-

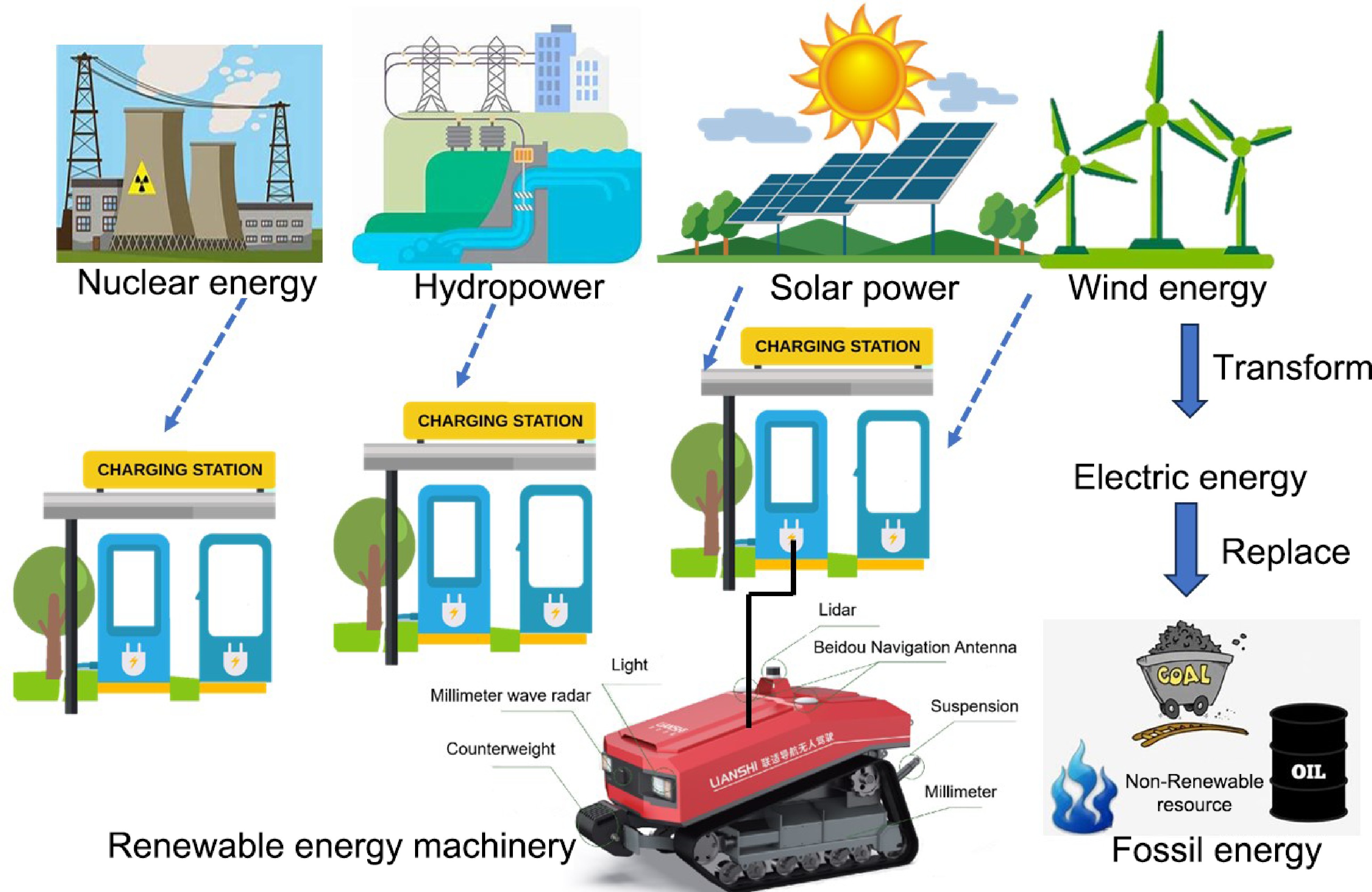

Figure 1.

A typical representative of intelligent agricultural machinery is an intelligent electric tractor, which uses millimeter wave radar sensors, LiDAR sensors, and BeiDou satellite positioning system to achieve automatic walking. To realize the optimum operation path of intelligent agricultural machinery, the installed sensors and position systems can largely improve the field working efficiency. In this way, the required energy can decrease accordingly. A solar charging station built in the field can conveniently charge intelligent agricultural machinery. It should be noted that the high cost has prevented large-scale production of electric tractors.

-

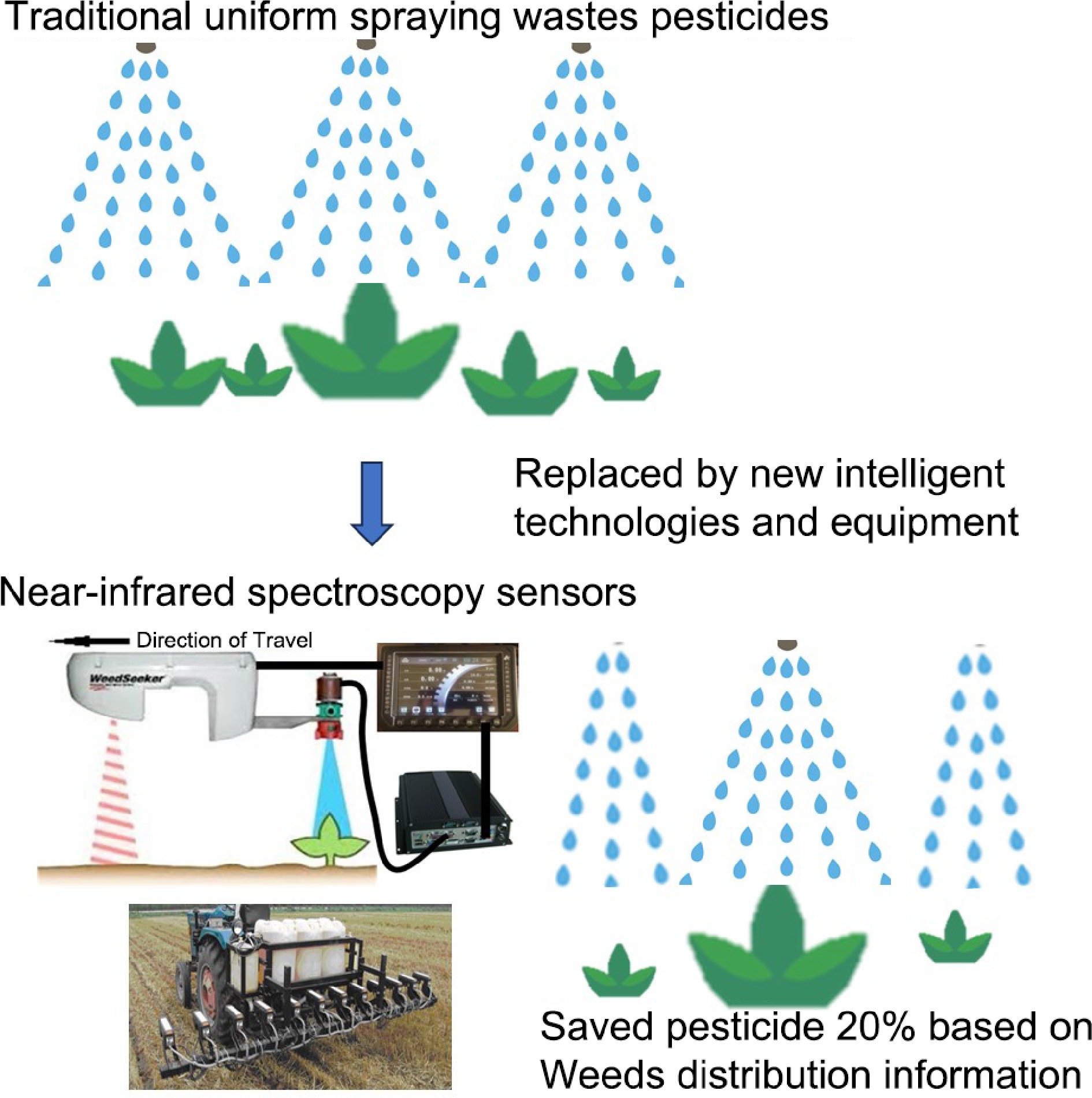

Figure 2.

Using near-infrared spectroscopy sensors for online detection, identify different types of weeds and wheat stubble, and based on the calculation results, control the spraying system in real-time to complete target spraying.

-

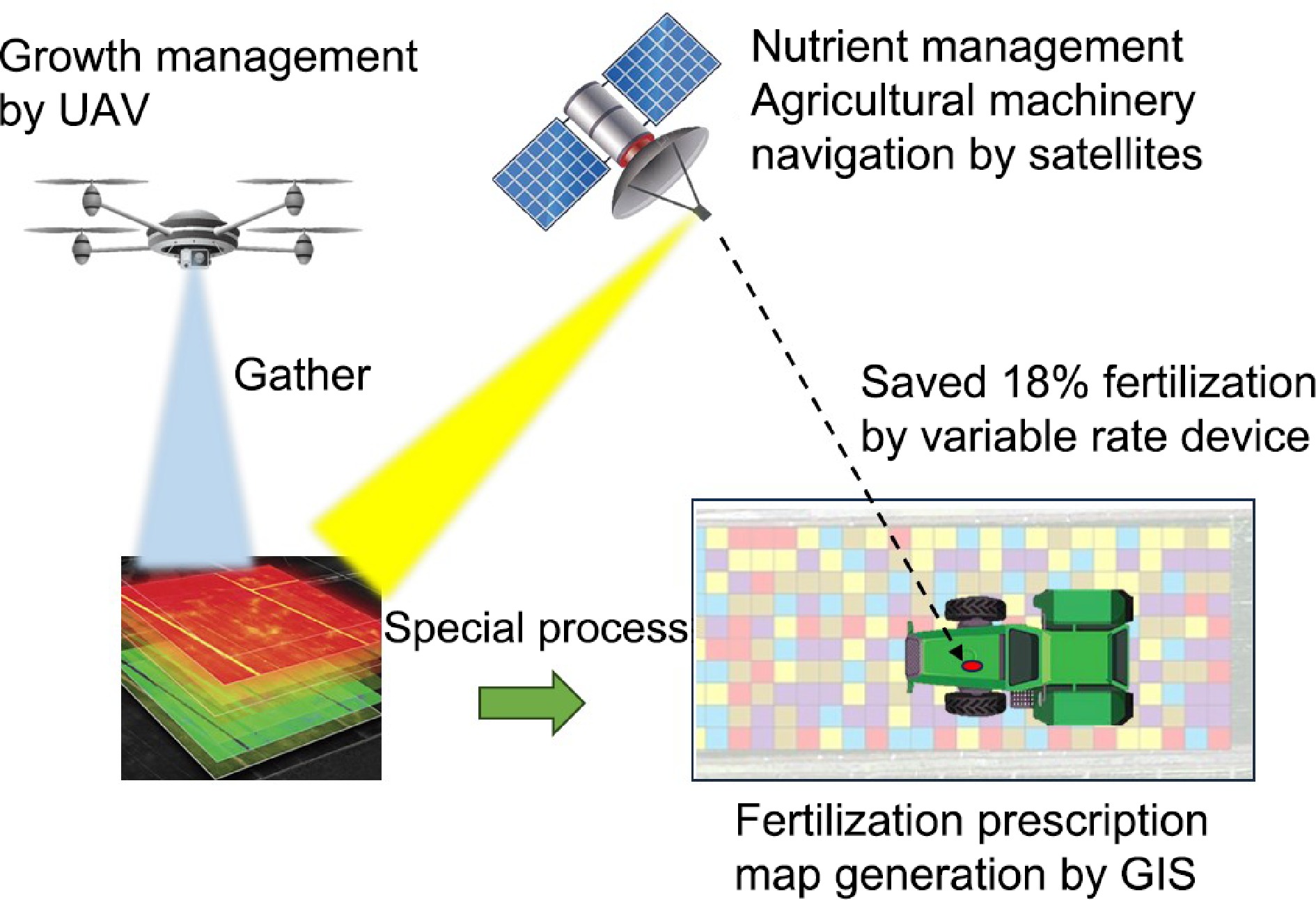

Figure 3.

A satellite positioning system is installed to obtain the longitude and latitude coordinates of the tractor in the field. Based on the coordinate information, the fertilization amount in the fertilization prescription map is obtained. Then, a variable controller is used to accurately control the hydraulic motor speed, driving the outer groove wheel to accurately and quantitatively discharge fertilizer to the soil through the fertilization pipe. This design of on-demand fertilization is according to soil nutrients, which can greatly save fertilizer, ensuring stable yield and low carbonization.

-

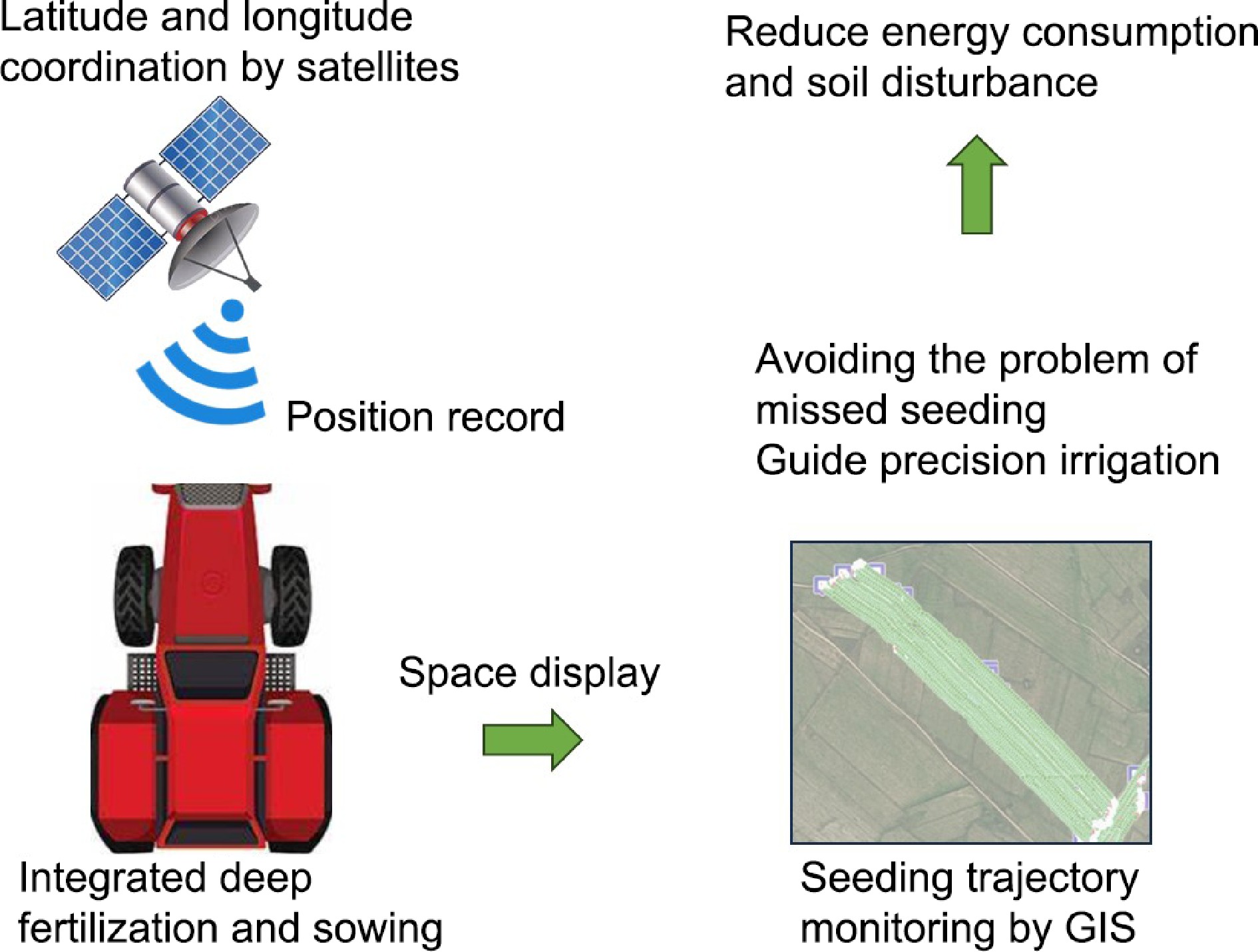

Figure 4.

An infrared sensor is used to detect the signal of seed falling and provide early warning for the blockage of the seeding tube, avoiding the problem of missed seeding. In order to achieve linear seeding and record the trajectory of the seeding, an automatic navigation system is applied. It can solve the problem of missed land seeding caused by overlapping seeding waste and excessive spacing. After recording the trajectory of sowing, the path can be downloaded to precision irrigation machines and precision spraying machines respectively. The subsequent management steps after sowing are based on straight-line sowing, which can greatly improve water and fertilizer utilization efficiency, meanwhile achieve low-carbon production.

-

Production

processKey technologies Intelligence level Cost Application scenario Assessment of carbon reduction potential Tillage Deep cultivation monitoring Very advanced General Grain and oil production Great potential Laser leveling Advanced General Grain and oil production Great potential Sowing Monitoring of seeding blockage Advanced General Grain and oil production Average potential Seeding overlap monitoring Advanced High cost Grain and oil production Average potential Cultivation Precision fertilization technology Very advanced General Grain and oil production; Great potential Fruit and vegetable production Target spraying of herbicides Very advanced General Grain and oil production; Great potential Fruit and vegetable production Harvesting Automatic recording of production Advanced High cost Grain and oil production Average potential Phased harvest General High cost Grain and oil production Great potential Transportation Internet of Things field scheduling General High cost Fruit and vegetable production Great potential Rough processing on farmland General High cost Fruit and vegetable production Great potential The assessments in the table are based on survey data and author experience. Table 1.

Intelligent agricultural machinery for carbon reduction.

Figures

(4)

Tables

(1)