-

Figure 1.

Dependencies of (a) mass and (b) MLR of beech wood on temperature at different heating rates.

-

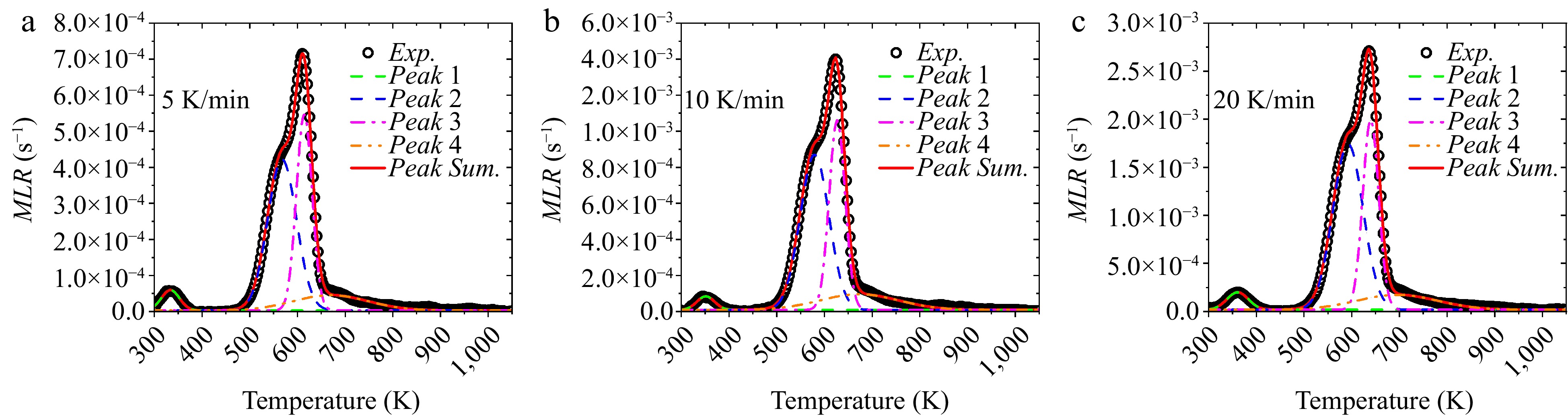

Figure 2.

Separated MLR curves using Gauss multi-peak fitting method at different heating rates.

-

Figure 3.

Linear fittings of

${\text{ln}}( {\beta /{T_p}^2} )$ $1/{T_p}$ -

Figure 4.

Linear fittings of

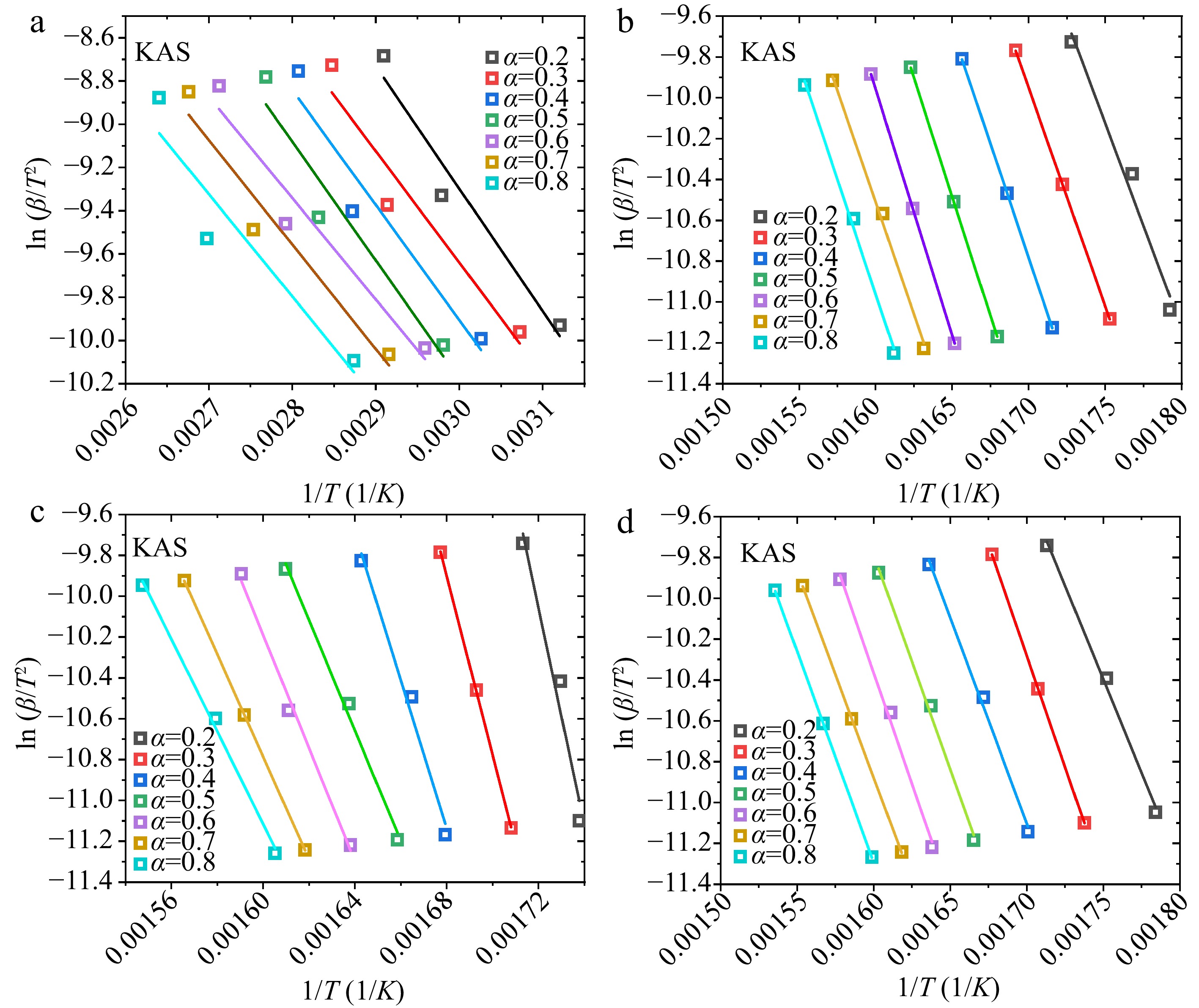

${\text{ln}}( {\beta /{T^2}} )$ $1/T$ -

Figure 5.

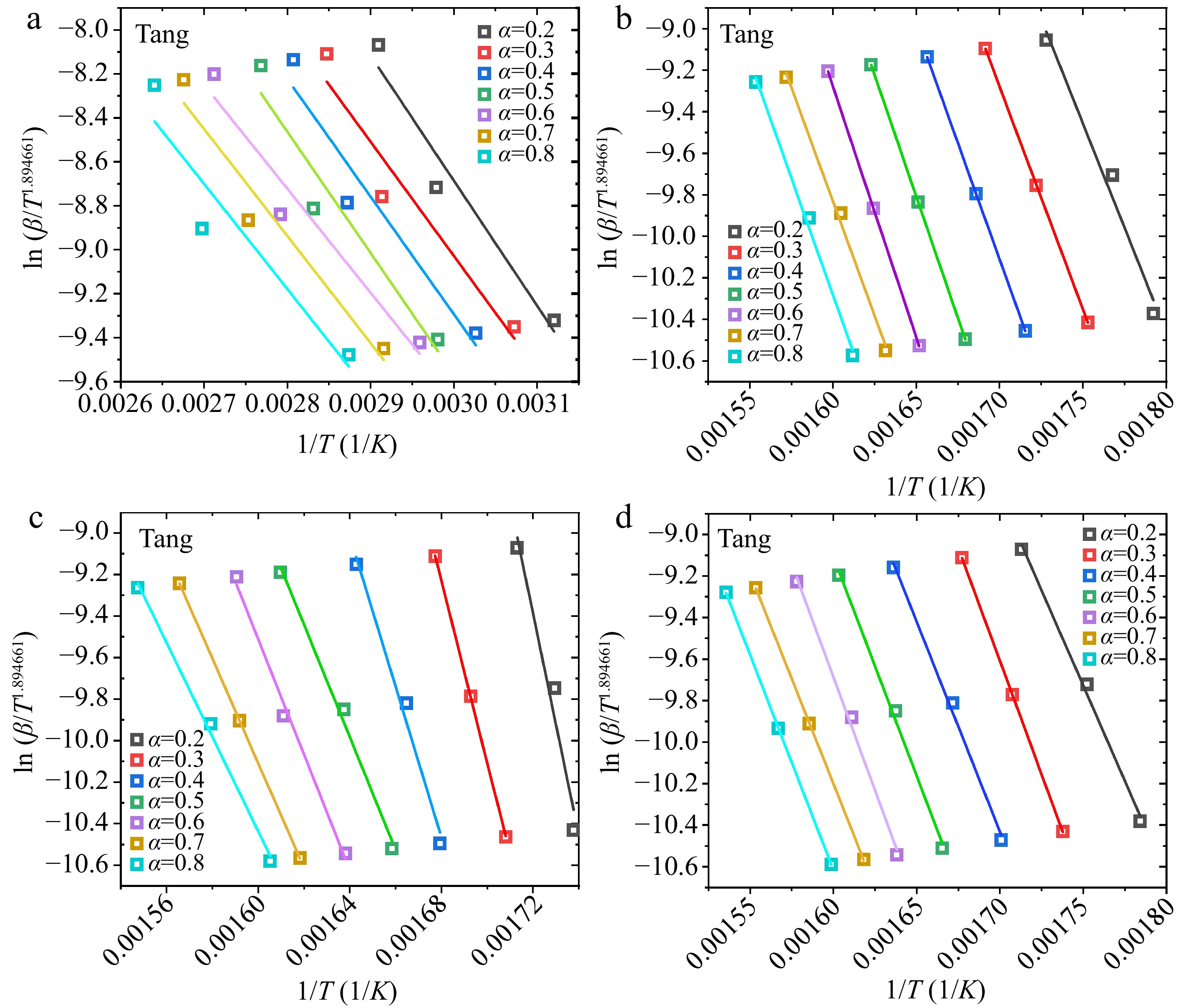

Linear fittings of

$\ln ( {\beta /{T^{1.894661}}} )$ $1/T$ -

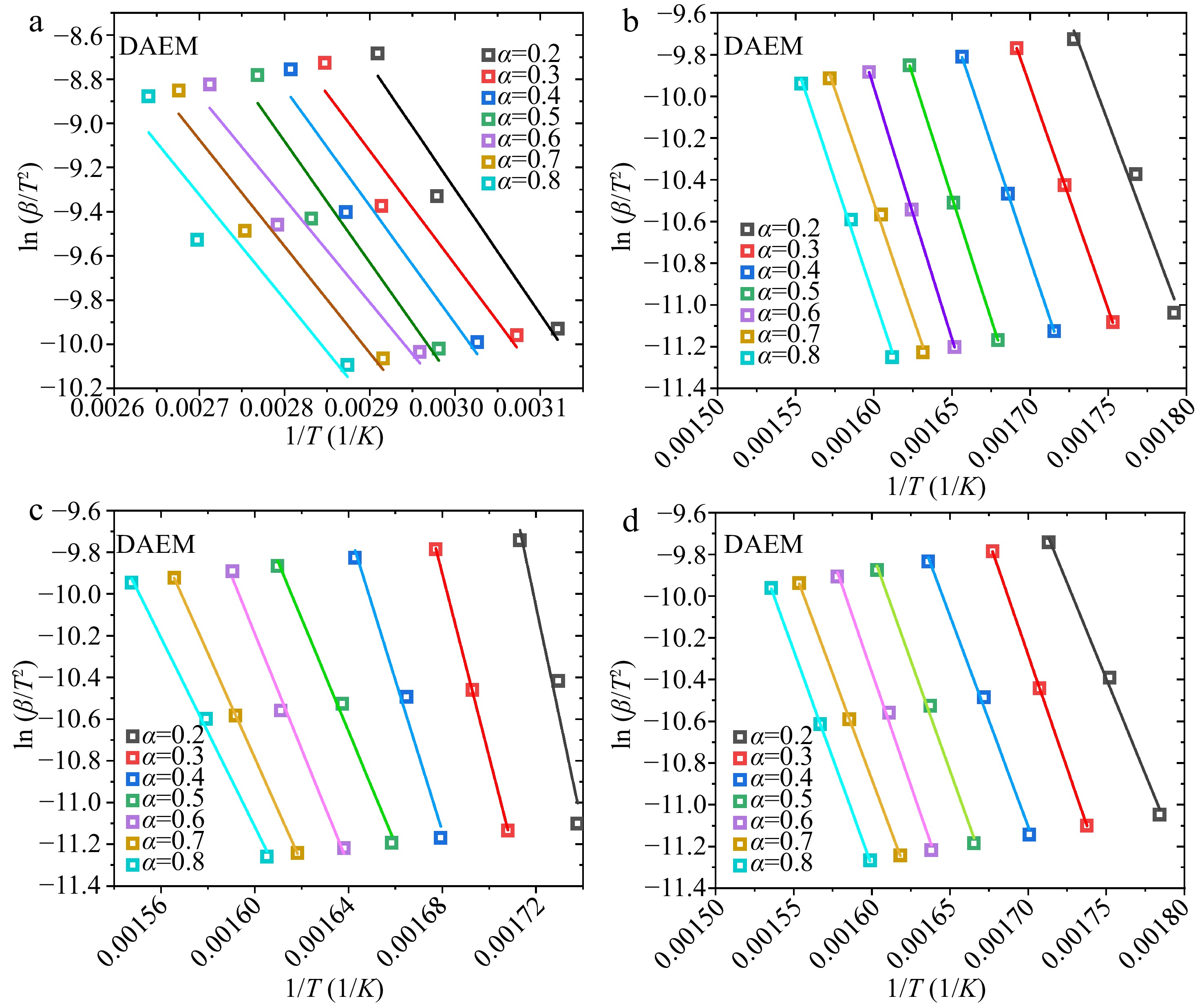

Figure 6.

Linear fittings of

${\text{ln}}( {\beta /{T^2}} )$ $1/T$ -

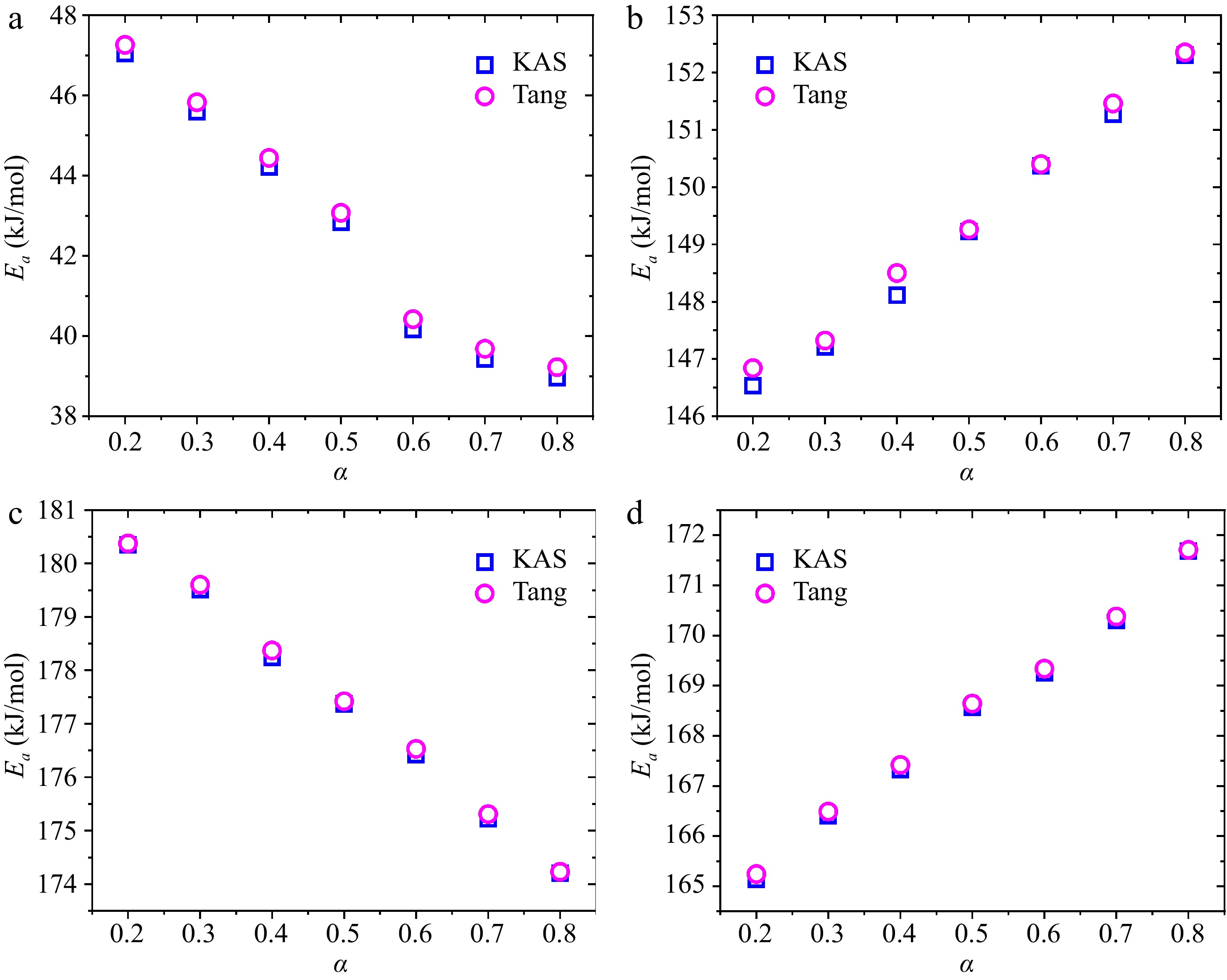

Figure 7.

Dependencies of calculated

${E_a}$ -

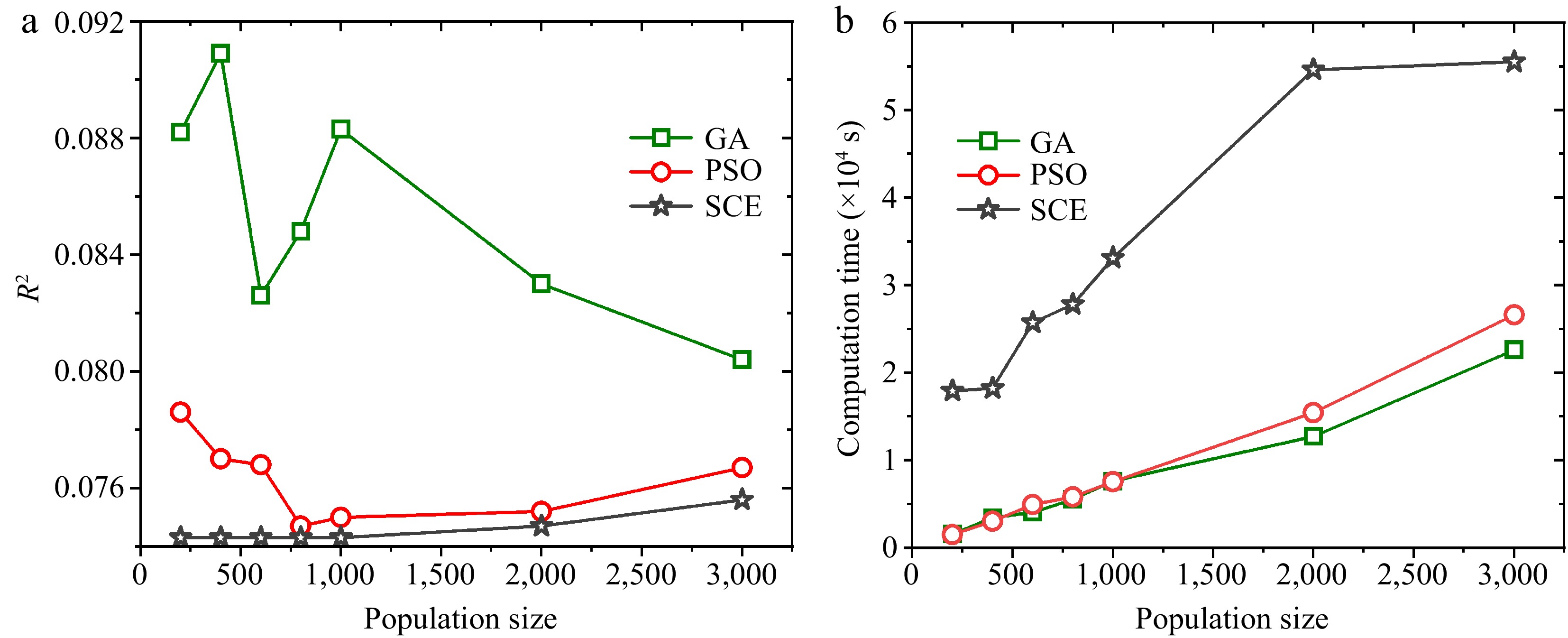

Figure 8.

Objective function values and the computation times of the three algorithms when optimizing kinetics of wood pyrolysis with 200-3000 population sizes and 200 iterations.

-

Figure 9.

Objective function value evolutions of the three algorithms when optimizing kinetics of wood pyrolysis with 3,000 population size and 6,000 iterations.

-

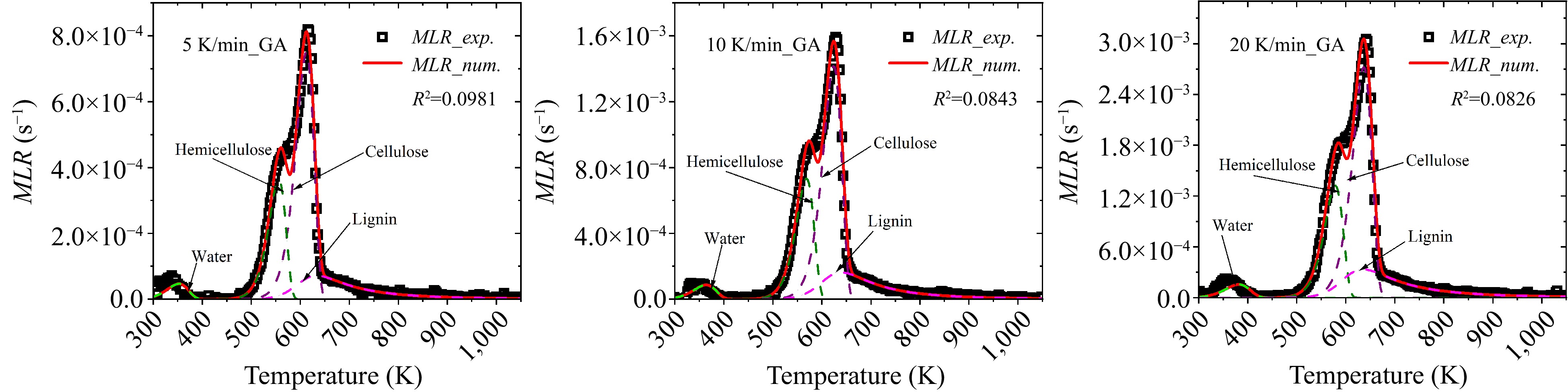

Figure 10.

Comparison between experimental and numerical MLRs using optimized parameters of GA at 5, 10 and 20 K/min heating rates.

-

Figure 11.

Comparison between experimental and numerical MLRs using optimized parameters of PSO at 5, 10 and 20 K/min heating rates.

-

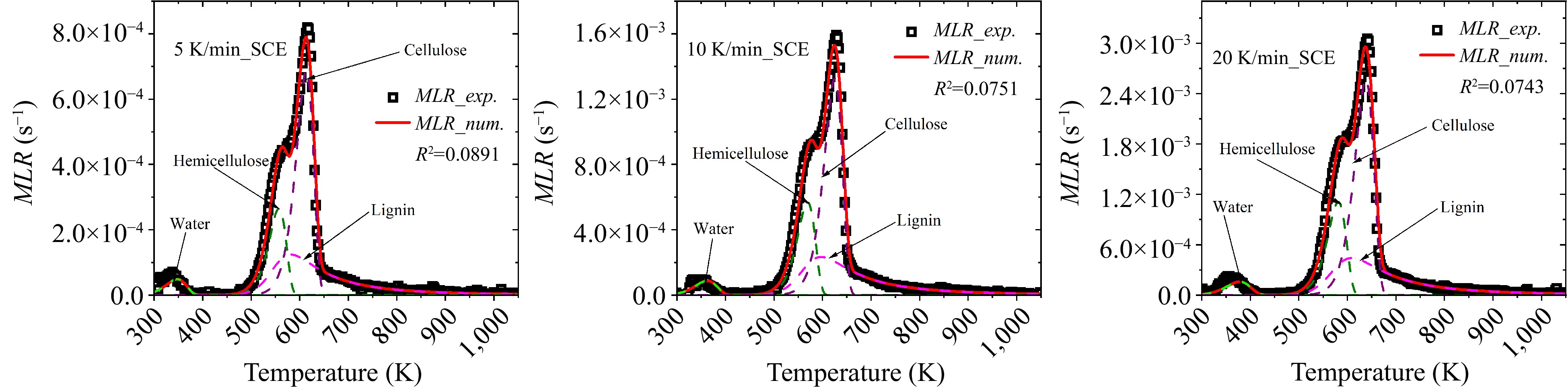

Figure 12.

Comparison between experimental and numerical MLRs using optimized parameters of SCE at 5, 10 and 20 K/min heating rates.

-

# Reaction 1 Water → Vapor 2 Hemicellulose → θ1 Char + (1−θ1) Gas_H 3 Cellulose → θ2 Char + (1−θ2) Gas_C 4 −Lignin → θ3 Char + (1-θ3) Gas_L Table 1.

Reaction mechanism of beech wood.

-

Component Kissinger KAS Tang DAEM Average A Ea A Ea A Ea A Ea A Ea Water 1.49 × 103 44.8 1.01 × 103 42.6 2.61 × 103 42.9 1.53 × 103 42.6 1.72 × 103 42.7 Hemicellulose 1.12 × 1012 147.8 1.30 × 1013 144.7 3.06 × 1013 154.9 9.31 × 1012 144.7 1.77 × 1013 148.1 Cellulose 4.09 × 1012 166.3 4.70 × 1012 174.8 4.84 × 1012 169.7 4.12 × 1012 174.8 4.55 × 1012 173.1 Lignin 2.34 × 1011 180.5 6.40 × 1011 170.7 1.46 × 1012 171.2 7.96 × 1011 170.7 9.66 × 1011 170.9 Table 2.

Estimated

$A$ ${E_a}$ -

Population size GA PSO SCE tcom × 104 (s) R2 × 10−2 tcom × 104 (s) R2 × 10−2 tcom × 104 (s) R2 × 10−2 200 0.16 8.82 0.15 7.86 1.79 7.43 400 0.34 9.09 0.30 7.70 1.82 7.43 600 0.40 8.26 0.49 7.68 2.57 7.43 800 0.55 8.48 0.58 7.47 2.78 7.43 1,000 0.76 8.83 0.75 7.50 3.31 7.43 2,000 1.27 8.30 1.54 7.52 5.46 7.47 3,000 2.26 8.44 2.66 7.67 5.55 7.56 Table 3.

Computation times and

${R^2}$ -

Component Parameter Search range GA PSO SCE Water A (s−1) 1.72 × 102−1.72 × 104 1.47 × 104 1.49 × 104 1.49 × 104 Ea (kJ/mol) 4.28 × 104−4.48 × 104 4.4 × 104 4.4 × 104 4.4 × 104 Hemicellulose A (s−1) 9.41 × 1011−9.41 × 1013 5.53 × 1012 4.49 × 1012 4.18 × 1012 Ea (kJ/mol) 1.38 × 105−1.58 × 105 1.4 × 105 1.38 × 105 1.38 × 105 θ 0−0.5 0.28 0.38 0.37 Cellulose A (s−1) 4.32 × 1011−4.32 × 1013 4.09 × 1012 3.95 × 1012 4.09 × 1012 Ea (kJ/mol) 1.6 × 105−1.8 × 105 1.63 × 105 1.63 × 105 1.64 × 105 θ 0−0.5 0.13 0.12 0.12 Lignin A (s−1) 6.0 × 1010−6.0 × 1012 2.22 × 1011 1.96 × 1011 1.15 × 1011 Ea (kJ/mol) 0−3.0 × 105 1.23 × 105 1.16 × 105 1.13 × 105 θ 0−1 0.14 0.01 0.01 n 0−5 4.67 4.99 5 Table 4.

Best optimized kinetics of wood pyrolysis by GA, PSO and SCE.

Figures

(12)

Tables

(4)