-

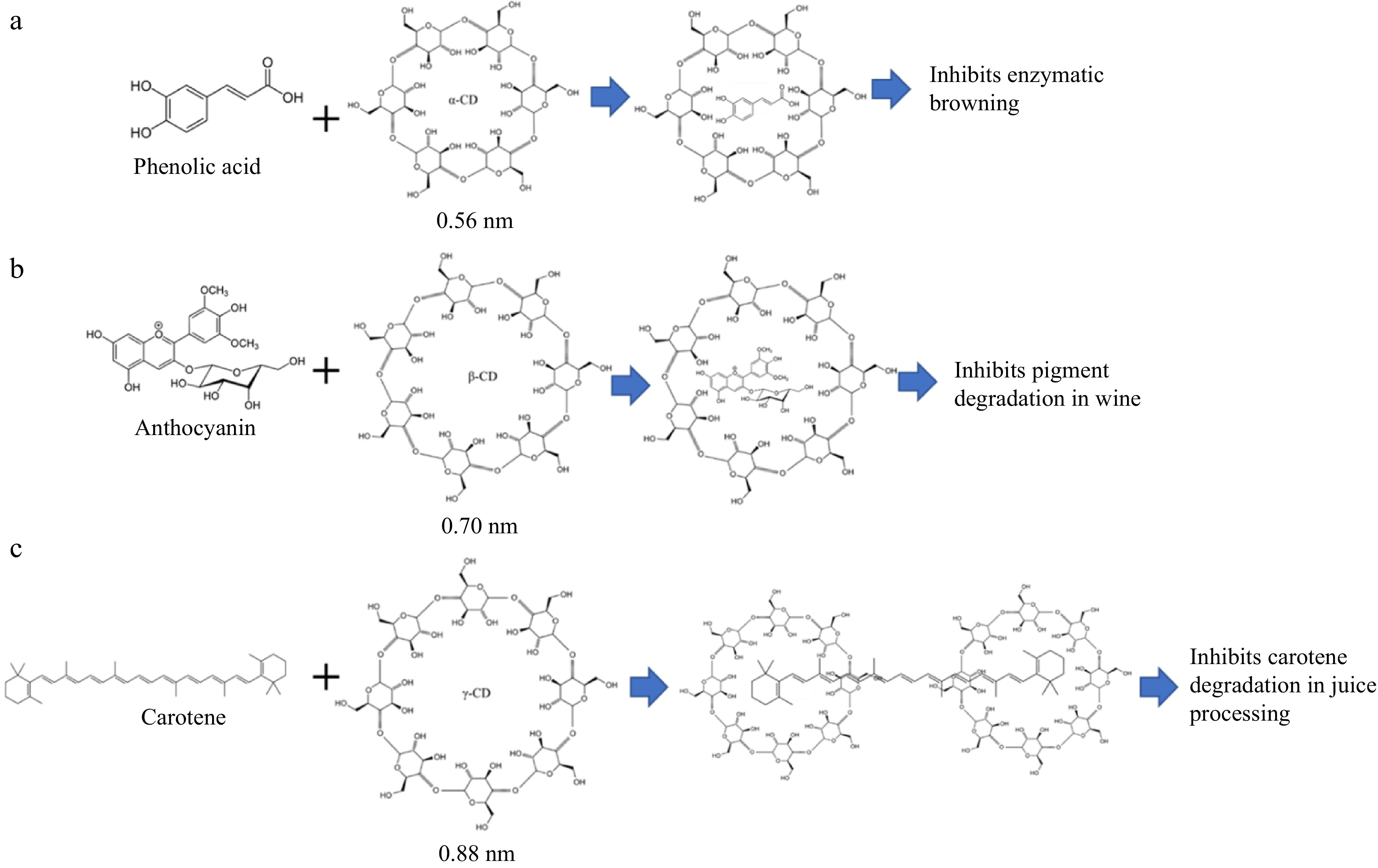

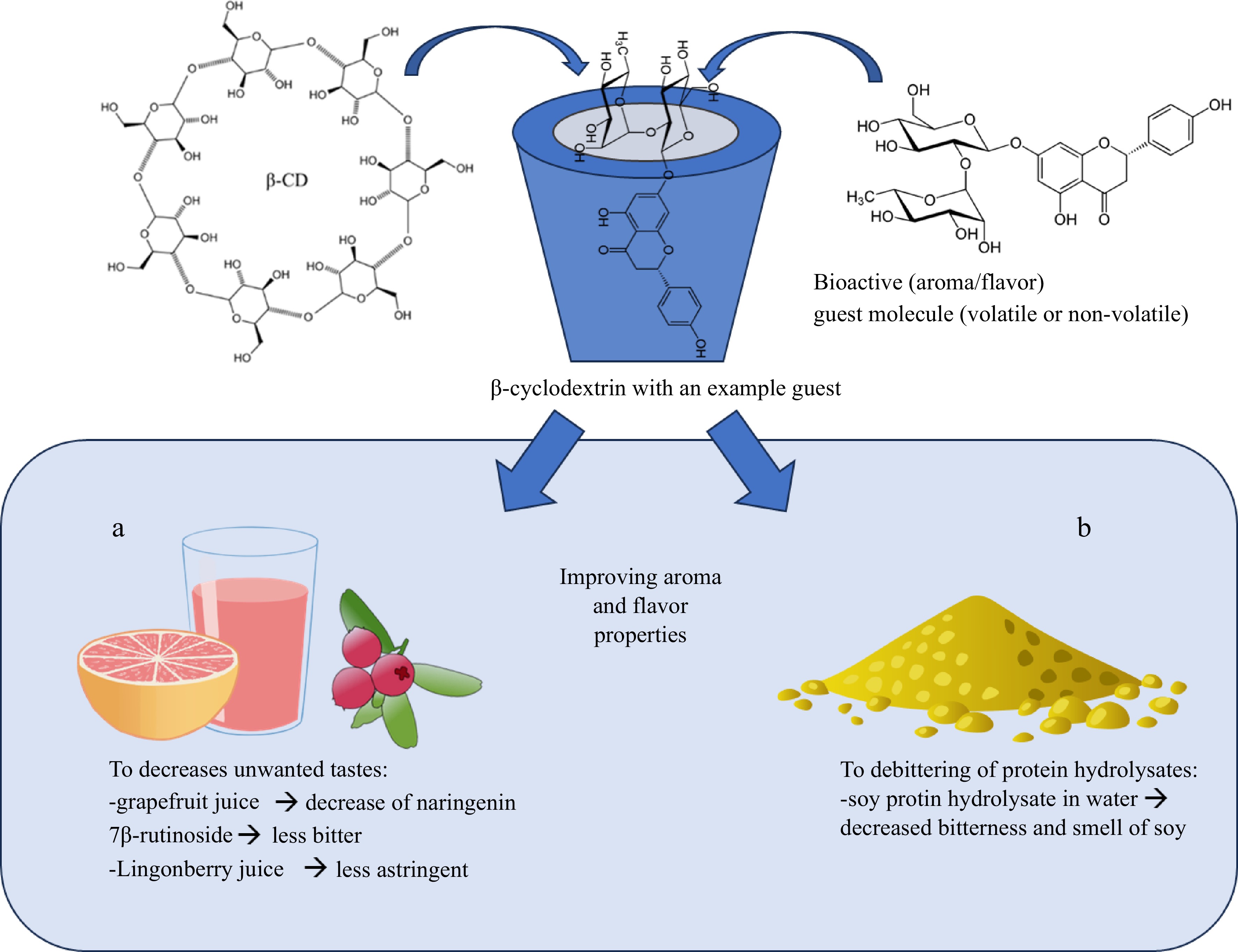

Figure 1.

Chemical structure of native cyclodextrins, α-CD, β-CD, and γ-CD, and examples of their possible use in improving sensory properties of food products. (a) α-CD can be used to prevent enzymatic browning in juice processing due it is capable to encapsulate substrate of polyphenol oxidases[3]. (b) β-CD can be used to prevent degradation of anthocyanin pigments in wine making[4]. (c) γ-CD can prevent carotene degradation during homogenization of juice[5].

-

-

Raw material Type of used cyclodextrin Methodology Analysed parameters Effects on chemical/food products Reference Instrumental analyses of sensory-active compounds Apple β-cyclodextrin

thiol-β-cyclodextrin700 µM (in 0.1 M sodium acetate buffer, pH 4.6) of β-CD or thiol-CD was added to apple slices, incubated at RT for 24 h. Inhibition of the enzymatic browning:

The CIE coordinatesThiol-CD exhibited considerably higher inhibition of the enzymatic browning. Thiol-CD treatment resulted lighter, less red and yellow color of apple slices, indicating less browning. [6] Apple M-β-cyclodextrin

(0, 30, 60, or 90 mM)CD in the 25 mL of distilled water. Color by the CIE coordinates Increased level of MBCD decreased more the total color difference and slowed down the changes of L*, a*, and b*. [51] Apple α- (10/30/40 mM) and β-cyclodextrins (5/10/15 mM) Apple juice with CD was treated with HPP (0/300/400/500 Mpa; 5 min, 22 °C). Browning index and phenolic compounds α-CD at 30 mM and β-CD at 15 mM level reduced the most HPP induced browning. [11] Chokeberry β-cyclodextrin

(0, 0.5%, 1%, or 3%)

in pH levels

(2.8, 3.2, 3.6)Different level of β-CD in different pH chokeberry juice. Storage at 25 and

4 °C for 2, 4, 6, 8 months.Monomeric anthocyanins Both pH and β-CD amount affected stability of anthocyanins during storage. Ambient storage temperature effected more on the degradation of anthocyanins than refrigerator temperature. [30] Peach α-cyclodextrin (0,

10, 30, and 60 mM)

M-β-cyclodextrin (MBCD, 0, 10, 20, and 30 mM)

β-cyclodextrin (0, 3, 5, and 10 mM)CD in 25 mL of distilled water. Color by the CIE coordinates Increased level of α-CD slowed down the changes of L* and ΔE*, and 60 mM of α-CD eliminated the change of L*. β-CD did not have effect on the color in any concentration. Increased level of MBCD slowed down the changes of L* and ΔE*. [81] Pomegranate β-cyclodextrin,

HP-β-cyclodextrin (0.5%, 1%, or 2%)Pomegranate juice treated with CDs and stored 3 months at 25 °C. Monomeric anthocyanins, TPC, FRSA CD type and level affected the degradation rate of anthocyanins. HP-CD stabilized more anthocyanins than β-CD. β-CD did not show protective effect on the TPC. 0.5% of HP-β-CD significantly increased TPC. FRSA did not change after 3-month storage in any sample. [9] Roselle extract β-cyclodextrin: anthocyanin (1:1) in extract Extract heated to 60, 70, 80, and 90 °C for 10−110 min. Total anthocyanin content The degradation of anthocyanins increased with increased heat and time, but presence of β-CD decreased the degradation. β-CD nearly doubled the half-time values of anthocyanins. [38] Tangerine β-cyclodextrin (1, 3, and 5 g%) Batch process, packed bed column process, and fluidized bed process with varying CD concentrations and process parameters were used. Limonin content Batch processing: direct correlation between CD content and limonin complexation. Column processing: 3 g% CD had better debittering result (94% limonin reduction) than batch processing. Fluidized bed process: juice flow rate effected on the binding rate of limonin, CD content did have only a little effect on limonin reduction. [60] Assessments by sensory panels and instrumental analyses Amanatsu

Grapefruit

Orange

β-cyclodextrin 0.3% (w/w) CD and 8% (w/w) of sucrose were added to the juice, heated to 95 °C for 10 min and cooled to RT. Bitterness (trained panel) Addition of CD decreased bitterness significantly of all studied citrus fruits. [80] Bitter gourd β-cyclodextrin

(0.25%−2%)β-CD was added to freshly pressed juice, stirred for 1 h at 25 °C, pH was adjusted to 3.5 and 2 g/L of stevia was added. Juice was pasteurized (95 °C, 2 min) Effect on sensory quality (trained panel), TPC, TAC, and antidiabetic potential All studied CD concentrations decreased bitterness. Addition of 1.5% of CD resulted the most acceptable juice. Increased level of CD increased TPC and TAC. Marginal reduction in antidiabetic activity was observed. [31] Grapefruit

Navel orangeβ-cyclodextrin 1 g/L in 50 mL of juice Cyclodextrin in the continuous flow fluid-bed or in batch process Concentration changes of limonin, nomilin, and naringin and impacts on the sensory properties (trained panel) Cyclodextrin polymer treatment decreased approximately 50% of bitter composition and sensory panel preferred debittered juices over non-treated. [82] Mandarin juice enriched with pomegranate and goji berries β-cyclodextrin and

HP-β-cyclodextrinJuice (mandarin 96%, goji berries 2%, pomegranate extract 1%, CD 1%) was pasteurized (98 °C, 30 s) and stored for 75 d at 4 °C. Stability of vitamin C, color, and retinol equivalents, antioxidant capacity and sensory properties (trained panel) Control juice without CDs had the most intense fresh mandarin aroma, β-CD had the second highest and HP-β-CD lowest. HP-β-CD had the best overall quality, the highest value of color intensity, vitamin C content, and retinol equivalents. [47] Orange juice β-cyclodextrin 13 mM of β-CD was added before juice pasteurization (98 °C for 20 s). Samples were stored at 20 °C for 145 d. TTS, acidity, pH, vitamin C, color by the CIE coordinates, carotenoids, antioxidant capacity, sensory quality (trained panel) Addition of β-CD did not have significant effect on the measured parameters. [46] Pear α-cyclodextrin (0,

15, 45, and 90 mM)Freshly pressed pear juice was mixed with distilled water containing CD. All juice samples were oxidized at stirrer for 20 min. Color by the CIE coordinates, volatile composition, and sensory evaluation (trained panel) Increased CD content delayed color changes. Oxidation increased concentrations of certain volatile compounds. Use of CD decreased contents of volatiles in concentration dependent manner. Only high CD content significantly modified volatile profile. 15 mM of CD had a significant positive effect on the sensory quality and 90 mM led to the deterioration of aroma and odor attributes. [83] Pear α-, β-, γ-cyclodextrins 15 mM of each CD was added to 25 mL of pear juice and mixed for 20 min. Enzymatic browning, volatile compounds, color, sensory properties (trained panel) CDs slower enzymatic browning by complexation of phenolic compounds. γ-CD significantly decreased the aroma and odor intensities, β-CD provided best color, and α-CD resulted increased global quality of pear juice. [26] CD(s) cyclodextrin(s); CIE coordinates: lightness (L*), red-green (a*), yellow-blue (b*), hue (H*), chroma (C*) total color difference (ΔE*), browning index (BI*); FRSA free radical scavenging activity; HP hydroxy propyl; HPP high pressure processing; MBCD maltosyl-β-cyclodextrin; TPC total phenolic content; TAC total antioxidant capacity; RT room temperature; TSS total soluble solids. Table 1.

Effects of the cyclodextrins on the individual compounds and sensory properties (appearance, flavor, taste) of food products.

Figures

(2)

Tables

(1)