-

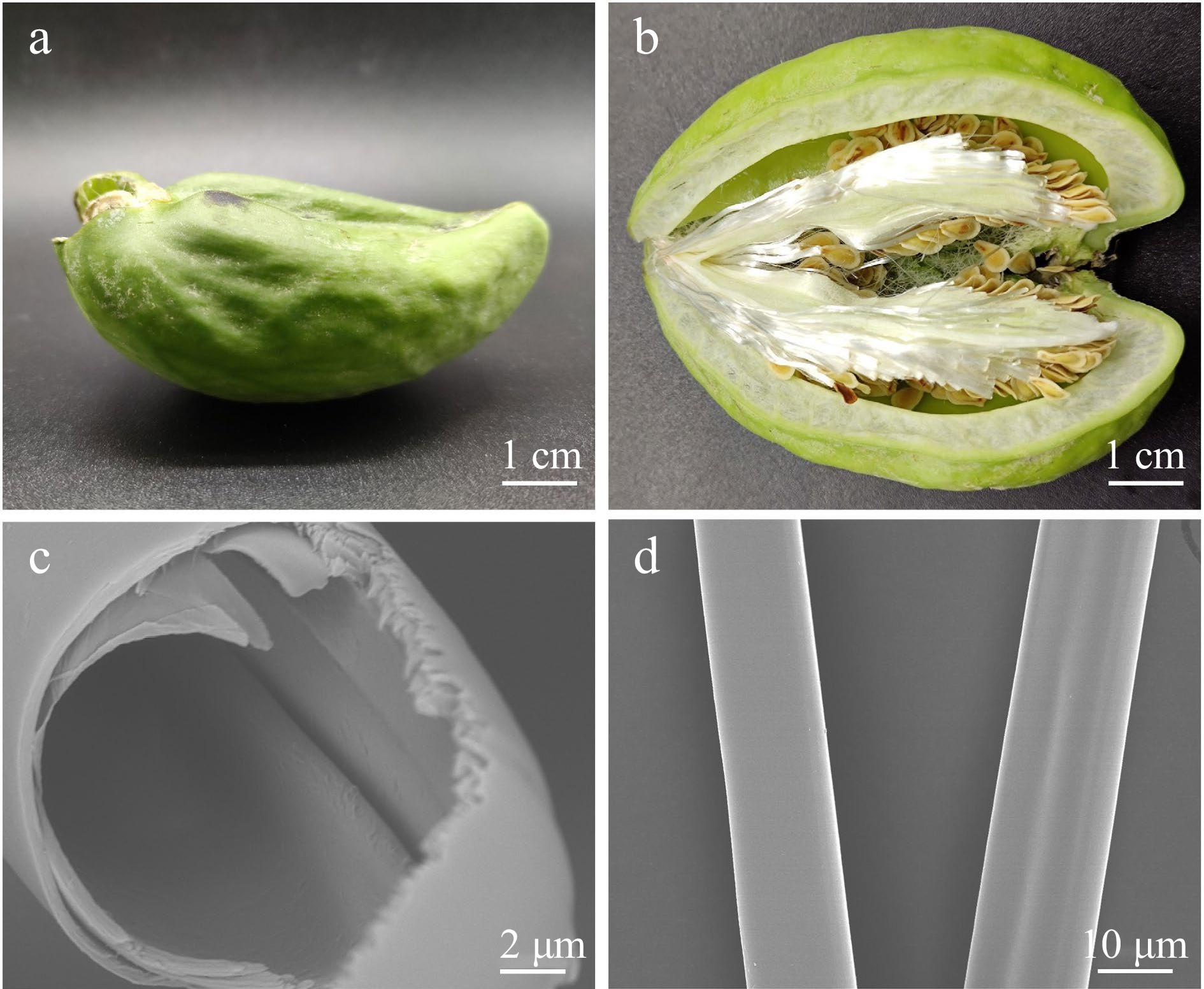

Figure 1.

(a) CG fruit. (b) CG seeds and fibers. (c) SEM image of the cross-section of the CGF. (d) SEM image of the longitudinal direction of the CGF.

-

Figure 2.

(a) The CGF microwave-opening equipment. (b) The CGF extracted from microwave-opening.

-

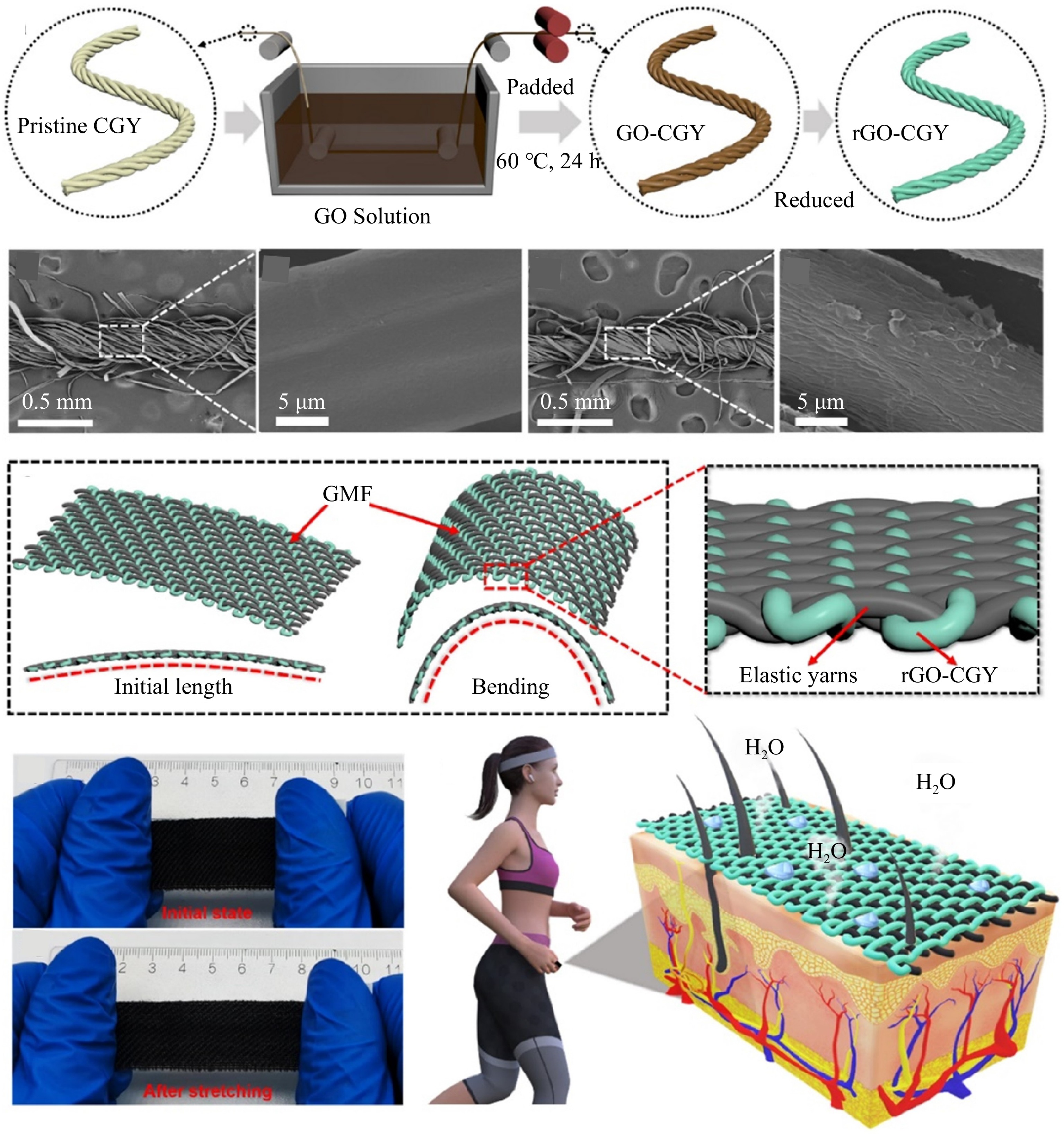

Figure 3.

Illustration of the graphene-modified fabric fabrication process[9].

-

Formation CGF Kapok fiber Cotton fiber Linen fiber Cellulose (%) 66 35−50 94 73−77 Hemicellulose (%) 21 22−45 0 7−9 Lignin (%) 8−9 13 0 2−6 Pectin (%) 3 < 1 1.2 5.2 Wax (%) 1.8−3 0.8 0.8−1.3 1.4 Ash (%) 1.7 1.6 1.27 0.22 Table 1.

Comparison of the main chemical components between the CGF and several cellulose fibers.

-

Formation CGF Kapok fiber Hemp fiber Cotton fiber Breaking strength (cN/dtex) 4.73 1.29 2.7−6.9 8.37 Elongation at break (%) 3.40 3.06 1.6 9.00 Length (mm) 23−33 8−32 8.3−14 34 Linear density (dtex) 0.93−0.97 0.9−1.2 1.8−3.7 1.43−2.22 Rate of moisture regain (%) 11.90 9.33 14.94 7.00 Rate of moisture absorption (%) 10.80 8.69 12 6.71 Table 2.

Comparison of the physical properties of the CGF, kapok, and cotton fiber.

-

Adsorbent material Processing Oil absorption

amount (g/g)Oil Ref. Kapok fiber Packed 36

43

45Diesel

Hydraulic oil

Motor oil[36] Calotropis

gigantea

fiberIn natura

NaClO2 + Carbonized60.59

84.71Kerosene [38] Cotton fiber Loose fiber

Fiber pad shape22.5

18.43Lubricating oil [41] Cellulose aerogel Methyltrimethoxysilane 40−95 Oil [41] Table 3.

Oil absorption of different materials with different treatments.

Figures

(3)

Tables

(3)