-

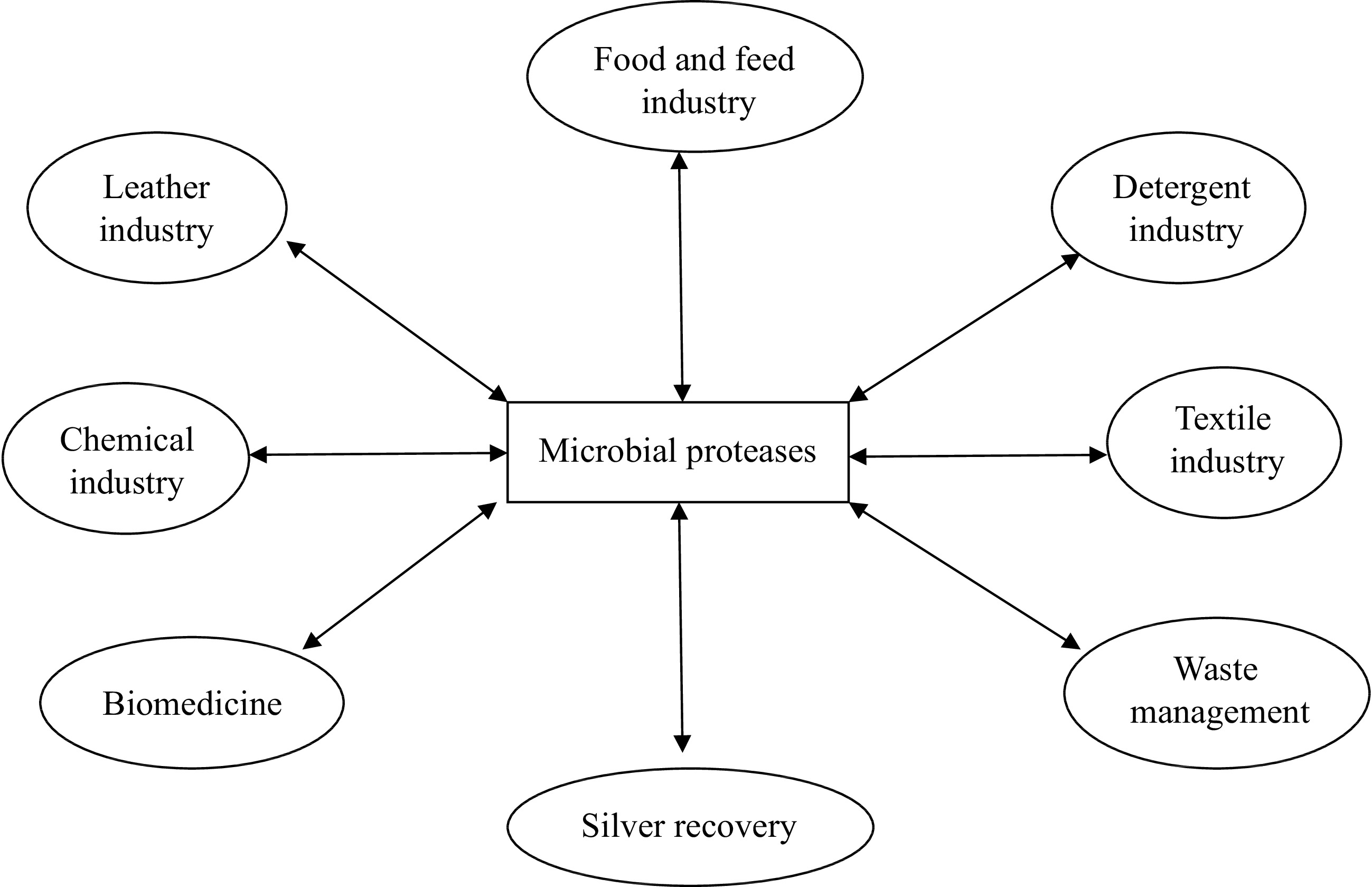

Figure 1.

Schematic diagram showing some potential biotechnological applications of microbial proteases.

-

Microorganism Reference Bacteria Bacillus sp. CL18 [29] Bacillus aryabhattai Ab15-ES [30] Bacillus stearothermophilus [31] Bacillus amyloliquefaciens [32] Geobacillus toebii LBT 77 [33] Pseudomonas fluorescens BJ-10 [34] Streptomyces sp. DPUA 1576 [35] Vibrio mimicus VM 573 [36] Lactobacillus helveticus M92 [37] Microbacterium sp. HSL10 [38] Serratia marcescens RSPB 11 [39] Listeria monocytogenes [40] Brevibacterium linens ATCC 9174 [41] Alteromonas sp. [42] Halobacillus blutaparonensis M9 [43] Staphylococcus epidermidis [44] Yersinia ruckeri [45] Geobacillus stearothermophilus [46] Stenotrophomonas sp. [47] Aeromonas veronii OB3 [48] Fungi Alternaria solani [49] Aspergillus niger DEF 1 [50] Penicillium sp. LCJ228 [51] Fusarium solani [52] Rhizopus stolonifer [53] Trichoderma viridiae VPG12 [54] Mucor sp. [55] Moorella speciosa [56] Beauveria sp. [7] Cephalosporium sp. KSM 388 [57] Yeasts Wickerhamomyces anomalus 227 [58] Metschnikovia pulcherrima 446 [58] Candida spp. [13] Yarrowia lipolytica [59] Rhototorula mucilaginosa KKU-M12C [60] Cryptococcus albidus KKU-M13C [60] Table 1.

Some protease-producing microorganisms.

-

Purification method Advantage Disadvantage Ultrafiltration High product throughput; lower complexity; economical; low maintenance; requires no chemicals Clogging of membrane hinders purification process Precipitation Simple; reduces enzyme solubility in aqueous solution Not efficient for complete enzyme purification; time consuming; difficult to use for large-scale enzyme purification Ion-exchange chromatography High separation efficiency; simple; controllable Buffer requirement; pH dependence; inconsistency in columns; expensive columns Affinity chromatography High sensitivity and specificity; gives high degree of enzyme purity Difficult to handle; requires limited sample volume; low productivity; uses expensive ligands; non-specific adsorption Hydrophobic interaction chromatography Versatile; non-denaturing Requirement for non-volatile mobile phase Table 2.

Advantages and disadvantages of protease purification methods.

-

Microorganism pH optima Temperature optima (°C) Kinetics parameter

(Km and Vmax)Substrate specificity Reference Bacillus sp. CL18 8.0 55 − Casein and soy protein [29] Bacillus caseinilyticus 8.0 60 − Casein, bovine serum albumin, gelatin and egg albumin [161] Bacillus licheniformis A10 9.0 70 0.033 mg/ml & 8.17 µmol/ml/min Casein [162] Bacillus licheniformis UV-9 11.0 60 5 mg/ml & 61.58 µM/ml/min Casein, haemoglobin and bovine albumin [163] Bacillus pumilus MCAS8 9.0 60 − Bovine serum albumin, casein, haemoglobin, skim milk, azocasein and gelatin [164] Bacillus pseudofirmus 10 50 0.08 mg/ml & 6.346 µM/min Casein [26] Bacillus circulans MTCC 7942 10 60 3.1 mg/ml & 1.8 µmol/min Casein [165] Bacillus circulans M34 11 50 0.96 mg/ml & 9.548 µmol/ml/min Casein, ovalbumin and bovine serum albumin [166] Bacillus amyloliquefaciens SP1 8.0 60 0.125 mg/ml & 12820 µg/ml Casein [156] Bacillus sp. NPST-AK15 10.5 60 2.5 mg/ml & 42.5 µM/min/mg Gelatin, bovine serum albumin and casein [8] Stenotrophomonas maltophilia SK 9.0 40 − Bovine serum albumin, casein and gelatin [167] Stenotrophomonas sp. IIIM-ST045 10.0 15 − − [47] Aeribacillus pallidus C10 9.0 60 0.197 mg/ml & 7.29 µmol/ml/min Casein [168] Geobacillus toebii LBT 77 13.0 95 1 mg/ml & 217.5 U/ml − [33] Streptomyces sp. M30 9.0 80 35.7 mg/ml & 5 × 104 U/mg Casein, bovine serum albumin, bovine serum fibrin [169] Alternaria solani 9.0 50 − − [49] Beauveria bassiana AM-118 8.0 35−40 0.216 and 0.7184 mM & 3.33 and 1.17 U/mg − [170] Table 3.

Biochemical properties of some microbial proteases.

-

Industry Application Product Detergent Remove proteinaceous stains from clothes

Improve washing performance in domestic laundryClean fabrics Leather Soaking, dehairing and bating

Enhance leather quality

Reduce or eliminate dependence on toxic chemicalsSoft, supple and pliable leather Food Meat tenderization; modification of wheat gluten; cheese-making; preparation of soy hydrolysates; improves extensibility and strength of dough Protein hydrolysate; cheese; soy sauce and soy products; meat products; enhanced dough volume Waste management Solubilize (degrade) proteinaceous wastes Additives in feeds and fertilizer Biomedicine Antimicrobial agents, anti-inflammatory agents, anti-cancer agents, anti-tumor agents, thrombolytic agents Therapeutics and pharmaceuticals Photographic Recover silver from X-ray films Secondary silver Textile Silk degumming High strength silk fibre; sericin powder Table 4.

Some potential biotechnological applications of microbial proteases

Figures

(1)

Tables

(4)