-

Figure 1.

Fire triangle.

-

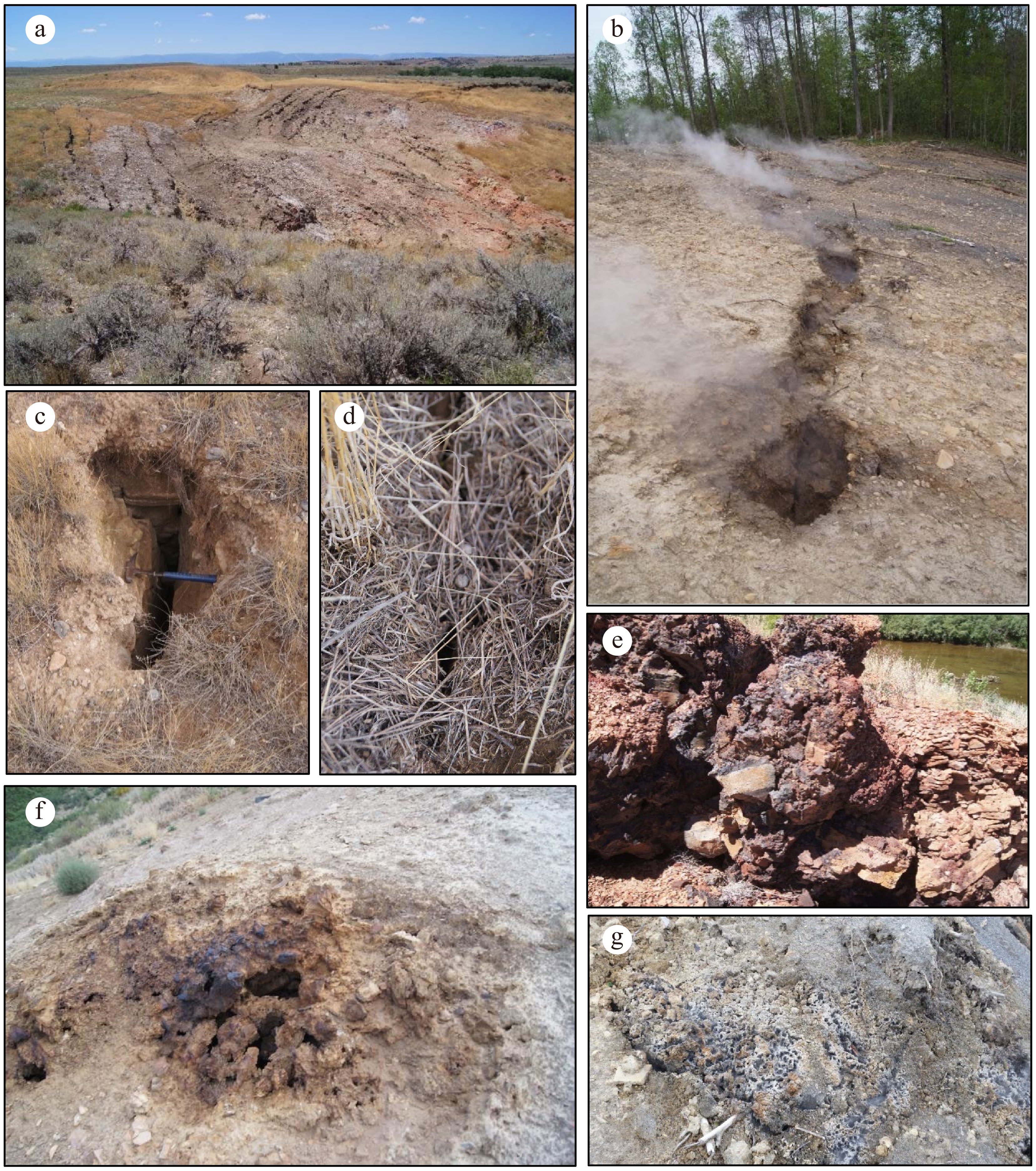

Figure 2.

Surface changes resulting from an underlying mine fire that allow the fire to breathe. (a) Ground fissures and slumping, (b) subsidence fissure venting hot combustion gases, (c) large open fracture, (d) microfractureing, (e) baked rock commonly known as 'clinker, scoria or red dog', (f) and (g) Pyrometamorphic paralava 'sponge' formations created by superheated exhaust vents.

-

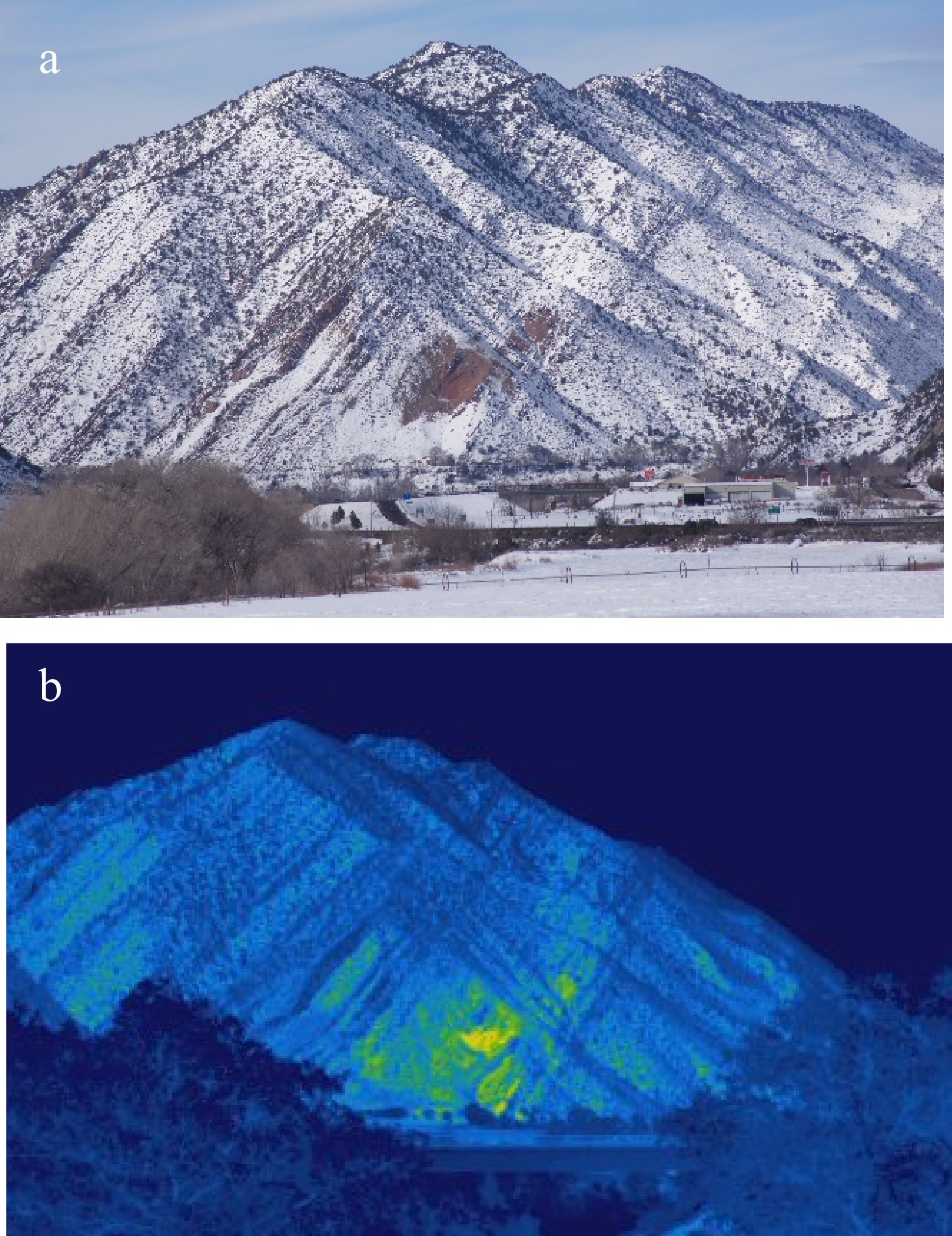

Figure 3.

Coal mine fire beneath rugged terrain in the Grand Hogback at Newcastle, Colorado, USA. (a) After recent snow and (b) with thermal infrared imagery. The rock strata dip to the left at 50 degrees.

-

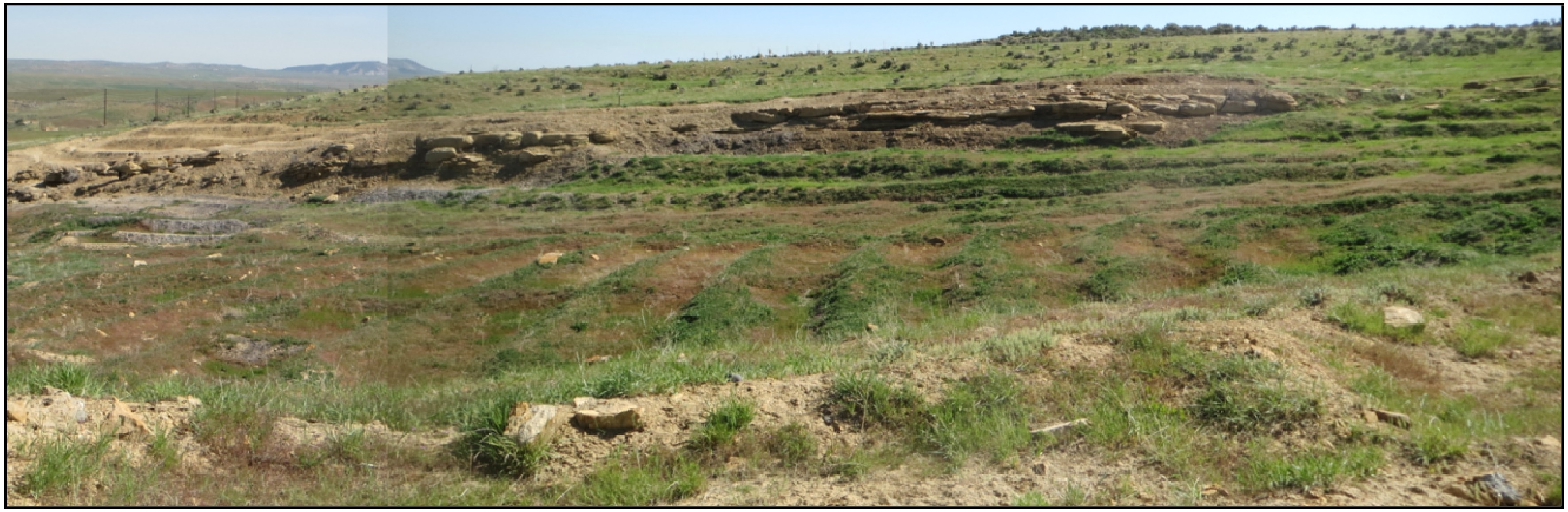

Figure 4.

South Canyon West coal mine fire, Colorado (USA) during snow. The coal bearing strata and mine workings plunge to the left at about 50 degrees and would be impossible to isolate.

-

Figure 5.

Surface water infiltration basins over a shallow mine fire.

-

Figure 6.

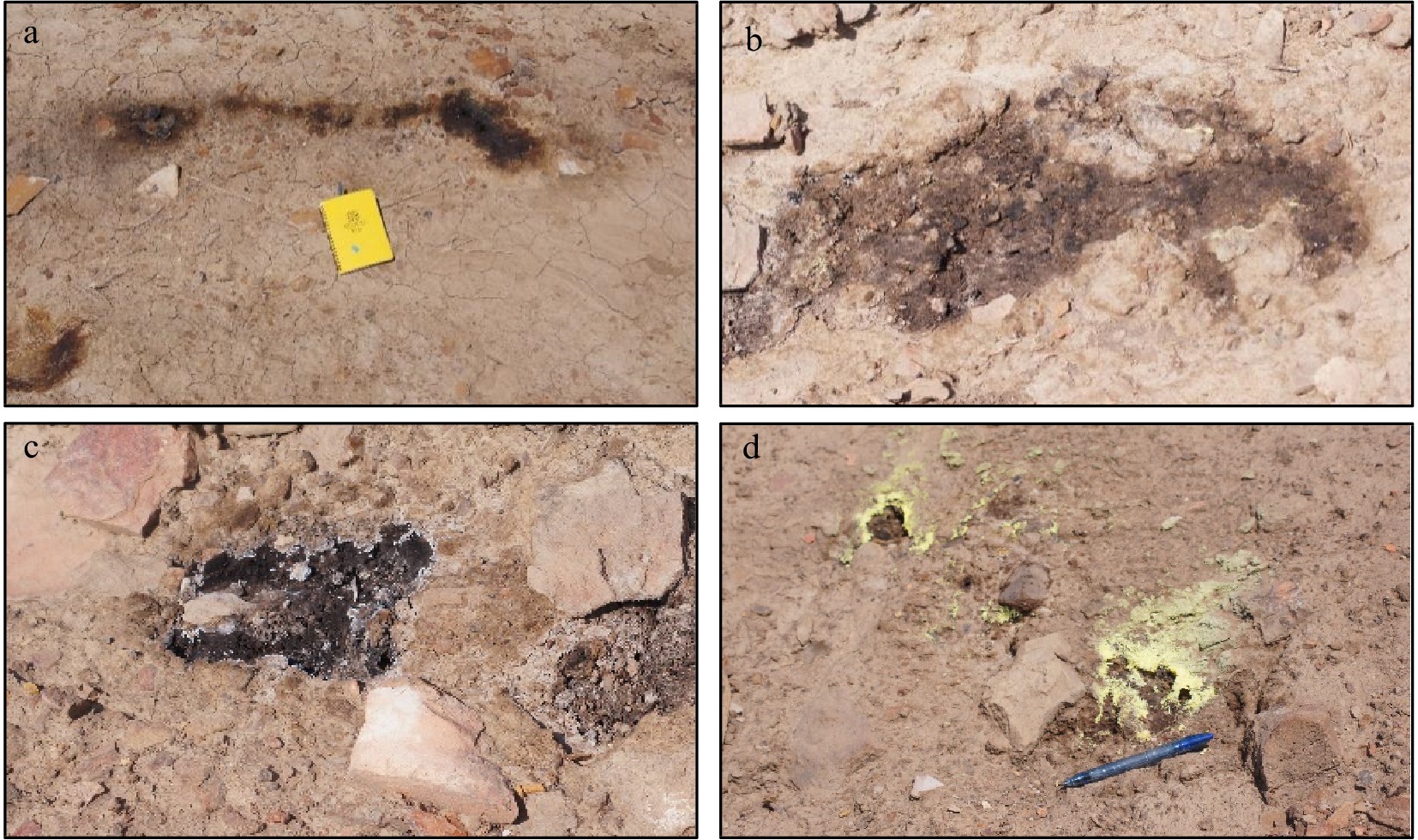

Examples of mine fires venting hot combustion gases through soil cover. (a) Coal tar residue condensed from gases upon venting through soil desiccation cracks; (b) and (c) Hydrocarbon and coal tar residues from venting through rocky cover material; (d) Sulphur crystals from H2S emissions through rocky cover soil.

-

Figure 7.

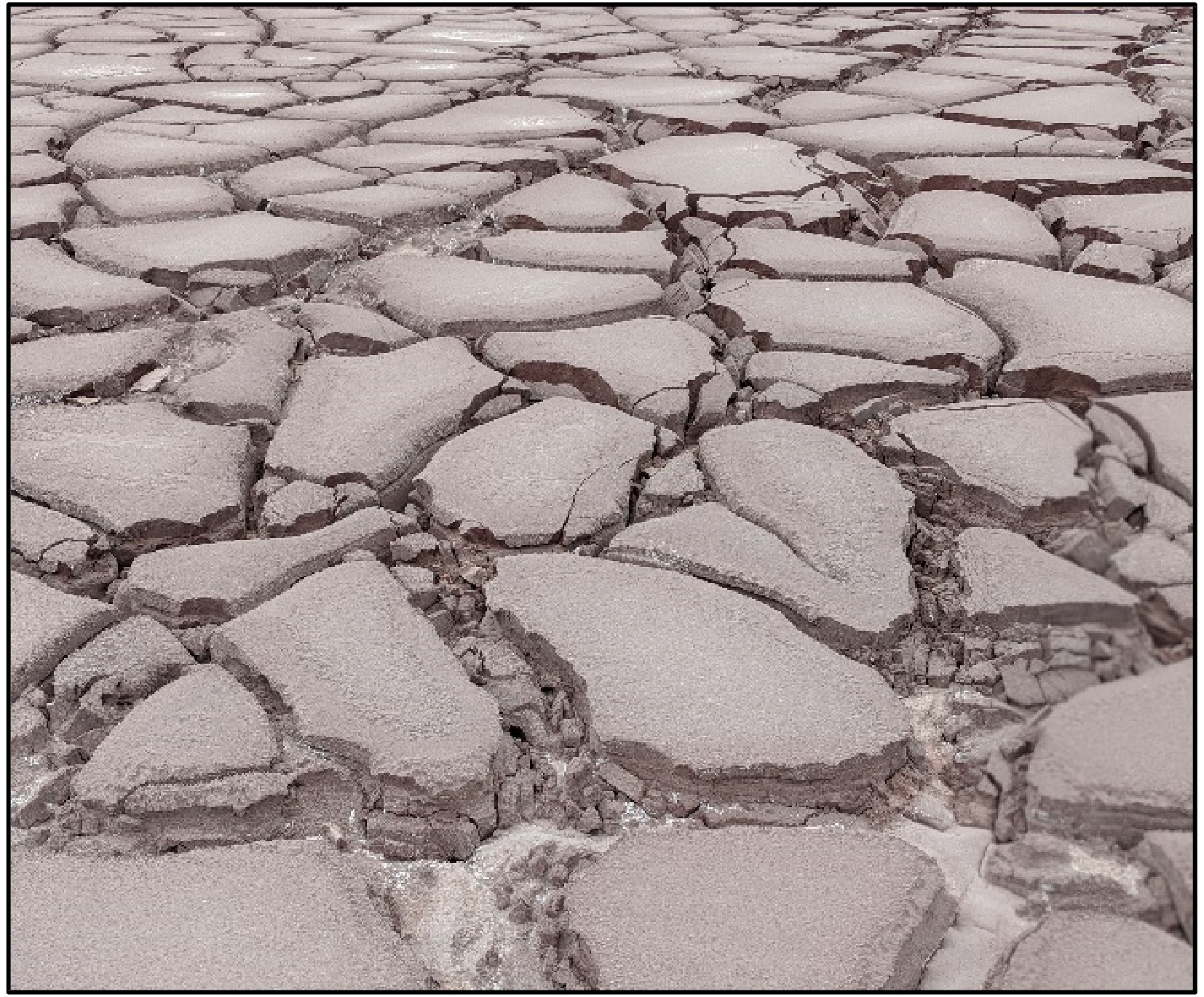

Large shrinkage or 'mud' cracks in fine grained sediments upon drying.

-

Figure 8.

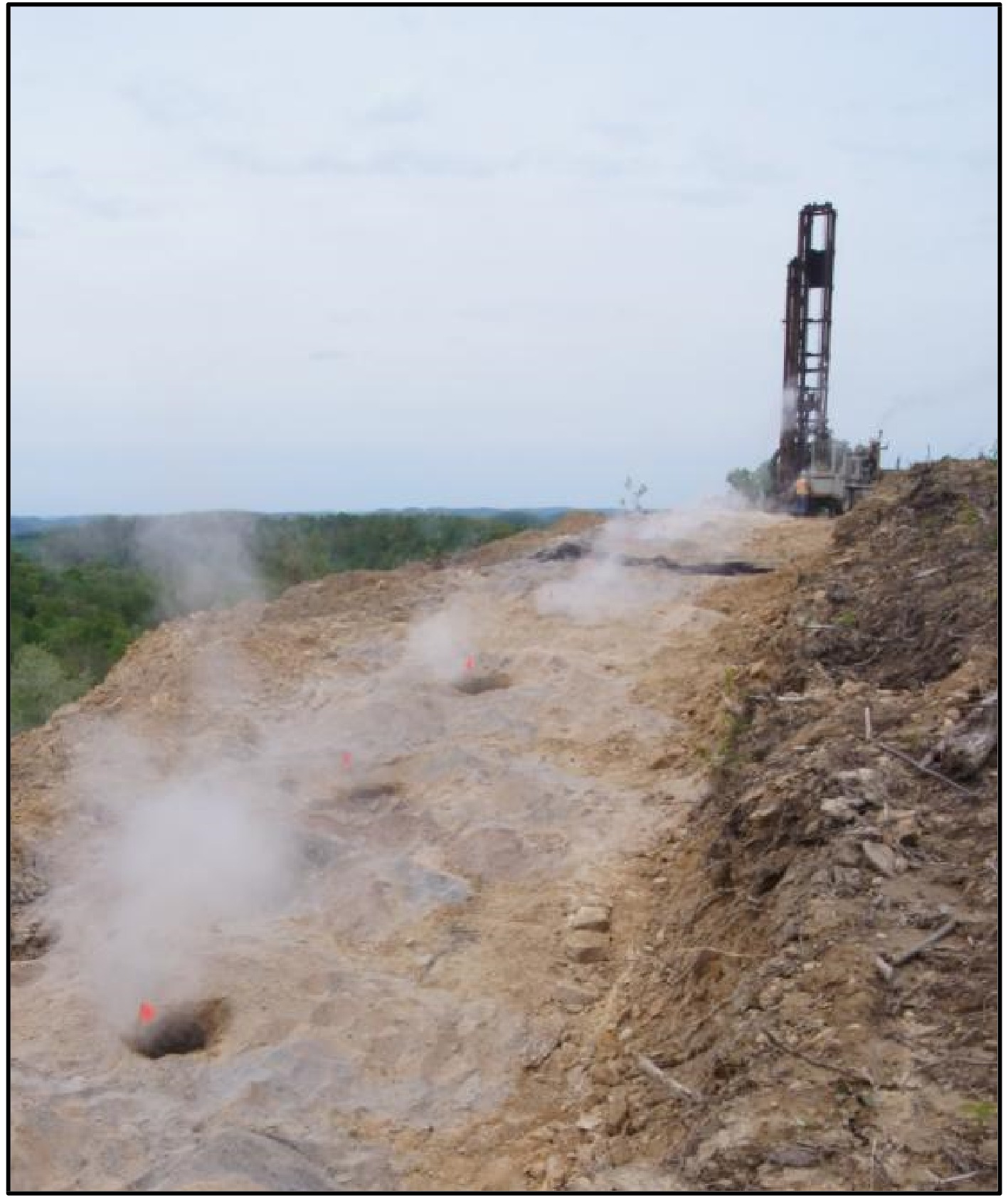

Grout injection holes venting combustion gases at the Scotch Hill mine fire, Newburg, West Virginia, USA.

-

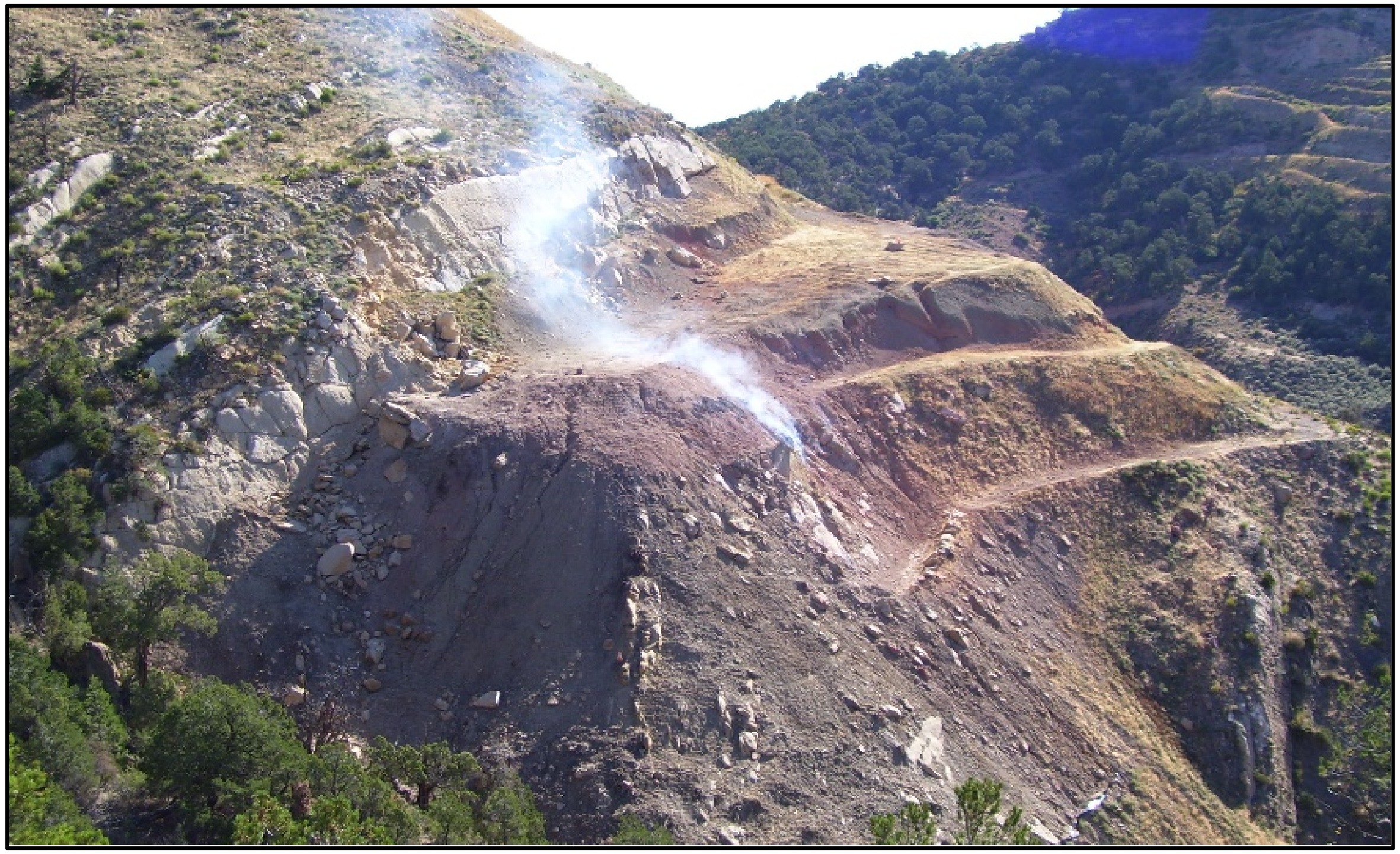

Figure 9.

IHI No.3 coal mine fire, Colorado (USA) which continues to burn vigorously despite multiple extinguishment efforts that included surface sealing, grouting and excavation.

-

Figure 10.

Starting with pit run sand, water is added to raise the moisture content to 1%−2% below field moisture content, then preformed foam is added to about 30% vol/vol solids to produce a highly flowable, pumpable slurry mixture.

-

Figure 11.

Foam transported sand backfill being placed in a room and pillar coal mine.

-

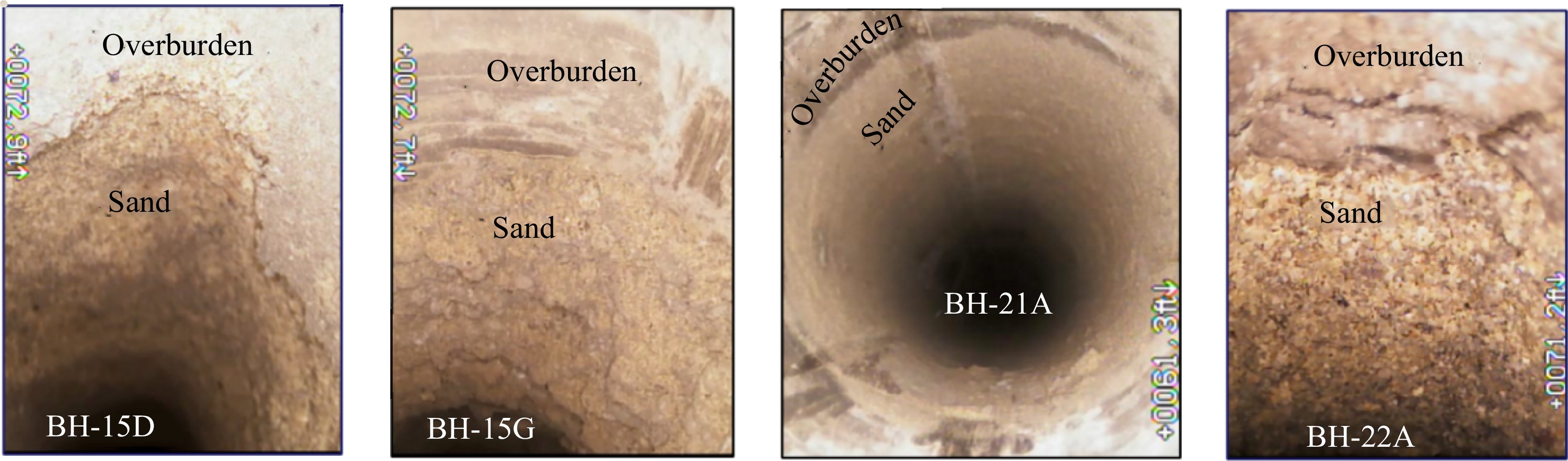

Figure 12.

Verification boring results showing tight contact between the final sand backfill and the roof or crown of the underground void opening.

-

Method Mine condition Depth Surface Impact Relative cost Comments Active Abandoned Bulkheads and stoppings Yes No Any None Low Good for reducing spontaneous combustion and recent fires in active mines; used with inerting Inerting Yes No Any Little to none Low to

moderateGood for reducing spontaneous combustion and recent fires in active mines; leakage an issue Ventilation control* Yes No Any None Low Requires active ventilation system Surface treatment** Yes No Any None Low Primary use is to inhibit spontaneous combustion High-expansion foam Yes Limited Any Little to none Low Good for recent fires in active mines Excavation Limited Yes Shallow Very high Very high Can't be used for developed areas, rugged terrain or deep fires Isolation No Yes Shallow High High Fire is left to burn indefinitely Surface seal No No Any High Low Low cost but also low effectiveness Remote seal Yes No Shallow Little to none Low Ineffective Barriers Limited Yes Any Little to none Moderate Largely ineffective Hydraulic backfill No Limited Any Little to some Moderate Effective for small mines in flat seams; large volumes of water required Pneumatic stowing Limited Limited Any Some to none Low Limited applicability except in active mines; primarily used for subsidence control. Beneficial use of waste. Grouting Limited Yes Any Little to some High Grout is subject to flash setting and thermal degradation Multi-phase Foam and gel*** Yes Yes Any Little to none Moderate Material dehydrates and cracks with time, limited duration of protection Cellular Grout**** Yes Yes Any Little to some High Good for spontaneous combustion in active mines; Portland cement prone to break down under sustained high temperature Foam-transported backfill No Yes Any Little to some Moderate Wide range of backfill materials possible, less cost than grout, un-tested on a coal fire * Includes dynamic pressure balancing as well as reversal. ** Includes chemicals, powders or other coatings. *** Includes foamed gel, and foam stabilized with fly ash, nanoparticles, etc. **** Cellular concrete, foamed concrete, inorganic solidified foam (ISF), inorganic curing foam (ICF) and cement-based foam material (CBFM). Table 1.

Summary of mine fire control methods.

Figures

(12)

Tables

(1)