-

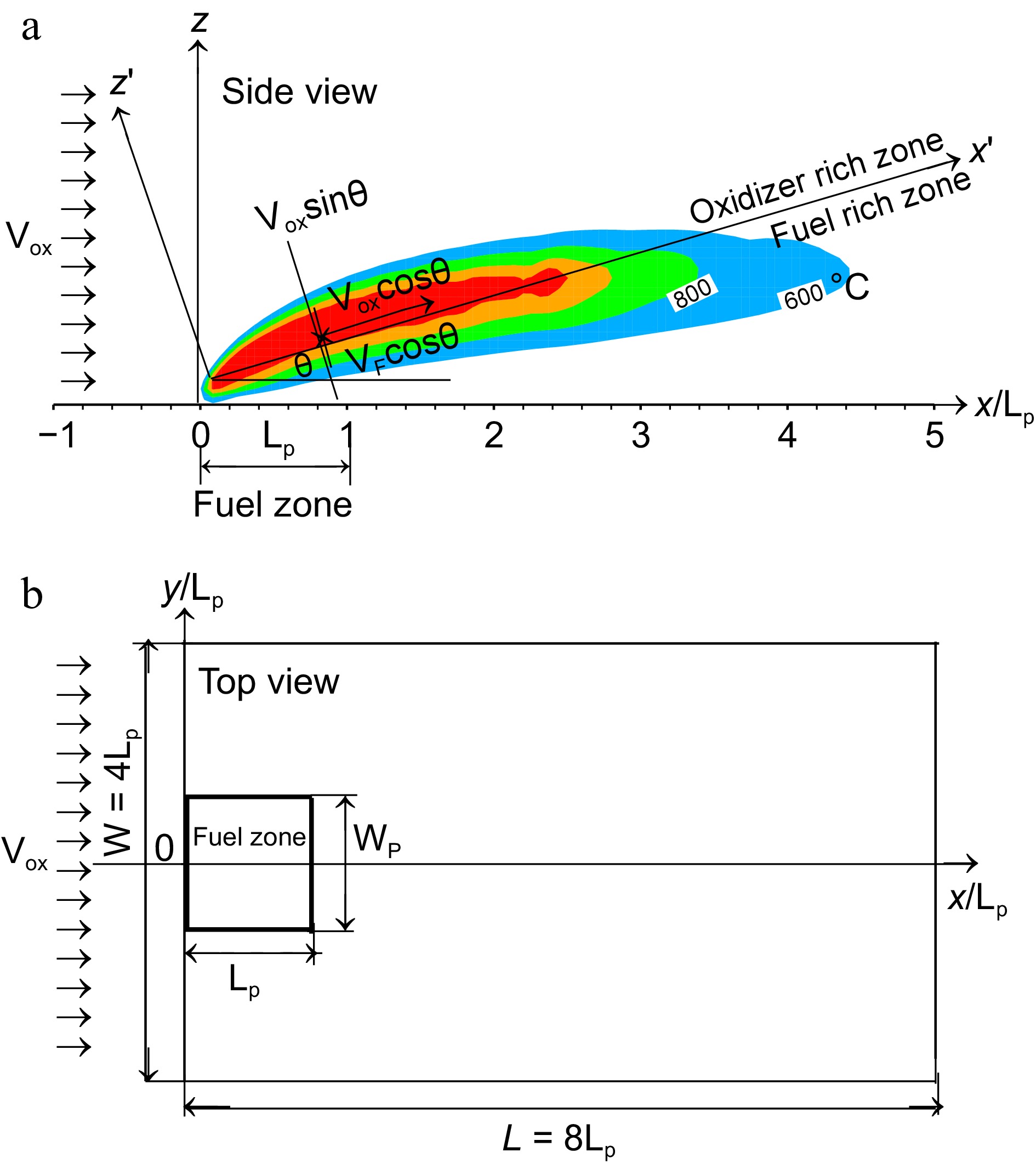

Figure 1.

Computational details and the coordinate system. (a) Flame structure in side view. (b) Disposition of the pyrolysis zone in top view.

-

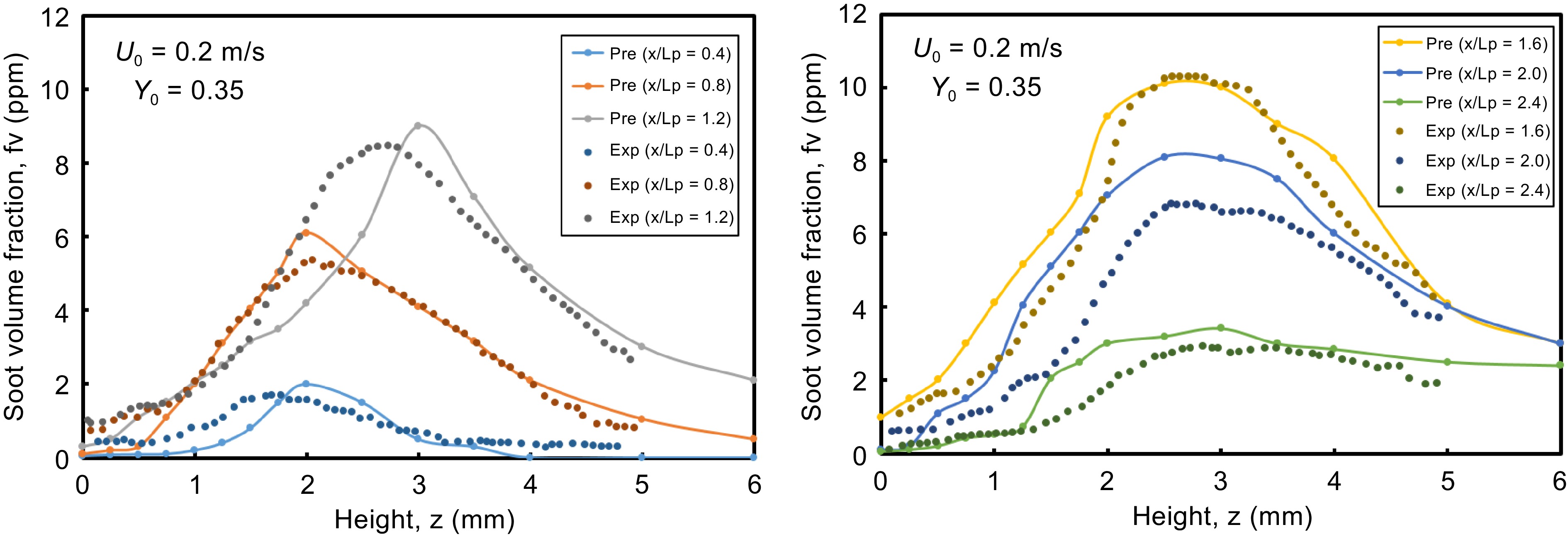

Figure 2.

Computed and experimental profiles of soot volume fraction for ethylene flame at different locations x along the height z.

-

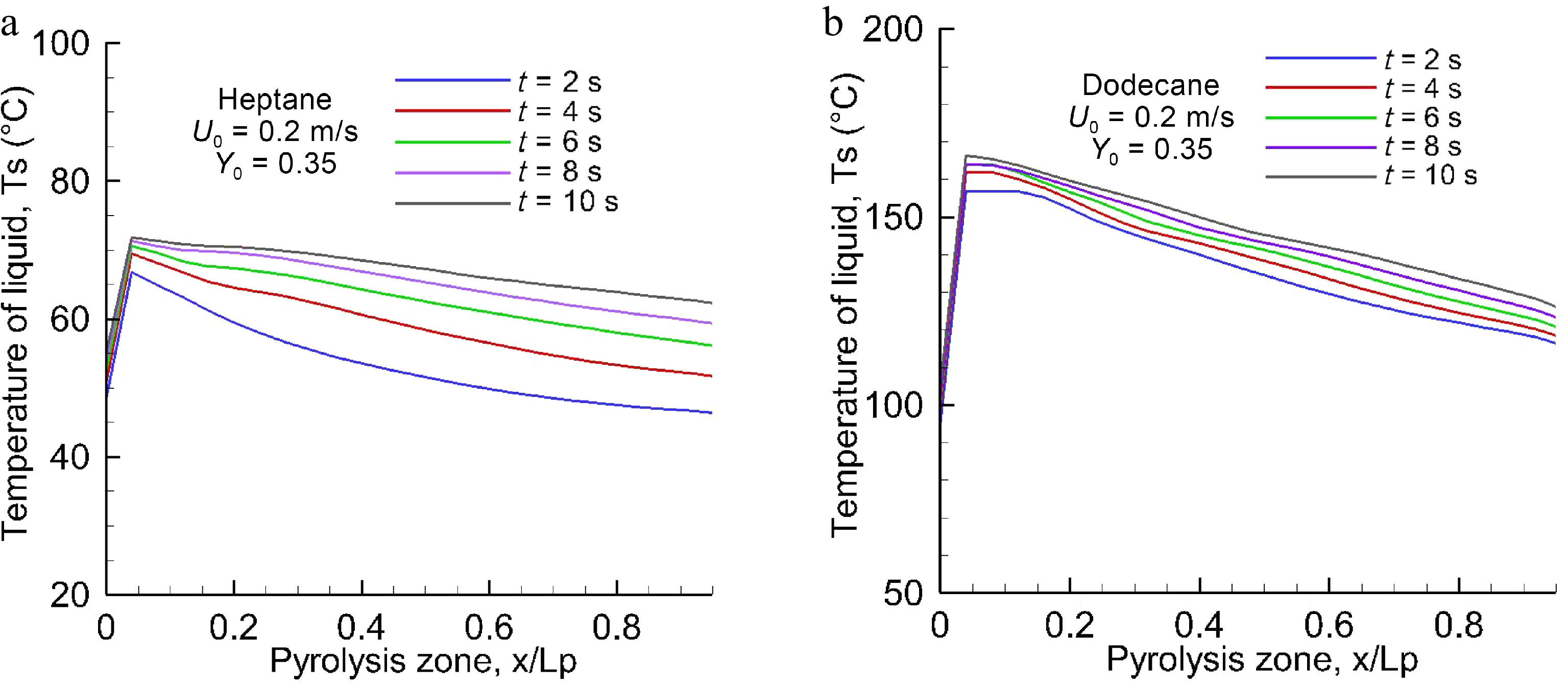

Figure 3.

Profiles of the surface temperature of (a)heptane and (b) dodecane as a function of time at U0 = 0.2 m/s.

-

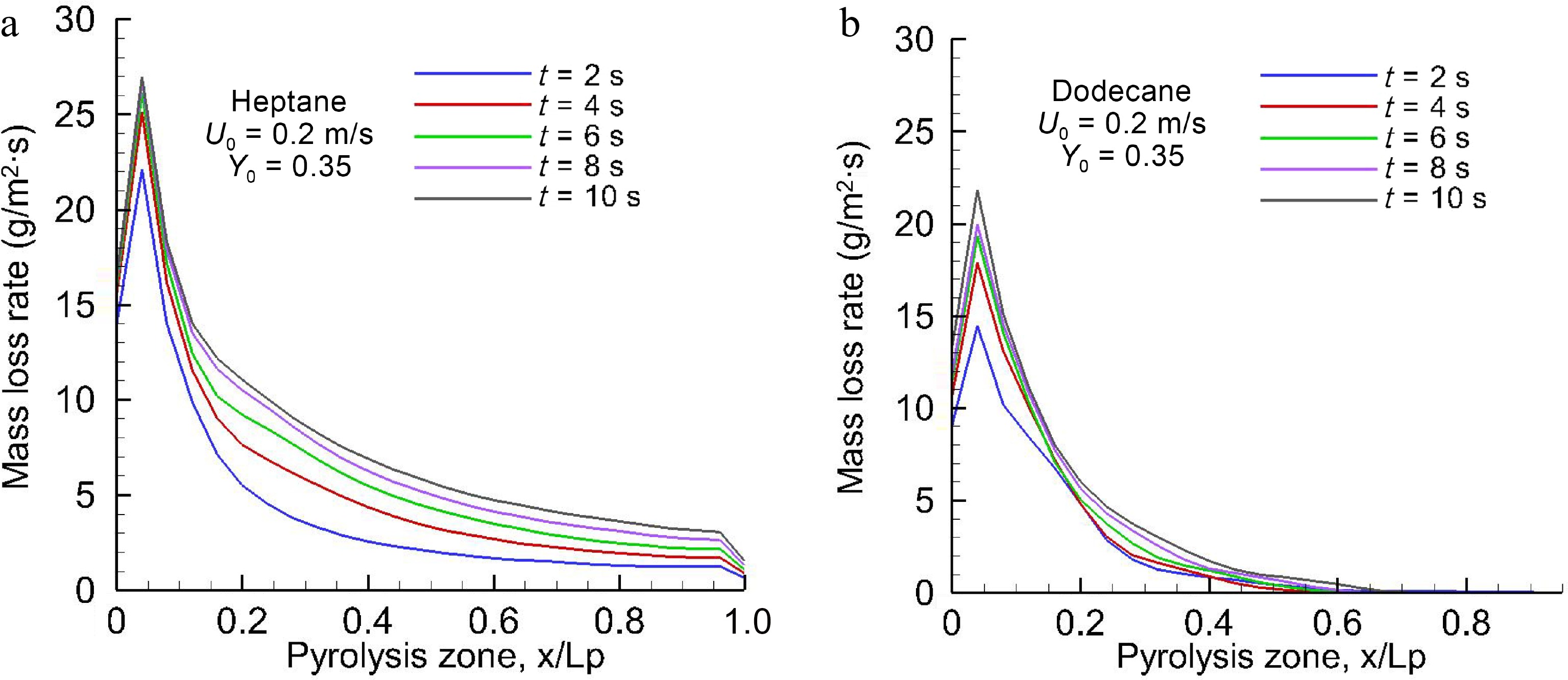

Figure 4.

Spatial distribution of the computed pyrolysis rate over (a) heptane and (b) dodecane surfaces for the different times at U0 = 0.2 m/s.

-

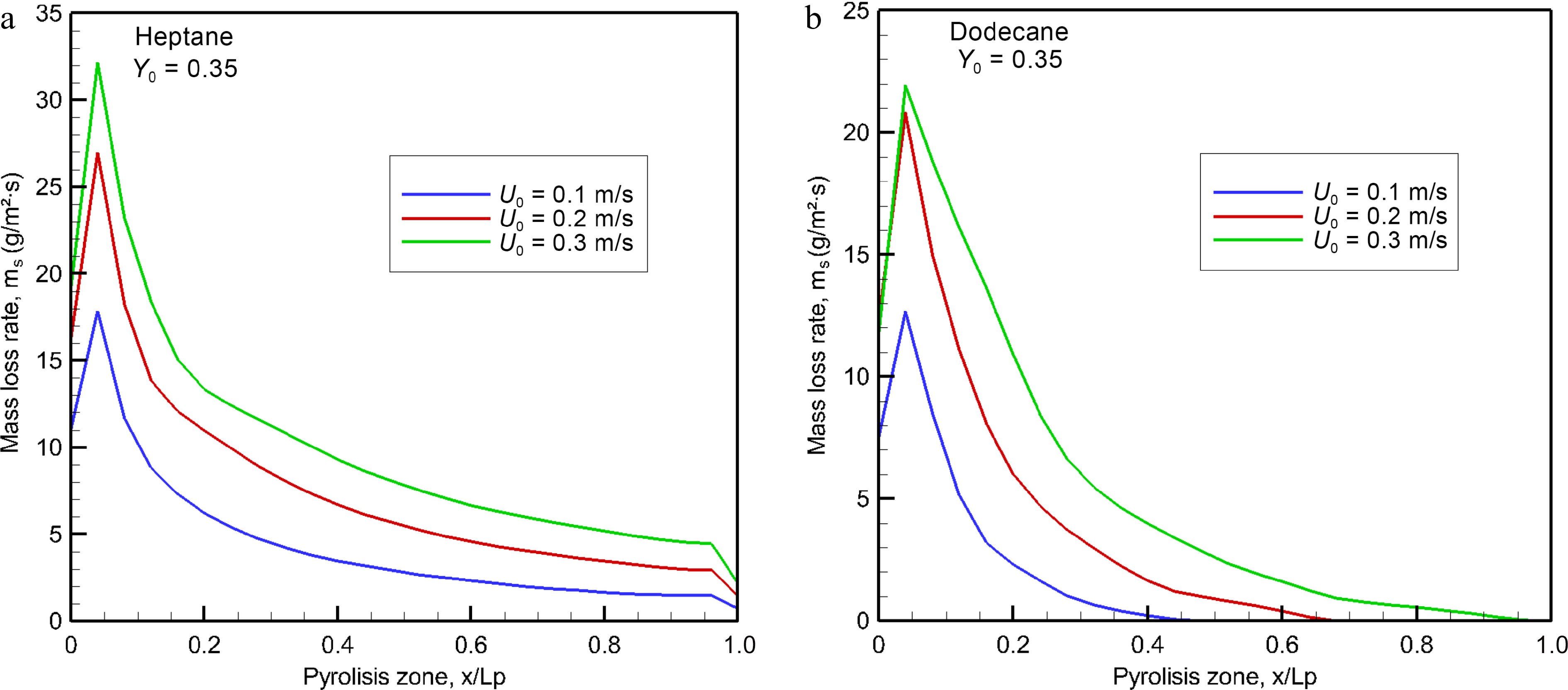

Figure 5.

Computed burning rates of (a) heptane and (b) dodecane at the steady mode as a function of oxidizer flow velocity.

-

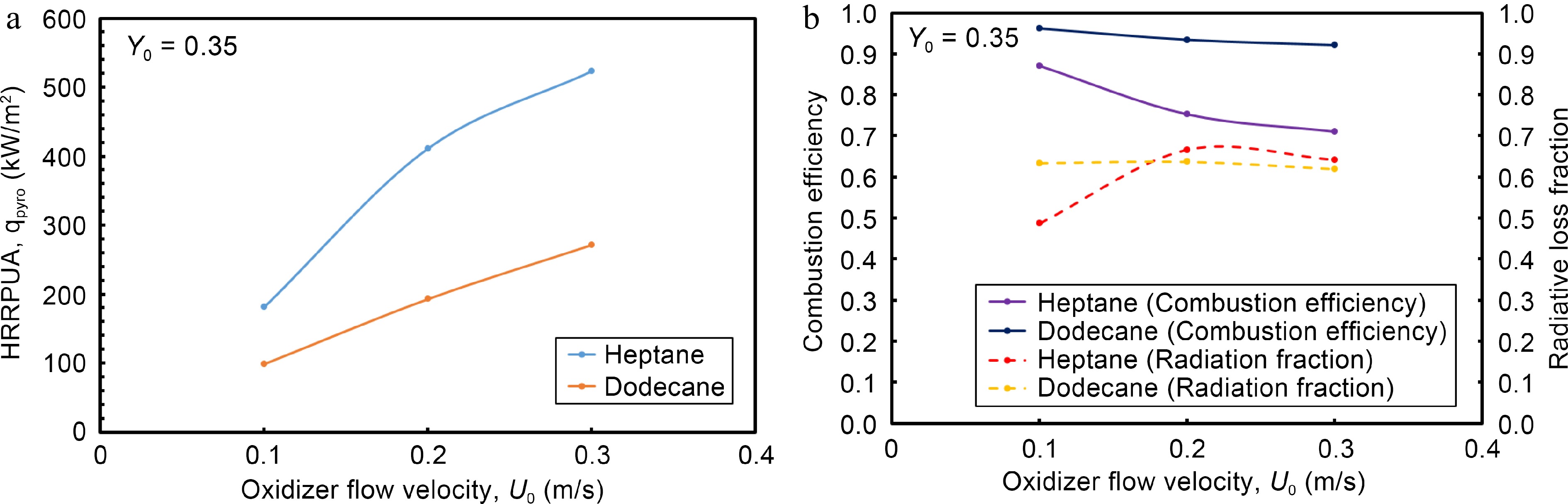

Figure 6.

Impact of oxidizer flow velocity on (a) HRRPUA, (b)combustion efficiency and radiation fraction at the steady mode.

-

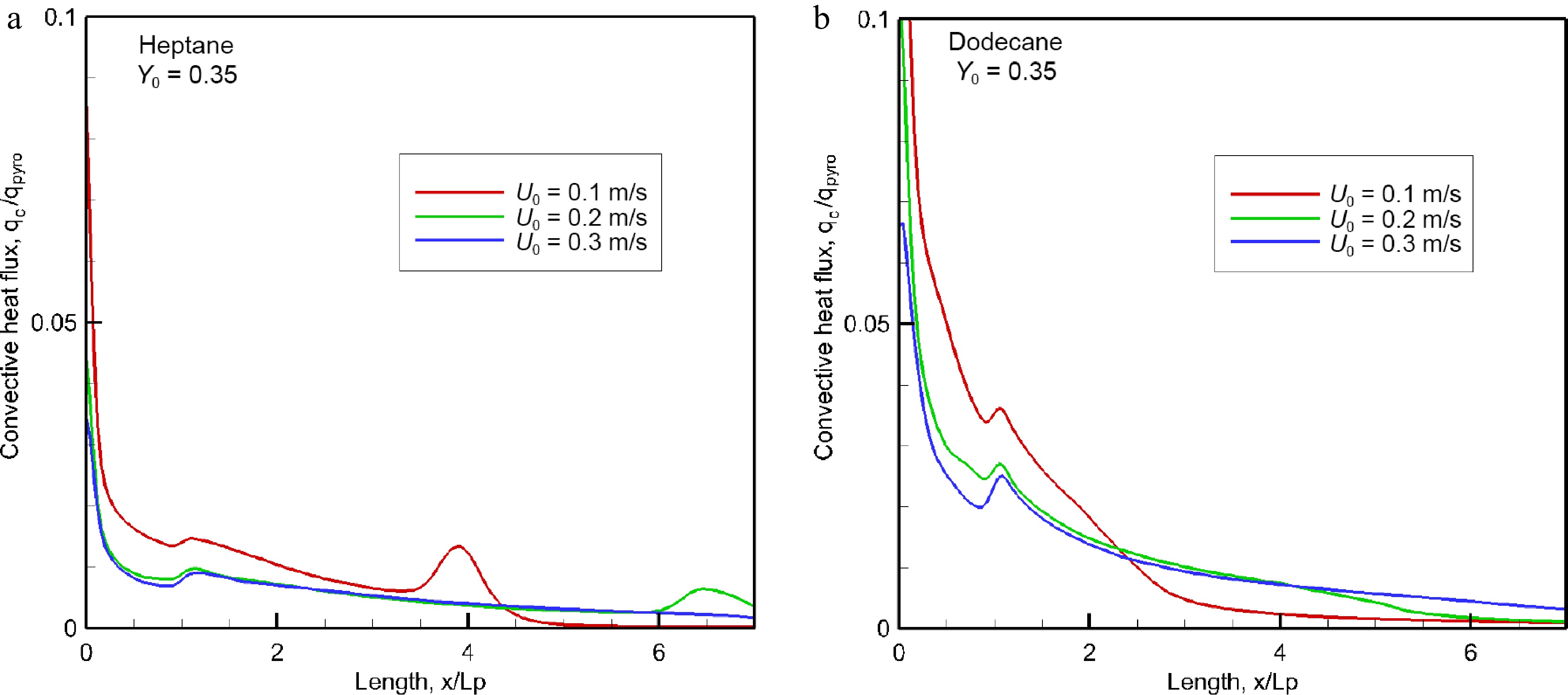

Figure 7.

Evolution of the convective fraction of HRRPUA over pyrolysis surface for different oxidizer flow velocity.

-

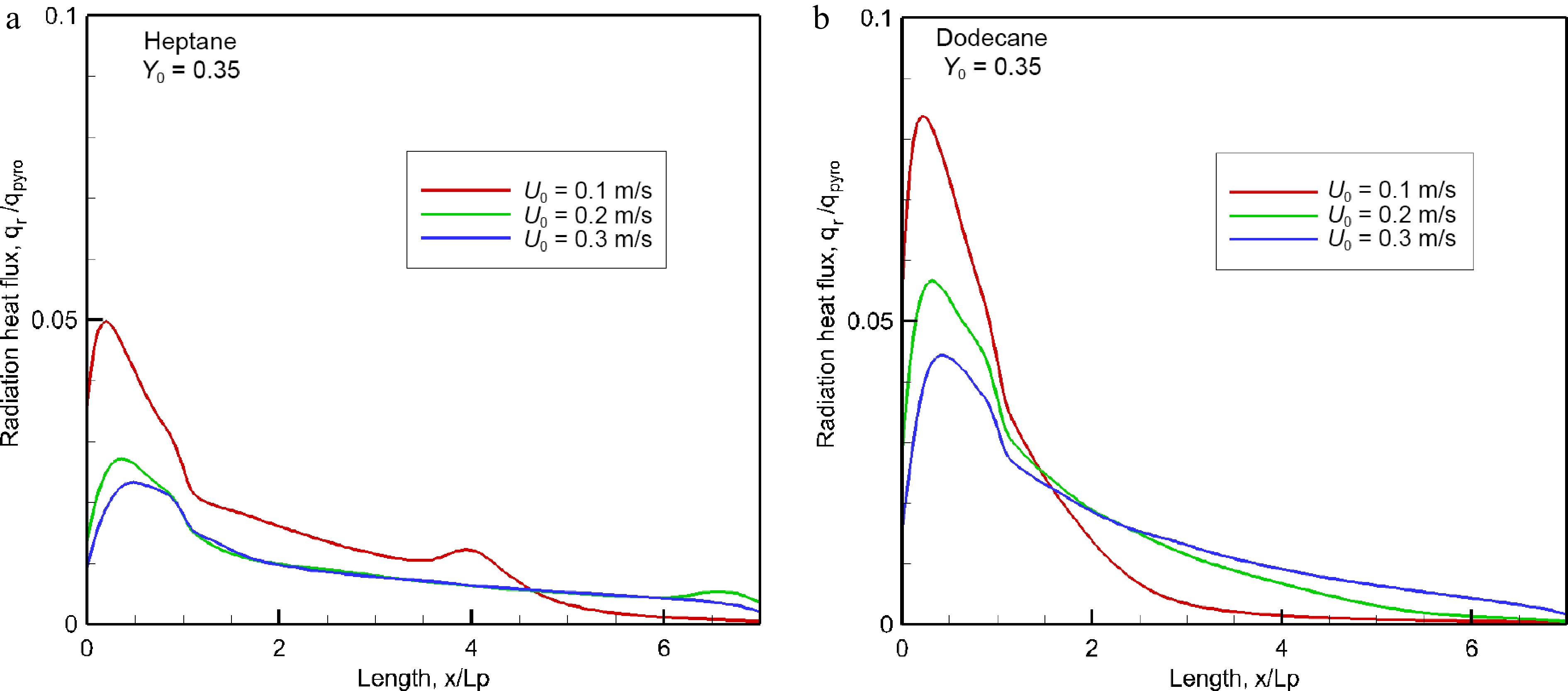

Figure 8.

Impact of oxidizer flow velocity on radiant heat flux over material surface at the steady mode.

-

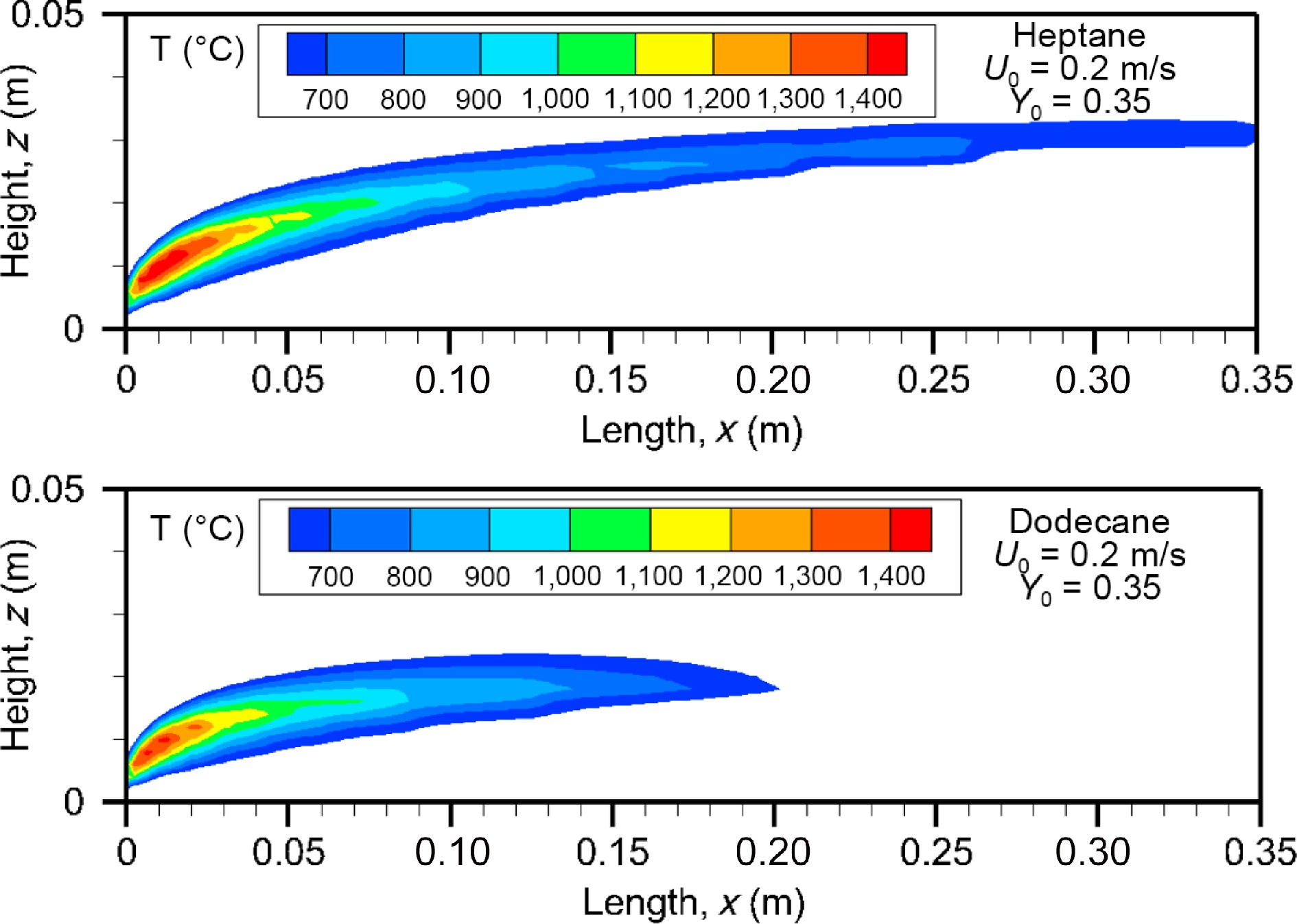

Figure 9.

Computed fields of gas temperature above 600 °C for heptane and dodecane at the steady mode (t = 10 s) at U0 = 0.2 m/s.

-

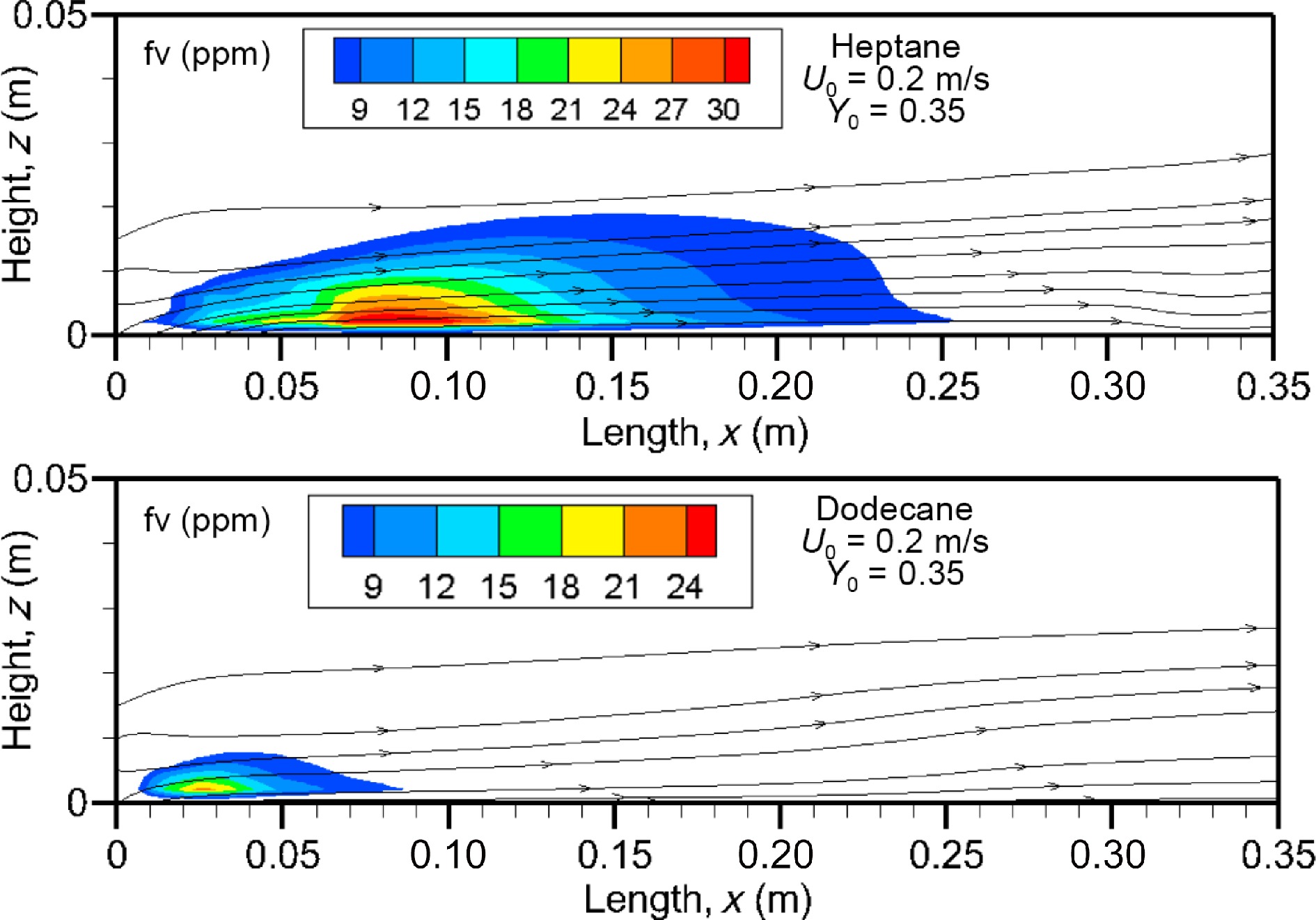

Figure 10.

Computed fields of soot volume fraction above 7 ppm on the axis of symmetry at U0 = 0.2 m/s.

-

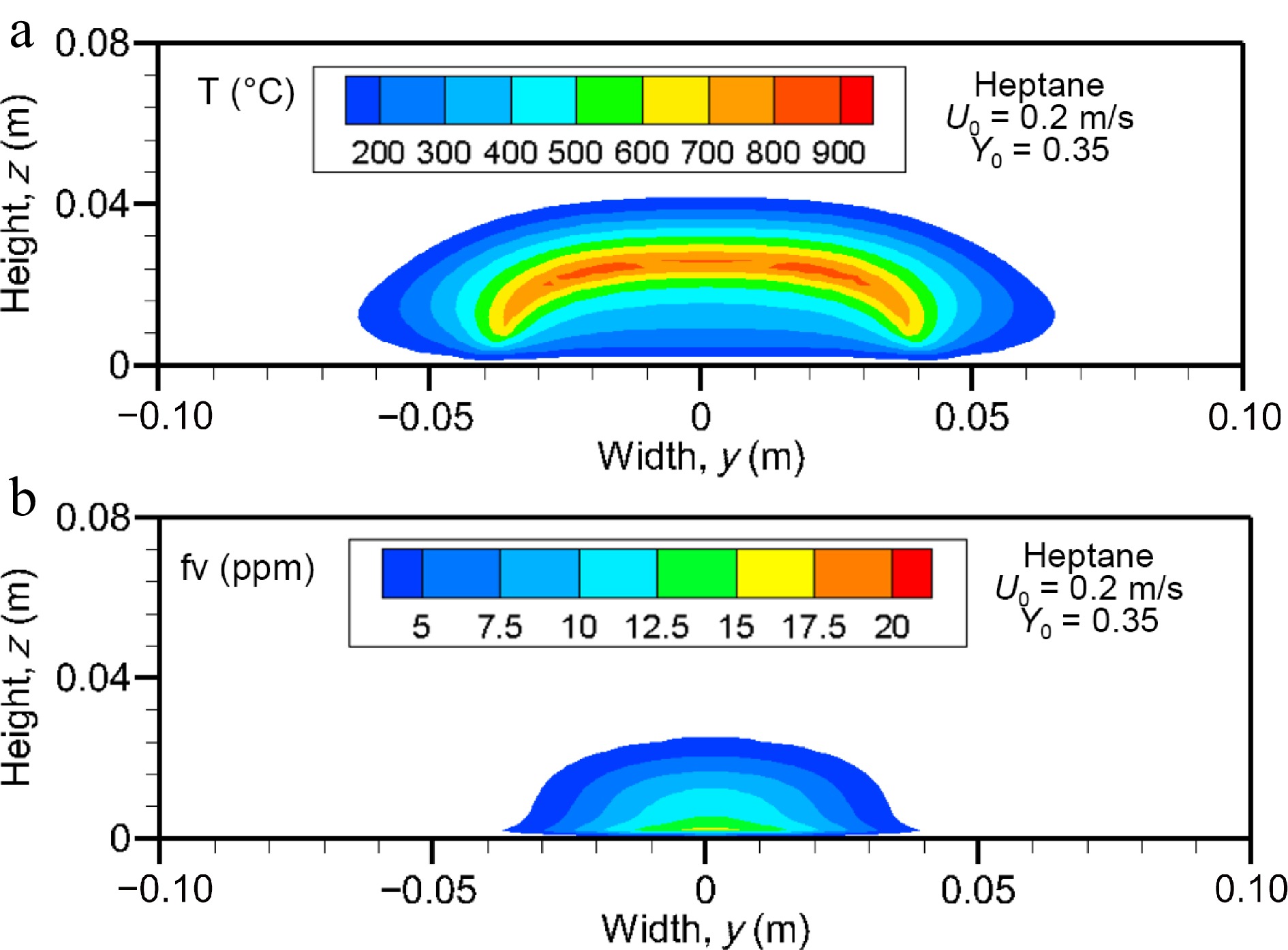

Figure 11.

Computed fields of (a) gas temperature and (b) soot volume fraction (above 2 ppm) on the cross-stream plane for heptane flame at x/Lp = 2 for U0 = 0.2 m/s.

-

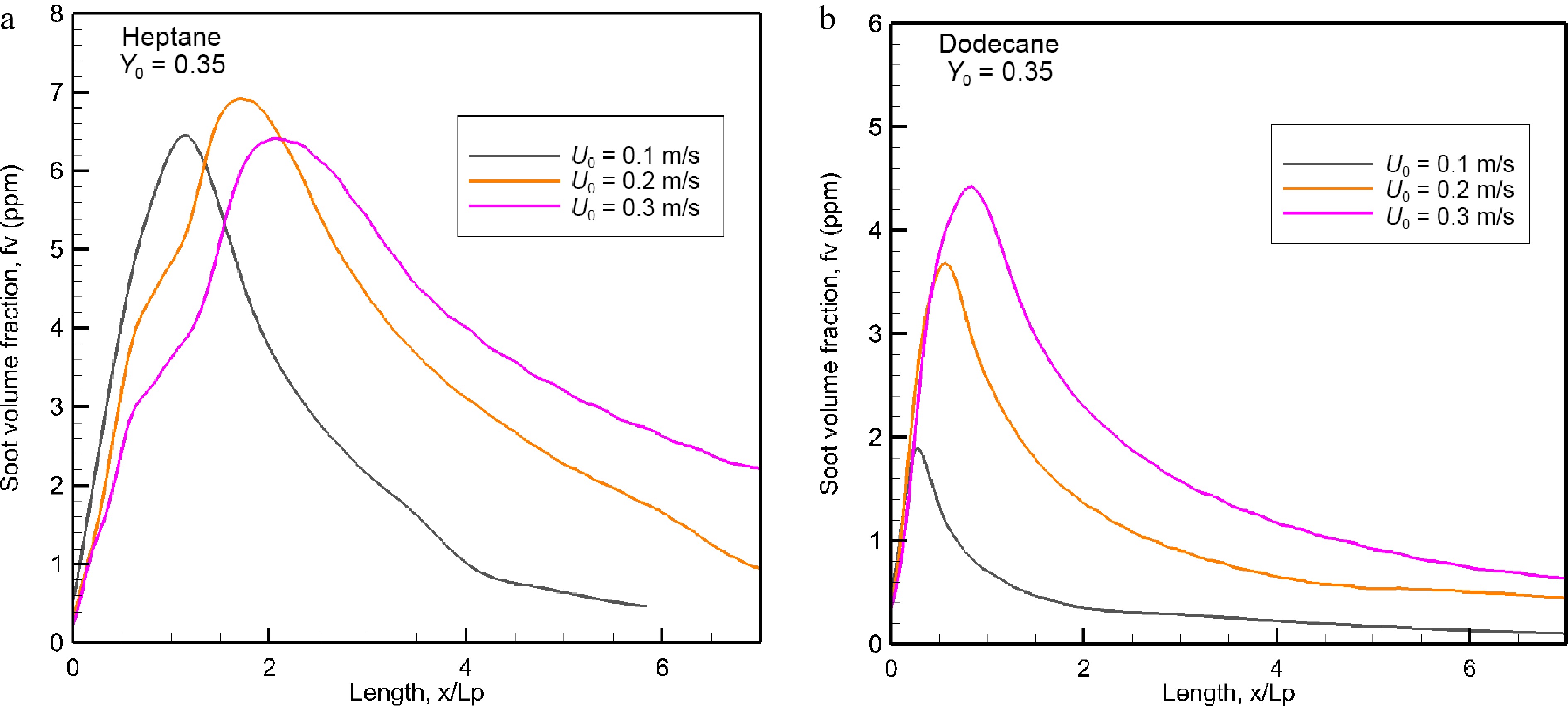

Figure 12.

Evolution of the mean value of soot volume fraction (ppm) in the windward direction as a function of oxidizer flow velocity.

-

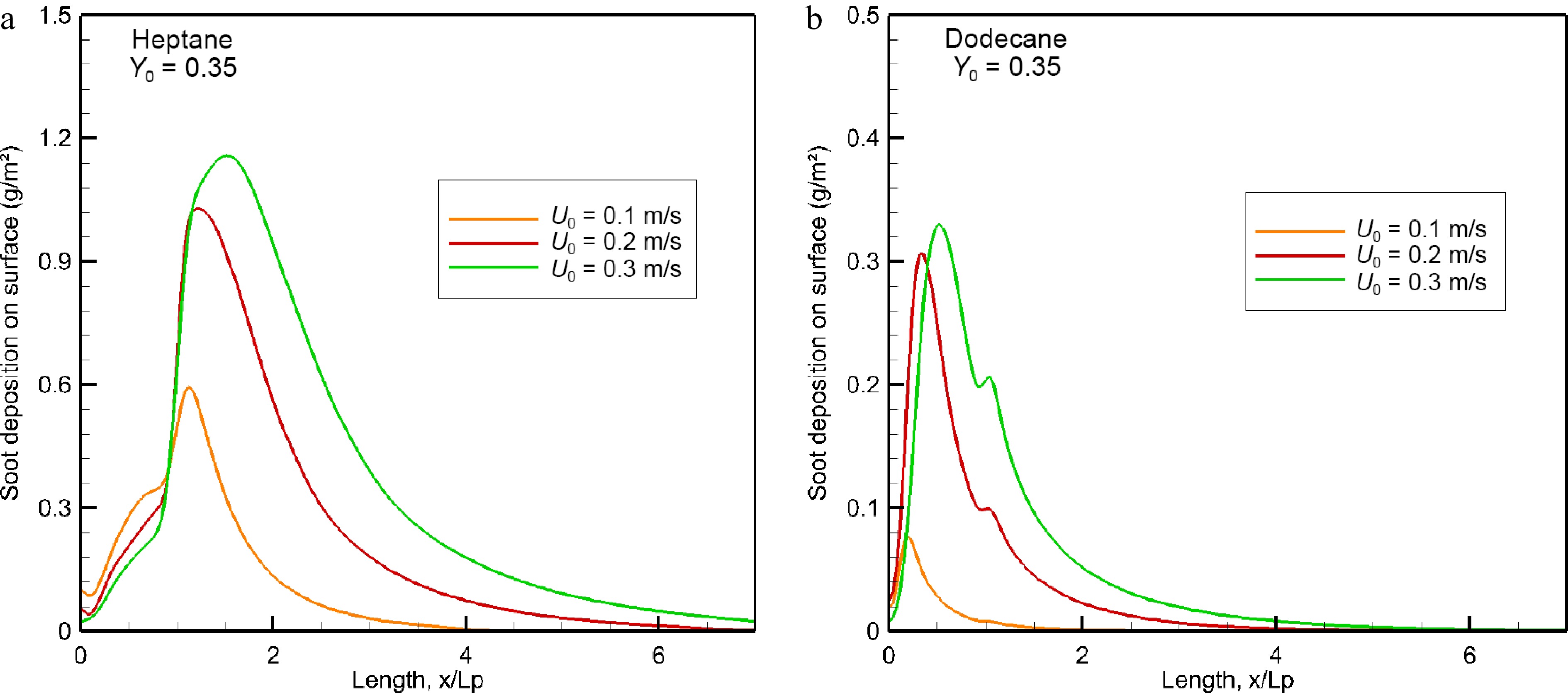

Figure 13.

Impact of oxidizer flow velocity on soot deposition (g/m2) over wall surface in the windward direction.

-

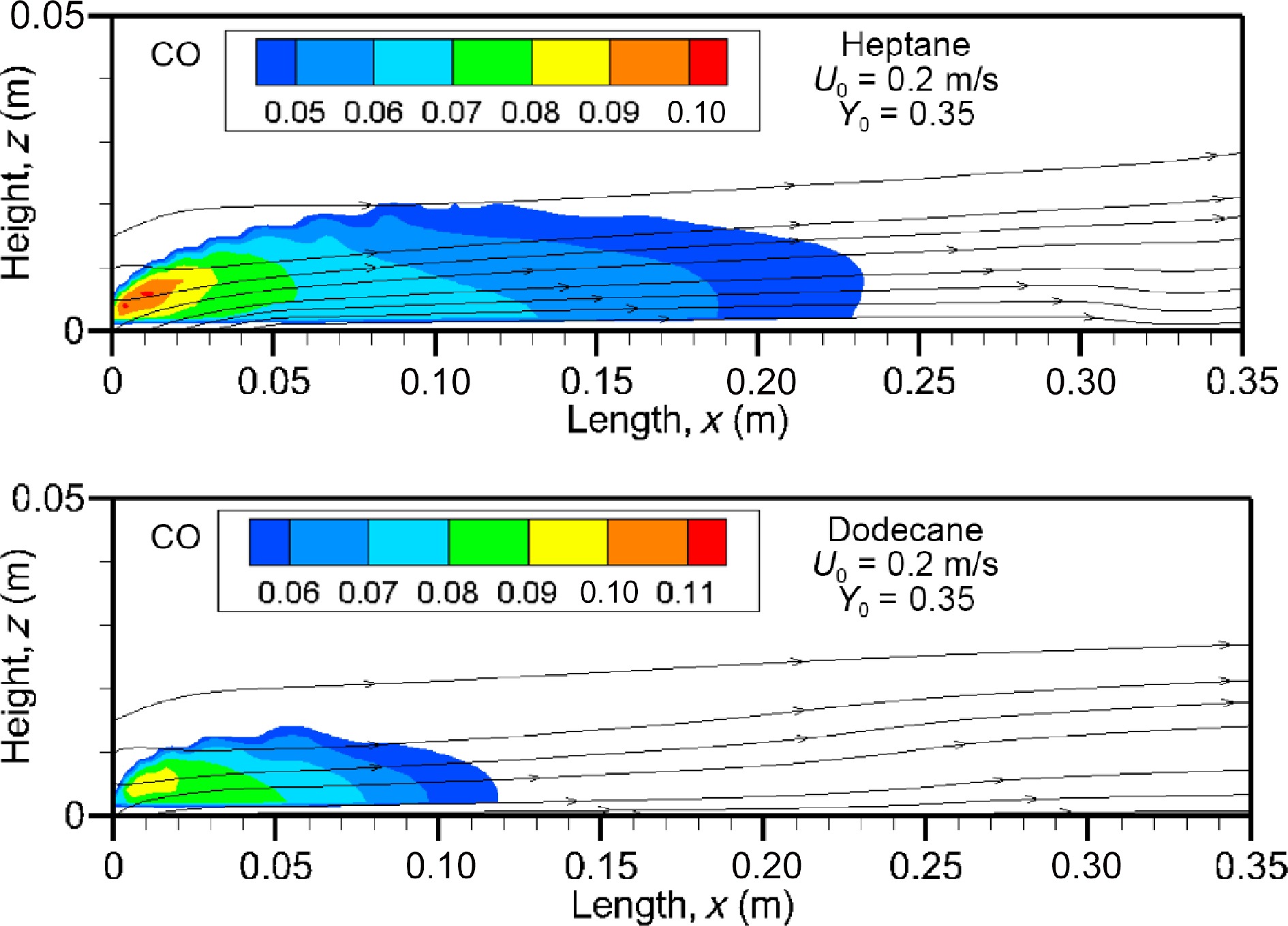

Figure 14.

Computed fields of CO volume fraction for heptane and dodecane flames at U0 = 0.2 m/s.

-

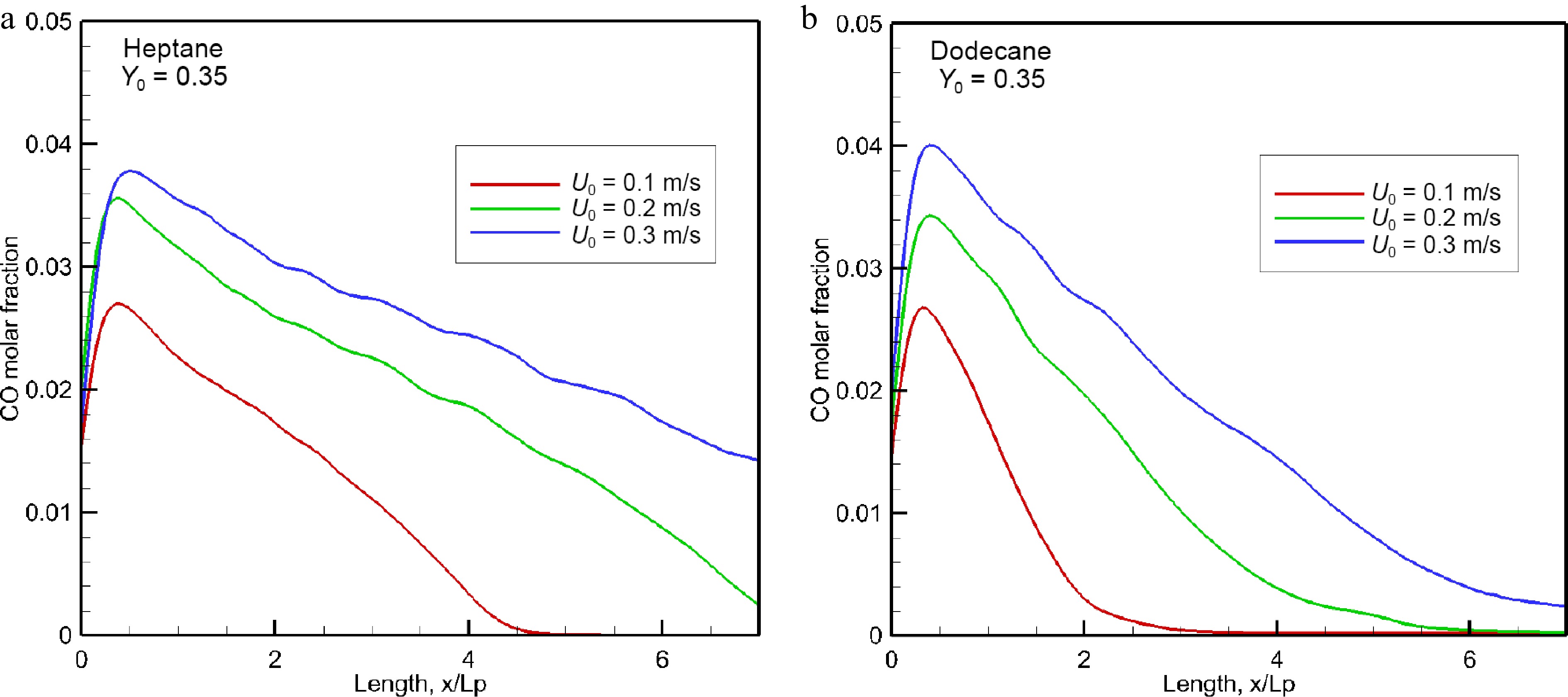

Figure 15.

Influence of oxidizer flow speed on the mean level of CO volume fraction in the forward direction.

-

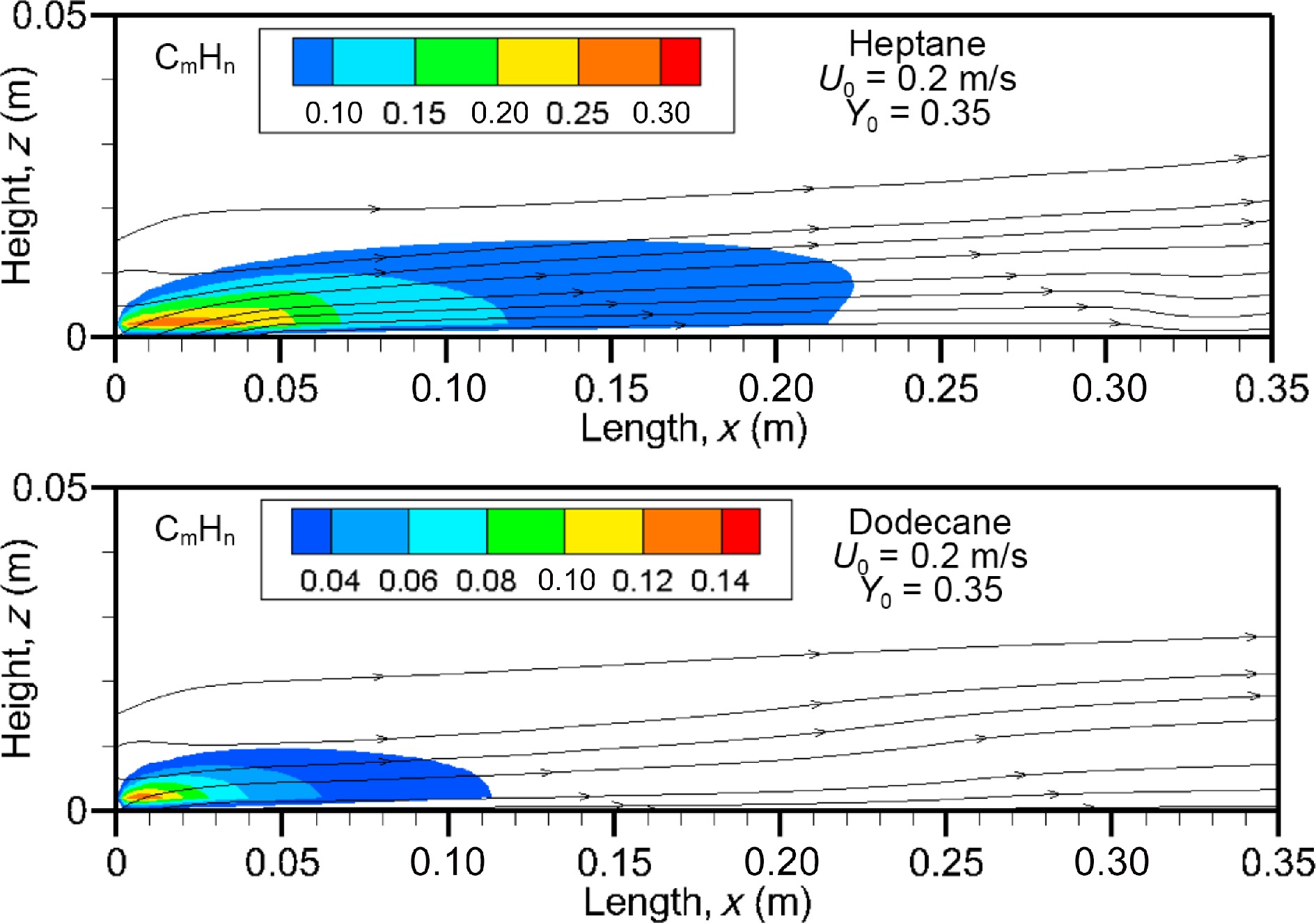

Figure 16.

Unburnt hydrocarbons field calculated at U0 = 0.2 m/s for heptane and dodecane flames.

-

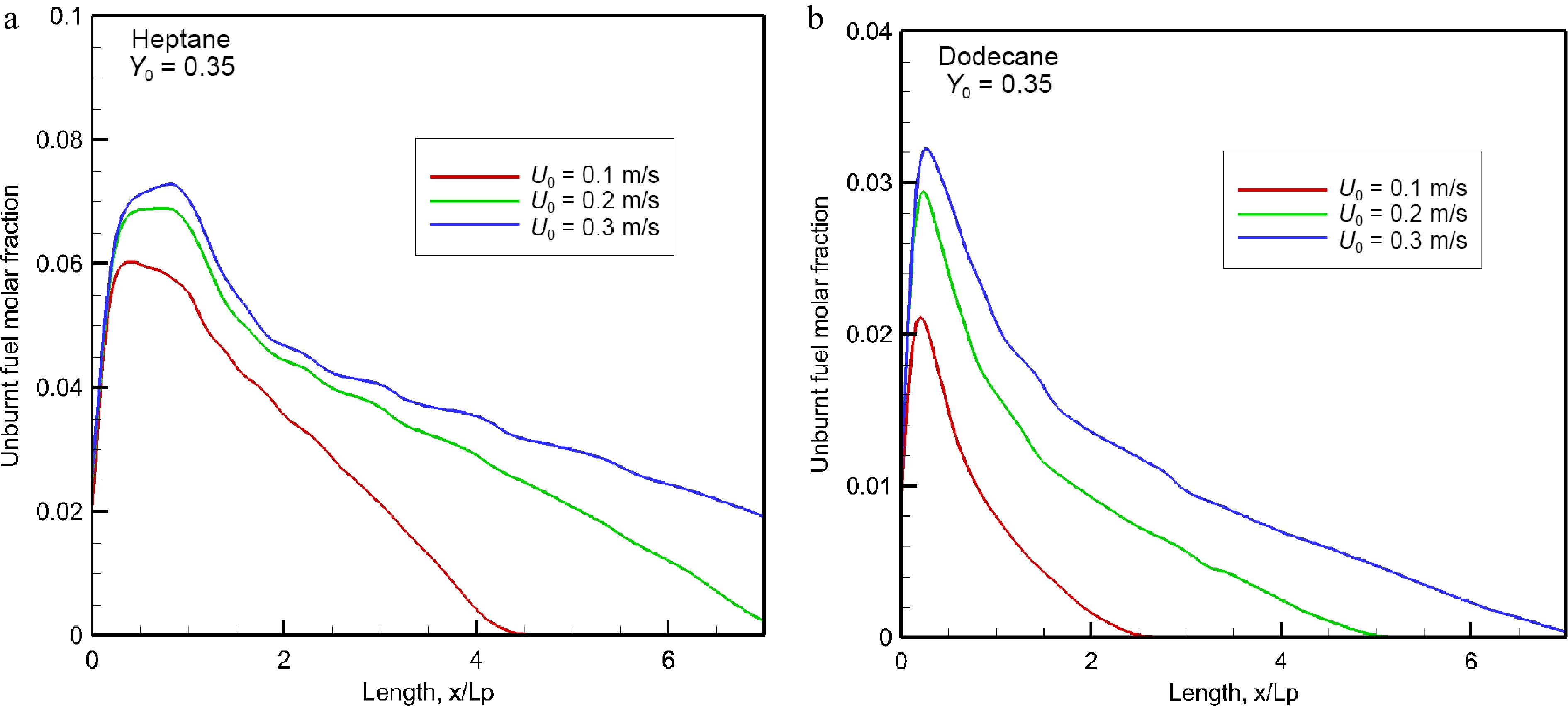

Figure 17.

Impact of oxidizer flow velocity on the mean concentration of unburnt hydrocarbons in the forward direction.

-

Fuel type LSP (m) Af Ethylene (C2H4) 0.106 4.1 × 10−5 Heptane (C7H16) 0.147 2.9 × 10−5 Dodecane (C12H26) 0.137 3.1 × 10−5 Table 1.

Summary of LSP height and pre-exponential factor, Af, for three types of fuel.

-

Property Heptane Dodecane Conductivity k (W/m·K) 0.17 0.14 Density ρ (kg/m3) 684 750 Heat capacity Cp (kJ/kg·K) 2.24 2.21 Pyrolysis heat, Lv (kJ/kg) 321 256 Heat of combustion, ΔHc (kJ/kg) 44500 44147 Boiling temperature Tb (°C) 98 216 Table 2.

Thermo-physical and combustion properties of heptane and dodecane.

Figures

(17)

Tables

(2)