-

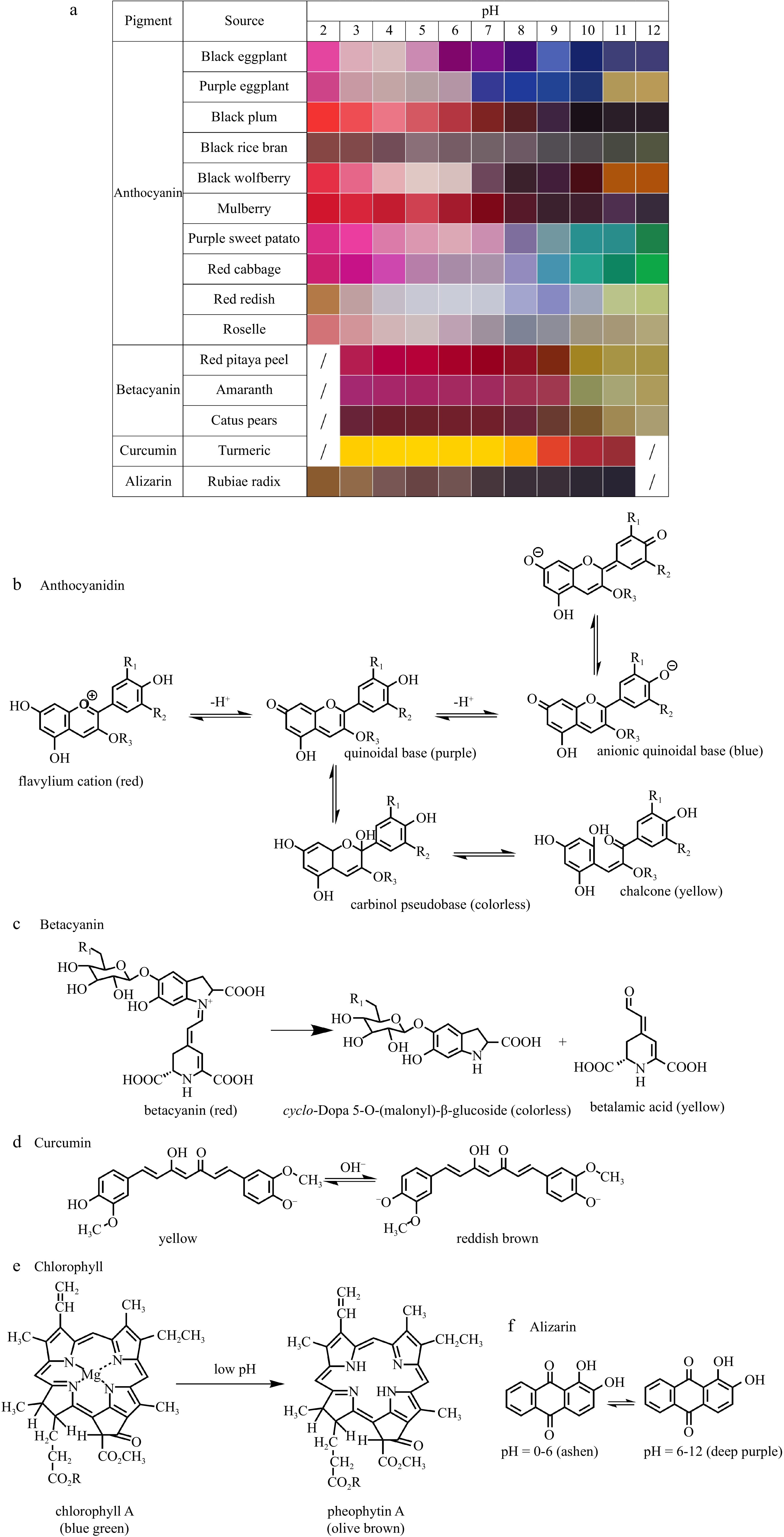

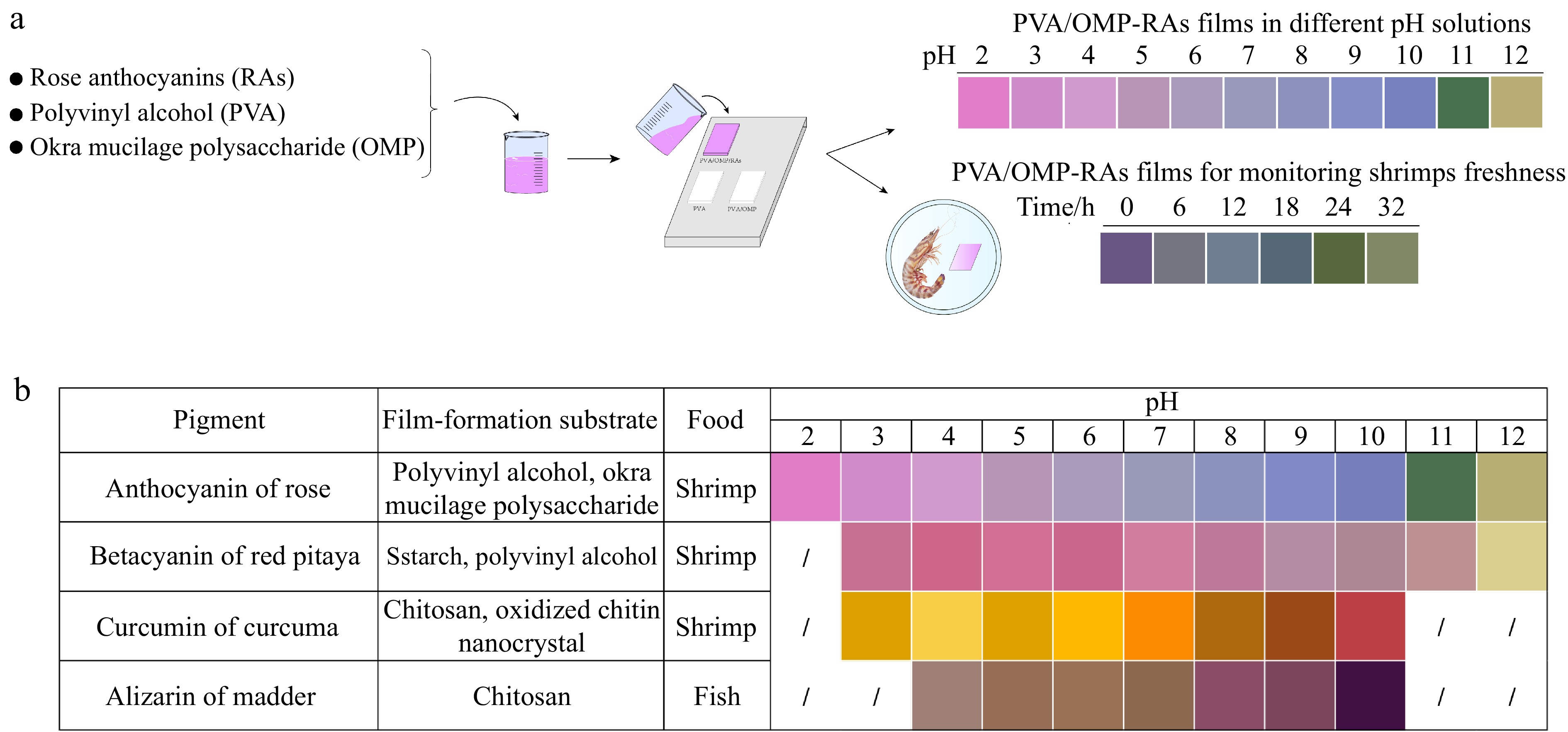

Figure 1.

The interrelationship among novel food packaging films. Note: Butyl hydroxyanisole (BHA), Butylated hydroxytoluene (BHT), Propylene glycol (PG).

-

-

-

Film properties Effects Explanation Structural characterization Cross-section Increases with more plant extract pigments. Pigments can be introduced into the substrate and interact with it. Crystalline character Decreased gradually with an increase in the concentration of plant extract pigments. The plant-derived pigment formed hydrogen bonds with the membrane matrix, thereby enhancing film uniformity and reducing crystallinity. Physical properties Surface color Deepens with more plant extract pigments. This is due to the dispersion of pigments extracted from plants into the film matrix, which imparts color to the films. Thickness Increase in the presence of pigments. The internal structure of the matrix is modified by plant-derived pigment. Moisture

contentIn most cases, there is a reduction in the presence

of the pigments.Plant extract pigments, which interact with each other to form more complex matrices. Water

solubilityIncreases with increasing the concentration

of plant extract pigments.Plant pigments can reduce the interactions between polymeric chains, facilitating the dissolution of the film matrix in water. Decrease in the presence of pigments. Plant pigments can form hydrogen bonds with the film matrix, thereby reducing the number of free hydroxyl groups. Light barrier

abilityThe UV–vis light transmission and the transparency of the films decreased proportionally with an increase in plant extract pigments content. The presence of multiple unsaturated bonds in the plant extract pigments enables them to absorb UV–vis radiation. Water vapor barrier ability Decrease in the presence of pigments. The intermolecular interactions between natural pigments and substrates reduce the membrane's hydrophilicity. Mechanical properties Tensile strength: increased with the increasing content of plant extract pigments. Increase, which was because plant extract pigments play a cross-linking effect on the film matrix. Elongation at break: increased with the increasing content of plant extract pigments content. Pigments enhance the mobility of polymer chains by reducing the intermolecular interactions that bind adjacent macromolecules together. Functional properties Antioxidant activity Increased with the increasing content of plant extract pigments. Mainly due to the antioxidant activity of plant extract pigments. Antimicrobial activity Increased with more plant extract pigments. Pigments can affect the permeability of cell membranes in food-borne pathogens, leading to their eventual death. pH-sensitive Sensitive when films were immersed in different

pH buffer solutions or exposed to ammonia.Films can alter their coloration due to the plant extract pigments in response to varying pH conditions. Table 1.

Impact of incorporation of plant extract pigments on the structural characterization, physical and functional properties of film.

-

Natural pigments Source Film formation substrate Food Application effects Reference Source Species Anthocyanins Mulberry Natural Sodium carboxymethyl starch, κ-carrageenan Fish The color of films is subject to variation based on the freshness of fish (red-blue-yellow). [61] Black rice bran Gelatin, oxidized chitin nanocrystals Shrimp and hairtail Films can be utilized to monitor the spoilage of shrimp and hairtail. The films undergo a color change from purple to gray blue or brown. [62] Black carrot Starch Milk The changes in hue of the label demonstrated a strong correlation with the physical, chemical, and microbiological alterations that occurred during milk spoilage, indicating the indicator's ability to distinguish between fresh, moderately fresh, and spoiled milk. [63] Black carrot Bacterial nanocellulose Rainbow trout, common carp At the stages of fresh fish (dark red), best edible fish (attractive pink), and rotten fish (jelly bean blue and khaki), recognizable color variations are exhibited by the pH indicator film. [64] Echium amoenum flowers Bacterial cellulose Shrimp The color of the film may undergo substantial changes over time, exhibiting fresh (purple), utilized young (gray), and ruined (yellow) shrimp. The TVC and TVB-N values of shrimp are consistent with these color variations. [65] Grape skin κ-carrageenan, hydroxypropyl methylcellulose Pork When the TVB-N level in pork reaches 14.63 mg/100 g (pork is considered spoiled when TVB-N exceeds

15 mg/100 g), the film changes from purple to green, indicating its effectiveness in monitoring pork freshness.[59] Rose Sodium alginate, sodium carboxymethyl cellulose Shrimp The color of the film changes from pink to pale yellow to yellow-green during shrimp storage at 4 °C, indicating that its chromatic response is influenced by pH or TVB-N content. [66] Purple cabbage Watermelon peel pectin Mutton The antioxidant and antibacterial activities of the films were proportional to the anthocyanin content. Furthermore, as the anthocyanin content increased, the film color intensified. [67] Blueberry residue Cassava starch Orange juice, corn oil and chicken pieces The film successfully established a correlation between the color of samples submerged in buffer solutions with varying pH values, simulants and food product. [68] Rose Synthetic and natural Polyvinyl alcohol, okra mucilage polysaccharide Shrimp The target film is capable of real-time monitoring of shrimp freshness, with color changes that can be easily distinguished by the naked eye. [15] Roselle Hydroxypropyl methylcellulose modified polyvinyl alcohol Shrimp The color of the film changed from rose-red to light green on day 4, indicating the onset of spoilage. Subsequently, it turned yellow on day 8 when the shrimp was severely spoiled. [69] Roselle Starch, polyvinyl alcohol, chitosan Pork When utilized for assessing the freshness of pork stored at 25 °C, the film transitioned from red to green prior to the gradual increase of TVB-N value in pork reaching its rejection threshold (15 mg/100 g) after 36 h. [70] Purple cabbage Polyvinyl alcohol, cellulose nanocrystals Shrimp Anthocyanin-containing films exhibit exceptional pH (2−13) and volatile ammonia sensitivity, rendering them ideal for detecting shrimp freshness. [71] Grapes Polyvinyl alcohol, starch Pork The resulting film exhibits color variations within the pH range of 2 to 12, enabling real-time monitoring of pork freshness in the package. [72] Mulberry Polyvinyl alcohol, chitosan nanoparticles Fish The film's color transitioned from red to green due to fish spoilage. [73] Betalain Amaranth Natural Quaternary ammonium chitosan, fish gelatin Shrimp After 24 h of storage, the TVB-N value of the shrimp slightly exceeded the limit, and the color of the films turned yellow as an indicator of decreased freshness. [21] Amaranth Chitosan, gelatin Fish Films enriched with amaranth anthocyanins exhibit active and intelligent properties, including antioxidant, antibacterial, and pH-responsive capabilities. [74] Bougainvillea glabra Choisy flowers Potato starch Fish A starch film containing 15% betacyanin was capable of visually detecting the changes in Caspian sprat quality during cold storage by undergoing a color change from pink to yellow, coinciding with microbiological and chemical alterations in the fish samples. [75] Cactus pears Synthetic and natural Quaternary ammonium chitosan, polyvinyl alcohol Shrimp The films containing 2 and 3 wt% of betalains exhibited a color change from purple to orange when shrimp was not fresh. [22] Amaranth Polyvinyl alcohol, gelatin Fish and chicken The film showed discernible color change from red to yellow on spoilage. [52] Red pitaya peel Starch, polyvinyl alcohol Shrimp The film containing 1.00 wt% of the extract presented visible color changes due to the accumulation of volatile nitrogen compounds during shrimp spoiling. [8] Curcumin / Natural κ-carrageenan, gelatin, zein Grass carp fillets The film indicates a deterioration in freshness through a color change from yellow to red as storage time increases. [76] / Chitosan, oxidized chitin nanocrystal Hair tail and shrimp The color of the films gradually shifted from yellow (day 0) to orange-red (day 5), which may be attributed to the increase in TVB-N levels in seafood samples during storage. [35] / Zein, chitosan Blueberry The reactive film exhibits excellent UV resistance and displays a sensitive pH response to discoloration. [77] / κ-carrageenan Pork and shrimp The color of the film clearly changed from yellow to red on the 3rd day for pork and shrimp storage. [27] / Synthetic and natural Pectin, sulfur nanoparticles Shrimp The film exhibited a pH-responsive color transition that was highly distinctive, changing from yellow to orange in response to variations in shrimp quality. [78] / Chitosan, polyvinyl alcohol Pork and shrimp With the prolongation of storage time, the color of the indicator film shifts from yellow to orange, which serve as an effective means for assessing pork freshness. [79] / Tara gum, polyvinyl alcohol Shrimp The color of the film exhibited a slight yellow hue, which transitioned to an orange-red tint after 3 d due to the increasing pH levels of the stored shrimp. [34] Chlorophyll / Natural Chitosan / Color can be changed from green to yellow by using films containing chlorophyll and chitosan at temperatures between 50 °C and 75 °C. [37] Alizarin / Natural Chitosan Fish The film exhibited a discernible shift in color from khaki to light brown upon the onset of fish spoilage. [7] / Cellulose-chitosan Minced beef The color of the indicator changed from brown to purple as the TVB-N reached a critical level. [39] Anthocyanins

/CurcuminPurple sweet potatoes Synthetic and natural Starch, polyvinyl alcohol Fish The incorporation of anthocyanins and curcumin into the film enabled the packaging of fish with three distinct colors, each indicating a different level of freshness: high, medium, and spoiled. [14] Saffron petals Natural Bacterial cellulose nanofiber substrate Fish The nanofiber loaded with curcumin-anthocyanin exhibited a distinct color change upon exposure to spoiled fish meat in a transparent plastic package. [80] Anthocyanins

/BetacyaninLycium ruthenicum, red pitaya peel Synthetic and natural Starch/polyvinyl alcohol Pork The film, which contained a mixture of anthocyanins and betacyanins in a weight ratio of 1:3, exhibited noticeable color changes when employed as an indicator for monitoring the freshness of pork. [25] Red cabbage, red pitaya Polyvinyl alcohol/sodium carboxymethyl cellulose Pork The diverse colors of CPA-3A1B film can be utilized to distinguish the states of freshness, medium freshness, and deterioration of pork. [81] Table 2.

Implementation of natural pigment-based pH-sensitive intelligent packaging films in food industry.

-

Natural pigments Source Film formation substrate Food Application effects Reference Source Species Anthocyanins Amaranth Natural Hydroxypropyl methylcellulose Salmon oil The films provided superior protection against lipid oxidation by enhancing their barrier properties against light and oxygen. [82] Cranberry Gelatin Olive oil The film inhibited the oxidative deterioration of olive oil. [50] Grape pomace Guar gum Pomegranate arils The developed films exhibited notable antimicrobial activity against diverse food-borne pathogens. [83] Grape pomace Cassava starch Sunflower oil The impact of films on the inhibition of sunflower oil oxidation (peroxide value). [84] Grape pomace Cassava starch Olive oil The incorporation of anthocyanins in the packaging material can effectively inhibit the oxidation of EVOO, thereby prolonging its shelf life. [85] Pomegranate peel Zein Himalayan cheese The utilization of film as a packaging material for kalari cheese effectively inhibited oxidation reactions and microbial spoilage during storage. [4] Prunus maackii juice κ-Carrageenan/

hydroxypropyl methylcelluloseLard The films exhibit greater efficacy in retarding the oxidation of lard. [86] Red rice flour Starch Sunflower oil The film exhibited a noteworthy photoprotective effect of sunflower oil and retarded its oxidation process. [87] Betacyanin Amaranthus leaf Synthetic Polyvinyl alcohol /gelatin Fish/chicken The films exhibited activity in the preservation of chilled fish/chicken by delaying microbial growth and minimizing oxidative rancidity. [21] Curcumin Turmeric Natural Gelatin Ground pork The developed films were applied to fresh ground pork to prolong its shelf life, demonstrating favorable antioxidant activity and effectively preventing lipid oxidation of pork. [32] Table 3.

Implementation of natural pigment-based active packaging films with antioxidant and antimicrobial properties in food.

Figures

(3)

Tables

(3)