-

Figure 1.

Diagram showing the generation of plasma.

-

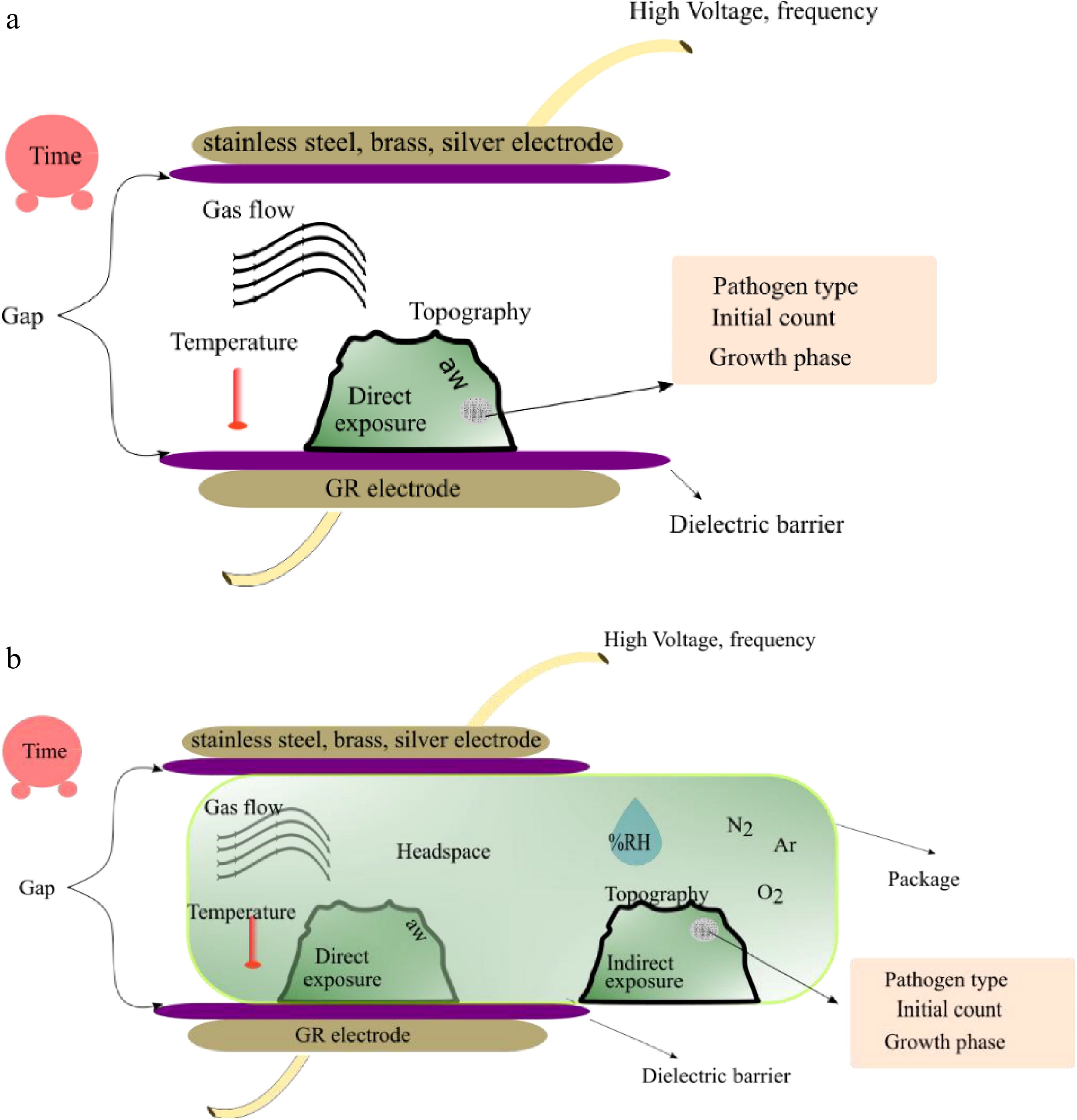

Figure 2.

Basic configuration and treatment of DBD device. (a) Open treatment, (b) packaging treatment.[33]

-

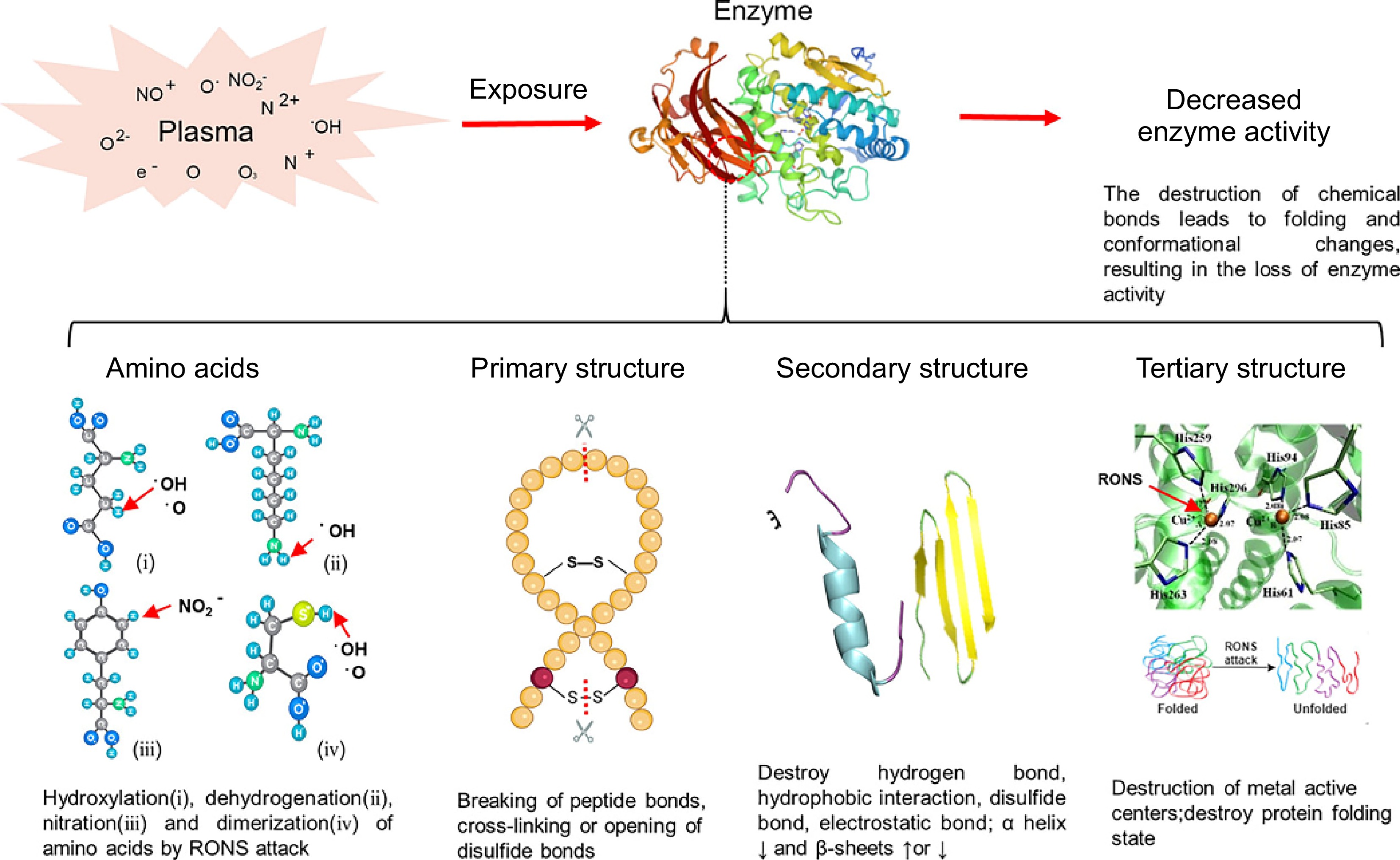

Figure 3.

Mechanism of CP affecting enzyme activity[35].The red dotted line and arrow indicate the position where the plasma exposure destroys the chemical bond. RONS: reactive oxygen species and reactive nitrogen species.

-

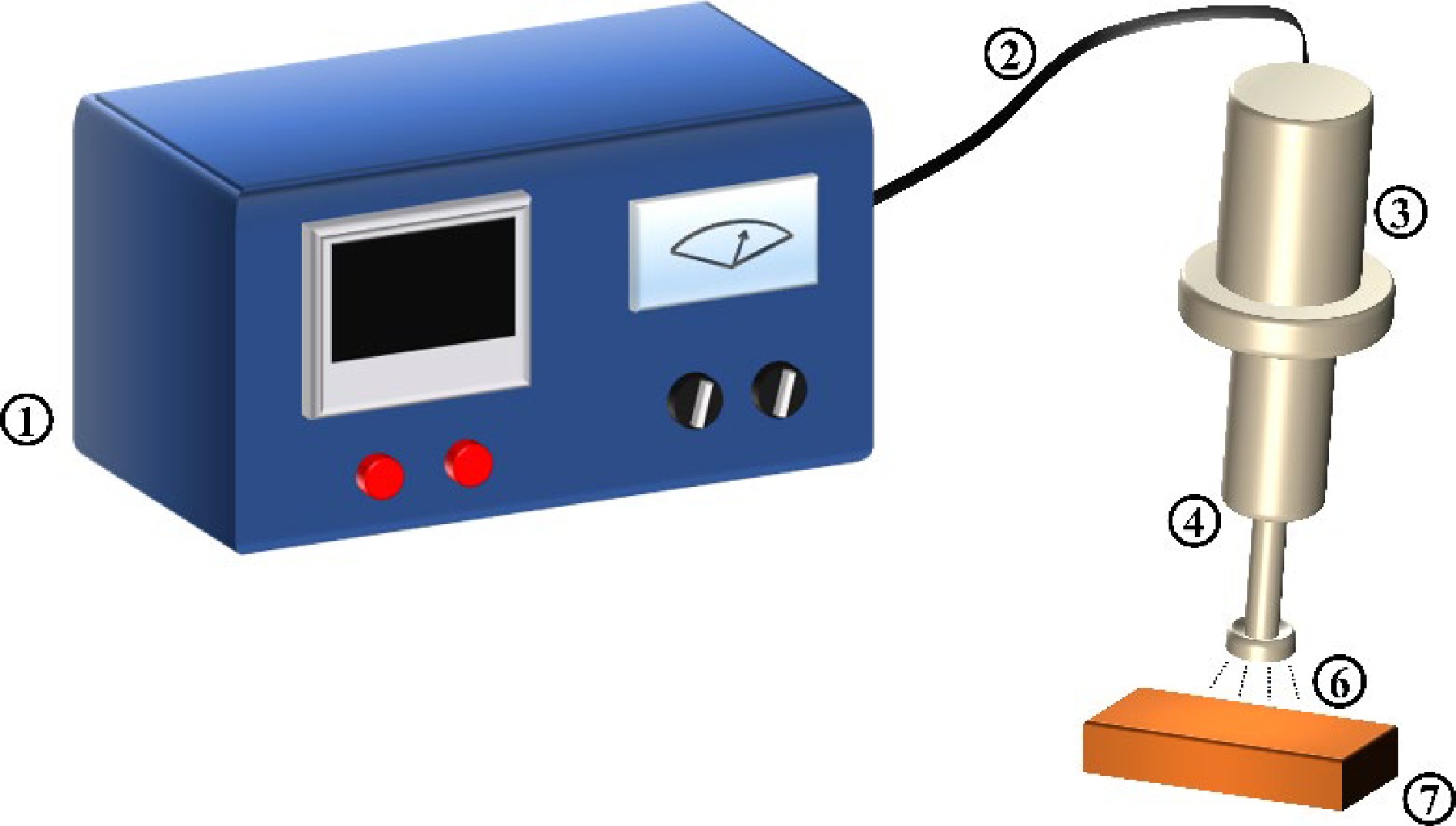

Figure 4.

Acoustic wave generating system. 1. Ultrasound generator, 2. electric energy, 3. ultrasound transducer, 4. emitter, 6. ultrasound, 7. samples.

-

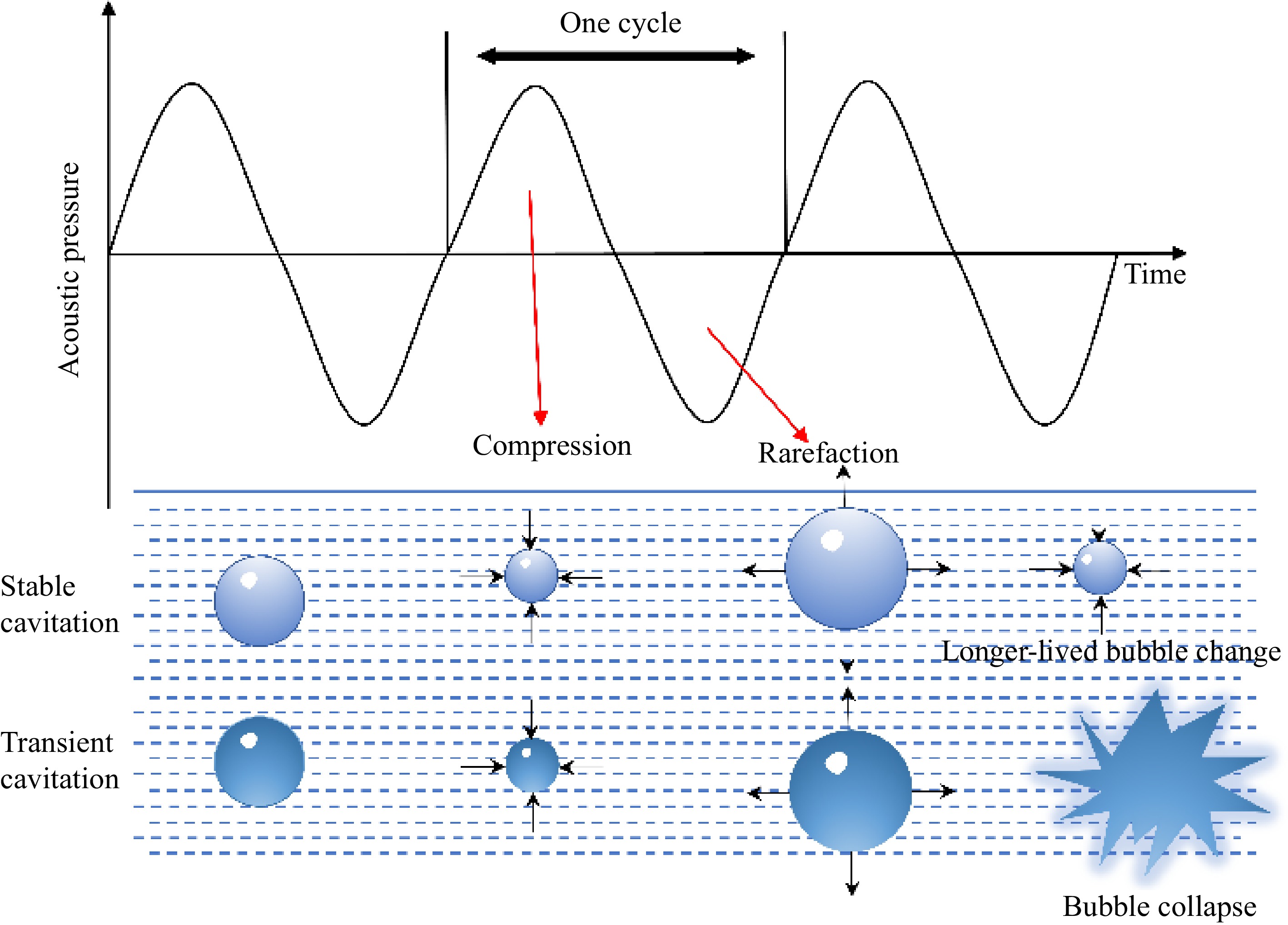

Figure 5.

Ultrasound waves and the cavitation phenomenon.

-

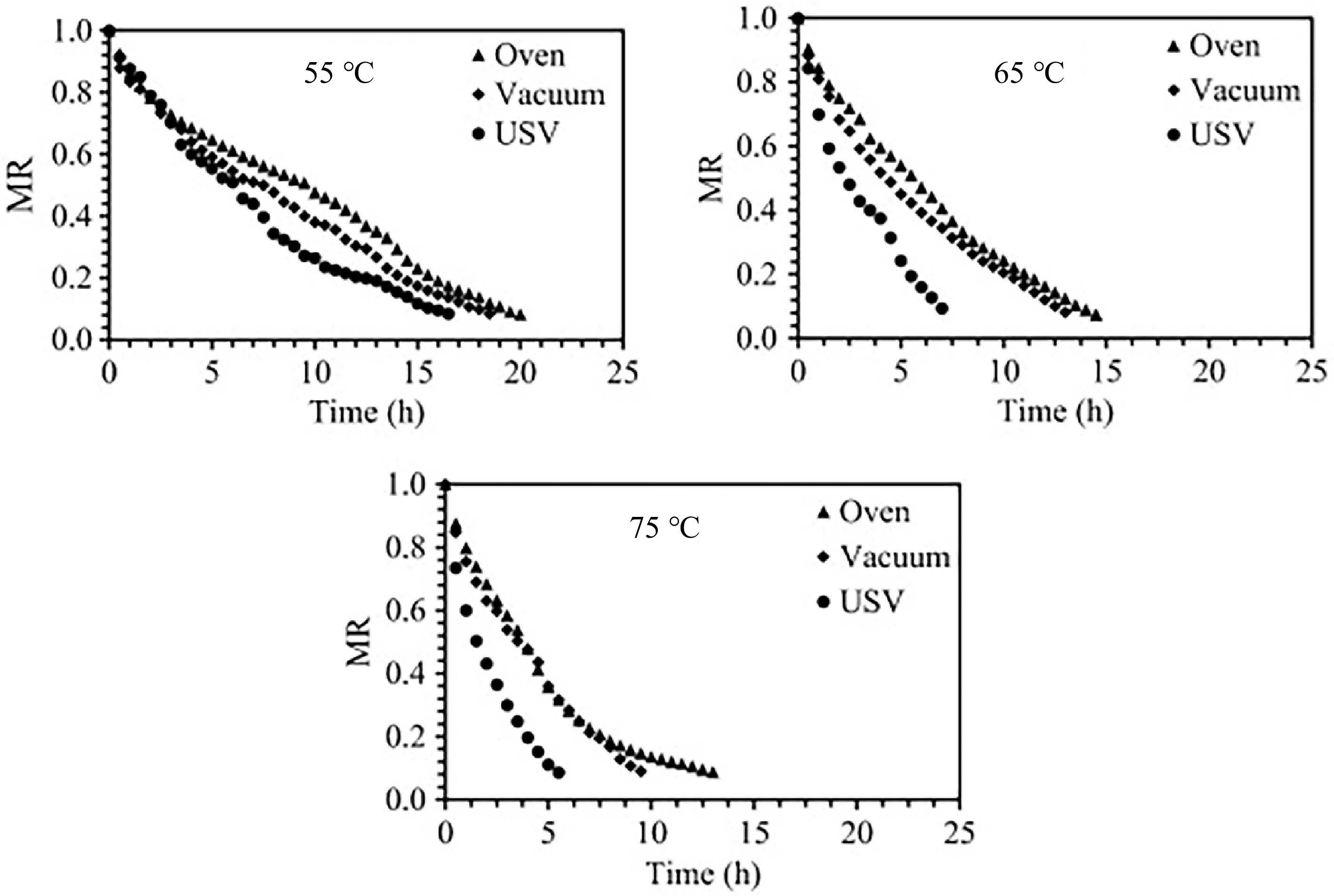

Figure 6.

Drying curves of chicken breast meat dried with different techniques[91].

-

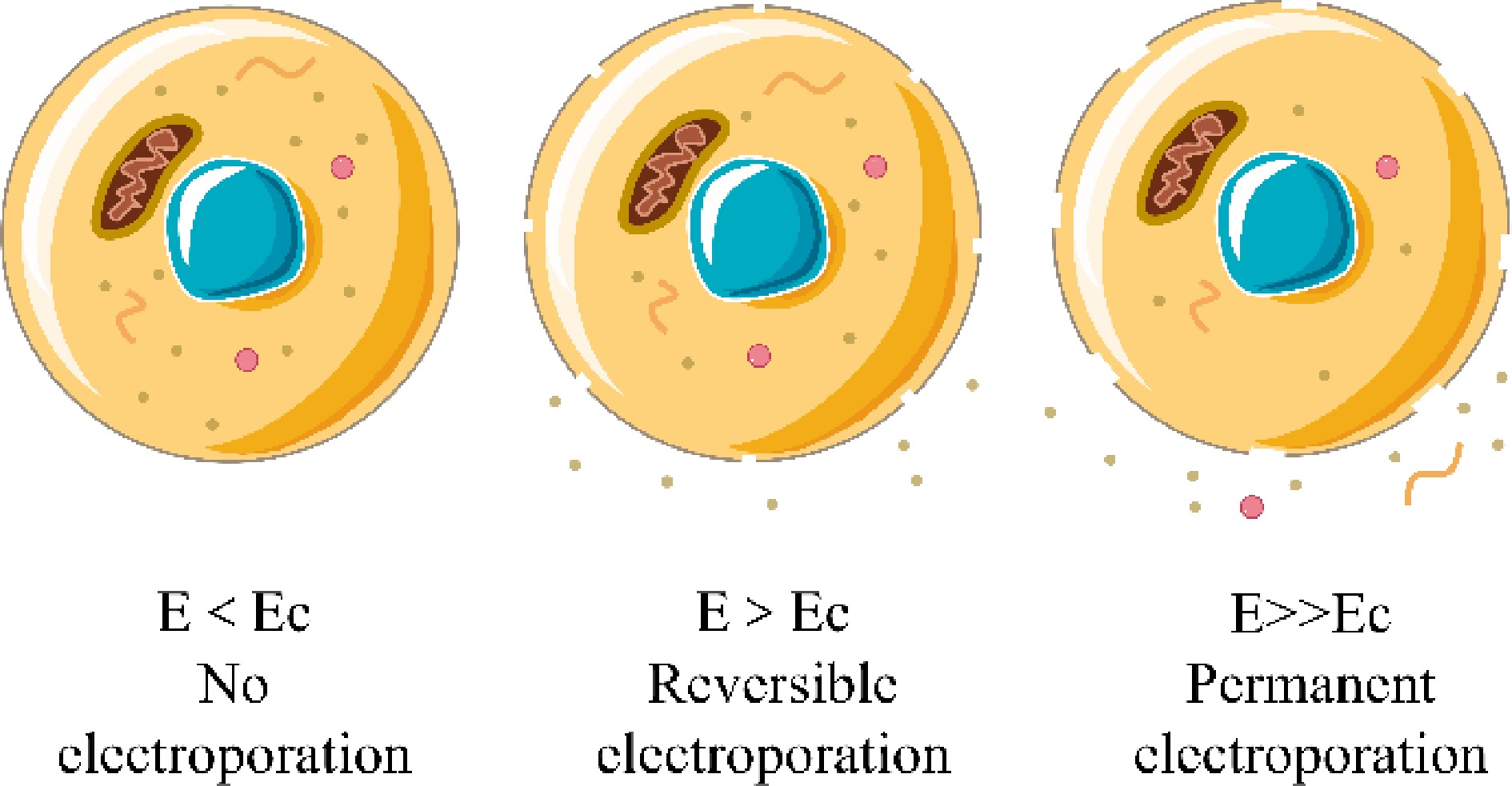

Figure 7.

Schematic representation of electroporation.

-

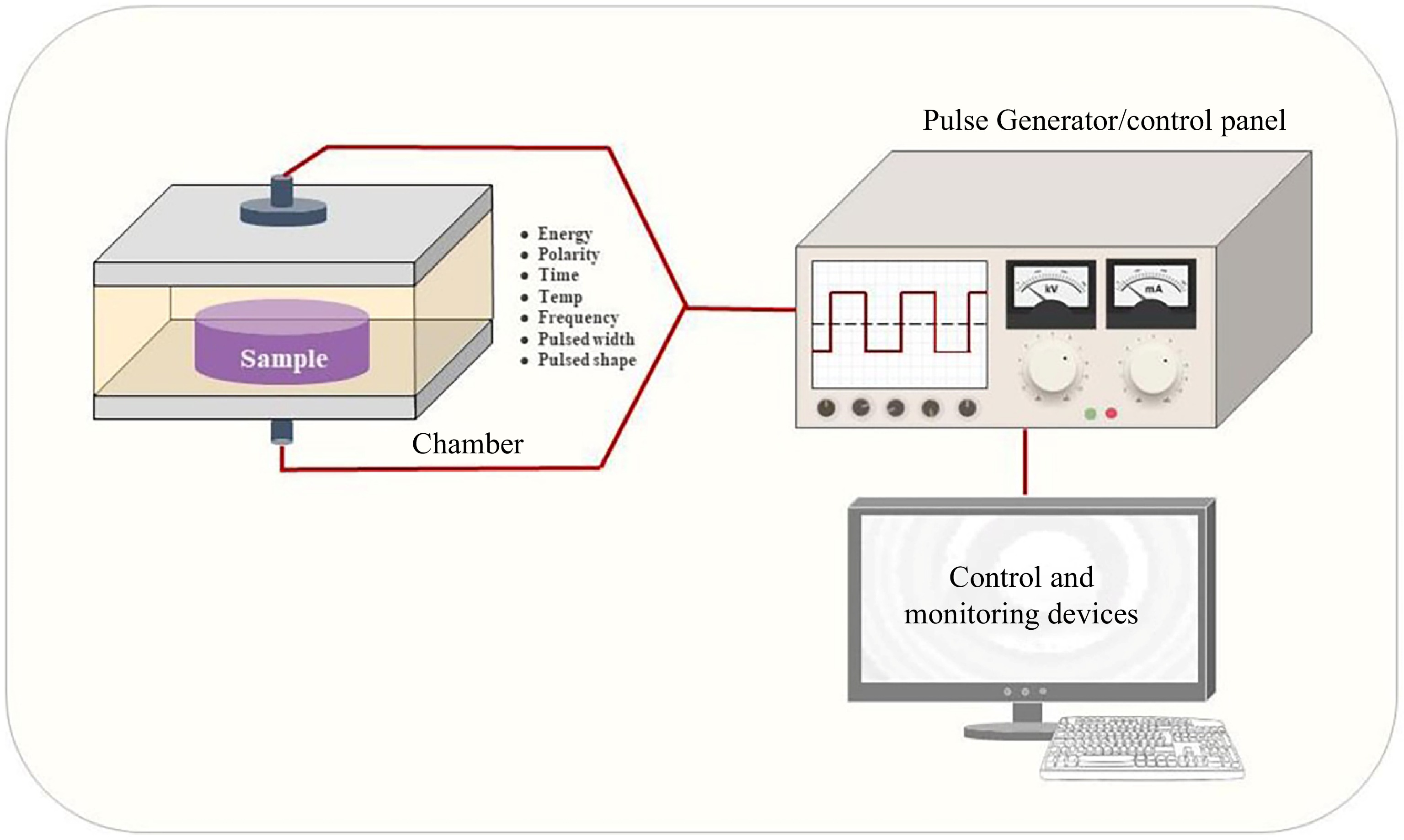

Figure 8.

Schematic diagram of the primary components of pulsed electric field (PEF) food processing systems[116].

-

Material Conditions Drying method Main results Reference Tucumã 20 kV, 200/500/800 Hz, 10 min

(dielectric barrier discharge)Hot air drying The cells of tucumã treated by CP at 200 Hz and 800 Hz were deformed seriously and formed larger voids. The CP pretreatment improved the concentration of phenolic and antioxidant compounds. [37] Shiitake mushroom 650 W, 135 L·min−1,

10 min

(dielectric barrier discharge)Hot air drying The mushrooms treated with CP displayed greater microstructure changes and preserved higher nutritional attributes (sugars, vitamins, phenolic acids contents and antioxidant activity) compared to the control groups. [38] Whole jujube 5 kV, 650 W, 40 kHz,

1 min

(glow discharge)Hot air drying CP pretreatment significantly changed the surface morphology of jujube, shortened the drying time by 12%, increased the total phenol content by 12%, increased the antioxidant capacity (iron reduction antioxidant capacity) by 11%, and reduced the formation of 5-hydroxymethylfurfural by 15%. [10] Saffron 8 kV, 50 kHz, 15/30/45/60 s

(gliding arc discharge)Hot air drying The sample pretreatment (60 s) with CP reduced the drying time by 54.05% and the energy consumption by 39.52%. 30s pretreatment samples showed significantly higher crocin (12.28%), picrocrocin (19.29%), phenolic compounds (11.33%) and antioxidant scavenging activity (1.76%). [58] Goldenberry 10 kV, 300 W, 50 Hz, 15/30/45/60 s

(gliding arc discharge)Ultrasound-assisted convective drying CP pretreatment lowered the drying temperature from 60−90 °C to 50 °C. The retention of vitamin C, antioxidant activity and total phenolic content increased significantly, and the color retention, storage stability and water absorption capacity were better. [59] White grapes 500 W, 25 kHz, 40 L·min−1

(atmospheric plasma jet)Hot air drying The drying time was reduced by more than 20%, and the total phenol content and antioxidant capacity were increased by more than double. No toxic residues are left, and the product quality is successfully maintained. [60] Shiitake mushroom 650 W, 135 L·min−1,

10 min

(cold atmospheric plasma jet)Hot air drying CP pretreatment significantly altered the surface morphology of shiitake mushrooms, producing intracellular spaces, larger cavities and smaller densities, with reduced activation energy, drying time and energy requirements, and retained the highest amounts of phenolics (463.30 mg/100 g), flavonoids (100.70 mg/100 g) and 2,2-Diphenyl-1-picrylhydrazyl (DPPH) relative inhibitory activity (0.201). [61] Jujube slices 5 kV, 650 W, 40 kHz, 15/30/60 s

(glow discharge)Hot air drying The application of CP significantly changed the surface topography of jujube slice by etching larger cavities, increased the content of proanthocyanidins, flavonoids and phenolic compounds as well. [53] Wolfberry 20 kHz, 750 W, 3 L·min−1, 15/30/45/60 s

(glide arc discharge)Hot air drying CP pretreatment reduced drying time, improved rehydration capacity and color quality, while the retention of phytochemicals varied with the duration of CP treatment. [54] Table 1.

Study on the effect of CP pretreatment on the retention of active substances in the drying process of agricultural products.

-

Material Device Drying method Main results Reference Beef, chicken Ultrasonic water bath Ultrasound-assisted vacuum drying MR in ultrasonically treated chicken meat decreased exponentially with increasing time. The combination of ultrasound and vacuum showed higher water loss rate and lower drying time compared to oven and vacuum drying. [91] Chicken breast Probe Combined supercritical CO2-ultrasonic drying The synergistic effect of supercritical CO2 and ultrasound promotes drying kinetics. High-power ultrasound enhanced water extraction, greatly reduced drying time, and resulted in lower water activity and higher porosity of the final samples. [92] Minced meat Ultrasonic water bath Ultrasound-assisted vacuum drying Compared to vacuum drying, ultrasound-assisted vacuum drying showed lower drying times, higher rehydration values, higher porosity, more open structure and lower peroxide values at all temperatures. [93] Pork liver Airborne ultrasound Ultrasound-assisted hot air drying The application of ultrasound improves the drying rate and reduces the drying time by 40% at 30 °C, but power ultrasound has less effect on the drying rate at high temperatures (60 °C and 70 °C). [94] Salted cod Airborne ultrasound Ultrasound-assisted hot air drying Application of power ultrasound at low temperatures increased the drying rate, reducing the drying time by 35−50% on average and increasing the lightness (L*). Microstructural analysis showed that the application of ultrasound during drying caused changes in the cod fibers, resulting in higher rehydration capacity and softer samples. [95] Clipfish Airborne ultrasound Ultrasound-assisted convective drying The drying time at 20 °C can be reduced by 43% at an ultrasonic intensity of 25 W·kg−1. The energy consumption for ultrasonic drying increase multiple times despite its faster dehydration. In addition, the water distribution in batch drying is uneven and the ultrasonic energy in the system is excessive. [96] Table 2.

Progress of ultrasonic assisted drying applied to meat and aquatic products.

-

Material Conditions Drying method Main results Reference Apples tissue 1−2 kV·cm−1, 90 μs,

10−60 pulsesFreeze drying PEF treatment prior to FD saved the energy approximately 24.74% and greatly improved the rehydration ratio of apple tissue. [123] Black soldier fly, yellow mealworm 30 kV, 40 μs, 2 Hz,

5/20 kJ·kg−1Infrared drying PEF treatment promoted the evaporation of water of insect biomass obviously due to the acceleration of mass transfer during drying and maintained the soluble solids content as well as fresh color of products. [124] Apples 1000 V·cm−1, 120 μs,

30 pulsesVacuum freeze-drying The energy consumption was reduced by 20.46% and the drying time was shortened by 22.50%. [125] Carrots 5 kV·cm−1, 10 pulses Microwave-assisted drying PEF treatment reduces drying time by 50%, retains 93.7% of carotenoids, enhances rehydration, increases porosity, and maintains color. [126] Parsnip 0.9 kV·cm−1, 1000 pulses Convective drying The drying time decreased by 5% and 28%, and the effective diffusion of water increased by 38%, which had no significant effect on the mechanical properties. [127] Mango 30 kV, 40 μs, 2 Hz, 1.07 kV·cm−1, 1 or 3 kJ/kg Convective drying and vacuum drying The retention of phenolic compounds in the PEF pretreated materials was 70% higher than that of the untreated ones, but the antioxidant capacity of dried mangoes decreased after high energy PEF treatment. [128] Red pepper 2.5 kV·cm−1, 100 Hz, 4 s Hot air drying The drying time was reduced by 34.7%, and the color and quality of dried red pepper improved. [129] Table 3.

Major advances in PEF pretreatment to dry agricultural products.

Figures

(8)

Tables

(3)