-

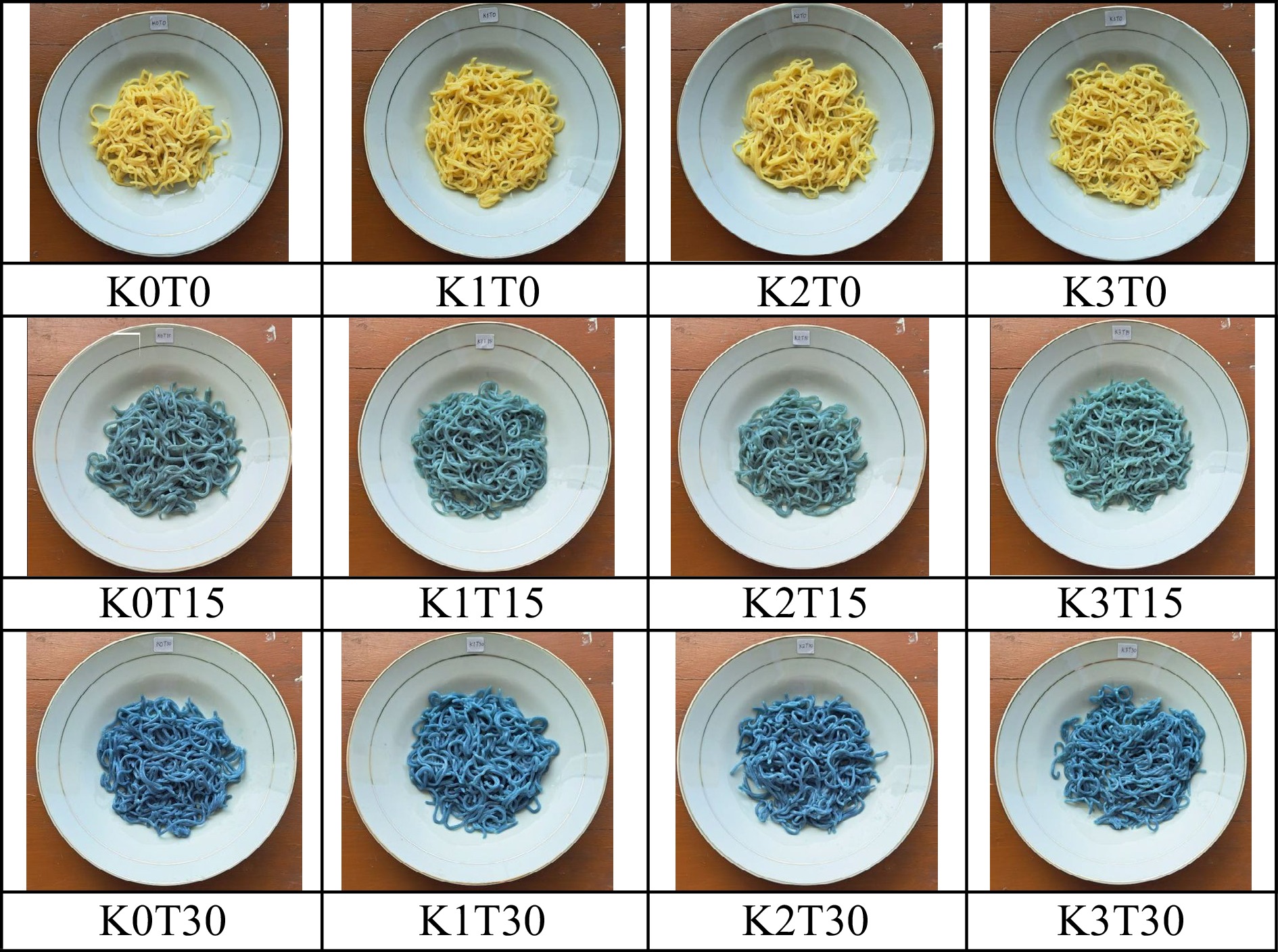

Figure 1.

Color of wet noodles with various proportions of composite flour and concentrations of butterfly pea flower extract.

-

Treatment Code Ingredients Salt

(g)Fresh

whole

egg (g)Water

(mL)Butterfly

pea extract

solution (mL)Composite

flour (g)1 K0T0 3 30 30 0 150 2 K0T15 3 30 0 30 150 3 K0T30 3 30 0 30 150 4 K1T0 3 30 30 0 150 5 K1T15 3 30 0 30 150 6 K1T30 3 30 0 30 150 7 K2T0 3 30 30 0 150 8 K2T15 3 30 0 30 150 9 K2T30 3 30 0 30 150 10 K3T0 3 30 30 0 150 11 K3T15 3 30 0 30 150 12 K3T30 3 30 0 30 150 K0 = wheat flour : stink lily flour : κ-carrageenan = 80:20:0 (%w/w). K1 = wheat flour : stink lily flour : κ-carrageenan = 80:19:1 (%w/w). K2 = wheat flour : stink lily flour : κ-carrageenan = 80:18:2 (%w/w). K3 = wheat flour : stink lily flour : κ-carrageenan = 80:17:3 (%w/w). T0 = concentration of the butterfly pea extract = 0%. T15 = concentration of the butterfly pea extract = 15%. T30 = concentration of the butterfly pea extract = 30%. Table 1.

Formula of wet noodles.

-

Samples Moisture content (% w/w) Water activity Swelling index (%) Cooking loss (%) Tensile strength (g) K0T0 67.94 ± 0.11 0.975 ± 0.008 126.39 ± 2.06 18.91 ± 0.03 0.102 ± 0.008 K0T15 68.31 ± 0.07 0.976 ± 0.005 126.84 ± 1.69 19.02 ± 0.10 0.094 ± 0.003 K0T30 67.86 ± 0.66 0.978 ± 0.008 131.85 ± 2.97 19.76 ± 0.75 0.095 ± 0.003 K1T0 67.64 ± 0.27 0.971 ± 0.009 127.45 ± 7.15 18.71 ± 0.13 0.108 ± 0.007 K1T15 68.34 ± 0.44 0.973 ± 0.004 131.46 ± 0.93 18.77 ± 0.11 0.116 ± 0.011 K1T30 68.63 ± 1.08 0.969 ± 0.005 141.83 ± 8.15 19.32 ± 0.29 0.108 ± 0.008 K2T0 68.64 ± 0.52 0.974 ± 0.008 132.81 ± 3.77 18.26 ± 0.12 0.140 ± 0.002 K2T15 69.57 ± 0.59 0.973 ± 0.004 138.12 ± 1.18 18.43 ± 0.06 0.138 ± 0.006 K2T30 68.46 ± 0.68 0.962 ± 0.002 141.92 ± 8.23 18.76 ± 0.06 0.138 ± 0.013 K3T0 69.71 ± 0.95 0.969 ± 0.008 155.00 ± 4.16 17.54 ± 0.27 0.183 ± 0.002 K3T15 69.08 ± 0.38 0.973 ± 0.005 158.67 ± 7.28 18.03 ± 0.28 0.170 ± 0.011 K3T30 69.76 ± 0.80 0.970 ± 0.005 163.66 ± 7.52 18.33 ± 0.03 0.161 ± 0.002 No significant effect of interaction between composite flour and butterfly pea extract on quality properties of wet noodles. The results were presented as SD of means that were achieved in triplicate. All of the data showed that no interaction of the two parameters influenced the quality properties of wet noodles at p ≤ 0.05. Table 2.

Quality properties of wet noodles at various ratios of composite flour and concentrations of butterfly pea flower extract.

-

Samples Moisture content (% w/w) Water activity Swelling index (%) Cooking loss (%) Tensile strength (g) K0 68.04 ± 0.40a 0.976 ± 0.01b 128.36 ± 3.30a 19.23 ± 0.55d 0.097 ± 0.097a K1 68.20 ± 0.74a 0.971 ± 0.01a 133.58 ± 8.42b 18.93 ± 0.34c 0.112 ± 0.111b K2 68.89 ± 0.73b 0.970 ± 0.01a 137.62 ± 6.05b 18.48 ± 0.23b 0.141 ± 0.139c K3 69.52 ± 0.73c 0.971 ± 0.01a 159.11 ± 6.77c 17.96 ± 0.40a 0.173 ± 0.171d All of the data showed that there was a significant effect of composite flour on the quality properties of wet noodles at p ≤ 0.05. The results were presented as SD of means that were achieved in triplicate. Means with different superscript letters in the same column are significantly different, p ≤ 0.05. Table 3.

Effect of composite flour proportions on quality properties of wet noodles.

-

Samples Moisture content (% w/w) Water activity Swelling index (%) Cooking loss (%) Tensile strength (g) T0 68.48 ± 0.96 0.970 ± 0.010 135.41 ± 12.72a 18.35 ± 0.57a 0.134 ± 0.034b T15 68.67 ± 0.66 0.974 ± 0.000 138.77 ± 13.12a 18.56 ± 0.41a 0.130 ± 0.030ab T30 68.83 ± 1.00 0.970 ± 0.010 144.82 ± 13.55b 19.04 ± 0.67b 0.129 ± 0.028a All of the data showed that there was a significant effect of butterfly pea extract concentration on the quality properties of wet noodles at p ≤ 0.05. The results were presented as SD of means that were achieved in triplicate. Means with different superscript letters in the same column are significantly different, p ≤ 0.05. Table 4.

Effect of butterfly pea extract concentration on quality properties of wet noodles.

-

Samples L* a* b* C oh K0T0 66.10 ± 0.30f 0.90 ± 0.10f 15.70 ± 0.10f 15.70 ± 0.10f 86.60 ± 0.20a K0T15 48.70 ± 0.20c −11.40 ± 0.30bc −3.50 ± 0.20c 12.00 ± 0.30c 197.00 ± 0.70c K0T30 44.00 ± 0.60a −12.80 ± 0.20a −6.50 ± 0.30a 14.40 ± 0.20e 206.90 ± 1.00d K1T0 67.10 ± 0.40f 0.90 ± 0.20f 15.80 ± 0.60f 15.80 ± 0.60f 86.60 ± 0.50a K1T15 51.50 ± 1.80d −10.80 ± 0.40cd −3.00 ± 0.20cd 11.30 ± 0.40bc 195.60 ± 0.60c K1T30 45.50 ± 0.20b −11.80 ± 0.80b −6.30 ± 0.30a 13.40 ± 0.70d 208.40 ± 2.30d K2T0 67.10 ± 0.20f 1.00 ± 0.10f 16.30 ± 0.10fg 16.30 ± 0.10fg 86.40 ± 0.10a K2T15 53.40 ± 0.30e −10.30 ± 0.80de −2.80 ± 0.10d 10.70 ± 0.80b 195.50 ± 1.30c K2T30 46.00 ± 0.40b −10.40 ± 0.20de −6.10 ± 0.40a 12.10 ± 0.40c 210.60 ± 1.30e K3T0 67.40 ± 0.30f 1.20 ± 0.10f 16.80 ± 0.70g 16.90 ± 0.70g 85.90 ± 0.20a K3T15 53.80 ± 1.30e −9.80 ± 0.70e −1.20 ± 0.20e 9.90 ± 0.70a 187.50 ± 1.10b K3T30 47.90 ± 0.70c −10.10 ± 0.40de −5.50 ± 0.30b 11.60 ± 0.20bc 208.40 ± 2.30d All of the data showed that there was a significant effect of interaction between composite flour and butterfly pea extract on the quality properties of wet noodles at p ≤ 0.05. The results were presented as SD of means that were achieved in triplicate. Means with different superscript letters in the same column are significantly different, p ≤ 0.05. Table 5.

Effect of interaction between composite flour and butterfly pea extract on wet noodle color.

-

Samples TPC (mg GAE/kg

dried noodles)TFC (mg CE/kg

dried noodles)TAC (mg define-3-glucoside/kg

dried noodles)DPPH (mg GAE/kg

dried noodlesFRAP (mg GAE/kg

dried noodles)K0T0 126.07 ± 0.90a 16.74 ± 6.26a 0.00 ± 0.00a 2.99 ± 0.16a 0.009 ± 0.001a K0T15 172.57 ± 2.14e 36.66 ± 2.84d 2.67 ± 0.21b 21.54 ± 1.71d 0.023 ± 0.002c K0T30 178.07 ± 2.54f 48.36 ± 3.29f 3.94 ± 0.28c 39.23 ± 0.91f 0.027 ± 0.002e K1T0 137.07 ± 1.32b 21.66 ± 3.67b 0.00 ± 0.00a 3.13 ± 0.19a 0.011 ± 0.001a K1T15 178.48 ± 0.95f 36.95 ± 3.05d 2.74 ± 0.21b 21.94 ± 0.68d 0.023 ± 0.001cd K1T30 183.65 ± 1.67g 52.28 ± 3.08g 3.84 ± 0.19c 41.42 ± 1.30g 0.029 ± 0.001f K2T0 150.40 ± 0.52d 27.49 ± 5.39c 0.00 ± 0.00a 7.45 ± 0.69c 0.014 ± 0.001b K2T15 202.48 ± 0.63j 48.28 ± 2.41f 2.95 ± 0.57b 24.70 ± 0.90e 0.025 ± 0.001d K2T30 206.90 ± 2.43i 56.99 ± 7.45h 3.93 ± 0.42c 47.55 ± 1.31i 0.034 ± 0.002g K3T0 141.15 ± 1.28c 25.37 ± 3.46c 0.00 ± 0.00a 5.45 ± 0.49b 0.013 ± 0.001b K3T15 186.32 ± 1.15h 43.57 ± 2.28e 2.66 ± 0.21b 22.45 ± 0.48d 0.024 ± 0.001cd K3T30 189.90 ± 0.63k 54.95 ± 3.72gh 3.98 ± 0.37c 44.93 ± 1.28h 0.031 ± 0.001f All of the data showed that there was a significant effect of interaction between composite flour and butterfly pea extract to bioactive compounds and antioxidant activity of wet noodles at p ≤ 0.05. The results were presented as SD of means that were achieved in triplicate. Means with different superscript letters in the same column are significantly different, p ≤ 0.05. Table 6.

Effect of interaction between composite flour and butterfly pea extract on wet noodle's bioactive compounds and antioxidant activity.

-

Parameter TPC TFC TAC DPPH T0 T15 T30 T0 T15 T30 T0 T15 T30 T0 T15 T30 TPC 1 1 1 TFC 0.955 0.946 0.765 1 1 1 TAC 0.153 −0.092 0.067 0.028 −0.239 −0.020 1 1 1 DPPH 0.893 0.815 0.883 0.883 0.739 0.753 0.123 0.127 0.194 1 1 1 FRAP 0.884 0.425 0.859 0.902 0.464 0.742 0.056 −0.122 −0.131 0.881 0.321 0.847 Correlation significant at the 0.05 level (2-tailed). Table 7.

Pearson correlation coefficients between bioactive contents (TPC, TFC, and TAC) and antioxidant activity (DPPH and FRAP).

-

Samples Color Aroma Taste Texture Index effectiveness test K0T0 8.69 ± 3.31a 7.41 ± 3.80a 8.71 ± 3.16a 10.78 ± 2.86abcde 0.1597 K0T15 8.96 ± 3.38b 7.75 ± 3.89b 9.35 ± 3.36cde 11.19 ± 3.10abcd 0.6219 K0T30 8.93 ± 3.50bc 7.71 ± 3.76c 9.26 ± 3.17bcd 11.13 ± 3.09a 0.6691 K1T0 8.74 ± 3.62a 8.13 ± 3.56ab 9.58 ± 3.13ab 11.33 ± 3.12de 0.4339 K1T15 9.98 ± 3.06bc 8.40 ± 3.28c 10.16 ± 2.59def 10.61 ± 2.82ab 0.7086 K1T30 10.08 ± 3.28bc 9.10 ± 3.08c 10.44 ± 2.32bcd 10.36 ± 2.81ab 0.7389 K2T0 10.41 ± 3.01a 9.39 ± 3.27ab 11.04 ± 2.44ab 10.55 ± 2.60cde 0.3969 K2T15 10.8 ± 2.85bc 9.26 ± 3.10c 10.11 ± 2.76f 10.89 ± 2.65abcd 0.9219 K2T30 10.73 ± 3.02c 9.10 ± 3.46c 9.85 ± 2.99def 10.16 ± 2.74abc 0.9112 K3T0 10.73 ± 3.42a 9.19 ± 3.38b 9.93 ± 2.50bc 10.34 ± 2.84e 0.5249 K3T15 10.91 ± 3.23bc 9.48 ± 3.56c 10.45 ± 2.82cde 10.49 ± 2.68bcde 0.9235 K3T30 10.88 ± 3.14c 9.49 ± 3.59c 10.81 ± 2.74ef 10.86 ± 2.60bcde 1.0504 All of the data showed that there was a significant effect of interaction between composite flour and butterfly pea extract on the sensory properties of wet noodles at p ≤ 0.05. The results were presented as SD of means that were achieved in triplicate. Means with different superscript letters in the same column are significantly different, p ≤ 0.05. Table 8.

Effect of interaction between composite flour and butterfly pea extract to sensory properties of wet noodles and the best treatment of wet noodles based on index effectiveness test.

Figures

(1)

Tables

(8)