-

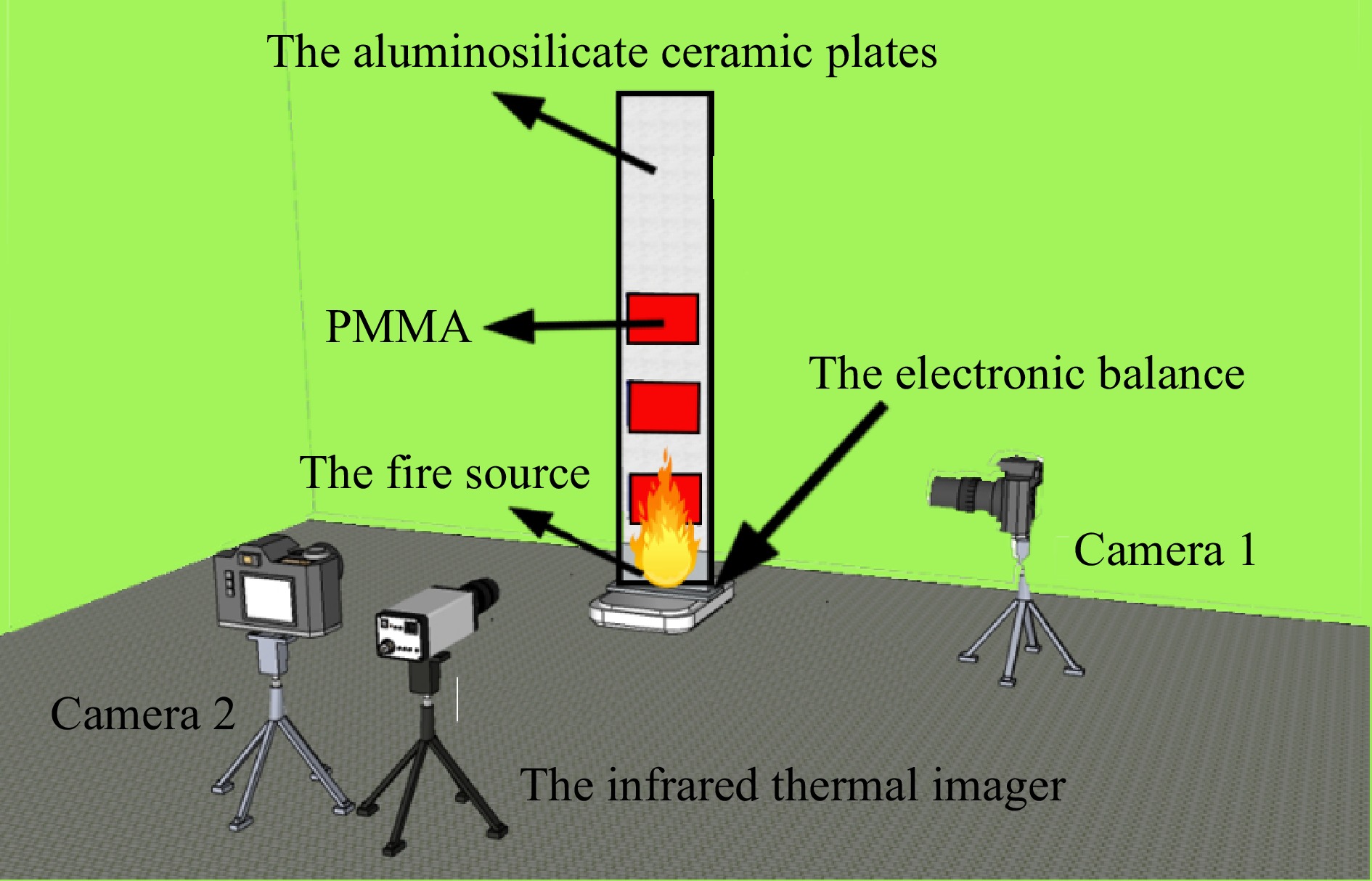

Figure 1.

Experimental apparatus.

-

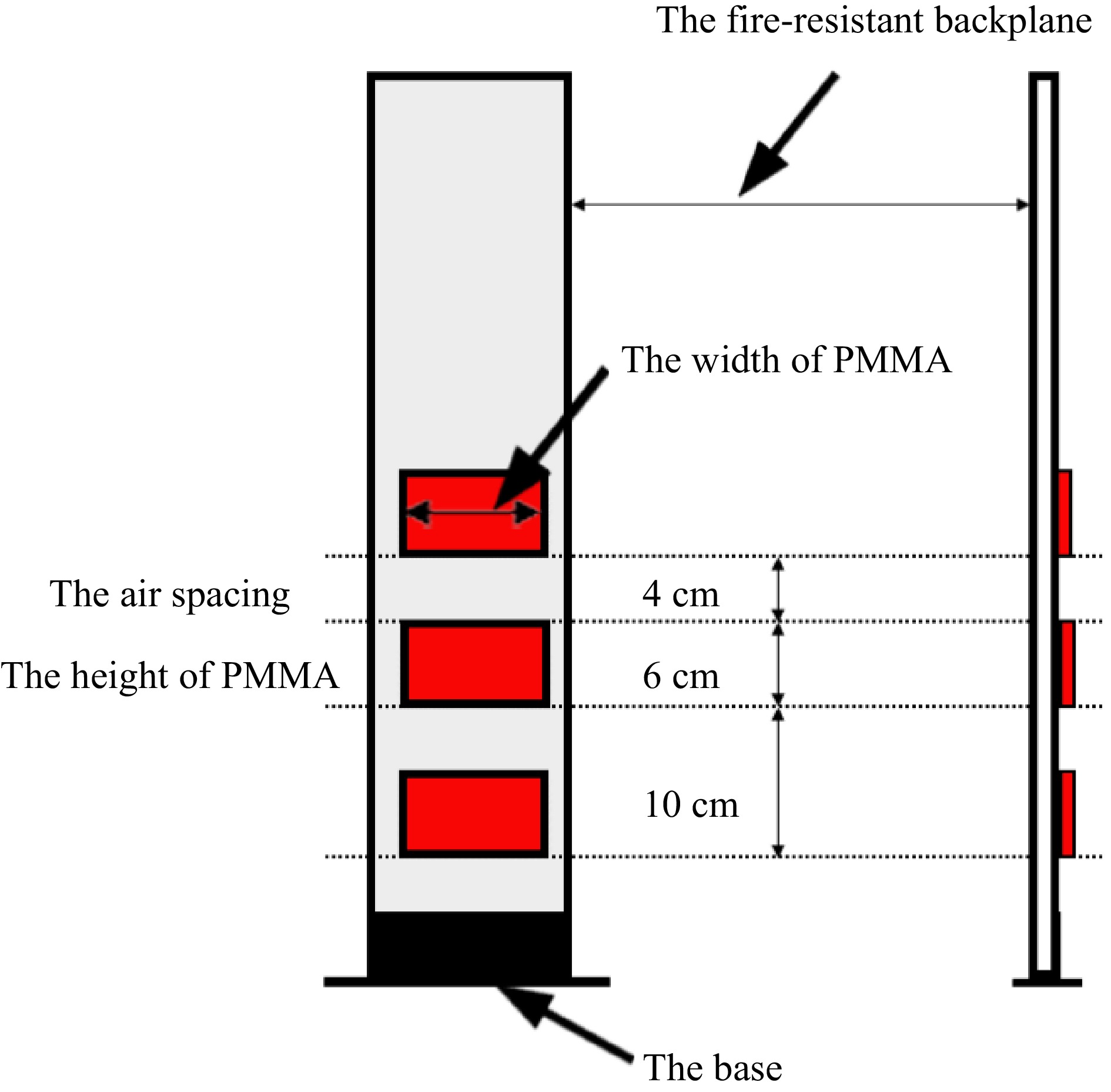

Figure 2.

Experimental device for PMMA.

-

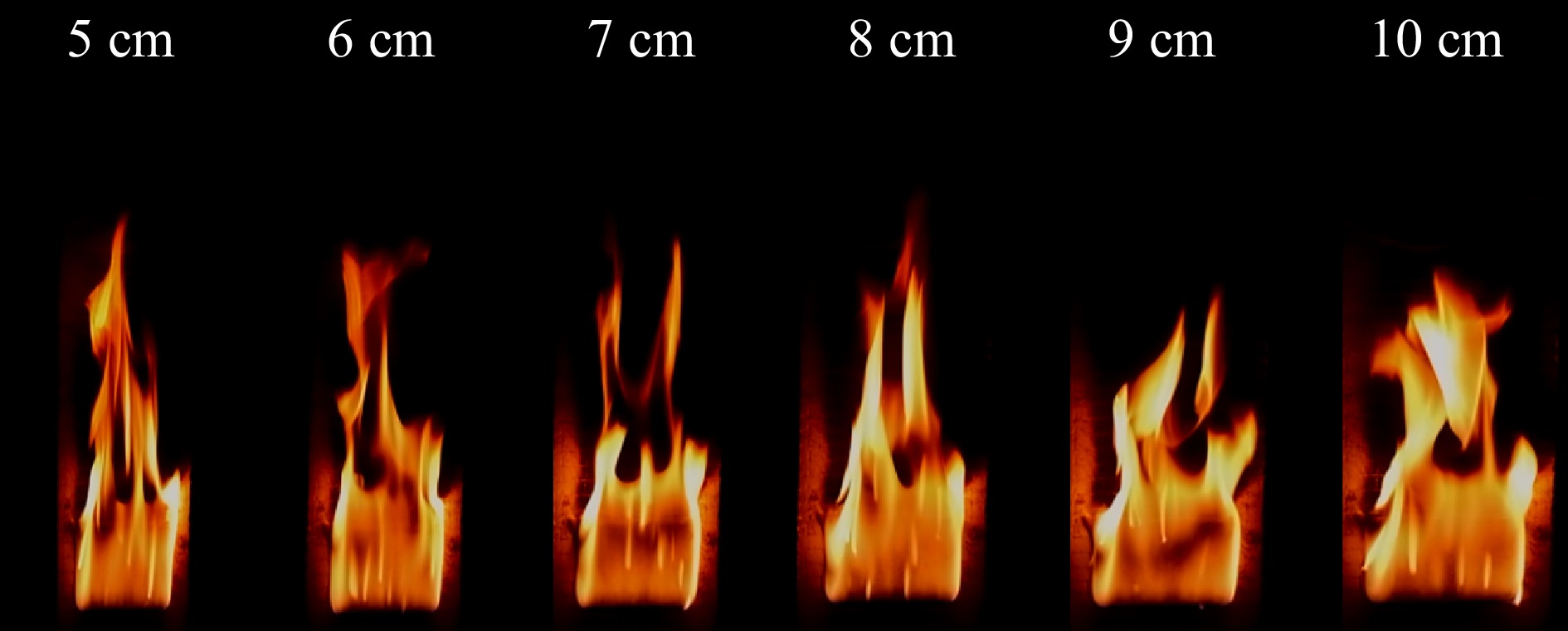

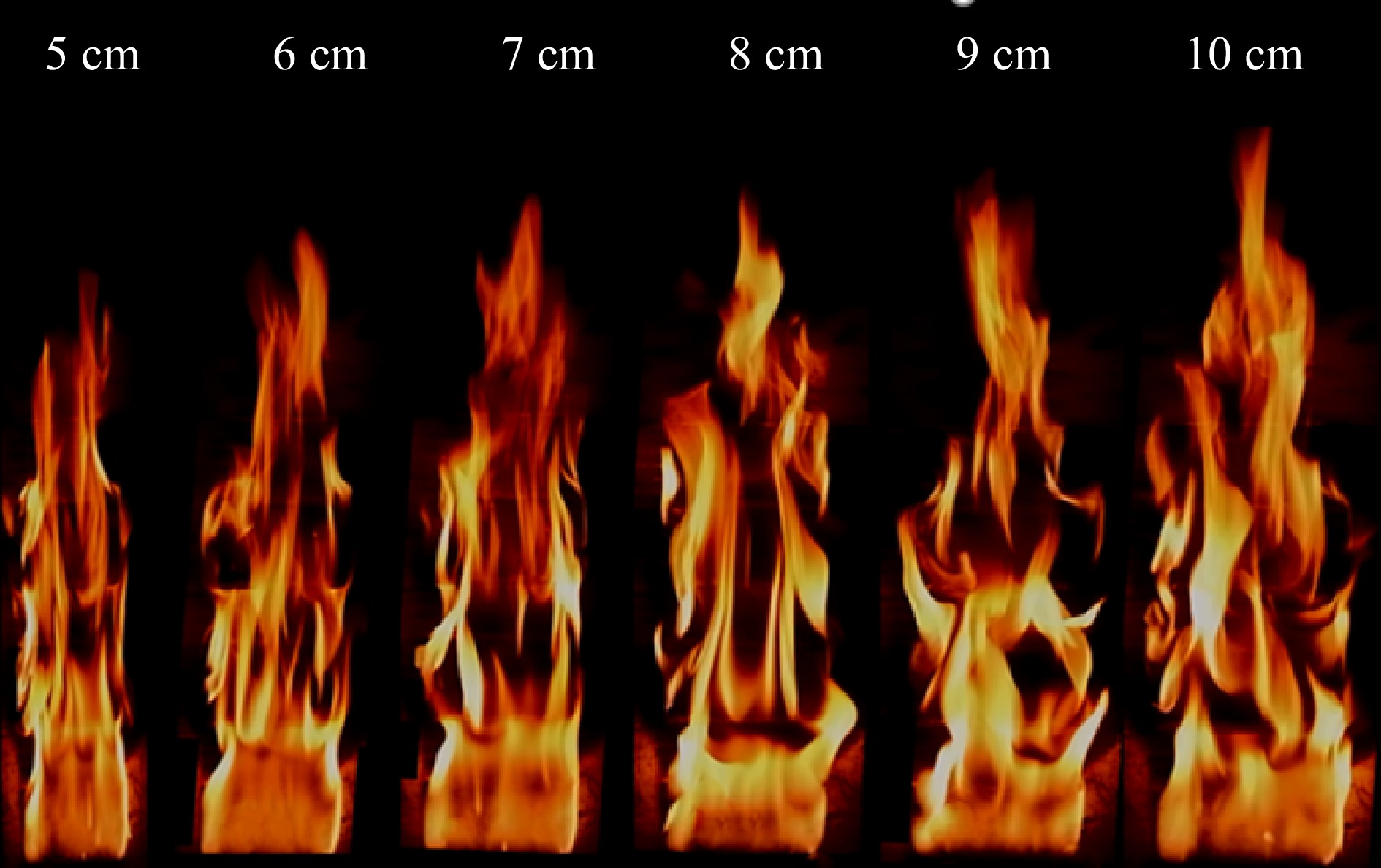

Figure 3.

Schematic diagram of the front side of a single piece of PMMA burning with different widths.

-

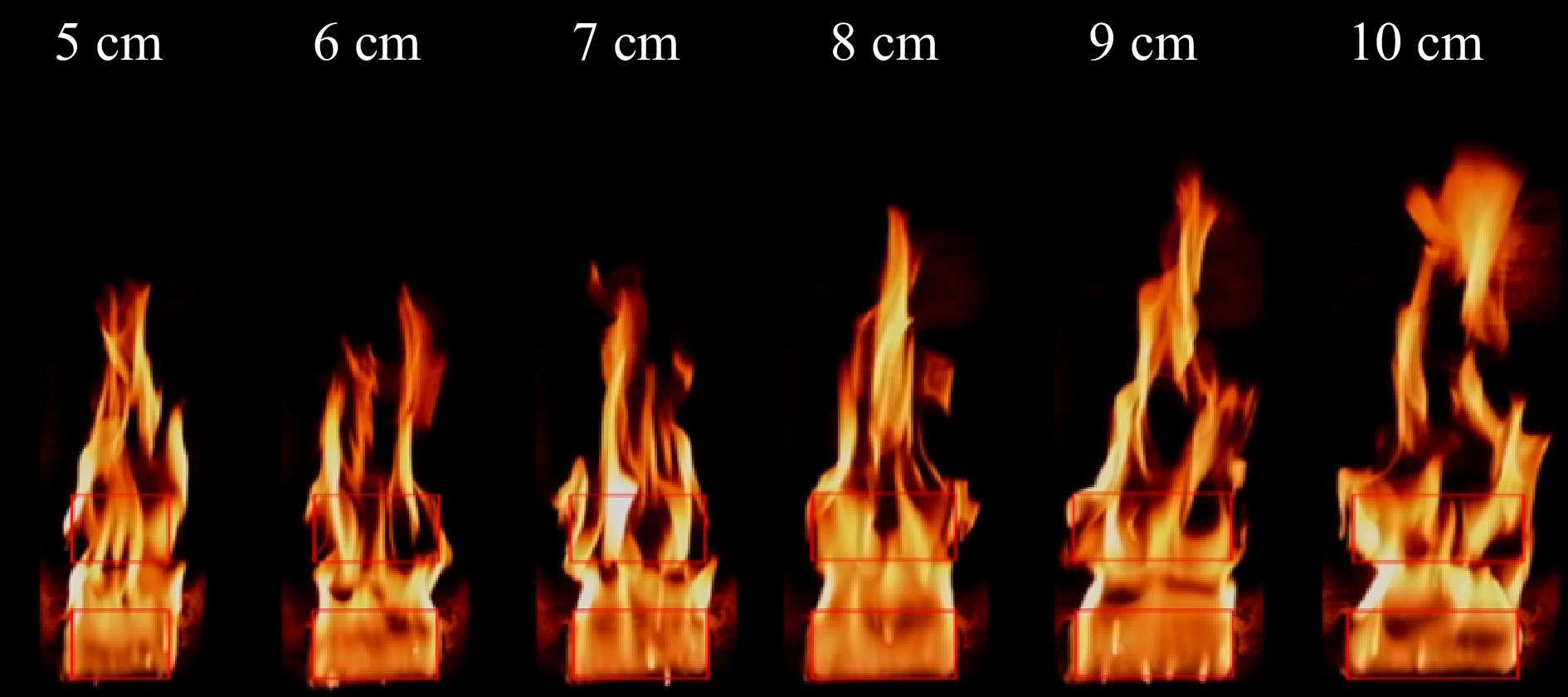

Figure 4.

Schematic diagram of the burning front side of two pieces of PMMA with different widths.

-

Figure 5.

Schematic diagram of the burning front side of three PMMA plates with different widths.

-

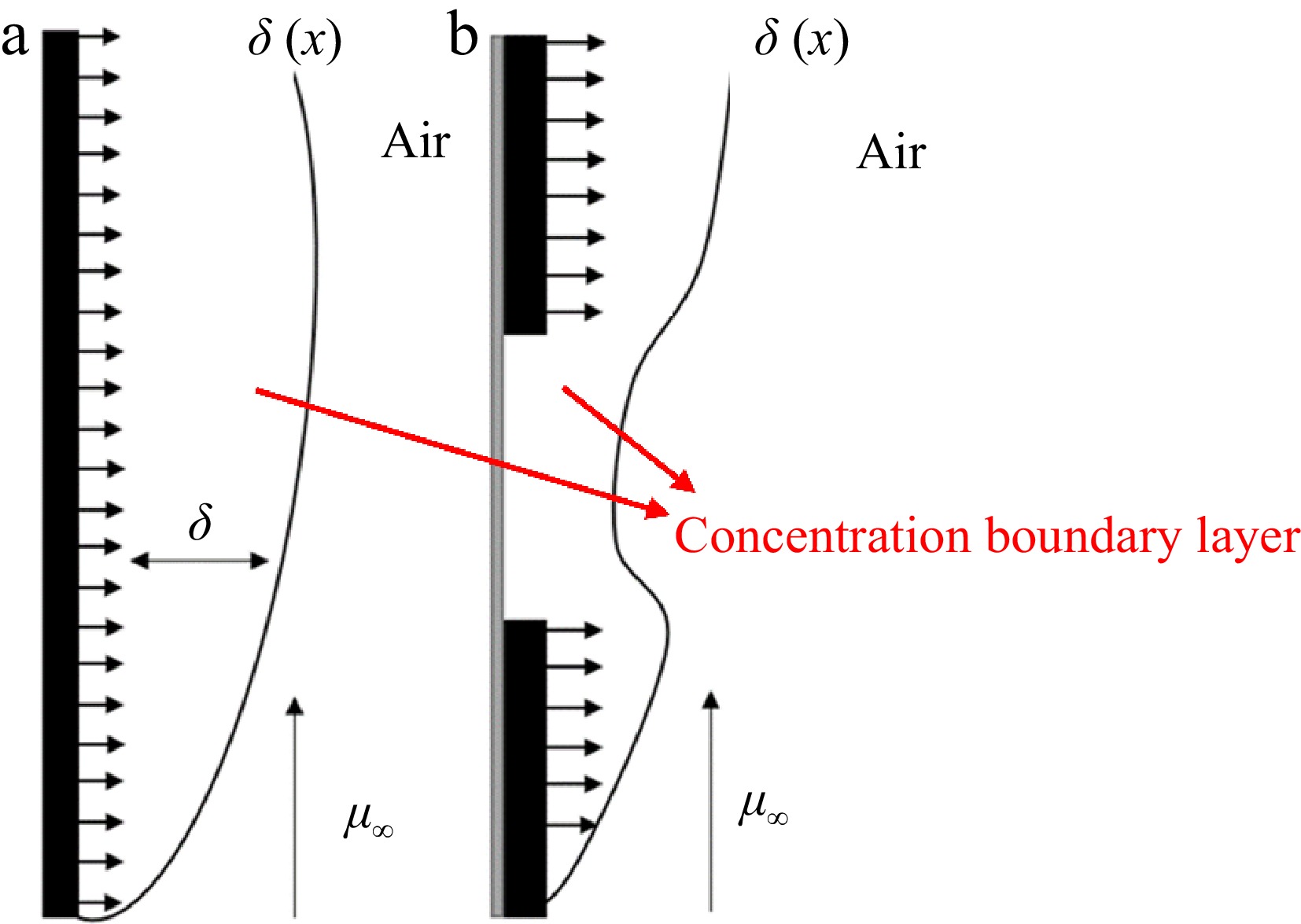

Figure 6.

Concentration boundary layer (a) continuous, and (b) discontinuous.

-

Figure 7.

Schematic diagram of flame height at the steady stage.

-

Figure 8.

The relationship between average flame height and width.

-

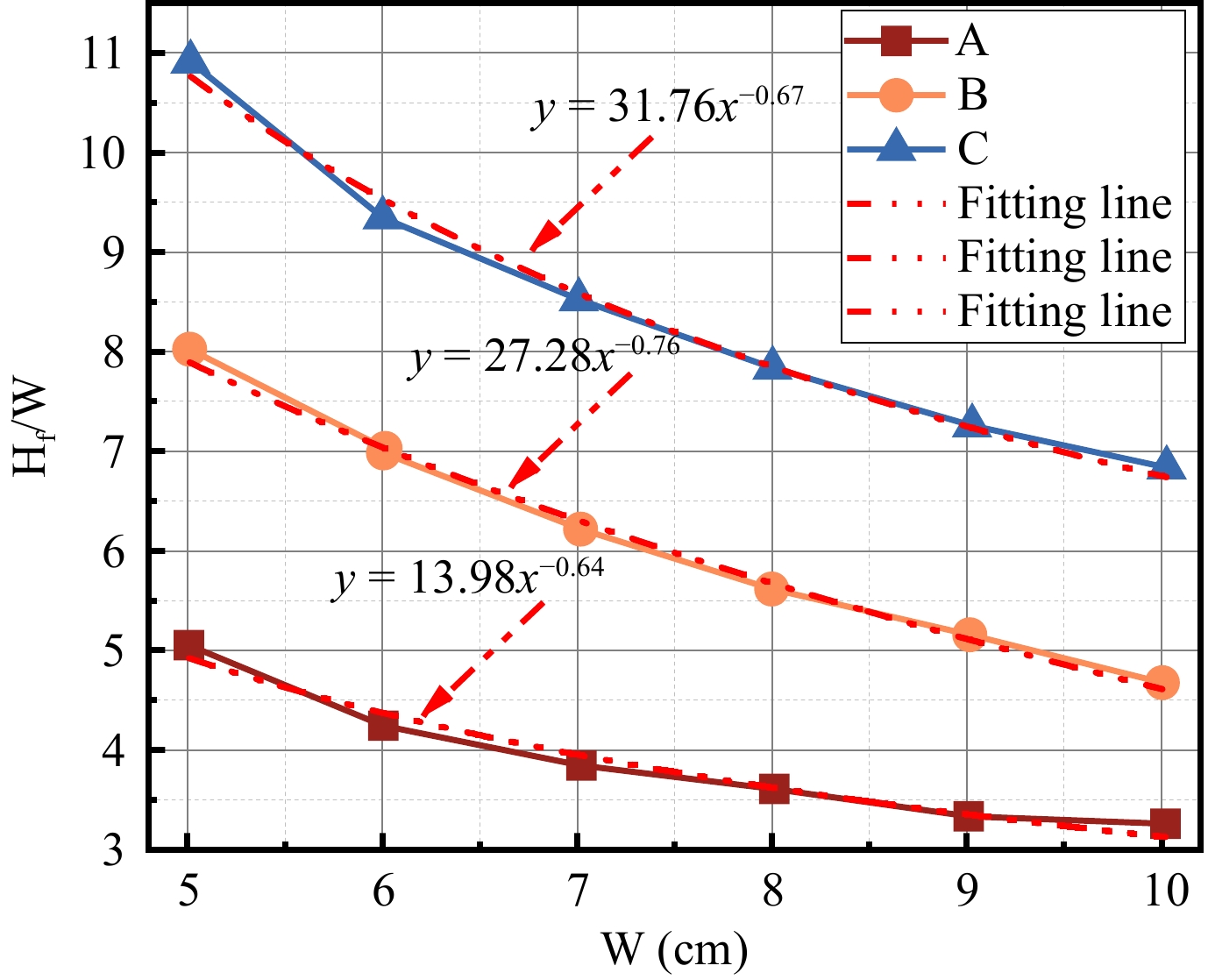

Figure 9.

The relationship between dimensionless flame height and sample width.

-

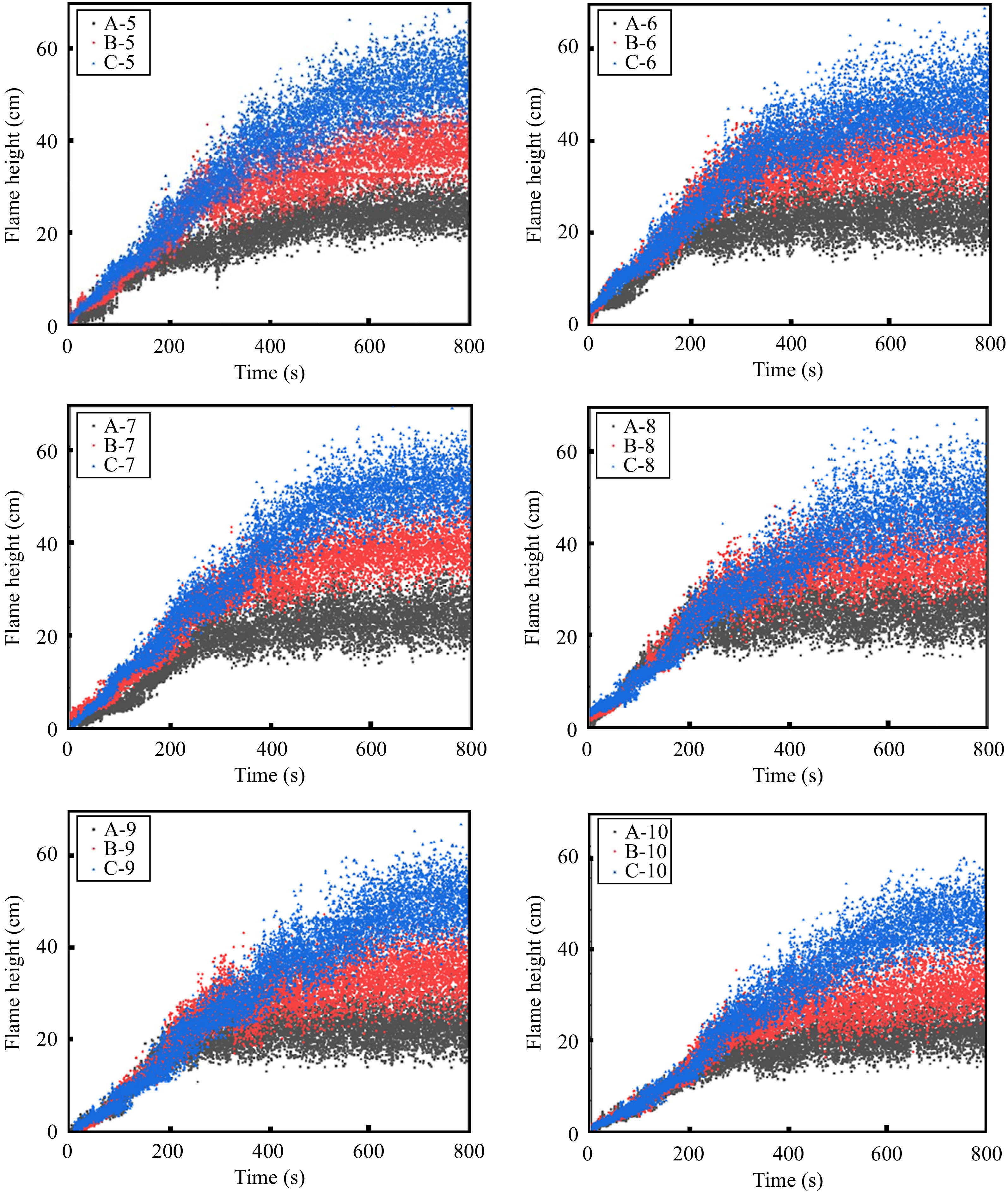

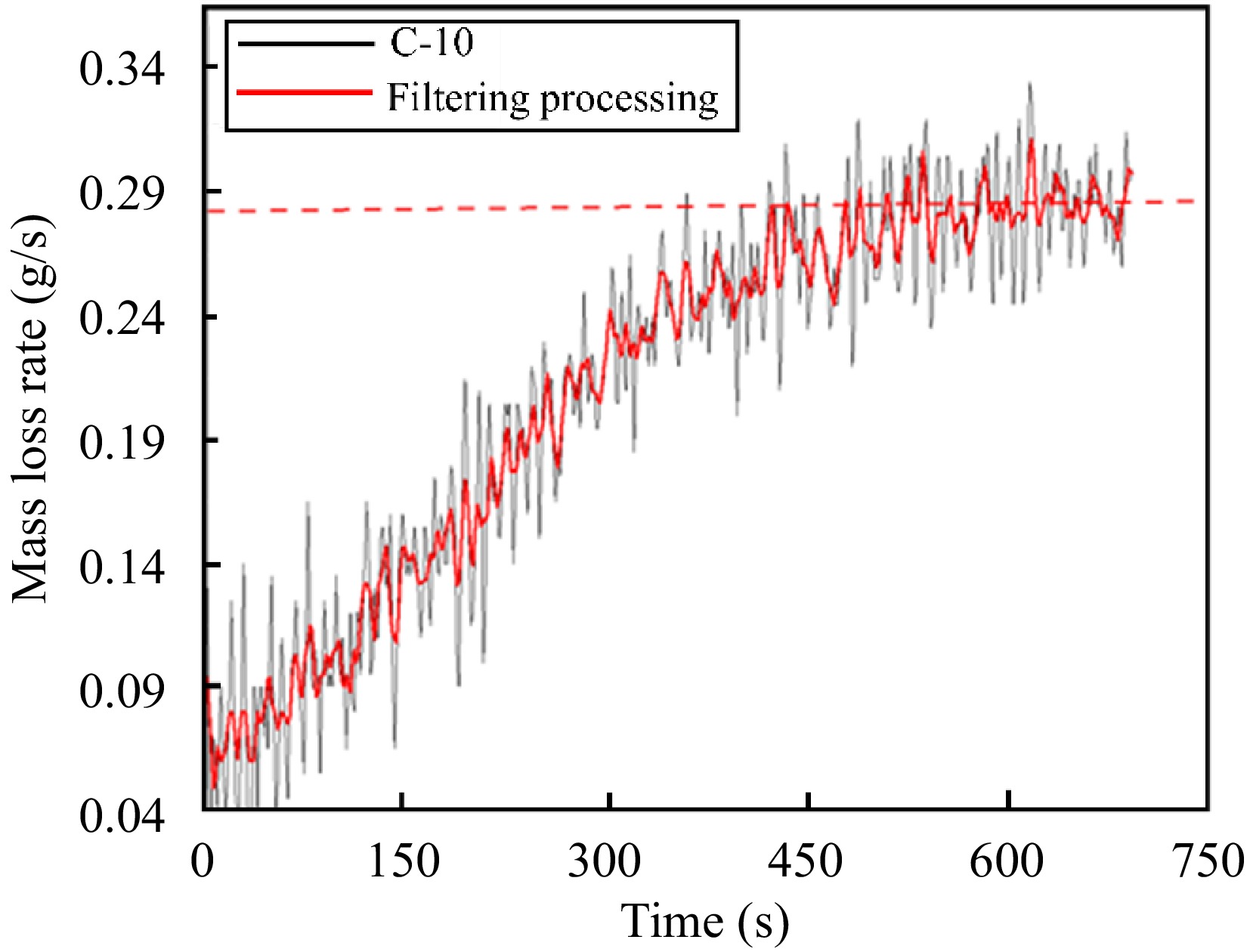

Figure 10.

C-10 Mass loss rate processing diagram.

-

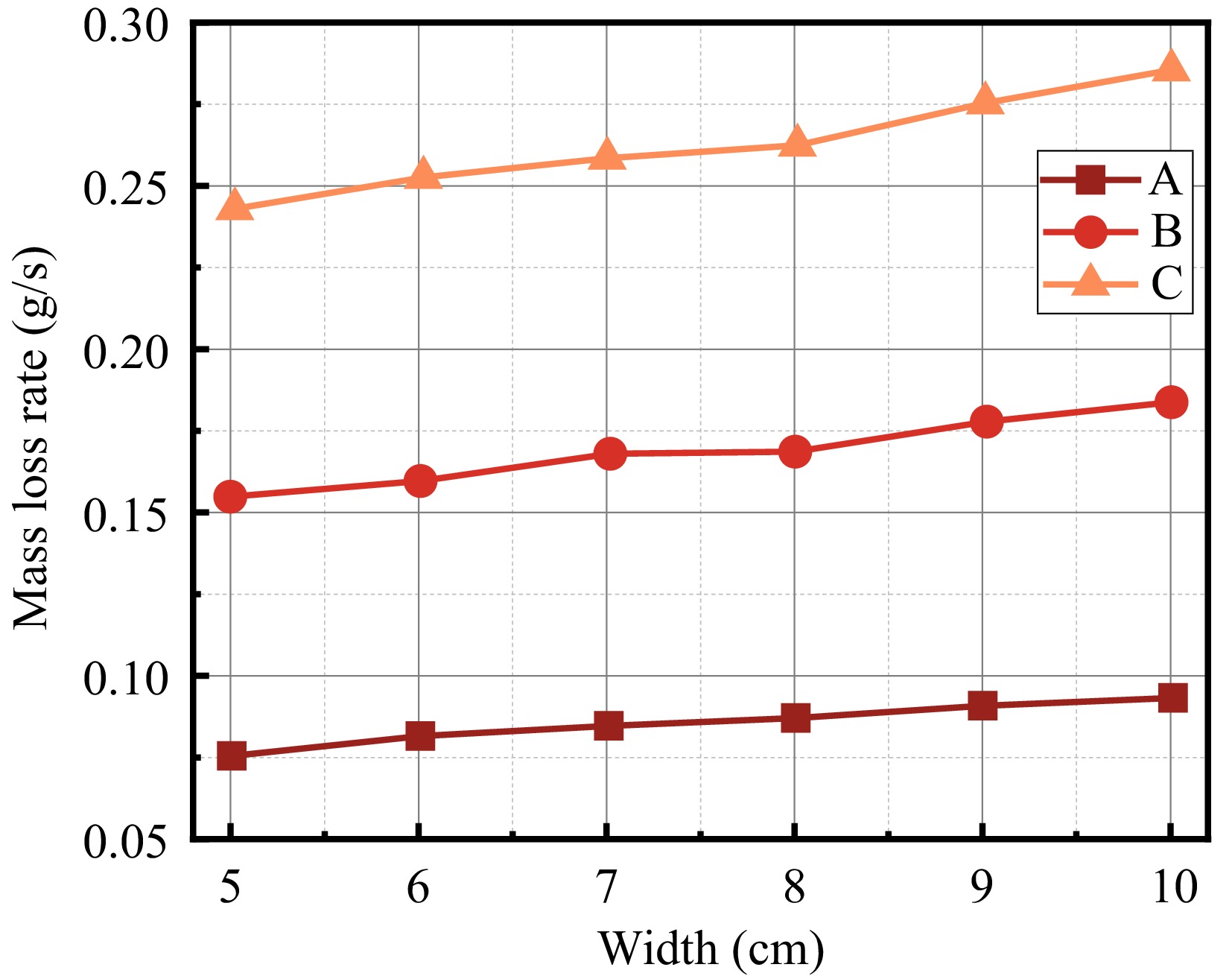

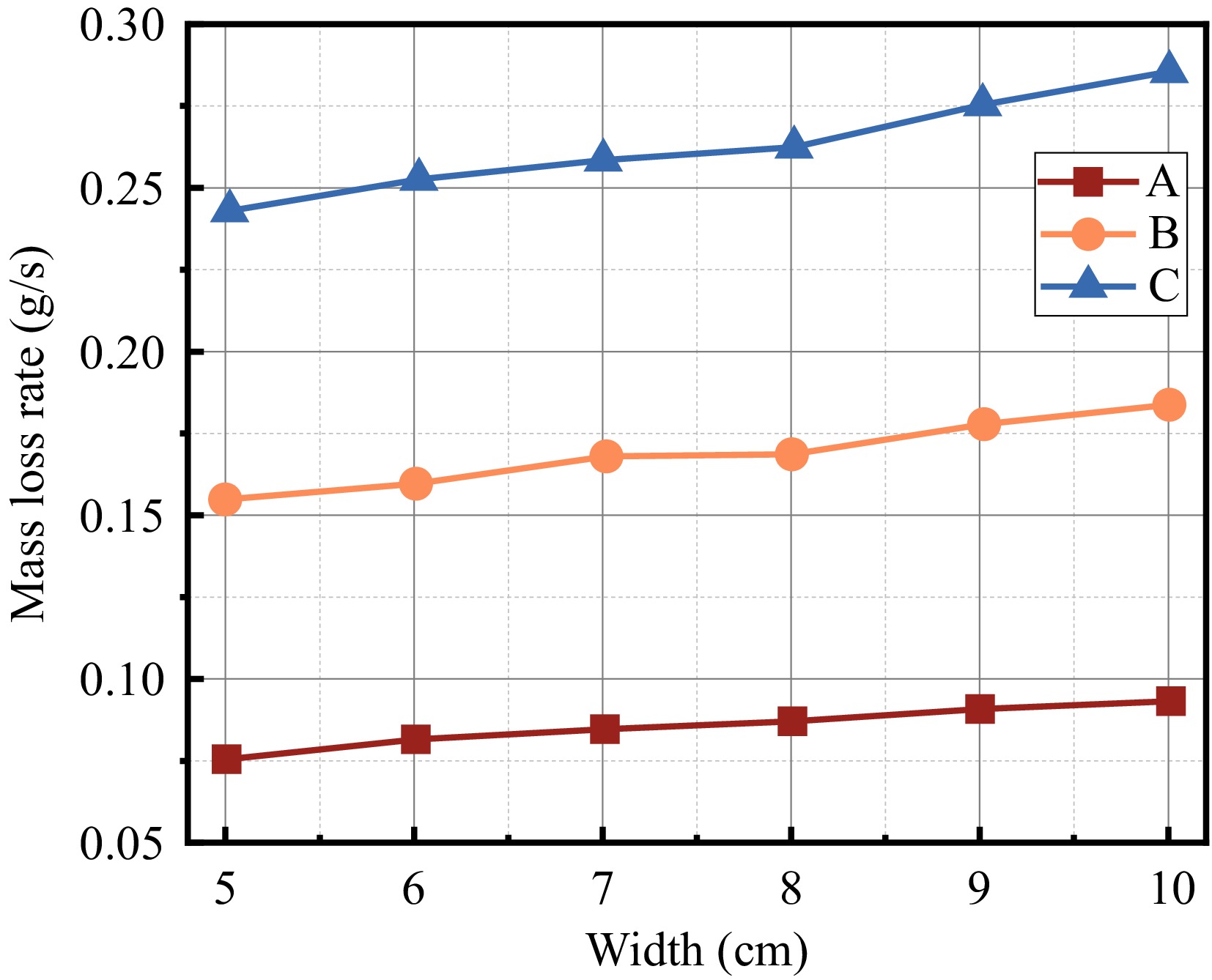

Figure 11.

The relationship between mass loss rate and width.

-

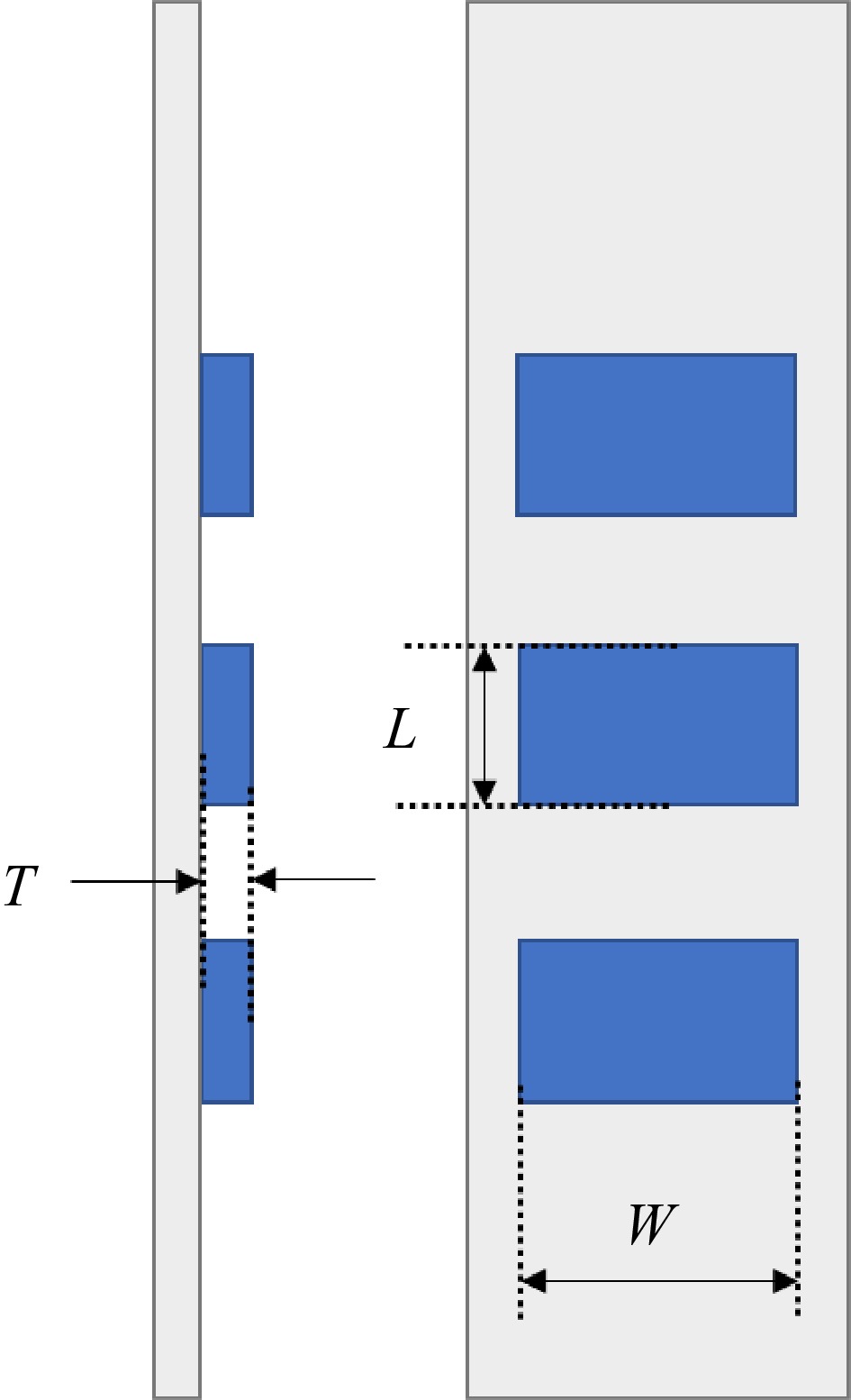

Figure 12.

Schematic diagram of solid area parameters.

-

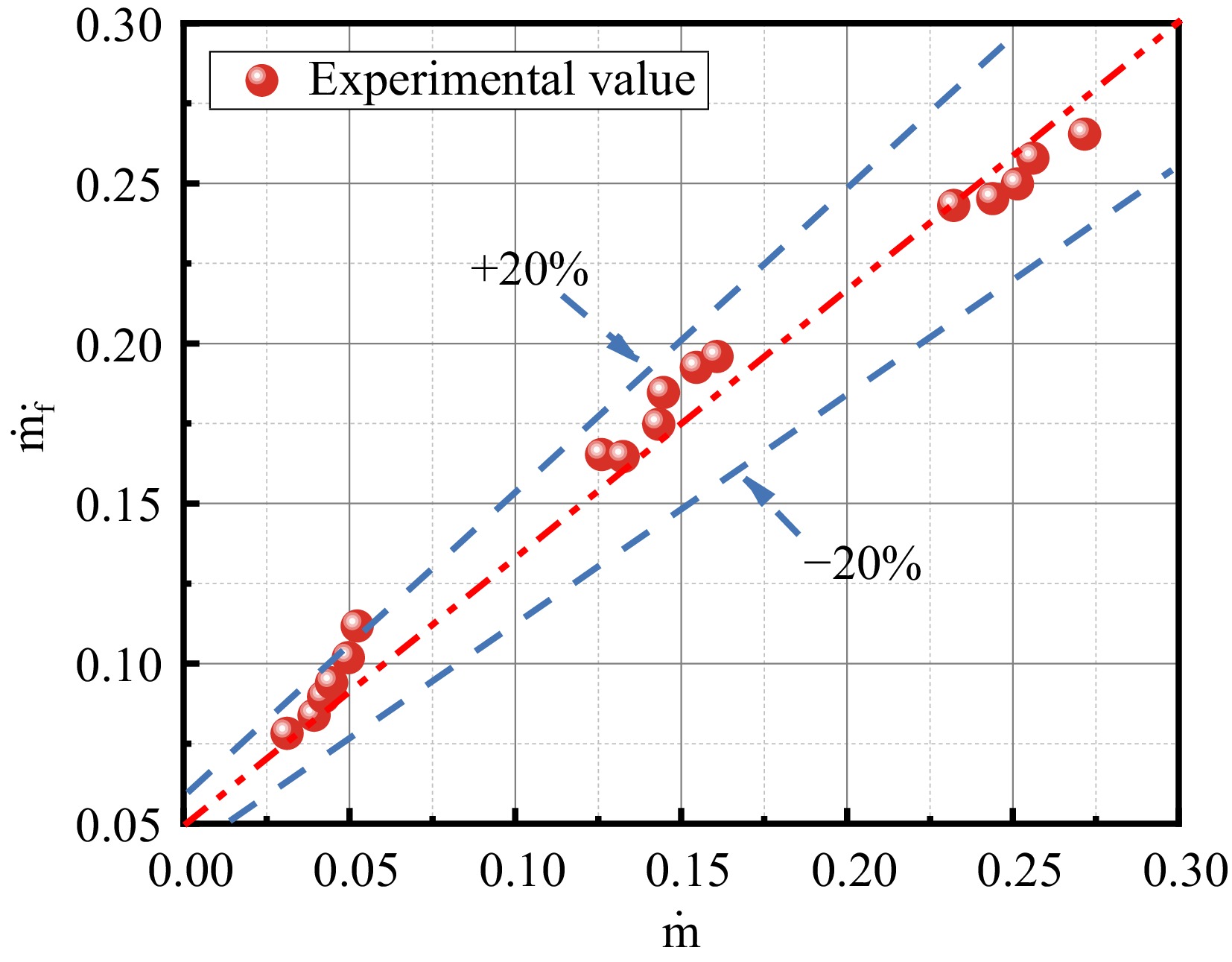

Figure 13.

Comparison of predicted mass loss rate data with experimental data.

-

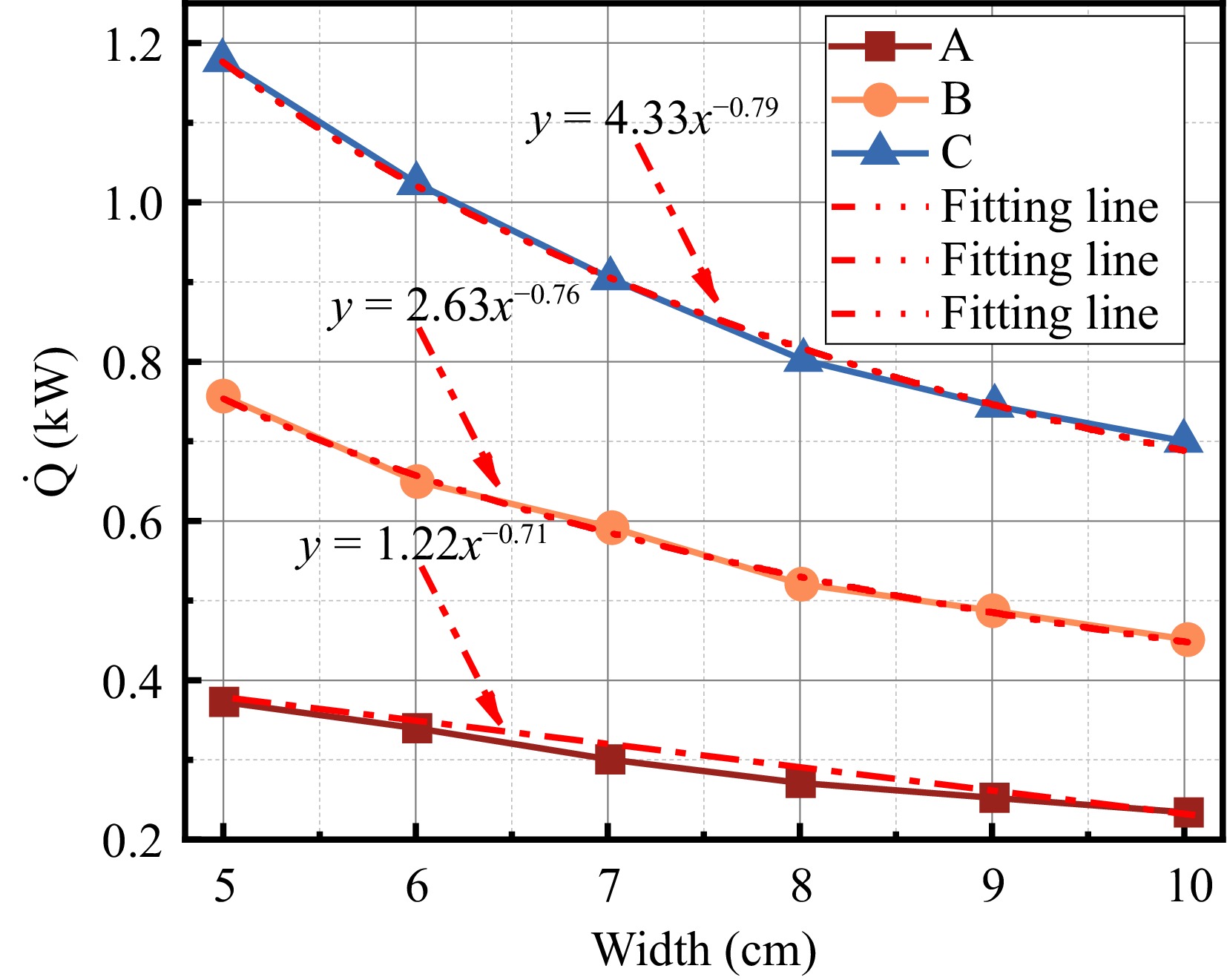

Figure 14.

The relationship between heat release rate and width.

-

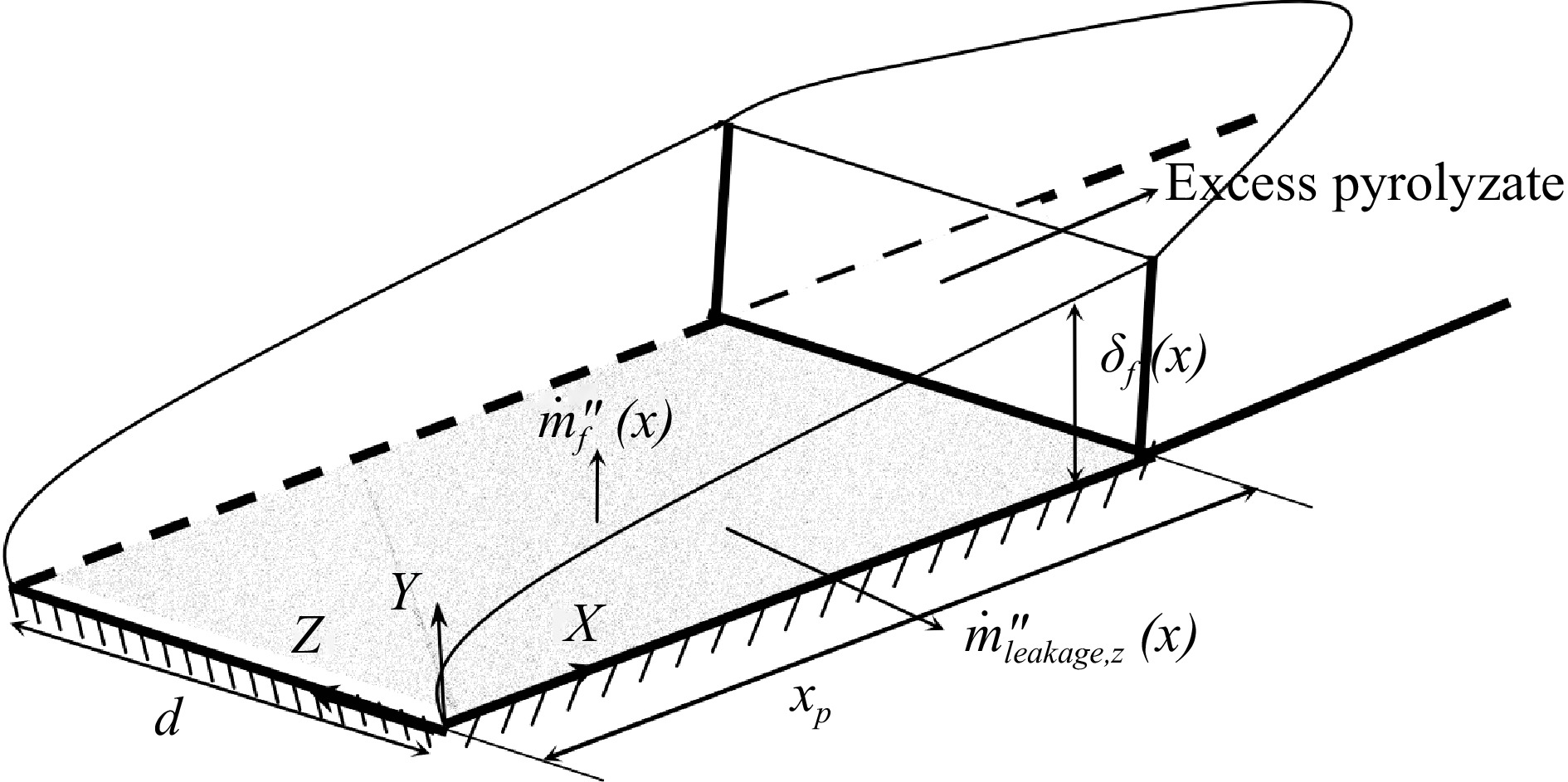

Figure 15.

Physical model of width-influenced flame spread[24].

-

Width (cm) 5 6 7 8 9 10 Single piece of PMMA A-5 A-6 A-7 A-8 A-9 A-10 Two pieces of PMMA B-5 B-6 B-7 B-8 B-9 B-10 Three pieces of PMMA C-5 C-6 C-7 C-8 C-9 C-10 Table 1.

Table of conditions for discrete solids of different widths.

-

Conditions Height 5 6 7 8 9 10 A 0.076 0.082 0.085 0.087 0.091 0.093 B 0.155 0.160 0.169 0.170 0.179 0.184 C 0.243 0.253 0.260 0.263 0.276 0.286 Table 2.

Rate of material mass loss (g/s).

-

Parameters Characteristic Numerical value $ B $ Atomic weight of an element 1.32 $ {c}_{p} $ Specific heat capacity 1.207 kJ/(kg-K) $ {k}_{w} $ Heat conductivity 0.091 W/(m-K) $ Pr $ Prandtl (math.) 0.073 $ {T}_{f} $ Flame temperature 1,400 K $ {T}_{p} $ Pyrolysis temperature 623 K $ \alpha $ Thermal diffusivity 168 × 10 m−62 /s $ v $ Kinematic viscosity 121 × 10 m−62 /s Table 3.

Physical parameters of PMMA in Eqn (2)[8].

Figures

(15)

Tables

(3)