-

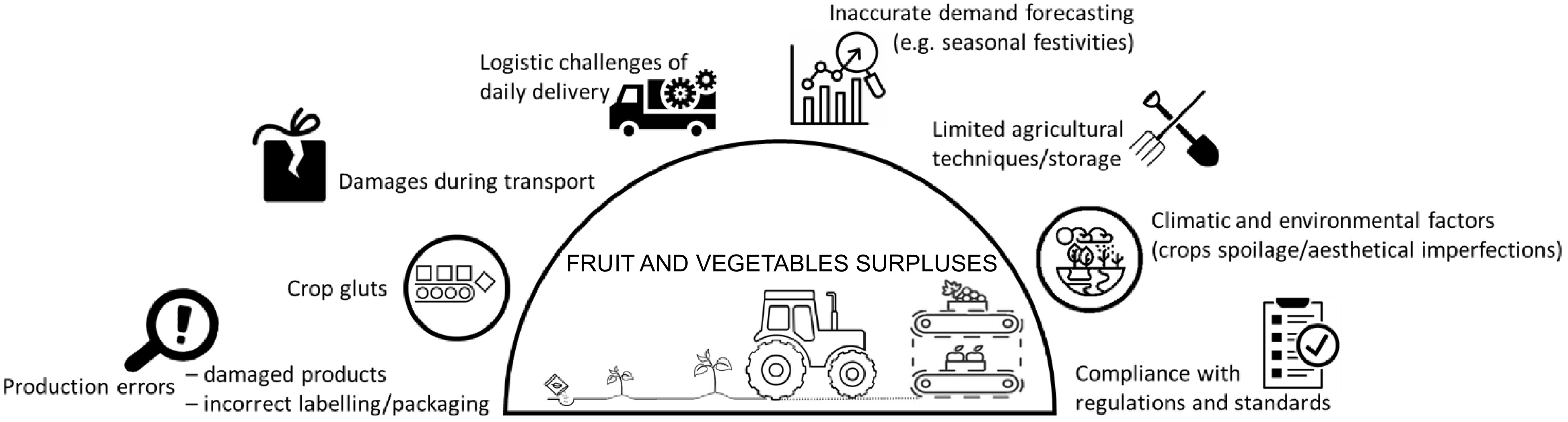

Figure 1.

Fruits and vegetables surpluses: the main causes.

-

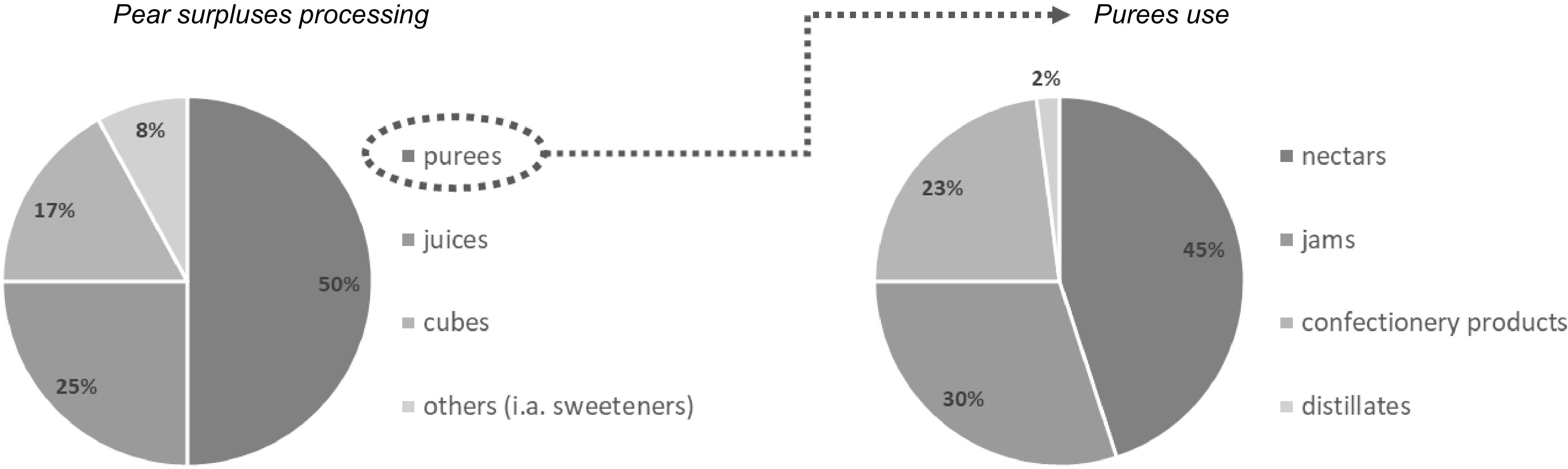

Figure 2.

Italian pear surplus recycling actions – the case of Emilia Romagna consortium.

-

Actions Challenges Reduce Collaboration/information exchange among all supply-chain stakeholders • Dearth of data mining (more sensors, energy counters and flow meters shall be installed for data-collection), elaboration and processing is an issue.

• There is the tendency of preferring the cheapest solutions rather than the most sustainable ones.Audit – detailed measuring of food productions Genetically engineered crops Improved forecasting process (consumers' demand, market trends) Thermal preservation (refrigeration, cold chains) and improved cold chain logistics Smart packaging, labelling and storage technologies Comprehensive analysis of pathogens virulence mechanisms to limit acidic fungi infections Simpler production processes Digital agriculture (Agriculture 4.0) for optimal real-time farm management Reuse Governmental awareness campaigns • Large-scale distributers foresee key specifications for food safety, that lack in farmers markets as well as during gleaning activities.

• It is necessary to resume solidarity approaches between farm owners and volunteers working for charities.

• Food donations are more common in the food retail industry than in restaurants.NGO programs Authenticity and sustainability food positioning Social media activities (e.g. food sharing apps) Farmers markets promotion Field gleaning Donations Recycle Food processing • Maintaining microbacterial and sensorial quality especially for minimally processed fruits and vegetables is the main challenge.

• Hidden risks besides each possible processing operation should be appraised.Shelf-life extension in derived products Study of food markets trends and consumers preferences Flexibility to foresee and allow creative surpluses repurposing Simulation-based approaches in food processing Animal feed Edible insects biorefinery – nutrients circularity Extraction of bioactive compounds Biomass-to-energy Table 1.

Actions to apply the 3Rs – Reduce, Reuse, Recycle – to fruits and vegetables surpluses.

-

Innovation technologies Reduce Invisible, edible coating made from wasted agricultural products to extend the shelf life of fruits and vegetables (up to five times)[42]. Perfect for developing countries where the difficulties involved in getting harvested products to market before they spoil is the major cause of food waste. Active packaging containing sachets for the release of 1-methylcyclopropene (1-MCP), a plant hormone which sends a signal to fruits that it is not yet time to ripen[43]. Suitable for climacteric fruits. Solar-powered cold storage[44] can help reduce costs for low-income producers. Plant extracts (e.g. phenolic compounds) and essential oils (i.a. eucalyptus, hinoki, nutmeg, cinnamon, oregano) to control post-harvest diseases[45]. Reuse Online platforms (i.a., FoodCloud[46] is an inspiring technology platform born in Ireland), and the IoT can help to optimally manage the timing and logistics for food-sharing, and intelligent redistribution. New business offering - 'trash-to-table' concepts[47]. Upcycling and redistribution business is booming. Indeed, it is growing the number of food companies and start-ups committed to 'circular' sustainable practices. Recycle Valorisation of food and beverage remains into luminescent carbon dots and their subsequent transformation into light-emitting diodes[47,48]. LEDs transform electricity to light by using quantum dots with luminescent properties[48]. Innovative technologies used to value waste and by-products (e.g. recovery of bioactive compounds with antioxidant capacity, which can be natural substitutes for traditional synthetic additives or energy-recovery intensification) from the agri-food industry. Among others laser ablation, electrotechnologies (pulsed electric fields, high voltage electrical discharges, non-pulsed electric fields - ohmic heating and moderate electric field), radiofrequency drying, ultrasound-assisted extraction (UAE), high hydrostatic pressure (HHP) and pressurized fluids (sub and supercritical fluid extraction), nanotechnology can be mentioned[49]. Use of natural fibres from vegetables and fruit surpluses for the production of bio-textiles[50]. Table 2.

Innovative technologies that can be applied on the 3Rs – Reduce, Reuse, Recycle – level.

Figures

(2)

Tables

(2)