-

Figure 1.

Polyethylene mulch being burned in the field in Florida. (Photo source: Gene Jones).

-

Figure 2.

Polyethylene mulch being stockpiled in California. (Photo source: RenGen).

-

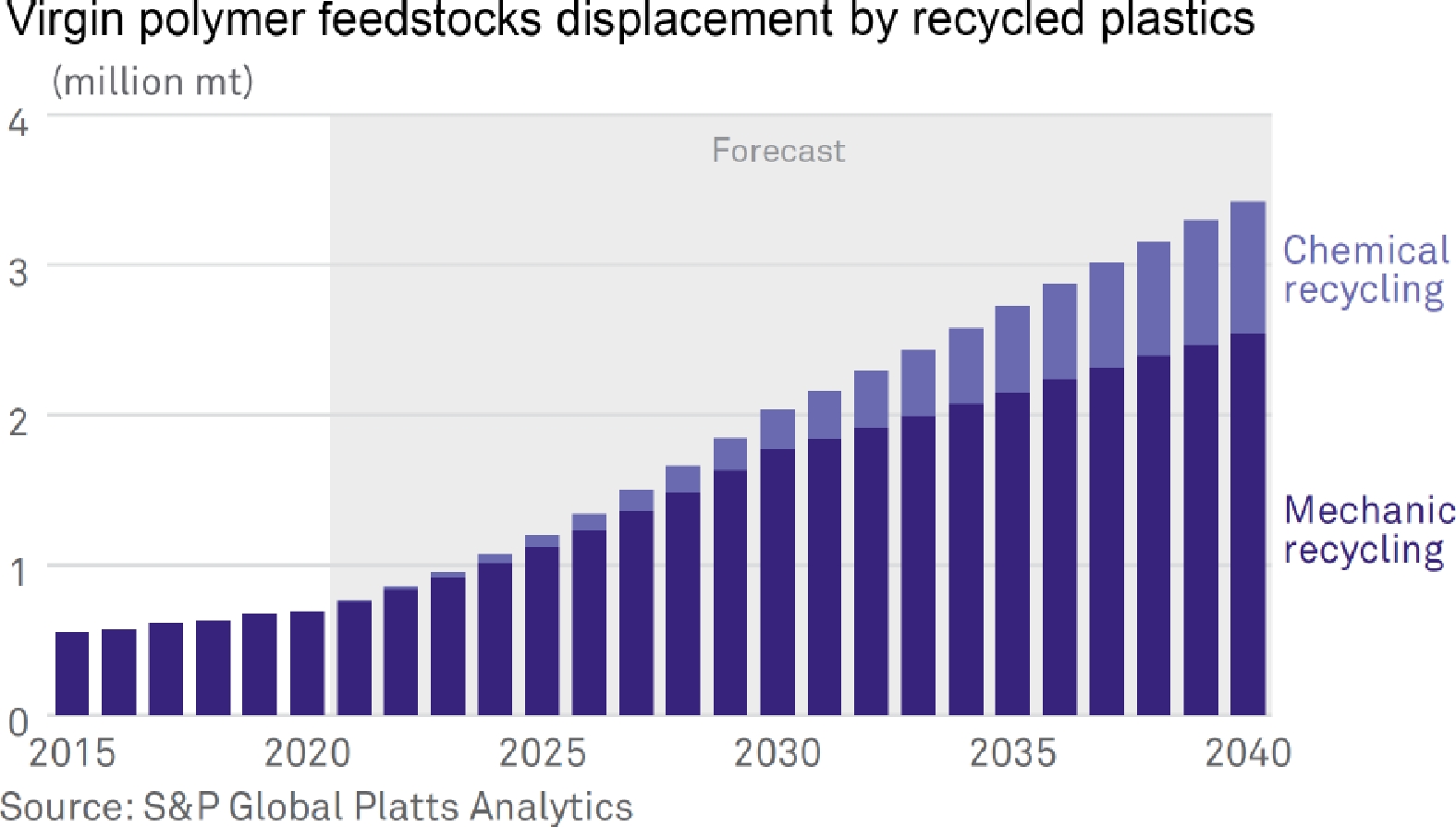

Figure 3.

Amount (million metric tonnes per day) of recycled plastic entering the market through mechanical and chemical recycling technologies from 2015 through 2020 (actual) and 2021 through 2040 (projected)[43].

-

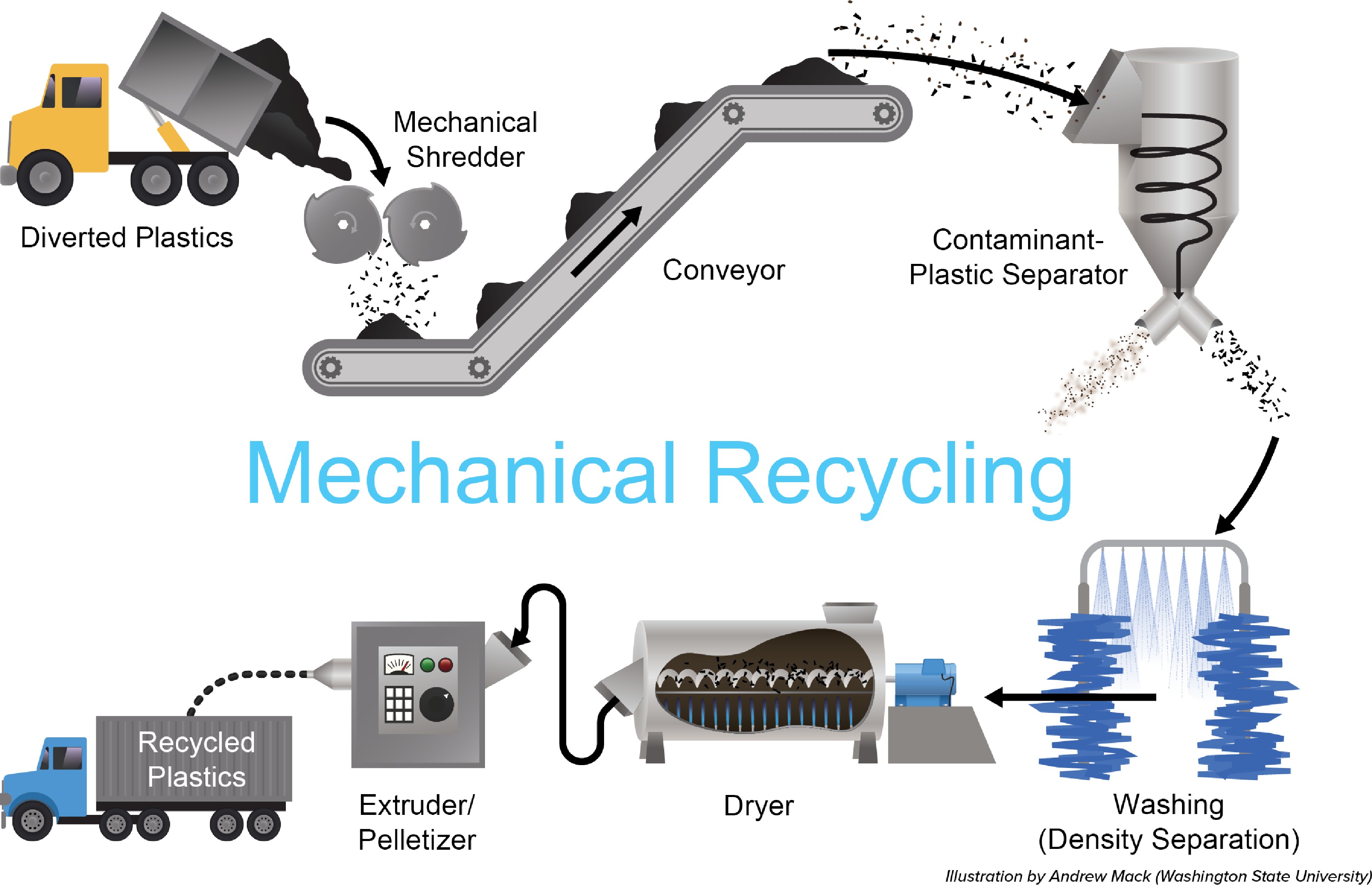

Figure 4.

Overview of the mechanical plastic recycling process.

-

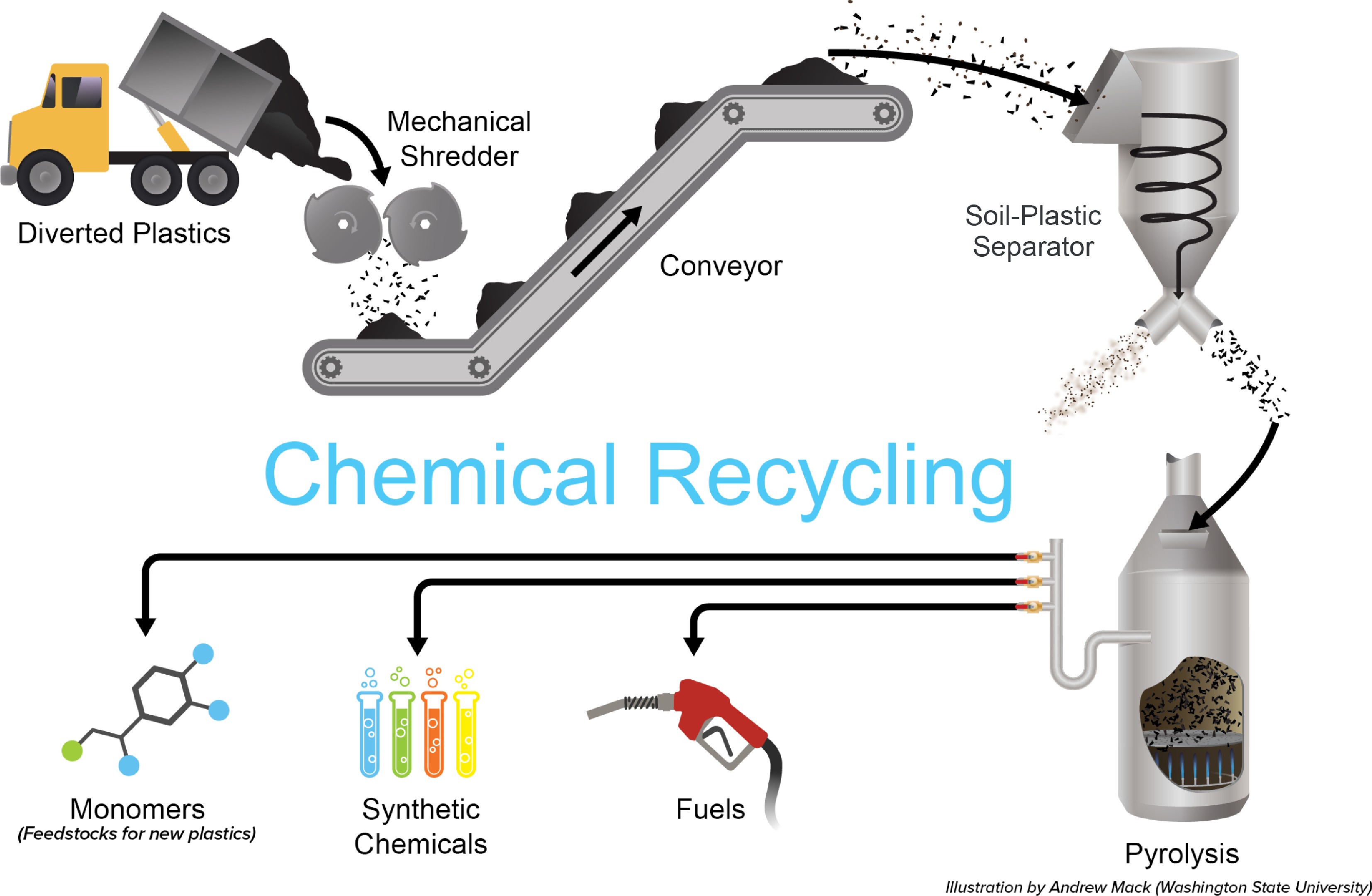

Figure 5.

Overview of a thermal pyrolysis plastic recycling process.

-

Mechanical Advanced (thermal and chemical) Biological Process description Physical shredding and melting of plastic to produce new products[52,83] Molecular breakdown of plastics into chemical components as feedstock for

new plastics or chemicals.

Thermal – pyrolysis or gasification.

Chemical – solvolysis[52,83−85]Using enzymes or microorganisms

to breakdown plastics into simpler substances[42,99]Types of plastics Limited to specific types of plastics, typically clean and separated such as PET, *HDPE and **LDPE[52] Can recycle a wider range of plastics, including mixed plastics (except PVC) depending upon the process[52] Currently limited to a few types of plastics (PET, polyurethane, and PE) to some extent[99] Allowable feedstock contaminate level ≤ 5%[19] 15% to 20%[106] Not available Efficiency Dependent on the quality and purity of the input waste plastic stream Dependent on the quality and purity

of the input waste plastic streamDependent on the quality and purity of the input waste plastic stream Product quality Lower quality products with lower mechanical properties with the exception of ***rPET[52] High-quality products with properties similar to new plastics in some cases[52] Potential to produce high-quality recycled materials, but further research is needed to optimize product properties[99] Economic viability Generally considered the most economical option due to established infrastructure and process[52] Capital intensive as it requires more investment and development of specialized equipment and facilities[52,105] Cost considerations include enzyme production, process optimization, and scaling up[42,99] Technological maturity Well-established and widely adopted[107] Under development, technological advancement needed to reduce

recycling cost[52,108]In early stages[42] Challenges Contamination, mixed plastic types, degradation of plastic properties[52] Contamination, economic viability considering low cost of virgin plastics, supply variability, sorting challenges especially films and other flexible plastics[52] Implementation costs, limited applicability (current enzymes limited to a few plastics)[42] * HDPE – high density polyethylene; ** LDPE – low density polyethylene; *** rPET – recycled PET. Table 1.

Comparison of mechanical, thermal, and biological plastic recycling processes.

Figures

(5)

Tables

(1)