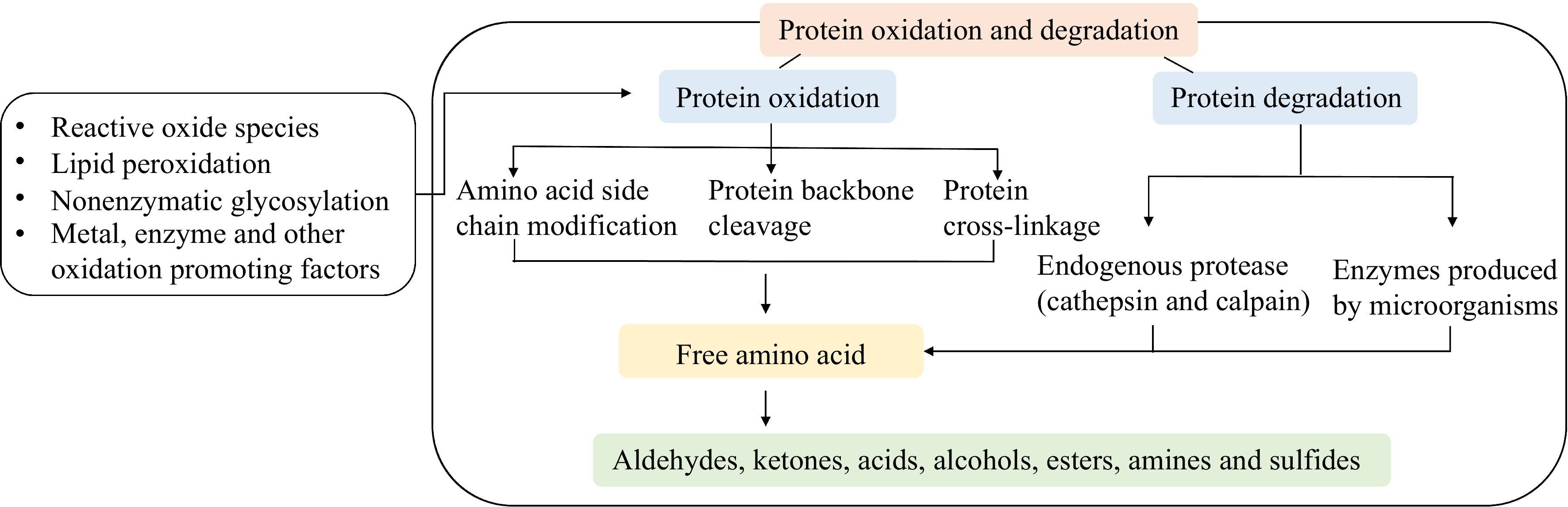

Figure 3.

Mechanism of flavor change in prepared aquatic products under protein oxidation and degradation.

-

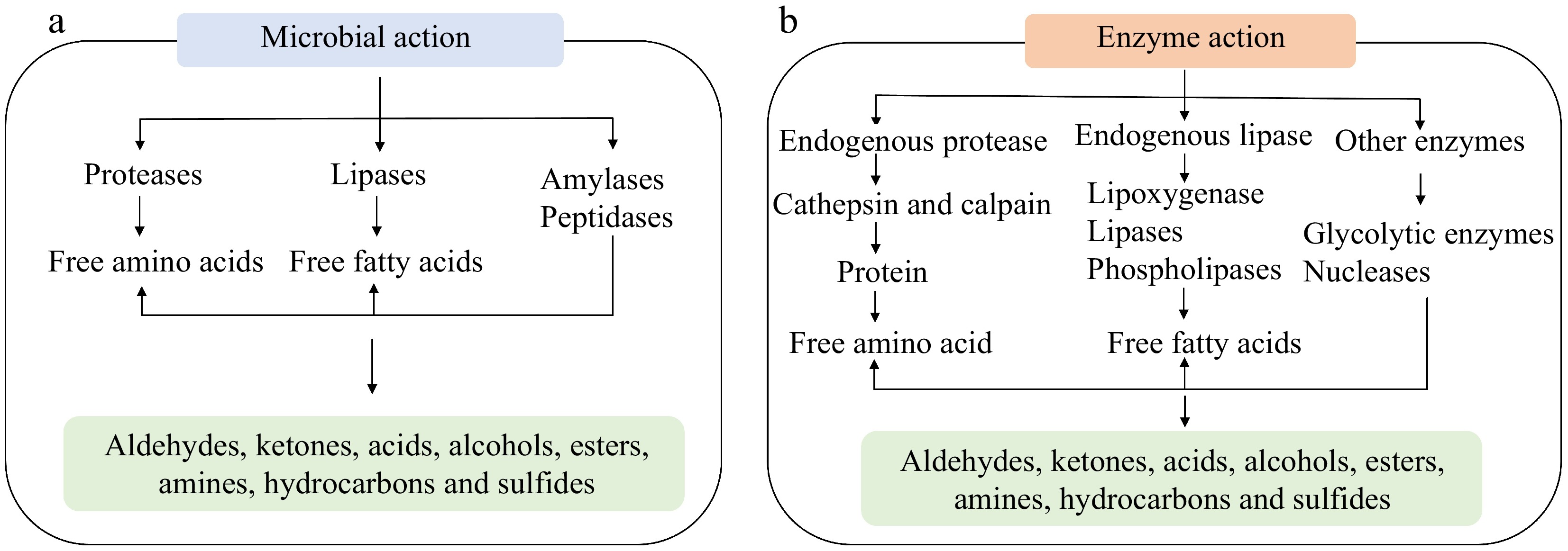

Figure 4.

Mechanism of flavor change in prepared aquatic products under (a) microbial action and (b) enzyme action.

-

Figure 5.

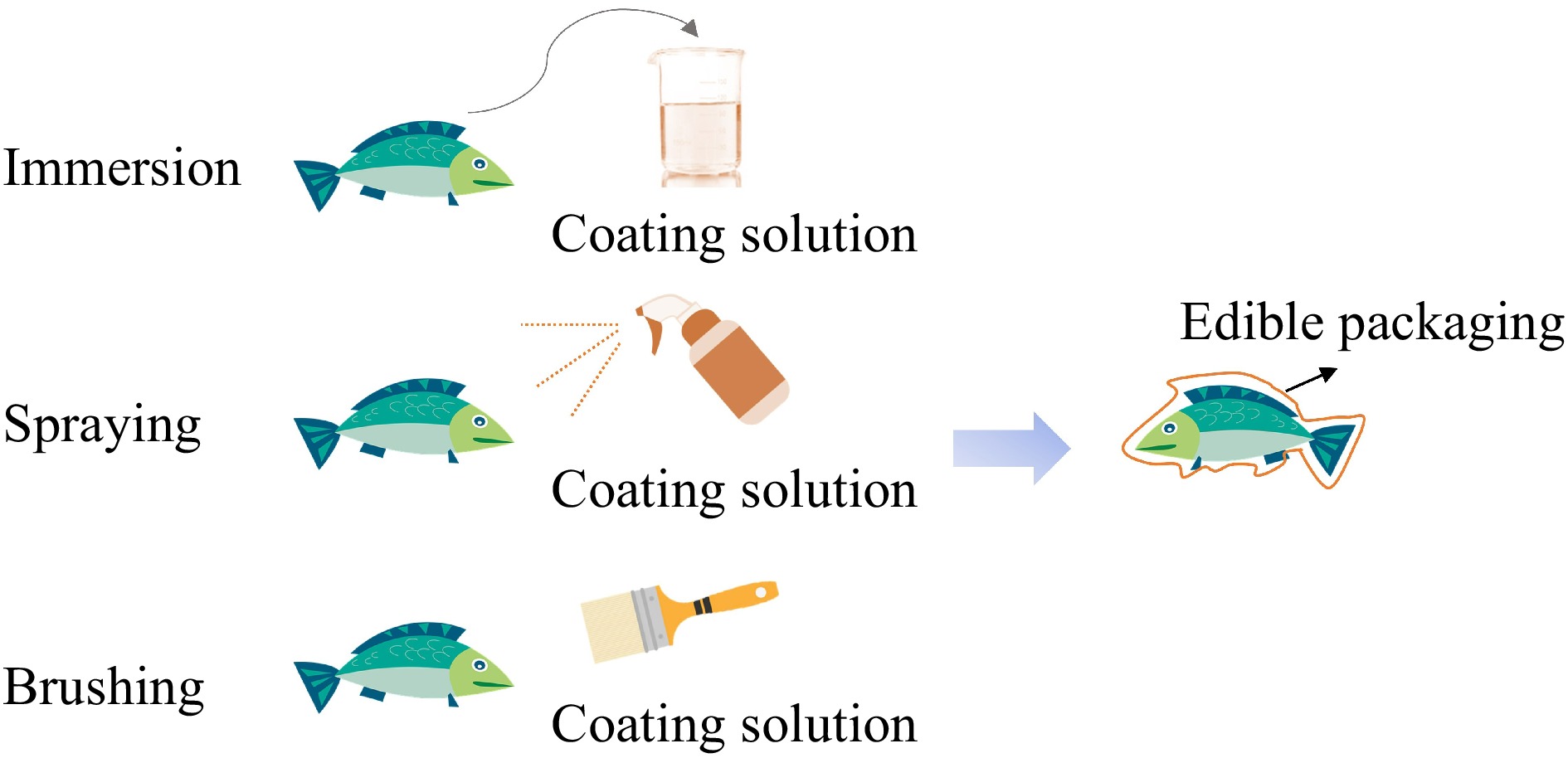

Preparation method of edible packaging for prepared aquatic products (adapted from Jafarzadeh et al.[88]).

-

Typical packaging Packaging methods Aquatic products Response effect of packaging References Vacuum packaging Vacuum packaging Tuna Vacuum packaging was adequate to postpone the lipid oxidation of tuna fillets at 4 °C. [11] Frozen and vacuum-packed Lethrinus atkinsoni fillets Frozen and vacuum-packed samples were a suitable strategy for preventing lipid oxidation in Lethrinus atkinsoni fillets, prolonging shelf-life of the samples. [45] Vacuum packaging (PE, polyester, and other packaging materials) Smoked salmon Polyester and PE had superior water vapor barrier qualities and inhibited the formation of total volatile base nitrogen (TVBN) in smoked salmon. [12] Vacuum packaging (PA

and PET plastic)Surimi The sensory evaluation of surimi packed in PA was the least acceptable to consumers. [46] Modified atmosphere packaging 80% CO2 and 20% N2 Rainbow trout fillets When compared to aerobic packaging, MAP with 80% CO2 and 20% N2 reduced the total production of ammonia, TVBN, and putrescine of rainbow trout fillets. The shelf-life of rainbow trout was prolonged by at lowest two times owing to MAP, which slowed down microbial activity and biochemical alterations. [47] CO2 to N2 volume ratio

of 3:2Salmon The growth of spoiling bacteria was suppressed, and the shelf-life of fish fillets was prolonged for salmon under modified atmosphere packaging. [48] 30% N2, 40% CO2, and

30% O2Gray triggerfish MAP delayed the acceleration of TVB-N content in fish fillets and extended the shelf life of fish in comparison with air and vacuum packaging. [49] Super chilling in combination with 40% CO2 and 60% N2 Atlantic cod During storage, the association of super chilling and MAP suppressed microbial growth and TVBN generation. [50] Table 1.

Flavor regulation of prepared aquatic products associated with typical packaging.

-

Packaging types Packaging methods Advantages Disadvantages References Typical packaging Vacuum packaging Low oxygen content; suppresses the action of

aerobic microorganismsNonbiodegradable; hazards of microplastics; migration of plasticizers; texture deterioration [42, 43] Modified atmosphere packaging Inhibiting microbial growth; alters the gas environment High input costs; typically require refrigeration [48, 50] Innovative packaging Biodegradable packaging Renewable; degradable Weaken in physical, mechanical, and thermal properties [53, 54] Edible packaging Edible; good resistance to

lipids and oxygen; economicalMechanical properties, thermal properties, and air/moisture barriers need further improvement [55] Active packaging Antibacterial activity; delays lipid oxidation The active substance may be sensitive to temperature or humidity; the release velocity of the active substance [56] Intelligent packaging TTIs and colorimetric indicator labels have low cost and fast detection; bio/chemical sensors and RFID are responsive and sensitive in detecting TTIs are not easy to control; colorimetric indicator labels are easily affected by sample humidity; bio/chemical sensors and RFID reaction materials for food safety are unclear [3] Table 2.

Advantages and disadvantages of typical and innovative packaging for flavor regulation of prepared aquatic products.

-

Innovative packaging Packaging methods Aquatic products Response effect of packaging References Biodegradable packaging Starch/

carboxymethylcellulose/

gelatin/cellulose/green tea groundsSalmon This innovative packaging is readily biodegradable, inhibits the growth of specific spoilage organisms in salmon fillets, and delays the formation of biogenic amines. [63] Carboxymethyl-cellulose/starch/ purple sweet potato anthocyanins Grass crap The coating can degrade and be used as intelligent packaging to monitor fish quality by changing color when exposed to ammonia or varying pH levels from red to blue and green. [64] Polylactic acid (PLA)/tilapia fish gelatin-sodium alginate bilayer films Sea bass Compared to PLA and edible gelatin-based monolayer films, this combination enhanced the films’ ability to act as an oxygen and water vapor barrier. The films were highly antioxidant and antibacterial. [65] Sodium alginate films with Clitoria ternatea extract (CTE) Freshwater shrimp Owing to intermolecular interactions and crosslinking of polymeric networks, the addition of CTE to alginate coatings increased the heat stability of materials. The films showed outstanding colorimetric capabilities and could be applied as a biodegradable freshness indicator. [66] Edible packaging Ethyl lauroyl arginate and lemon essential oil added to edible chitosan film coating Mackerel The film-treated mackerel could store at 2 °C for 9 days, and its biogenic amine content was 30%−40% lower than that of the uncoated group. [67] Pectin combined with plant essential oils Large yellow croaker The coating technology can effectively slow water migration, inhibit endogenous enzyme activity, and slow the oxidation process of large yellow croaker rhubarb protein during storage. [68] Chitosan film incorporated with thinned young apple polyphenols Grass carp The accumulation of peroxide, thiobarbituric acid values, and TVBN content have been decreased in grass carp and the shelf life of fillets has been extended for 4 days. [69] Rice starch films with oregano essential oil Genidens genidens During chilled storage, fish fillets wrapped in oregano essential oil and rice starch film had lower malondialdehyde content. The packaging components can be used as active packaging. [70] Active packaging Chitosan-nisin (CS-nisin) microcapsules Small yellow croaker CS-nisin microcapsules observably inhibited microbial growth, lipid oxidation, and protein degradation. This active packaging extended the shelf-life of the small yellow croaker for 6−9 days. [71] Polyhydroxy butyrate-co-valerate (PHBV) with gallic acid/sodium carbonate Fatty food simulants Gallic acid was released into food simulants during contact with fatty food simulants. The PHBV active packaging offers significant potential for protecting food quality by combining anti-free radicals and oxygen scavenger functions. [72] Starch-based films with potato peel phenolic extracts Smoked fish The newly created starch/0.5% phenolics-based coatings enable the dehydration of smoked fish fillets. [73] Bacteriocin GP1 of Lactobacillus rhamnosus GP1 Cod Applying bacteriocin GP1 in stored fish could effectively control the growth of spoilage organisms. Bacteriocin treatment inhibited spoiling by reducing the formation of volatile amines during storage. [74] Intelligent packaging Colorimetric indicator labels Shrimp The colorimetric film of polyvinyl alcohol/okra mucilage polysaccharide/ rose anthocyanins was sensitive to volatile ammonia. The indicator label had color variations between pH 2−12. [75] Shrimp The film consisted of starch/polyvinyl alcohol/ betalains-rich red pitaya peel extract. The formation of volatile nitrogen during the shrimp spoilage process caused color changes in the film. [76] Bio/chemical sensors Squid and large yellow croaker Xanthine oxidase was immobilized onto a biocompatible copper-based metal-organic framework nanofibers film. When applied to detecting frozen squid and large yellow croaker, the electrochemical biosensor for xanthine and hypoxanthine shows good recovery. [77] TTIs Oysters TTIs can both identify the growth of psychrotrophic spoiling microorganisms and monitor the shelf life of refrigerated oysters. [78] RFID Sea bass RFID can detect temperature changes in fish in styrofoam boxes. [79] Table 3.

Flavor regulation of prepared aquatic products associated with innovative packaging.

Figures

(5)

Tables

(3)