-

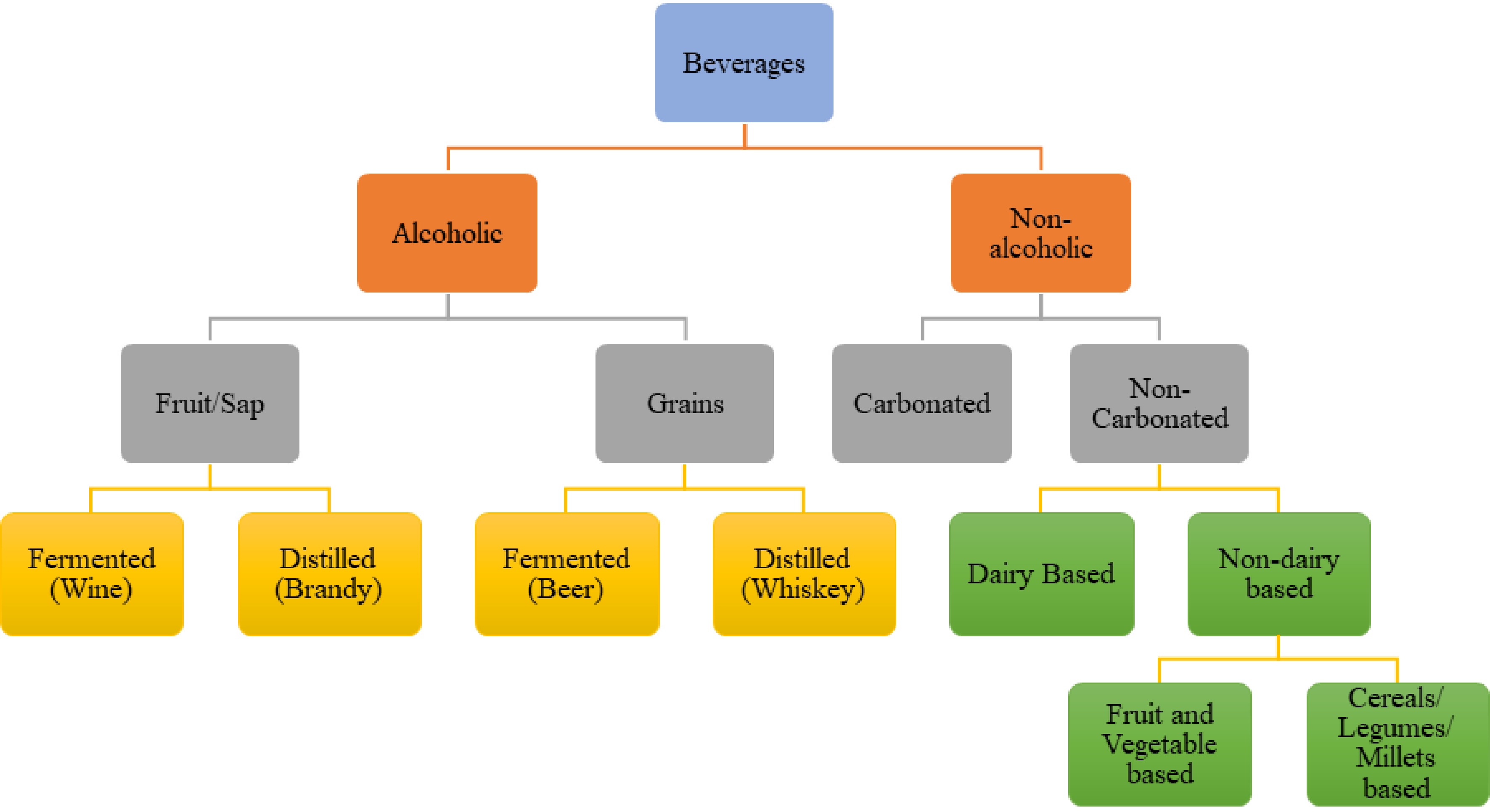

Figure 1.

Basic classification of beverages.

-

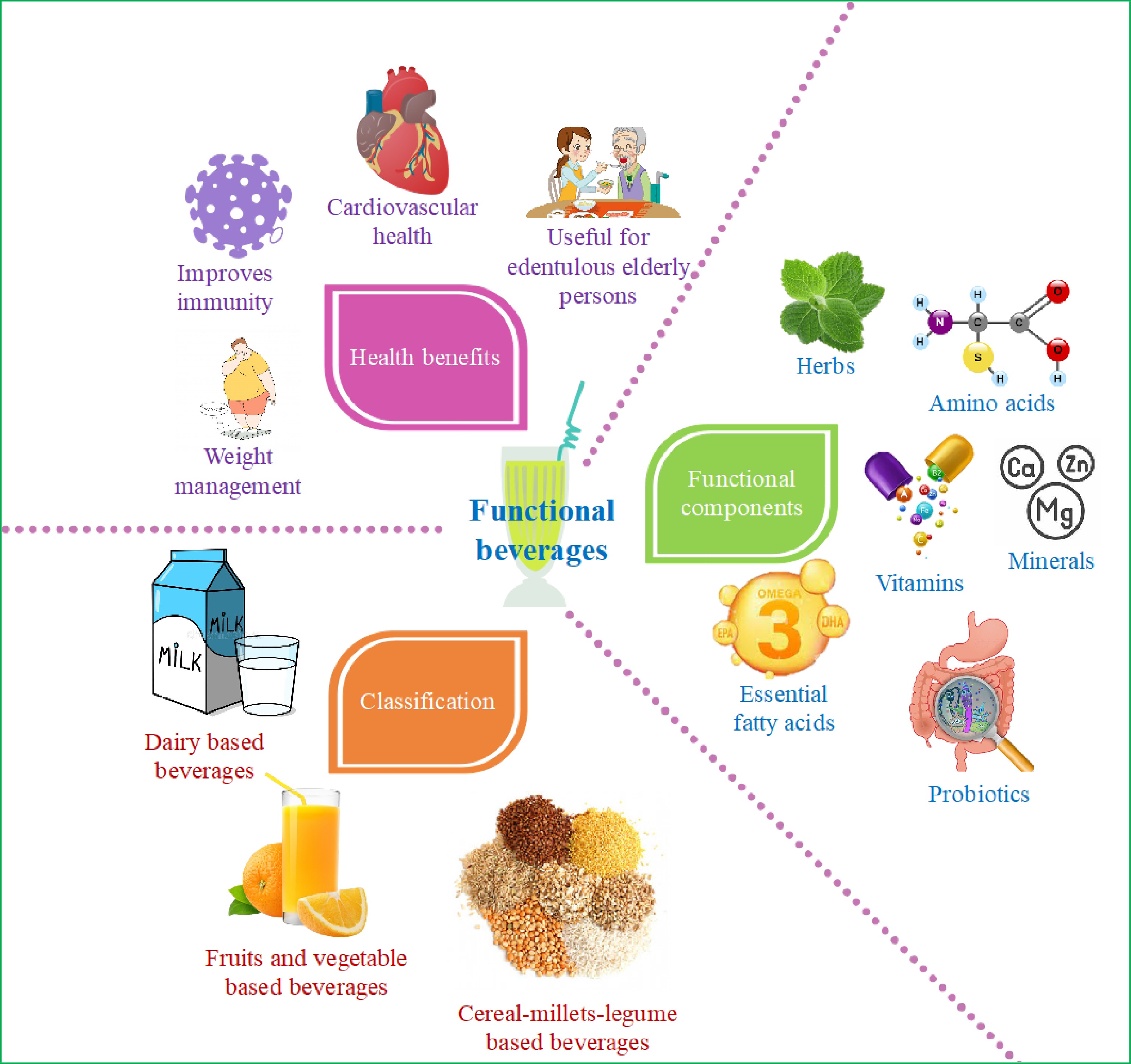

Figure 2.

Classification, functional components and health benefits of functional beverages.

-

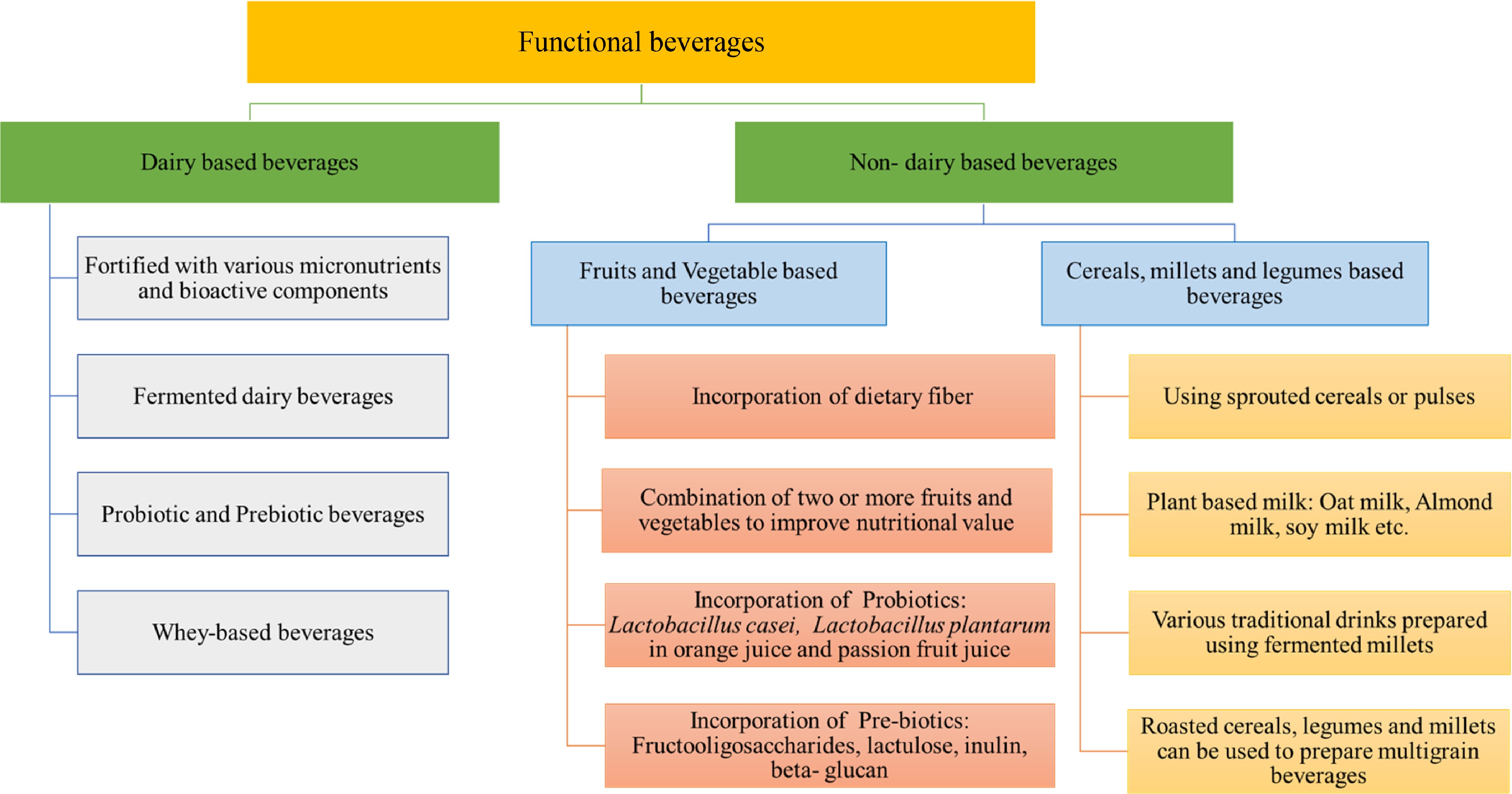

Figure 3.

Schematic flowsheet for dairy and non-dairy functional beverages.

-

Beverage type Description Reference Dairy-based Whey protein-based beverage • Whey protein isolate was used for the preparation of the beverage mix.

• Additional antioxidant components (polyphenols from marjoram extract, astaxanthin, and vitamins) were incorporated into the feed.

• Spray drying was carried out to get instant beverage powder.[50] Kefir powder • Fermented milk product

• Kefir grains are used for fermentation.

• Spray drying was carried out using skim milk powder/ whey permeate/ maltodextrin as carrier agent.[51] Probiotic pineapple lassi powder • Freeze drying was used to develop the product.

• Bifidobacterium bifidum was used as probiotic culture.

• Probiotic curd was blended with pasteurized pineapple juice along with addition of sugar, maltodextrin and CMC (Carboxymethyl cellulose).[52] β-glucan fortified milk powder • β-glucan is a soluble dietary fibre.

• β-glucan in liquid milk causes instability.

• Spray drying technique was used to formulate the beverage mix.[53] Fruits and vegetable-based White dragon fruit juice powder • Dragon fruit is rich in antioxidants and helps lowering the blood cholesterol.

• Spray drying technique was employed using maltodextrin as wall material.

• RSM was used for process optimization.[54] Sugarcane juice powder • Sugarcane juice is used for treatment of jaundice and health issues related to liver.

• Vacuum evaporation of sugarcane juice was done to achieve 30°Brix.

• Maltodextrin was added to aid in spray drying.[55] Beetroot extract-based

beverage powders• Beetroot, quince fruit and cinnamon extracts were used (75:24:1).

• Foam-mat freeze drying (FMFD) and foam-mat hot air-drying (FMHD) methods were used.

• 3% albumin powder and 20% of maltodextrin were used for foam preparation.

• Beverage prepared with FMFD powders had more overall acceptability.[56] Mix fruit and vegetable instant drink powder • Red spinach, red bean, guava and beetroot were used.

• Foam mat drying technique was used.

• Mix juice was rich in iron content.[57] Cereals-millets-legume based Millets based instant health mix

(millets : legumes - 3:1)• Millets used: Ragi, sorghum, bajra

• Legumes used: green gram

• Malting of all the grains followed by extrusion of malted flour and then grinding

• 1% probiotic culture of Lactobacillus rhamnosus[58] Quinoa based fermented probiotic beverage mix • Raw and roasted quinoa grains were fermented for 6 h and 9 h respectively

• Fermentation using Lactobacillus plantarum

• Reduction in phytate content

• Fruit flavours were used to improve the acceptability[59] Pearl millet-based beverage powder • Two varieties of pearl millet were used

• Raw and malted pearl millet flour followed by extrusion, were used individually and in combinations also.

• Improved protein and starch digestibility[60] Black rice based instant beverage mix • Burma black rice was combined with germinated lentil flour, sweet potato and mulberry flour.

• Black rice was soaked for 30 min and then steamed (50 min) and dried to prepare flour.

• Improved nutritional characteristics.[61] Chickpea based enzyme treated

beverage powder• Raw and extruded chickpea flours treated with alcalase and alpha-amylase sequentially.

• Thermo-extrusion followed by enzymatic catalysis improves the nutritional profile.

• Protein digestibility and protein digestibility corrected amino acid score (PDCAAS) was improved.[62] Sattu mix (multigrain) • Canadian peas, maize, chickpea, wheat, barley and oats were used, to prepare two different formulations.

• Chickpea based traditional sattu was used as control.

• Roasting was carried out as preliminary processing of grains.

• Combination of cereals and legumes improved the nutritional quality of the product.[63] Table 1.

Recent studies on instant beverage mix based on dairy, fruits and vegetables and cereals, millets and legumes.

Figures

(3)

Tables

(1)