-

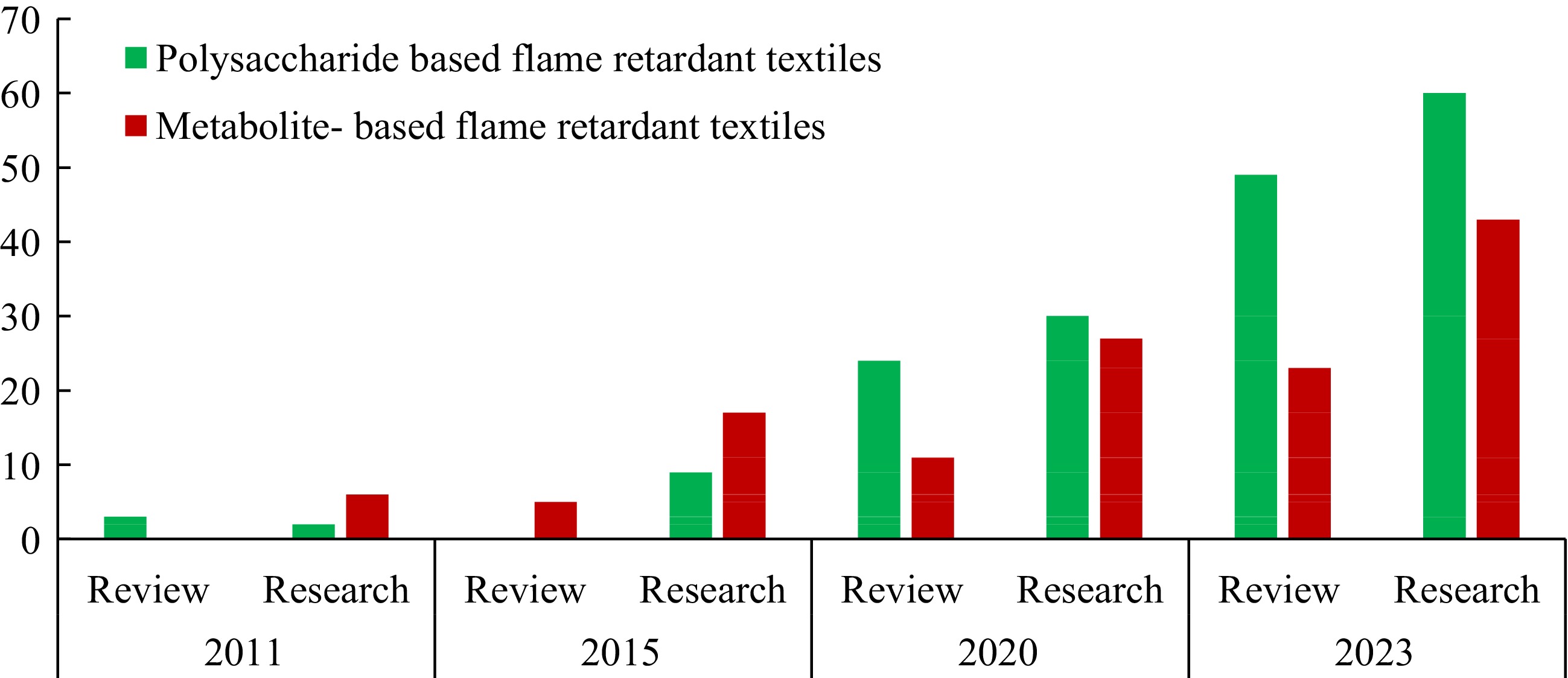

Figure 1.

Total number of publications (research and review) as per the Scopus data base from 2011 to 2023. Key words used: Polysaccharide based flame retardant textiles; Metabolite- based flame-retardant textiles.

-

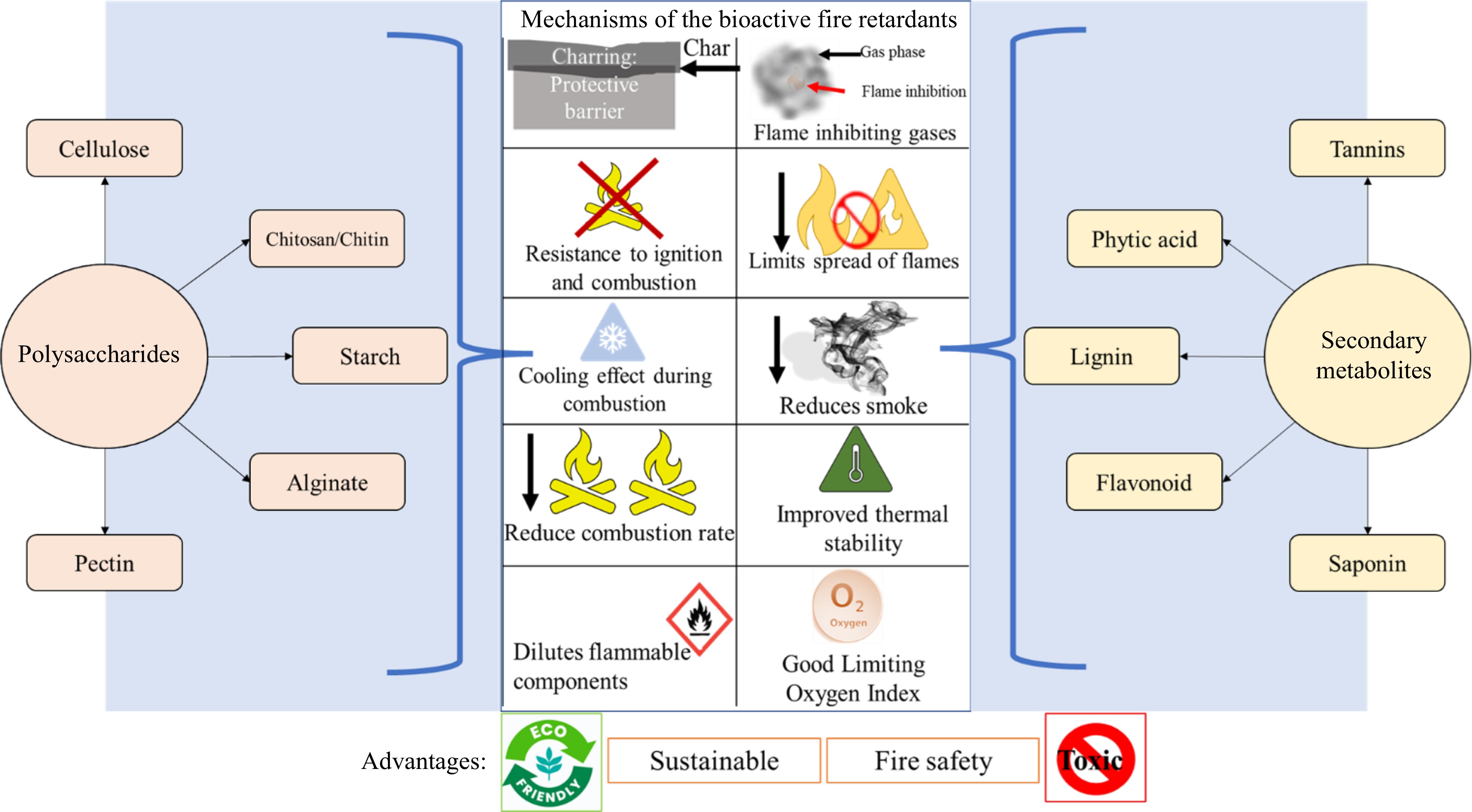

Figure 2.

Mechanism of fire-retardants.

-

Polysaccharide Source Mechanism Main finding of study Reference Cellulose Blanver (São Paulo, Brazil) Fire retardant made from graphite and cellulose by drying aqueous dispersions of graphite and cellulose on canvas and wood Surface temperature measurements and thermal images showed fast heat transfer from flamed spots and suppressing flare formation [52] Chitosan and microcrystalline cellulose Hangzhou, China Biobased flame retardant by surface-functionalizing microcrystalline cellulose with chitosan and sodium phytate via LBL assembly in water 15 wt% P-MCC@CS@PA-Na helped epoxy resin to pass UL-94 V-1 rating with LOI of 26.2%

Peak heat release rate, peak smoke production release, fire growth rate, and total heat release are greatly reduced, showing good fire retardance[53] Cellulose Viscose fibers obtained from Kelheim Fibres (Kelheim, Germany) Incorporation of silica (20%wt) into cellulose matrix during fiber formation, stabilization with aluminate treatment Incorporating silica reduced flammability, aluminate treatment prevented leaching.

Significant reduction in after glowing (−82%) and material destruction (−90%) observed.[54] Phosphorylated microcrystalline

celluloseAladdin Reagent Co. Ltd. (Shanghai, China) The cellulose spinning dope (2 kg) loaded with 20 wt% phosphorylated cellulose. The obtained lyocell fibers with 20% phosphorylated cellulose loading were called fire retardant fibers. The lyocell fibers loaded with 20 wt% P-Cell exhibited favorable thermal stability and fire retardancy.

The dehydration of the cellulose unit leading to the formation of phosphorus-containing oxides and a char layer, serving as a protective matrix layer[55] Chitosan Chitosan purchased from Sinopharm Chemical Reagent Company (China) Organic-inorganic composite aerogels (chitosan and aluminum chloride) prepared by freeze drying method CA1.5P aerogel showed high compressive strength of 8.55 MPa and specific modulus of 66.3 m

Inorganic components from AIP (7.7–20.1 wt%) showed increased LOI value (35%–41.1%)[56] Chitosan Chitosan derived from chitin flakes (LR grade), SD fine chemicals limited, Mumbai, India Chitosan underwent chemical modification using melamine and sodium pyrophosphate as sources of nitrogen and phosphorus, along with glyoxal as a crosslinking agent. Untreated cotton exhibits a low LOI than chitosan treated cotton fabric

Cotton fabric treated with modified chitosan, had enhanced thermal resistance with higher thermostability[36] Chitosan Chitosan derived from corn starch and sugarcane Chitosan was integrated into PLA to create flame-retardant and high-performance composite materials. Adding 3.75 wt% of chitosan furfural compound (CFU) along with 11.25 wt% of APP to PLA resulted in achieving the UL-94 V-0 rating, a nearly 28% increase in the LOI, and reductions of approximately 35% in total heat release and 90% in smoke release [57] Starch Synthesized from starch, phosphorus acid, and urea for cotton fabrics (Chengdu Kolon Chemicals Co, China) Biomass starch-based phosphorus-containing flame retardant, ammonium starch phosphate synthesized for cotton fabrics Phosphorus-based flame retardant (ammonium starch phosphate) showed flame retardancy for cotton fabrics (LOI: 45.2%, even after 50 laundry cycles), attributed to successful grafting onto cotton fibers with P-O-C covalent bonds [44] Starch Potato starch (Superior, Emslandstärke, Emlichheim, Germany) Thermal degradation of ammonium starch phosphate carbamates with varying degrees of substitution Increased charring and polyphosphate formation in condensed phase as DS of SPC rose showed reduced temperature mass losses and lower activation temperatures in comparison to native starch [45] Alginate Qingdao, China Fe3+- modified alginate coatings on PET fabrics by simple dip-coating technique ZnAlg/Ag3PO4 showed highest flame-retardant performance with LOI of 79.8% and HRC of 79.8 J/(g·K). Coated PET fabrics achieved a LOI of 29% and exhibited a significant 70.3% reduction in peak heat release rate [48] Pectin Purchased from Yantai Andre Pectin Co., Ltd, USA Biomass-derived polymer aerogels composed of pectin and aniline via polymerization–coagulation followed by supercritical drying process Biomass-derived polymer aerogels showed 3D hierarchical networks with high surface areas (103−205 m2 g−1), good compressive strengths (4.7−9.2 MPa), exhibited low thermal conductivity (0.033−0.038 W m−1 K−1) [50] Pectin Purchased from Aladdin Company, Shanghai Self-cross-linked aerogel, from pectin and MF using a freeze-drying method with water as solvent M10Pe5 aerogel showed compressive modulus of 23.2 MPa and specific modulus of 188 MPa cm3/g, showing both thermal stability and excellent water resistance [51] AIP: Acidic hydrolysis of aluminum isopropoxide; SPC: starch phosphate carbamates; PET: polyester; LOI: limiting oxygen index. Table 1.

Polysaccharide-based fire retardants.

-

Compound name Plant source Chemical structure Fire retardant properties Applications Reference Tannin Dioscorea cirrhosa tuber

Treated silk exhibited higher LOI values (>28%) and shorter char length (12 cm) than the untreated fabric with a LOI of 24.7% and a char length of 30 cm, and very low pHRR (18.1 W/g) and THR (1.3 kJ/g) indicating their remarkably reduced flammability Production of flame-retardant silk fabric [58] Tannin Cotton fabric treated with tannic acid, tartar emetic and Ca2+ showed excellent durable flame retardancy with pHRR ranging from 113.8-138.7 kW/m2. Additionally, even after 50 cycles of tap washing, treated fabric show much lower heat release and pass the horizontal flammability test Production of eco-friendly and durable flame-retardant coating for cotton fabrics [59] Phytic acid −

Treated cotton fabric showed LOI value of 34.6%, accompanied by damage length < 150 mm and burning time < 5 s. CCT revealed that PHRR reduced by 61%, THR by 74% Average residue improved to 21% at 650°C and exhibits significant delay in thermal decomposition time Production of flame-retardant cotton fabric [60] Phytic acid − Treated silk fabric exhibits lower smoke and heat generation, self-extinguishing behavior, and a char length of 13.5 cm even after 20 washing cycles Production of durable flame-retardant silk fabric [61] Phytic acid − Silk fabric with phytic acid, TiO2 and 1,2,3,4–butanetetracarboxylic acid show excellent flame retardancy with increased LOI and decreased char length and pHRR (56.3%) even after 25 times of washing Production of improved flame-resistant silk fabric [70] Phytic acid − Treated silk fabric showcased self-extinguishing properties in vertical burns with an add-on exceeding 10.7% maintained after 15 washes, coupled with remarkable reduction in heat and smoke release during combustion, showcasing high thermal stability Production of intumescent flame-retardant silk textiles [62] Lignin −

Inclusion of 8 wt% LF in PLA results in a UL-94 V-0 rating, and LOI value of 25.8%, signifying enhanced fire resistance and thermal stability. Moreover, the PLA/LF composite

exhibits increased elastic modulus while retaining the strength and ductility characteristics of pure PLAProduction of PLA biocomposites which can be used in packaging, fabrics, electronic, and automotive applications [63] Lignin − 30% [w/v] SLS treatment via hot padding reduced after-glow to 9 s and resulted in a 4 cm char length in treated cotton fabric. Additionally, TGA analysis indicated SLS enhanced char formation, preserved fabric structure and also improved UV protection without compromising fabric strength Used for home textile materials, curtains, sofa cover, tent, pandals and other products [16] Lignin An efficient flame-retardant effect in PLA fabric is achieved with 5 wt% of lignin and 5 wt% of ammonium polyphosphate and significantly reduces the heat release rate Additionally, ammonium polyphosphate slightly enhances the thermal stability of composites, with increased residue at 500 °C Used in packaging, textile [71] Flavonoids (baicalin, quercetin, rutin)

Silk fabric treated with flavonoid and metal salt (ferrous sulfate and titanium sulfate) exhibits increase in LOI (26.5-27%) and decrease in char length (< 12 cm) as the concentration increases. Further, fabric shows increased thermal stability of silk fiber at high temperature (600ºC) Production of colored and flame-retardant silk textiles with antibacterial and antioxidant functions [65] Flavonoids (daidzain, naringenin and luteolin) Cycloaddition of benzopyrone ring improved the crosslink density of natural flavonoid-based epoxy resin contributing to the synergistic improvement of mechanical properties and thermal stability of epoxy resin with glass transition temperature of 184.4 °C Development of high-performance bio-based epoxy resin with flame-retardant properties [72] Tea saponin

TS significantly impacts char layer structure, enhancing flame retardancy and pyrolysis performance in CTS-IFRCs, minimizes heat loss, contributing to dual effects as both a gas-phase blowing agent and a condensed-phase carbon agent Used as coating to enhance flame retardancy [66] Tea saponin TS exhibits significant impact on the combustion behavior and thermal stability of TS-IFRCs. It degrades into water vapor and carbon at high temperatures, forming a protective char layer that enhances flame retardancy and reduces smoke production Used as flame-retardant coatings [67] LOI = Limiting oxygen index; pHRR = peak heat release rate; THR = total heat release; CCT = cone calorimeter test; LF = lignin-derived fire retardant; PLA = Polylactide; SLS = sodium lignin sulfonate; TGA = Thermo-gravimetric analysis; TS = Tea saponin; CTS-IFRCs = composite tea saponin intumescent flame-retardant coatings; TS-IFRCs = Tea saponin intumescent flame-retardant coatings. Table 2.

Secondary metabolites from plants as fire retardant material.

Figures

(2)

Tables

(2)