-

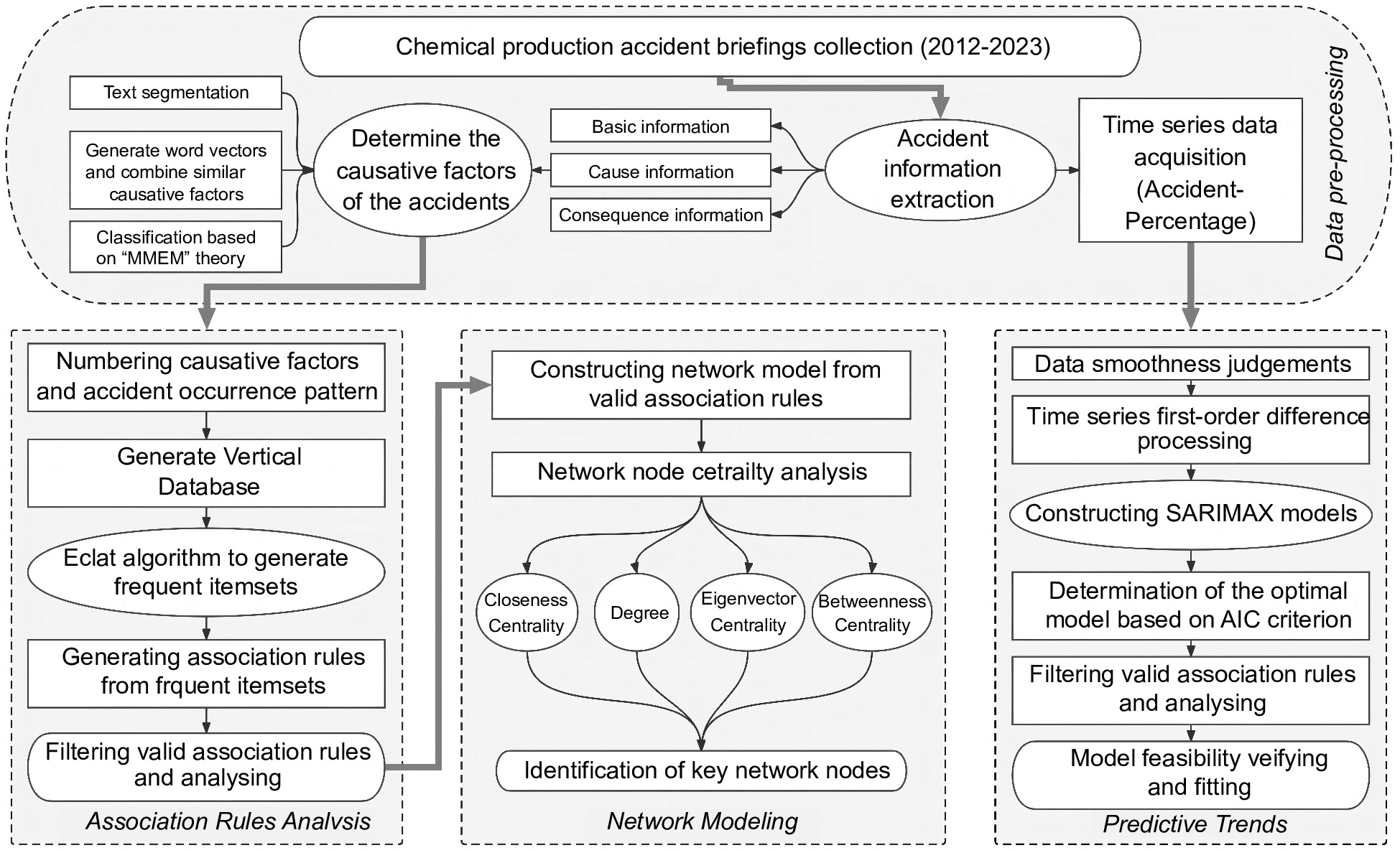

Figure 1.

Process of analyzing chemical production accidents based on data mining.

-

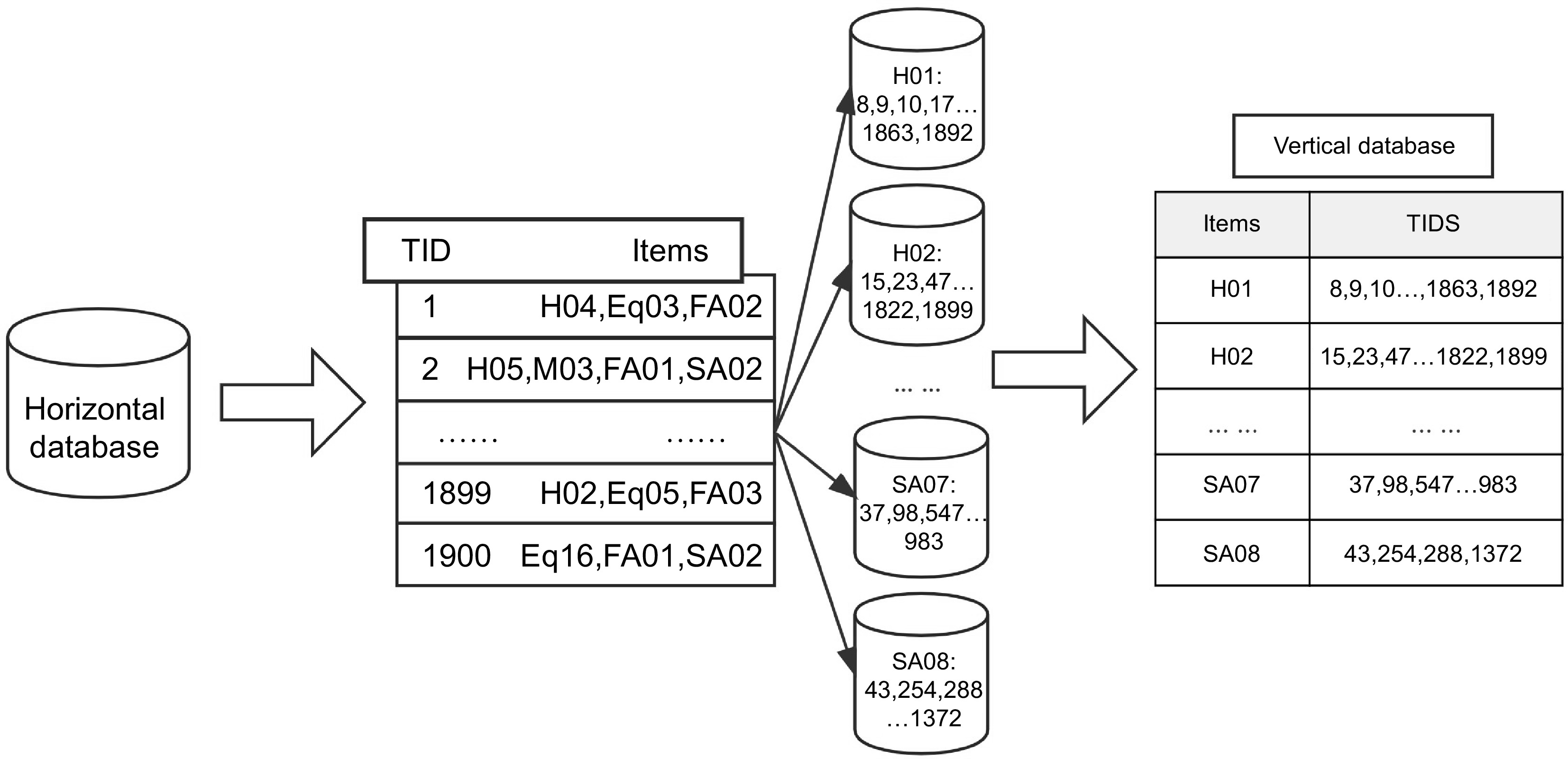

Figure 2.

Example of a vertical database.

-

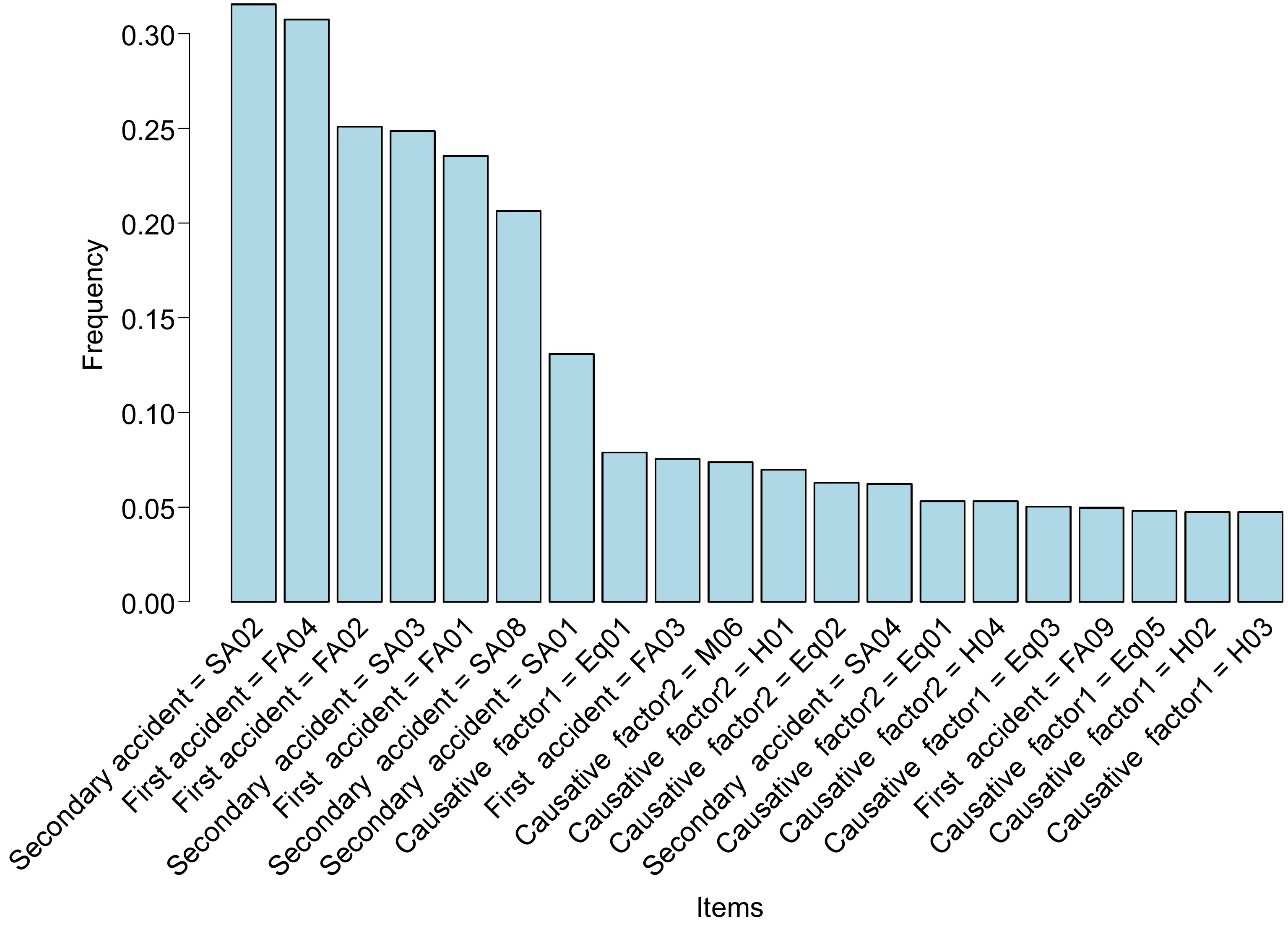

Figure 3.

Histogram of the top 20 frequency ranked items.

-

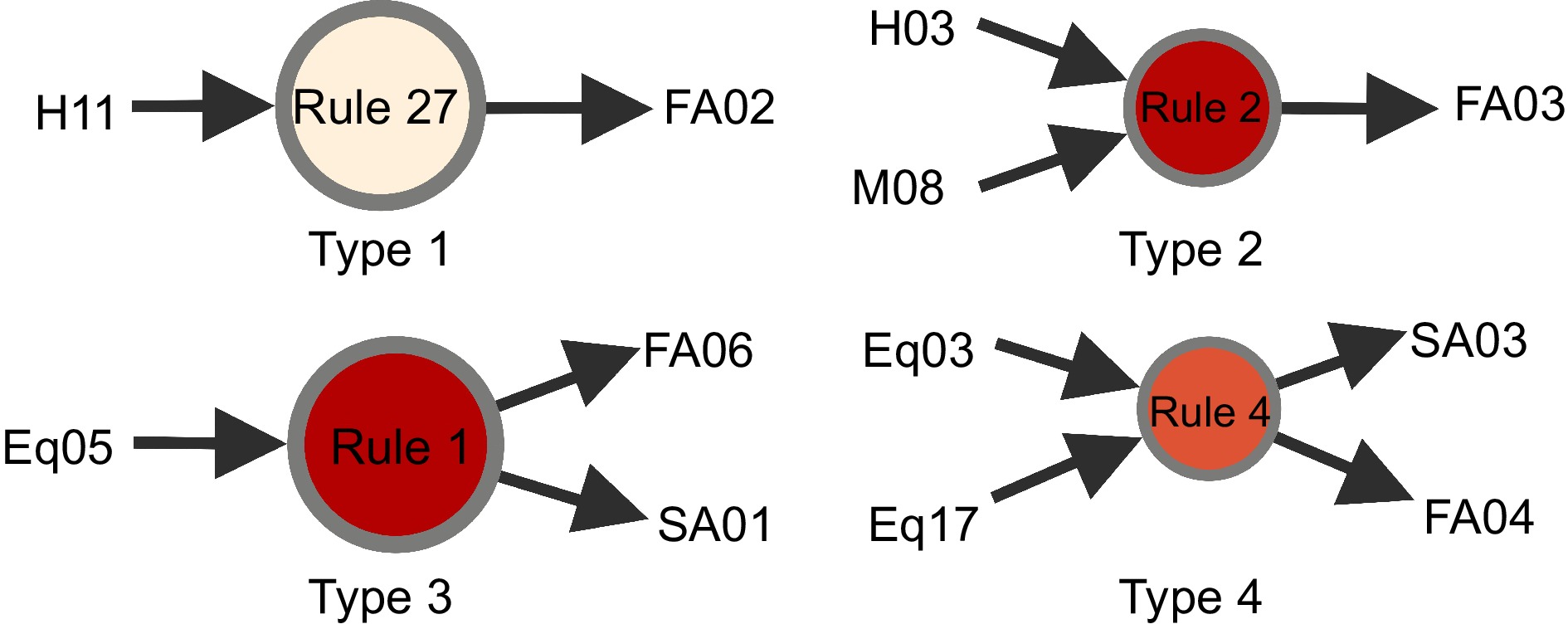

Figure 4.

Examples of different association rule types.

-

Figure 5.

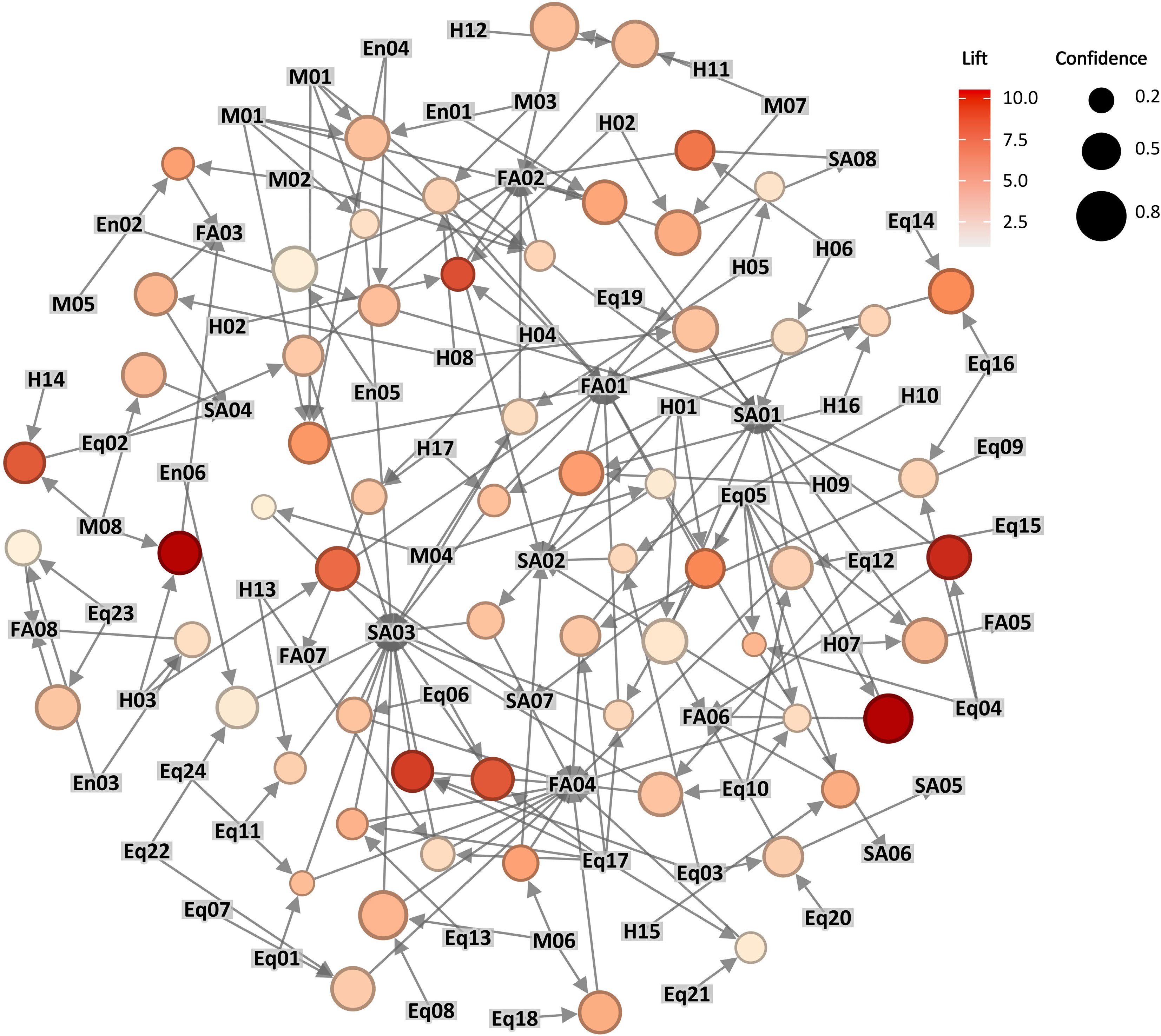

Visualization of valid association rules.

-

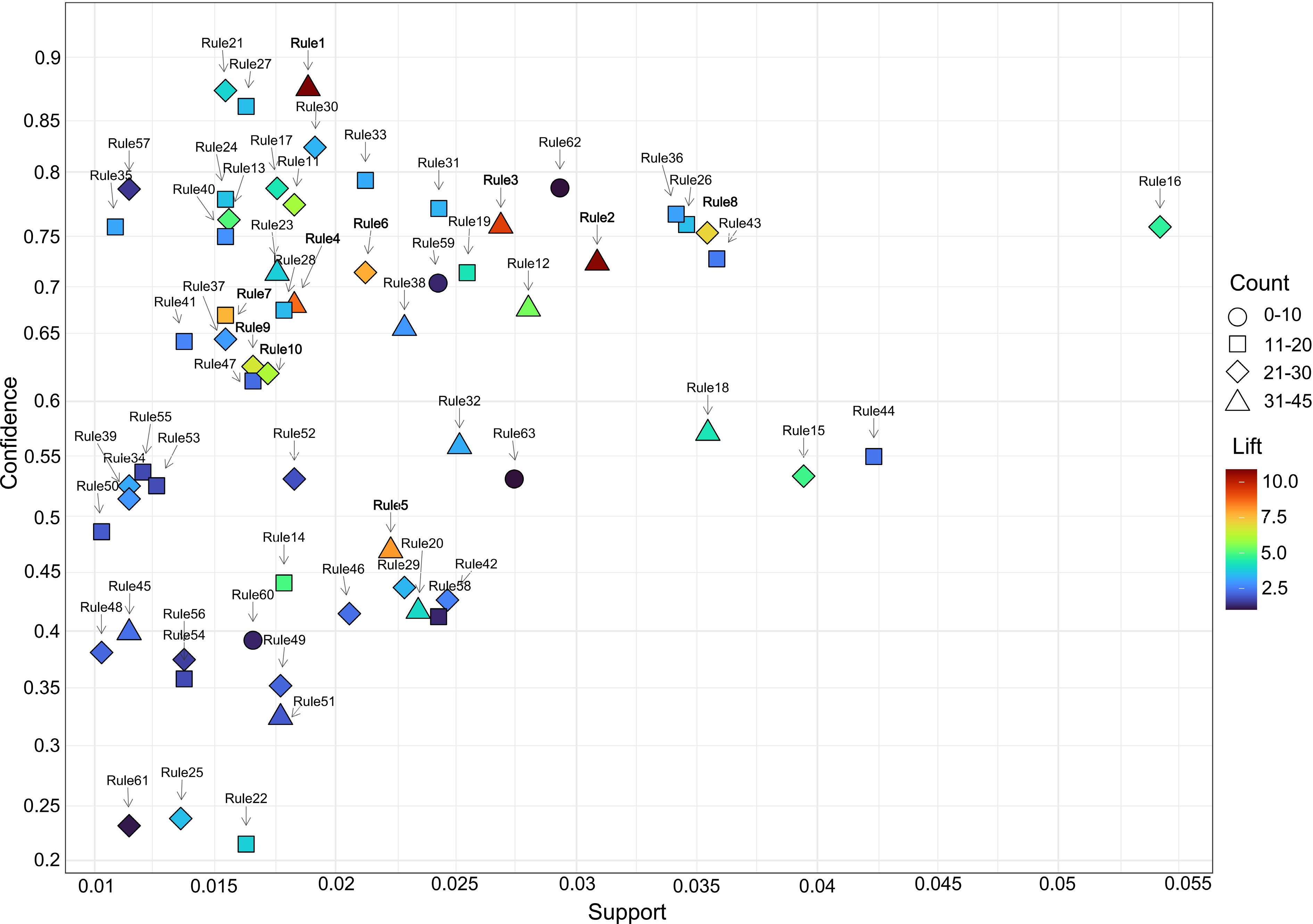

Figure 6.

Scatter plot of the distribution of important values of association rules.

-

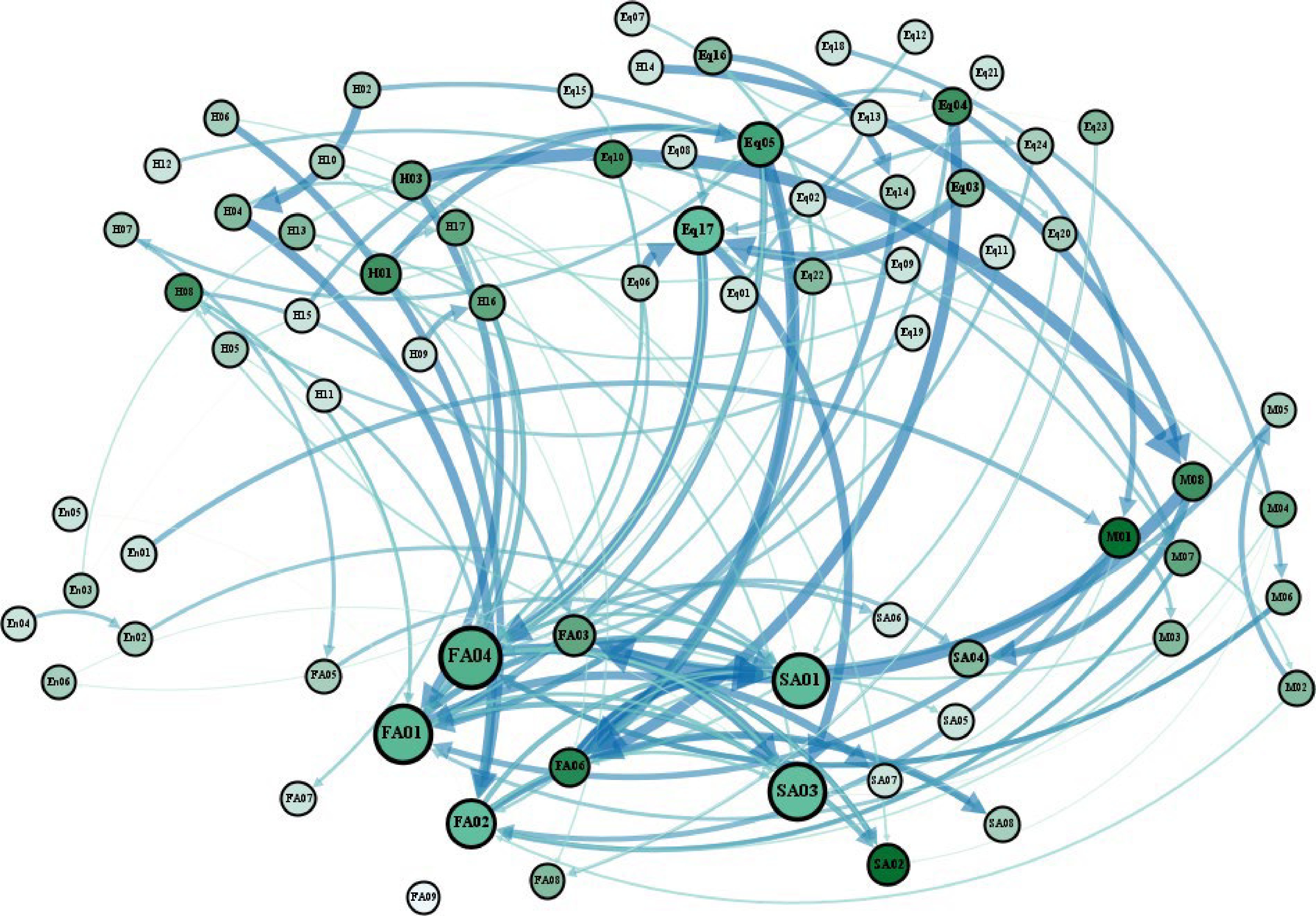

Figure 7.

Network modeling of accident causative factors.

-

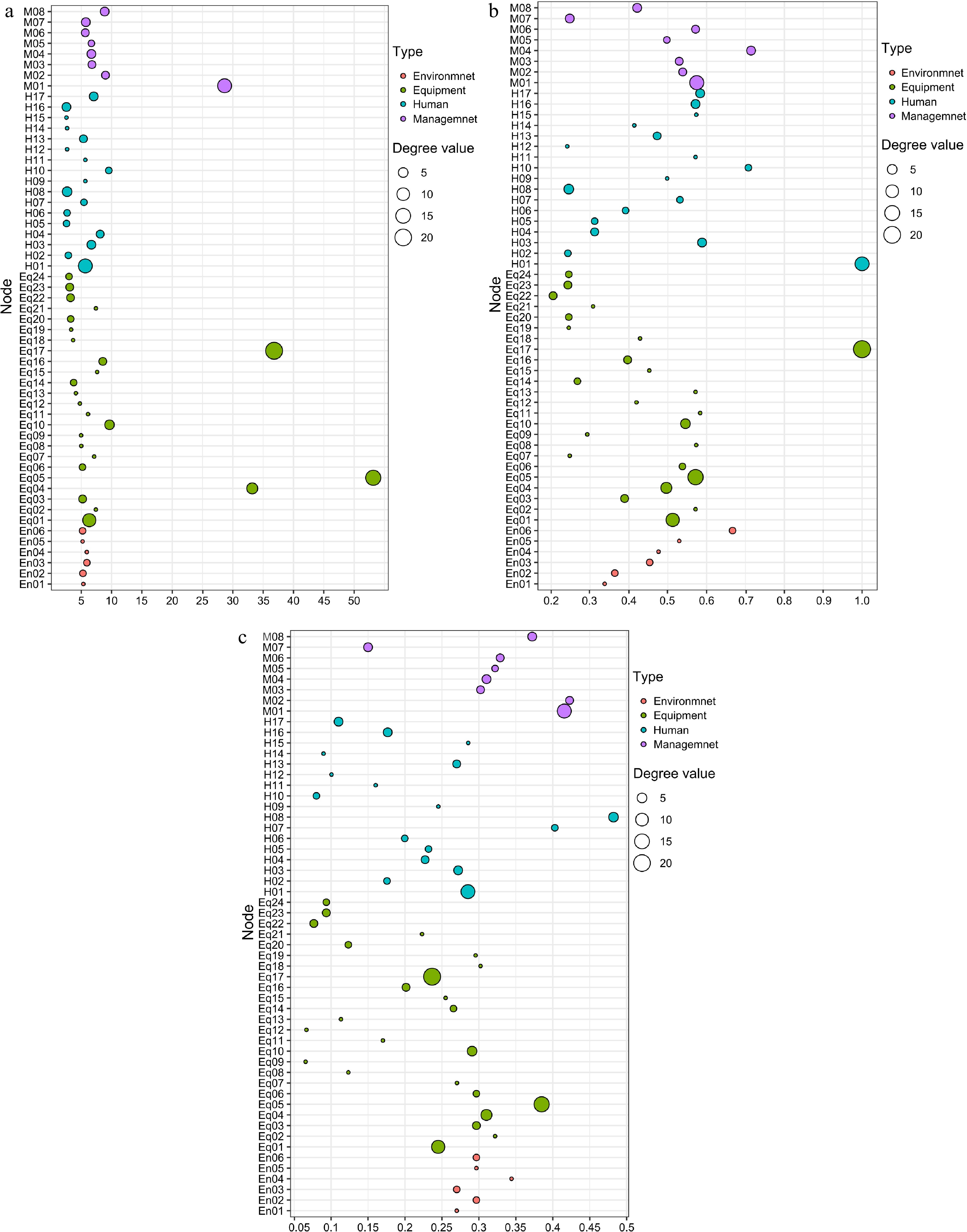

Figure 8.

Distribution of each centrality value of nodes. (a) Betweenness-degree centrality distribution, (b) Closeness-degree centrality distribution, and (c) Eigenvector-degree centrality distribution.

-

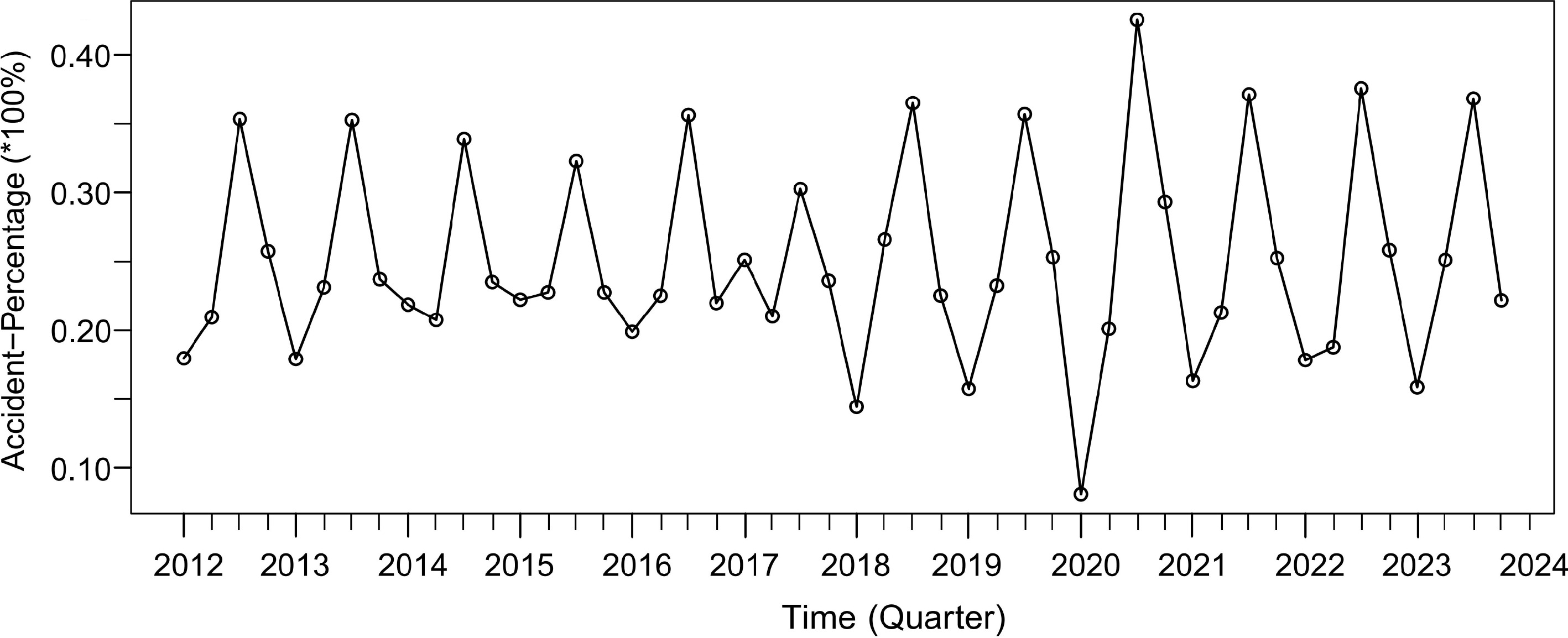

Figure 9.

Trend of Accident-Percentage from 2012 to 2023.

-

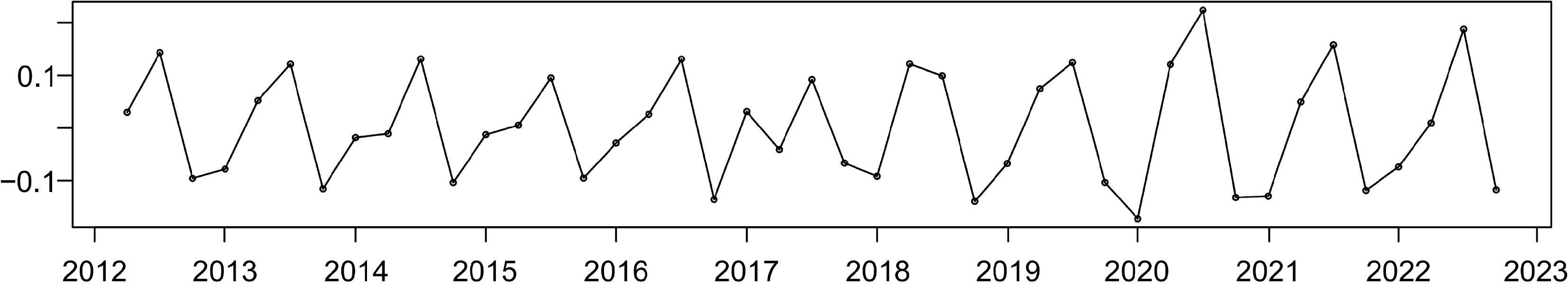

Figure 10.

The trend of the time series data after first-order differencing.

-

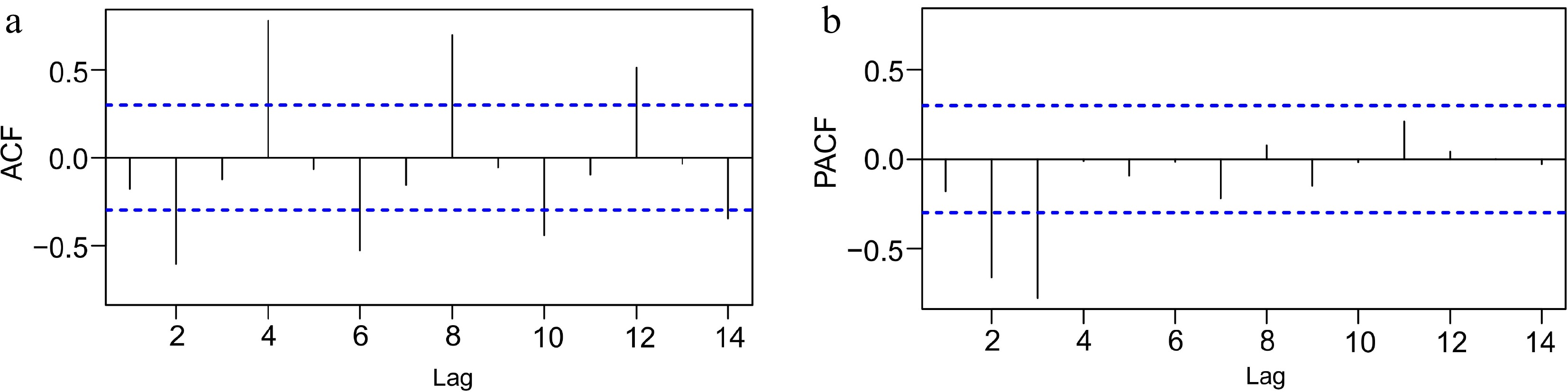

Figure 11.

(a) Auto correlation functions plot. (b) Partial auto correlation functions plot.

-

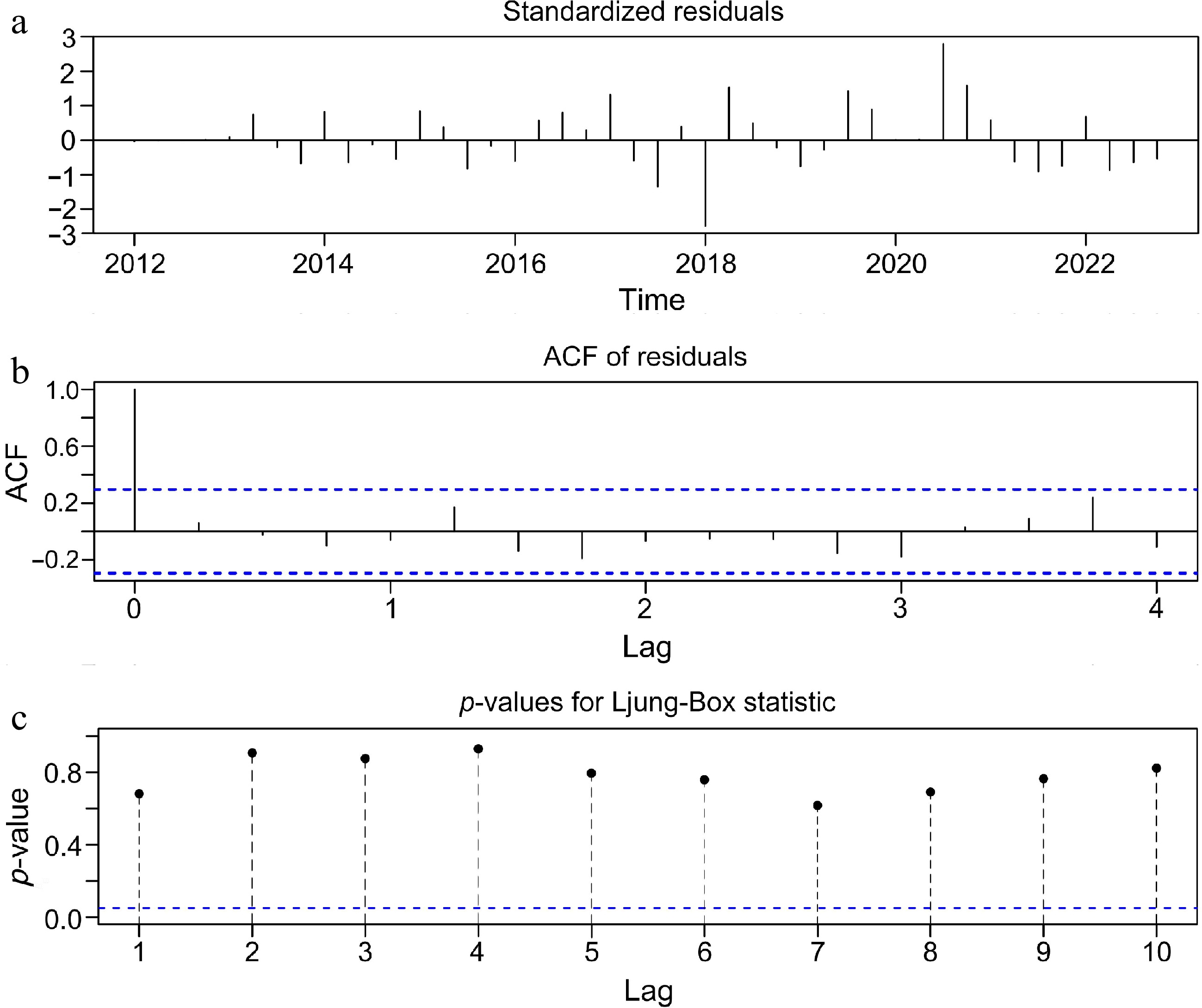

Figure 12.

Correlation plot for model feasibility validation. (a) Standardized residual. (b) ACF of residual. (c) p-value for Ljung-Box Statistic.

-

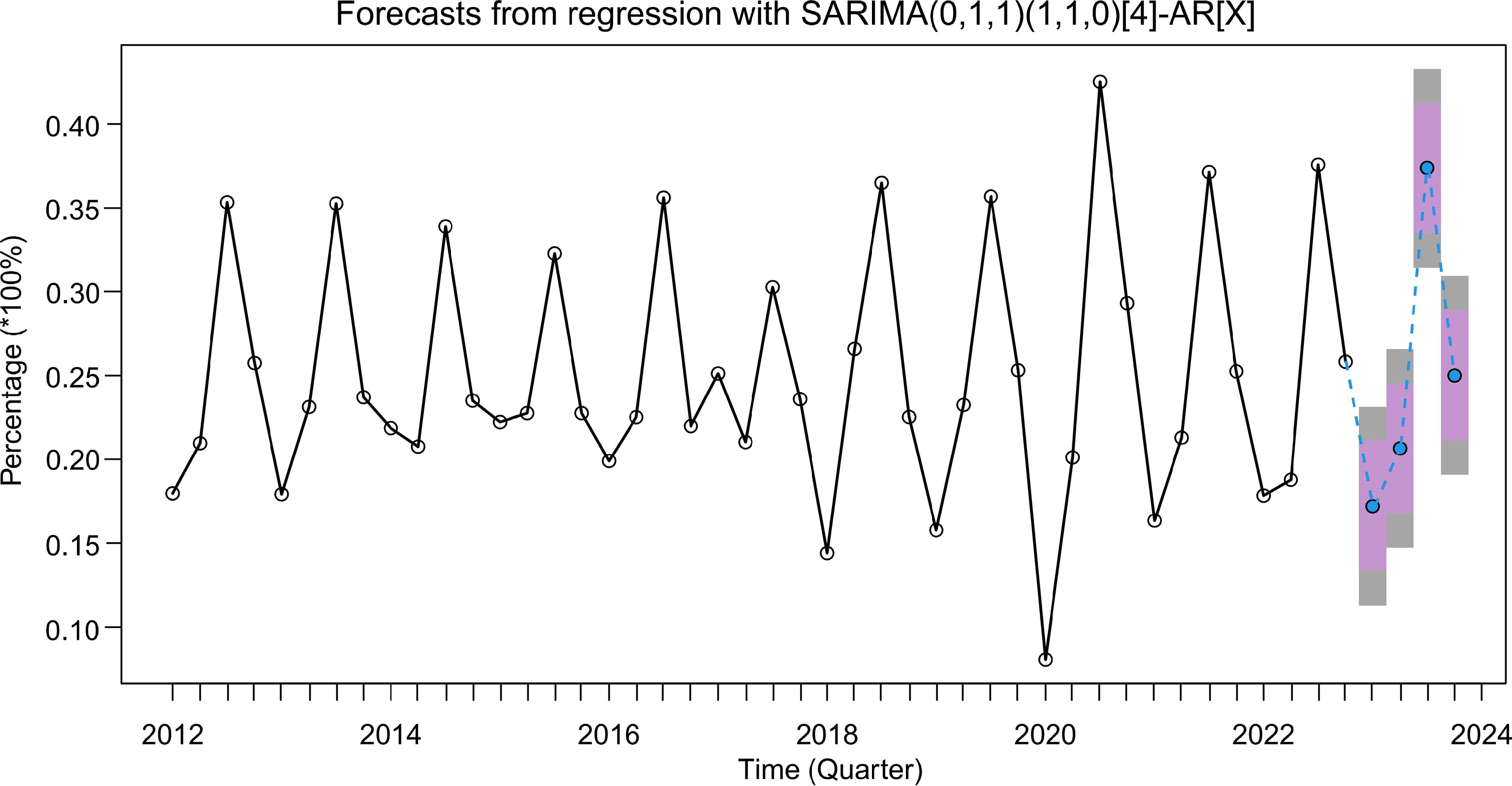

Figure 13.

Trend predition with historical Accident-Percentage data.

-

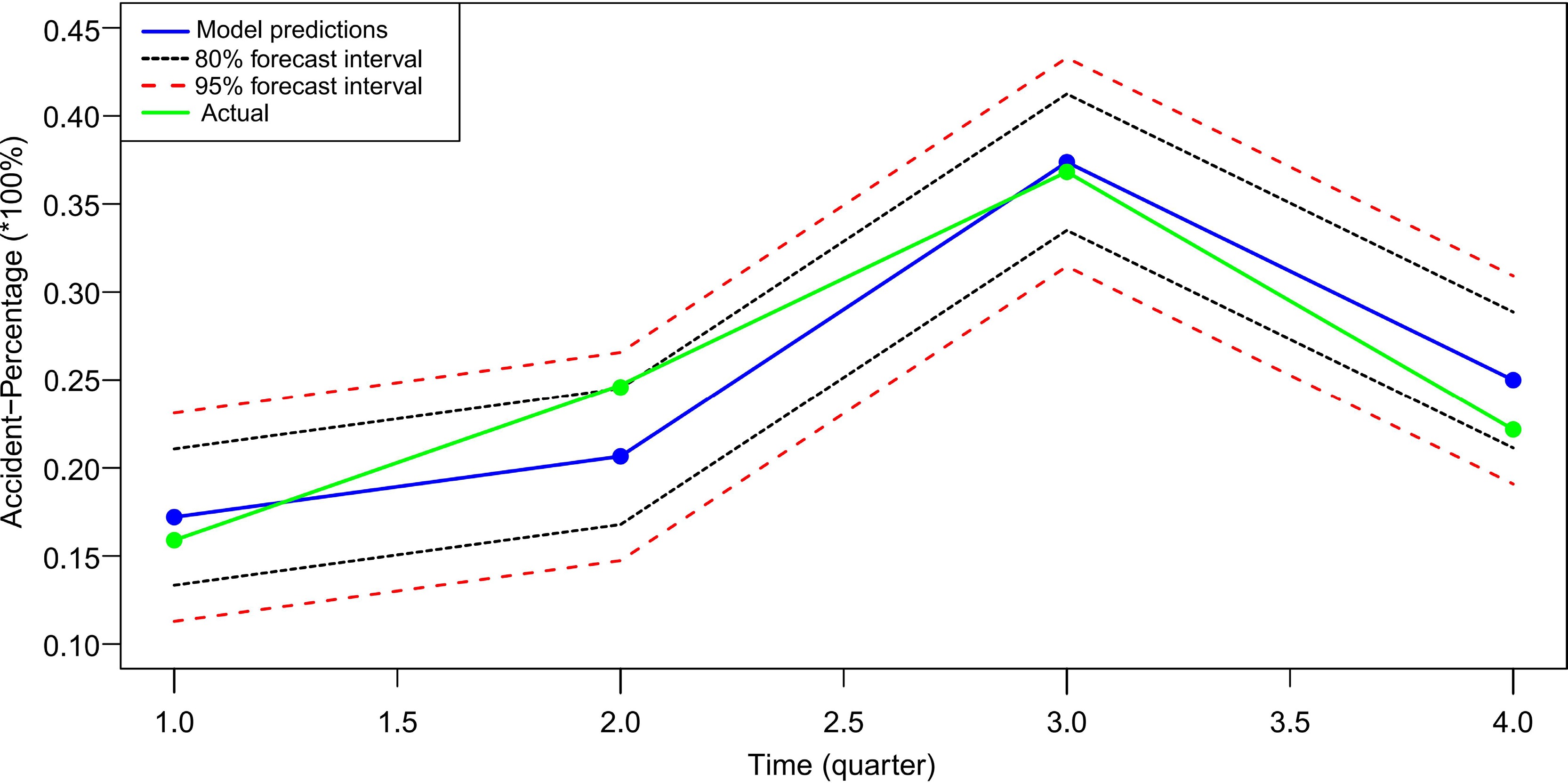

Figure 14.

Comparison of the model predicition values with the actual values in the year 2023.

-

Category Information extraction content Basic information Times: years, months, season, time period. Corporations: nature of enterprise, industry, province. Addressees involved: operational phase, fixtures, type of hazardous chemical. Cause information Accident patterns: first accident, secondary accident. Causative factor layer: man, machine, environment, management. Consequence information Accident casualties: number of deaths, number of injuries. Classification of severity: fatal, injury, harmless. Table 1.

Category of accident information extraction.

-

Layers Causative factors Human Improper or faulty operation (H01) Illegal changes in production processes or procedures (H10) Unauthorized welding operation (H02) Smoking violation (H11) Work without safety equipment (H03) Human-caused fires (H12) Violation of safety operating regulations (H04) Human-caused damage to equipment or piping (H13) Unauthorized use of equipment or raw materials that pose a safety hazard (H05) Failure to close valves promptly after operation (H14) Failure to carry out fire separation or clearance of flammable material prior to operation (H06) Unauthorized absence (H15) Incorrect or excessive addition of reaction materials (H07) Command error (H16) Failure to conduct safety tests prior to operating in a limited space (H08) Lack of specialized skills (H17) Operating equipment without appropriate qualifications (H09) Machine Equipment or system failure (Eq01) Equipment ageing leakage (Eq13) Circuit short or power supply system failure (Eq02) Equipment not equipped with electrostatic discharge device (Eq14) Pipe rupture (Eq03) Valve failure (Eq15) Problems with process or technology (Eq04) Heat or static electricity from mechanical friction (Eq16) Reaction kettle over-temperature or over-

pressure (Eq05)Material strength defects (Eq17) Tank rupture leak (Eq06) Clogged pipes (Eq18) Seal failure or ineffective sealing (Eq07) Failure of ventilation equipment (Eq19) Valve internal leakage (Eq08) Pump body failure (Eq20) Broken or disconnected pipe connections (Eq09) Boiler rupture (Eq21) Safety defects in equipment or failure of safety interlocking devices (Eq10) Flange leakage (Eq22) Loose or dislodged valve (Eq11) Collapse of support frame (Eq23) Seal dislodged or corroded (Eq12) Safety valve trip (Eq24) Environment High temperature exposure (En01) Ambient moisture corrodes equipment or reacts with substances (En04) Rainstorm (En02) Lightning fire (En05) Gale (En03) Cold temperatures (En06) Management Failure to rationalize storage according to the nature of the chemical (M01) Illegal handling of reaction gases or wastes (M05) Illegal business (M02) Failure to regularly service equipment (M06) Ventilation not switched on due to chaotic management (M03) Deficiencies in fire management (M07) Deficiencies in security management (M04) Insufficient training in emergency response capacity (M08) First

AccidentExplosion (FA01) Over-pressure (FA06) Fire (FA02) Object strikes (FA07) Poisoning (FA03) Fall from height (FA08) Leakage (FA04) Other (FA09) Over-temperature (FA05) Secondary Accident Explosion (SA01) Leakage (SA05) Fire (SA02) Object strikes (SA06) Poisoning (SA03) Fall from height (SA07) Blindly Rescue (SA04) No secondary accidents (SA08) Table 2.

Causative factors and patterns of chemical production accidents.

-

Algorithms No. of rules generated No. of valid

rules (lift > 1)Time

(t/s)Apriori 167 49 87 Eclat 96 63 62 Table 3.

Comparison of two algorithms.

-

Lhs Rhs Support Confidence Lift Count 1 {Eq05} => {FA06, SA01} 0.018857 0.872609 10.594386 39 2 {H03, M08} => {FA03} 0.030857 0.720602 10.445452 45 3 {Eq04} => {FA06, SA01} 0.026857 0.752778 9.130587 35 4 {Eq03, Eq17} => {FA04, SA03} 0.018286 0.683636 8.462905 41 5 {H02, H04} => {FA02} 0.022286 0.469881 7.873096 34 6 {Eq06, Eq17} => {SA03} 0.021238 0.712457 7.567132 25 7 {H14, M08} => {SA04} 0.015429 0.675116 7.467463 18 8 {H03} => {FA01, SA07} 0.035429 0.746988 6.903249 21 9 {H06} => {FA02, SA08} 0.016571 0.630435 6.513123 29 10 {H01, Eq05} => {FA01, SA01} 0.016571 0.627705 5.947571 25 11 {Eq16, Eq14} => {FA01} 0.018286 0.771429 5.811594 26 12 {En04, M01} => {FA01} 0.028001 0.680556 5.299092 31 13 {H09, H16} => {FA01, SA02} 0.015571 0.758333 4.946804 22 14 {M02, M05} => {FA03} 0.017857 0.441861 4.857999 19 15 {M06} => {FA04, SA02} 0.039429 0.534884 4.739863 22 16 {En01, M01} => {FA02, SA01} 0.054223 0.752121 4.562423 24 17 {H02, M07} => {FA02, SA08} 0.017571 0.785714 4.232118 18 18 {H15, Eq05} => {FA06} 0.035452 0.572254 4.225193 31 19 {Eq18, M06} => {FA04} 0.025461 0.712252 4.195752 19 20 {Eq13, Eq17} => {FA04, SA03} 0.023429 0.417101 3.941898 41 21 {Eq08, Eq17} => {FA04, SA02} 0.015429 0.870968 3.833074 21 22 {Eq05, Eq04} => {FA01, SA06} 0.016286 0.214286 3.746835 18 23 {H08} => {FA03, SA04} 0.017571 0.711628 3.722009 34 24 {Eq05, H07} => {FA05, SA01} 0.015429 0.776191 3.509662 18 25 {Eq01, Eq24} => {FA04, SA03} 0.013571 0.236559 3.446755 22 26 {M08} => {SA04} 0.034569 0.754203 3.434612 19 27 {H11} => {FA02} 0.016286 0.857143 3.416856 14 28 {En04, En02} => {SA01} 0.017857 0.679570 3.387493 14 29 {H01, H17} => {FA01, SA03} 0.022857 0.437869 3.319013 25 30 {H12, M07} => {FA02} 0.019143 0.821429 3.274487 21 31 {M01, M03} => {FA01} 0.024286 0.768182 3.264962 16 32 {H01} => {FA04, SA03} 0.025143 0.560656 3.173137 31 33 {Eq19, H08} => {FA01, SA01} 0.021238 0.792662 3.157745 15 34 {Eq06} => {FA04, SA03} 0.011429 0.526316 3.117362 20 35 {Eq12, Eq10} => {FA04, SA03} 0.010857 0.752113 3.090149 19 36 {Eq23} => {FA08} 0.034137 0.763224 3.015276 12 37 {Eq09, Eq17} => {FA04, SA01} 0.015429 0.654225 2.927509 23 38 {Eq02} => {FA02, SA03} 0.022857 0.663636 2.862905 32 39 {H04, H17} => {FA07} 0.011429 0.515054 2.851092 20 40 {Eq07, Eq22} => {FA04} 0.015429 0.743754 2.744540 19 41 {Eq03, Eq20} => {FA06, SA05} 0.013714 0.652284 2.602230 17 42 {Eq11, H13} => {SA03} 0.024643 0.426992 2.541138 24 43 {Eq15, Eq10} => {FA04, SA01} 0.035824 0.724271 2.421214 12 44 {M03, H08} => {FA01, SA02} 0.042341 0.551981 2.348722 17 45 {M01, M02} => {FA02, SA01} 0.011429 0.398507 2.267932 31 46 {H01, H16} => {FA01} 0.020571 0.415082 2.253382 26 47 {Eq04, Eq16} => {SA01} 0.016571 0.617857 2.199636 19 48 {Eq17, Eq05} => {FA01, SA03} 0.010286 0.381255 2.131466 27 49 {Eq03, H10} => {SA02} 0.017714 0.352273 2.116807 21 50 {H13, Eq17} => {FA04, SA03} 0.010286 0.486486 1.957130 18 51 {Eq10, Eq05} => {FA04, SA02} 0.017714 0.324638 1.954165 31 52 {H05, M04} => {FA02, SA03} 0.018286 0.532432 1.836788 21 53 {En03, H03} => {FA08} 0.012571 0.526559 1.769477 15 54 {M01} => {SA03} 0.013714 0.358209 1.736471 18 55 {H06} => {SA01} 0.012001 0.538462 1.707079 14 56 {H05} => {FA01} 0.013714 0.375000 1.592841 24 57 {H01} => {FA06, SA01} 0.011429 0.785116 1.474553 20 58 {Eq21, Eq17} => {FA04} 0.024275 0.412414 1.265134 14 59 {Eq22, En06} => {SA03} 0.024254 0.703145 1.252132 10 60 {M04} => {SA02} 0.016571 0.391892 1.242411 13 61 {M04} => {SA03} 0.011429 0.230270 1.087294 20 62 {En05} => {FA02} 0.029312 0.786116 1.002431 7 63 {En03, Eq23} => {FA08} 0.027416 0.532441 1.000123 10 Table 4.

Table of results of association rules for chemical production accidents.

-

Evaluation indicators Causative factor nodes of chemical production accident Value Degree distribution Material strength defects (Eq17) 21 Reaction kettle over-temperature or over-pressure (Eq05) 16 Improper or faulty operation (H01): 13 13 Failure to rationalize storage according to the nature of the chemical (M01) 13 Equipment or system failure (Eq01) 11 Problems with process or technology (Eq04) 7 Safety defects in equipment or failure of safety interlocking devices (Eq10) 5 Failure to conduct safety tests prior to operating in a limited space (H08) 5 Betweenness centrality Reaction kettle over-temperature or over-pressure (Eq05) 53.159 Material strength defects (Eq17) 36.806 Problems with process or technology (Eq04) 33.199 Failure to rationalize storage according to the nature of the chemical (M01) 28.638 Safety defects in equipment or failure of safety interlocking devices (Eq10) 9.658 Illegal changes in production processes or procedures (H10) 9.542 Illegal business (M02) 8.993 Insufficient training in emergency response capacity (M08) 8.861 Closeness centrality Improper or faulty operation (H01) 1.0 Material strength defects (Eq17) 1.0 Deficiencies in security management (M04) 0.714286 Illegal changes in production processes or procedures (H10) 0.707421 Reaction kettle over-temperature or over-pressure (Eq05) 0.666667 Work without safety equipment (H03) 0.588235 Lack of specialized skills (H17) 0.583333 Failure to rationalize storage according to the nature of the chemical (M01) 0.574492 Eigenvector centrality Failure to conduct safety tests prior to operating in a limited space (H08) 0.482147 Illegal business (M02) 0.422739 Failure to rationalize storage according to the nature of the chemical (M01) 0.415532 Incorrect or excessive addition of reaction materials (H07) 0.402775 Reaction kettle over-temperature or over-pressure (Eq05) 0.384915 Insufficient training in emergency response capacity (M08) 0.372148 Ambient moisture corrodes equipment or reacts with substances (En04) 0.344168 Failure to regularly service equipment (M06) 0.328852 Table 5.

Key causative factors of chemical production accidents.

-

Data Dickey-Fuller Lag order p-value Alternative Original series ADF test Da1 −3.4473 5 0.06219 Stationary ADF test after first-order differencing Da2 −6.2364 5 0.01 Stationary Table 6.

ADF test results.

-

SARIMAX model Model evaluation criterion AIC Sigma2 SBIC Log likelihood SARIMA(1,1,2) (1,1,0)[4]-AR(X) −149.87 7.96 −144.02 76.03 SARIMA(1,1,1)(1,1,0)[4]-AR(X) −151.82 8.57 −144.31 77.31 SARIMA(0,1,1)(1,1,0)[4]-AR(X) −153.53 8.89 −146.88 80.77 SARIMA(0,1,2)(1,1,0)[4]-AR(X) −151.79 8.44 −145.97 80.93 SARIMA(2,1,2)(1,1,0)[4]-AR(X) −147.98 7.24 −143.73 75.92 SARIMA(2,1,0)(1,1,0)[4]-AR(X) −146.39 7.03 −144.68 75.41 SARIMA(2,1,1)(1,1,0)[4]-AR(X) −149.95 7.91 −144.27 76.58 SARIMA(1,1,0)(1,1,0)[4]-AR(X) −147.74 7.54 −145.53 76.21 Table 7.

Values of different evaluation indicators for the SARIMA models.

-

Forecast Lo80 Hi80 Lo95 Hi95 2023 Q1 0.1720433 0.1333529 0.2107337 0.1128714 0.2312152 2023 Q2 0.2065148 0.1678244 0.2452053 0.1473429 0.2656867 2023 Q3 0.3737203 0.3350299 0.4124107 0.3145484 0.4328922 2023 Q4 0.2499829 0.2112925 0.2886735 0.1908112 0.3091548 Table 8.

SARIMAX predition values for the year 2023.

Figures

(14)

Tables

(8)