-

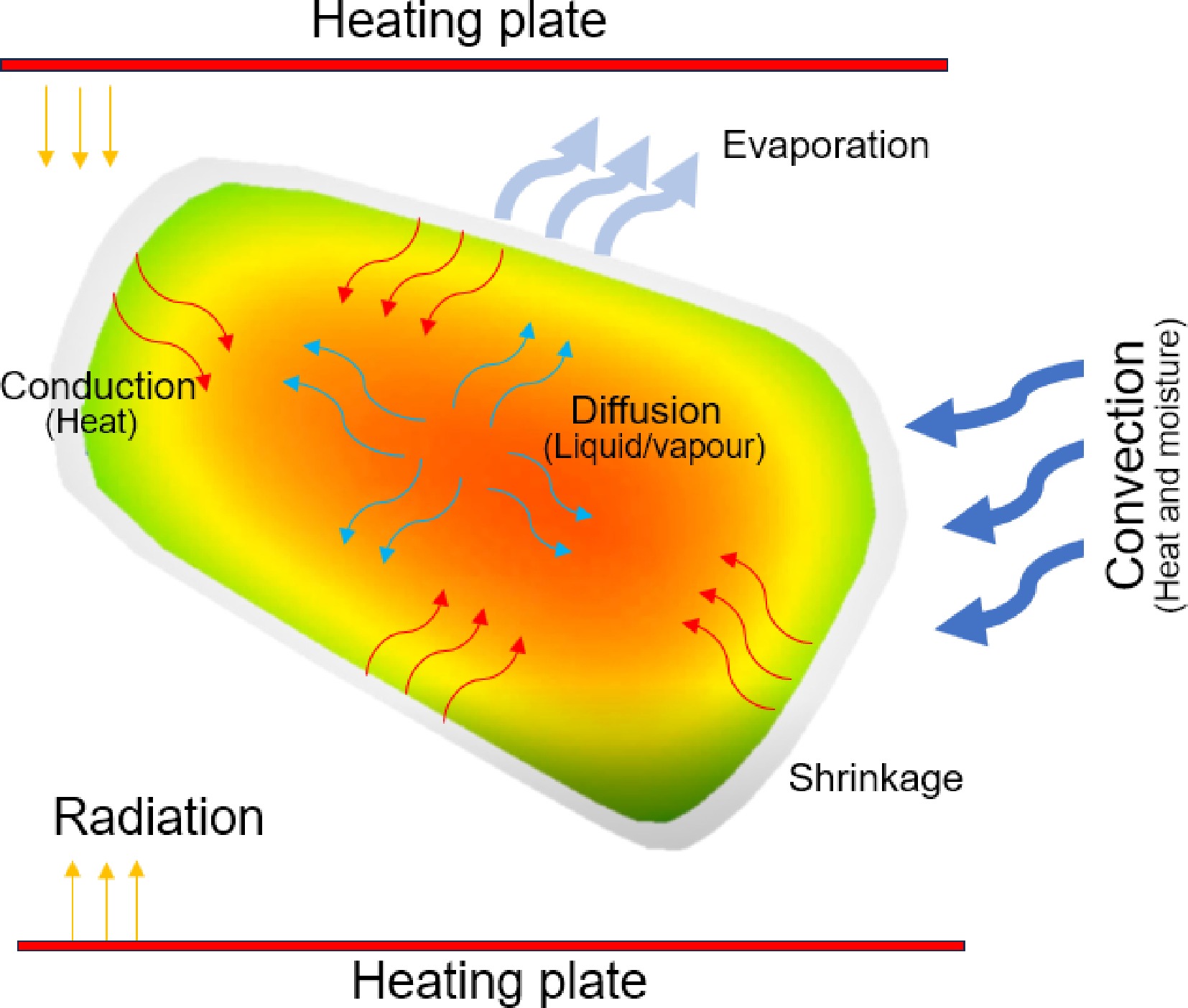

Figure 1.

A visual representation of the drying processes of solid materials.

-

Figure 2.

A typical breakdown of the material balance throughout the drying process for pomegranate aril.

-

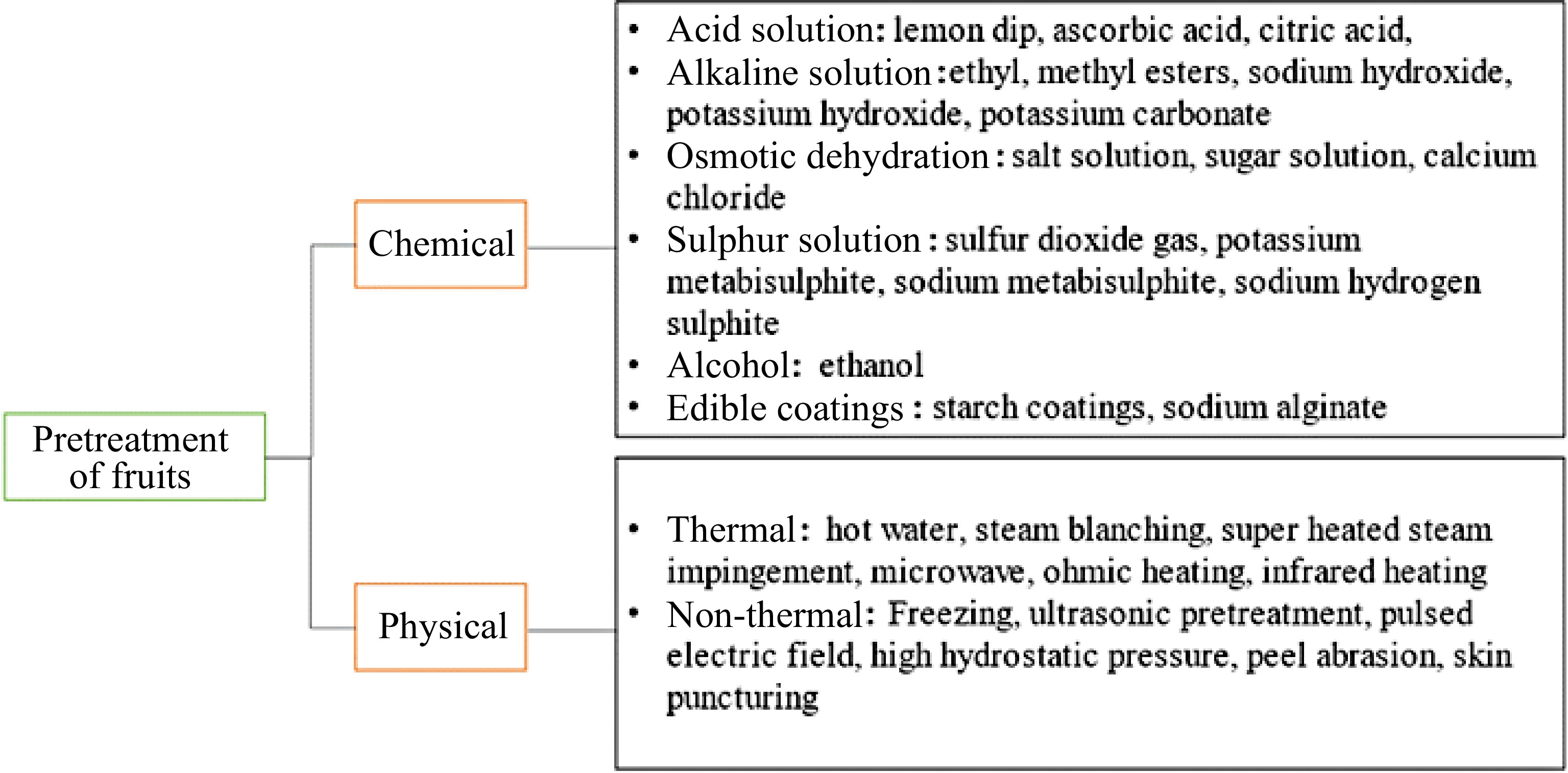

Figure 3.

A classification of the numerous pretreatment techniques utilized in the drying process for pomegranate aril.

-

Figure 4.

This image depicts a sample of wild pomegranate arils being dried in a solar tunnel drier. Reprinted from Thakur et al.[102].

-

Figure 5.

Illustration of dried pomegranate arils that have been dried using different methods. (a) Freeze drying, (b) vacuum drying, and (c) hot air drying. Adapted from Ozay-Arancioglu et al.[97].

-

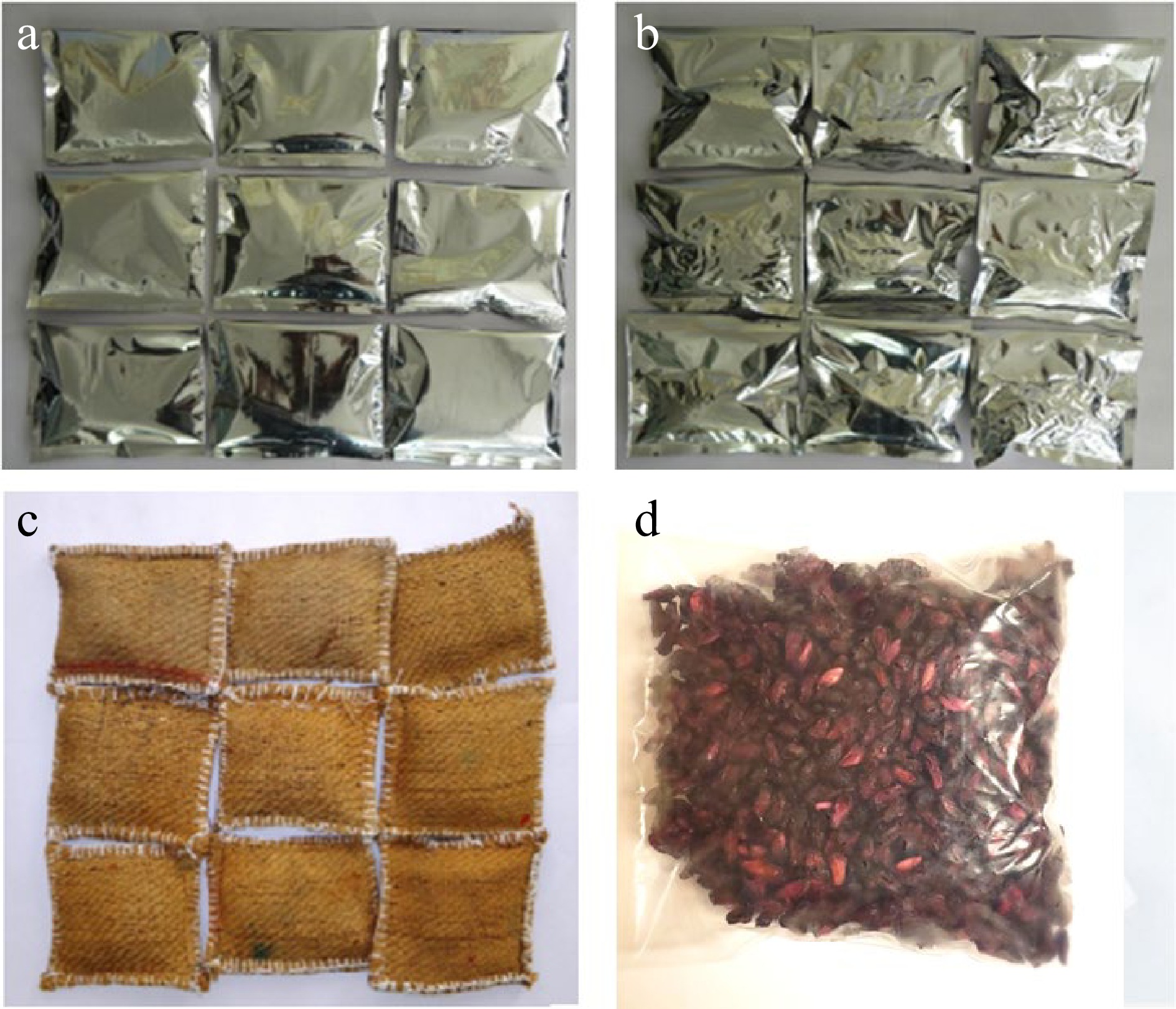

Figure 6.

Different types of storage bags for dried pomegranate arils. (a) Aluminum-laminated polyethylene pouches, (b) vacuum-sealed aluminum-laminated polyethylene pouches, (c) gunny bags and (d) transparent polyethylene pouch. From Thakur et al.[144], modified.

-

Nutrient Value Unit Water 77.9 g Energy 346 kJ Protein 1.67 g Total lipid fat 1.17 g Ash 0.53 g Total dietary fiber 4 g Total sugar 13.7 g Calcium 10 mg Phosphorus 36 mg Magnesium 12 mg Iron 0.3 mg Potassium 236 mg Sodium 3 mg Zinc 0.35 mg Vitamin C 10.2 mg Vitamin K 16.4 µg Vitamin E 0.6 mg Vitamin B-6 0.075 mg Total choline 7.6 mg Folate 38 µg Adapted from United States Department of Agriculture (Agricultural Research Service), FoodData Central[52]. Table 1.

The nutritional composition of 100 g of pomegranate arils.

-

Pretreatment method Pretreatment Drying technique Key findings Reference Blanching Water blanching at 90 and 100 °C Hot air oven drying Blanched samples had a shorter drying time. [24] Water blanching at 80 °C Hot air oven dryer Blanched samples had higher phytonutrient retention than unblanched samples. [69] Blanching using 0.1% citric solution

at 80 ± 2 °CCabinet tray dryer Drying process was shorter for blanched samples and there was a higher rate of bioactive compounds. [57] Sulphuring 1% potassium metabisulphide Solar drying

Cabinet tray dryer

Freeze dryerFruit of cv. Ganesh 1% potassium metabisulphide was of the highest quality and the highest acceptance. [23] Blanching and Sulphuring Hot water blanching 85 °C and 0.2% potassium metabisulphate Mechanical dryer

Solar dryerKeeping quality of mechanically dried arils was higher than the solar-dried arils. [70] Steam blanching, potassium metabisulphide and 0.3% Sulphur fumigation Cabinet tray dryer The highest dried aril quality was obtained from the combination of steam blanching and 0.3% Sulphur fumigation. [71] Steam blanching, sulphuring at 0.3% Vacuum dryer

Hot oven dryer

Sun drying

Poly-tent house drying

Room dryingSun drying had the highest moisture content reduction and the highest overall acceptance. [72] Hot water blanching 85 °C,

potassium metabisulphite varying

from 0.25% to 1%Hot air oven dryer The best treatment was blanching in hot water at 85 °C for 1 min and then dipping the arils in 0.25% potassium metabisulphite. [70] Steam blanching, sulphuring Sun drying

Cabinet dryerBlanching reduced drying time. Cabinet drying of blanched samples without sulphuring was considered optimum for anthocyanins. [73] Acidic solution 2%, 3% and 4% citric acid Cabinet tray dryer 3% acidic treatment was found to be the most acceptable. [56] Microwave 100 and 200 W. Hot air oven dryer 200 W pretreatment resulted in minimum energy utilization and drying time. [74] 100 and 200 W Hot air oven dryer 200 W had the highest drying rate. [75] Osmotic treatment Sugar syrup, freezing at minus 18 °C Open sun drying,

Solar tunnel dryer,

Cabinet tray dryerOsmotic treatment and cabinet tray dryer produced dried arils with better physicochemical and sensory qualities. [63] • 100% pomegranate juice

• 50% pomegranate and 50% chokeberry juice

• 50% pomegranate and 50% apple

• 50% apple and 50% chokeberry

• 75% apple and 25% chokeberryFreeze drying

Convective pre-drying vacuum microwave finish drying

Vacuum-drying and freeze dryingPomegranate and chokeberry concentrated juice improved the quality of the dried arils. [12] Sucrose solution Hot air oven drying Pretreatment increased the drying time of the samples. [64] Table 2.

Key findings in pomegranate aril pretreatment and drying studies.

-

Cultivar Drying method Drying

time (h)Drying condition Initial moisture

content (%)Final moisture

content (%)Key findings Reference Wonderful Freeze dryer 96 −80 °C

5,999.1 Pa74.7 (w.b.) − FD showed a higher color shift (19.6% ± 2,77%) at week 4 compared to hot air drying at week 0. [94] Ganesh, Bhagwa and Arakta Freeze dryer 24−48 −45 °C 79.9 (w.b.)

80.5 (w.b.)

78.9 (w.b.)9.65−9.9 (w.b.)

9.8−10.2 (w.b.)

9.8−9.9 (w.b.)Arakta pre-treated with 1% potassium metabisulphide had the highest ascorbic acid concentration (6.81 ± 0.07 mg 100 g−1). [23] Assiuty Freeze dryer 36 −70 °C − − TA (18.80, 2.80 mg 100 g−1), TP (608.09a, 41.26 mg 100 g−1), DPPH (68.91, 0.72%), and ABTS (2,956.59c, 120 mol trolox

100 g−1) were all higher in frozen pomegranate arils than in freeze-dried arils.[95] Mollar de Elche 24 −60 °C, 65 Pa, 81.5 (w.b.) − FD showed higher anthocyanin content (646 mg kg−1) compared to osmotic drying and conventional drying. [12] Hicaznar 36 −20 °C, 100 Pa for

12 h

−70 °C, 0.26 Pa76.96 (w.b.) 10 (w.b.) Arils dried using FD had the highest magnesium content (96.17 ± 6.95 mg kg−1), manganese content (0.96 ± 0.05 mg kg−1) and zinc content (3.93 ± 0.07 mg kg−1) compared to sun drying, hot air drying and vacuum drying. [91] Keben Freeze dryer 57 −55 °C 77.6 ± 1 (d.b.) 20 ± 1 (d.b.) FD had lower bioactive recovery during in-vitro gastrointestinal digestion (TPC of 2.92%, ABTS of 6.12% and CUPRAC of 38.85%) compared to vacuum drying, hot air drying and ultrasound-assisted vacuum drying. [97] Keben Vacuum dryer 10.8 55 °C 77.6 ± 1 (d.b.) 20 ± 1 (d.b.) Vacuum drying had the highest bio accessibility recovery of bioactive compounds at 10.32% compared to HAD, FD and ultrasound-assisted vacuum drying. [97] Hicaznar Vacuum dryer 3.7

4.6

7.875 °C

65 °C

55 °C

85,000 Pa78.1 ± 0.2 (w.b.) 16 (w.b.) Drying temperatures of 75°C resulted in higher degradation of anthocyanins, phenolic compounds and antioxidant capacity (20.0%, 51.0%, 29.7% ± 0.28% respectively). [99] Hicaznar Vacuum dryer 24 55 °C

3 500 Pa76.96 (w.b.) 10 (w.b.) FD had the highest quality attributes such as TAC-1288.73 mg/kg) compared to VD and HAD however, due to physical changes that were undesirable physical changes, VD and HAD are recommended for pomegranate aril drying. [91] Wild pomegranates (cultivar- unspecified) Vacuum dryer 13 42 ± 2 °C − − VD had a higher sensorial overall acceptance (17.1) compared to sun drying (16.2) and room temperature (12.6). [72] Bassein Sun drying 17 − 15.73

(unspecified)Drying rate of pomegranate arils is affected by tray load and the recommended tray load is 1.25 kg m−2 [73] Wild pomegranates (cv. Unspecified) Solar poly-tunnel 140 14.9−28.4 °C

48.5%−74% -RH

0.639−0.944 -wind speed− − Arils dried in the solar poly-tunnel had higher ascorbic acid, anthocyanins, and phenol content, 12.7 mg 100 g−2, 28.12 mg 100 g−2, and 108.60 mg 100 g−2 respectively than open sun drying. [100] Sefri Indirect solar dryer 75

10

6

440 °C

50 °C

60 °C

75 °C78 ± 0.1(w.b.) − The optimal water activity for drying and storing arils is 0.3684 ± 0.03. [101] Wild pomegranates

(cv. Unspecified)Solar tunnel − 30−45 °C − − Arils from the Karsog location had the highest TSS, sugars, anthocyanin, total phenols and antioxidant activity [102] − Microwave 2.3

1.3

0.7270 W

450 W

630 W70.25 ± 0.5(w.b.) 10(d.b.) Color changes increased from 6.77−13.11 with an increase in microwave power from 270−630 W and were lower compared to arils dried using HAD. [85] Hicaz Microwave 1.2

0.6

0.4210 W

350 W

490 W23.93 ± 1.4 (unspecified) 22.2

(unspecified)Based on quality parameters, a microwave drying power of 350 W was recommended for drying pomegranate arils. Sweet acid

(cv. Unspecified)Infrared 4.3

2.2

1.650 °C

60 °C

70 °C78 ± 0.2 (w.b.) 9 ± 0.2 (d.b.)

22.2

(unspecified)Drying time for infrared drying was less than for HAD. [103] Hicaz HAD 24 50, 60, 70 °C at

1.0 m/s air velocity− − To obtain better dried aril quality, 60 °C was recommended for drying pomegranate arils. [104] Wild pomegranates

(cv. Unspecified)HAD 16.5 42 ± 2 °C − − Sun drying resulted in a maximum loss of moisture compared to VD, HAD, poly-tent house drying and room drying. [72] Wild pomegranates

(cv. Unspecified)HAD 10 62 ± 2 °C − − HAD achieved the highest total soluble solids (39.6°Brix) and drying rate compared to solar drying and open sun drying. [105] Keben HAD 5 55 °C; with 1.3 m s−1 constant air velocity 77.6 ± 1 (d.b.) 20 ± 1 (d.b.) In comparison to hot air oven drying, ultrasound-assisted vacuum drying and freeze-drying have higher quality characteristics. [97] Bassein seedless HAD 5−6 60 ± 5 °C. Airflow in

the dryer was 1.2−1.8 m s−1.− 8.98 ± 0.091 For the finest preparation of anardana, blanched samples (with sulphur) should be dried in a cabinet. [73] Mollar de Elche Vacuum-

microwave− 240, 360, 480 W and pressure ranging

from 4,000−6,000 Pa80.4 (w.b.) − Arils dried using vacuum microwave drying at 240 W had the highest sensorial scores for odour and aroma at 3.1 and 5.6 respectively. [106] Table 3.

A summary of the many techniques for drying pomegranate arils.

-

Table 4.

A summary of the mathematical equations that are most commonly used to model the drying kinetics of pomegranate arils is shown here.

-

Cultivar Drying method Drying parameters Pretreatment Suitable drying model Reference cv. Hicaz HAD 55, 65, 75 °C 0.1% citric acid Page and Modified Page [57] cv. Hicaznar HAD 55, 65, 75 °C − Sigmoid [116] − HAD 55, 55, 60 °C − Page [137] − HAD 50, 60, 70 °C − Page [85] MD 270, 450, and 630 W − Page [85] cv. Hicaznar VD 55, 65, 75 °C Hot water blanching Page and Modified page [69] − HAD 45, 50, 55, 60, 65, and 70 °C Microwave Midili [75] cvs. Acco, Herskawitz and Wonderful HAD 60 °C Hot water blanching (at 90 and 100 °C, each for 30 s

and 60 s)Logarithmic, Page,

Midili for unblanched arils

Midili and Page for blanched[24] Table 5.

A synopsis of the results of mathematical modeling of the kinetics of drying pomegranate arils.

-

Drying method Drying temperature Packaging material Storage period (months) Shelf-life performance Reference MC drier

Solar cabinet drier

Open sun62−64 °C

50−55 °C

18−24 °CAluminum laminated polyethylene pouch, polyethylene pouches and thermoform trays. 6 Aluminum laminated polyethylene pouches were best for packaging. [105] Microwave-vacuum drying 38 °C High-density polypropylene (HDPP) and aluminum laminated polyethylene (ALP). 3−6 Pomegranate arils stored showed that ALP is more protective than HDPP. [35] Solar tunnel 30−45 °C Gunny bags, aluminum laminated polyethylene pouches (ALP) and vacuum-sealed aluminum laminated polyethylene pouches (ALPV). 12 Both refrigerated and ambient storage can securely preserve dried pomegranate samples for 12 months. Best performance was ALP with vacuum and cold storage. [144] Hot air dryer 60 °C Aluminum laminated polyethylene pouch (ALP), polyethylene pouch (PEP), and thermofoam tray (TT) covered in shrinkable polypropylene transparent sheet. 6 Moisture absorbers aid in the preservation of samples. [100] Table 6.

A list of the several types of containers used to store dried pomegranate arils.

Figures

(6)

Tables

(6)