-

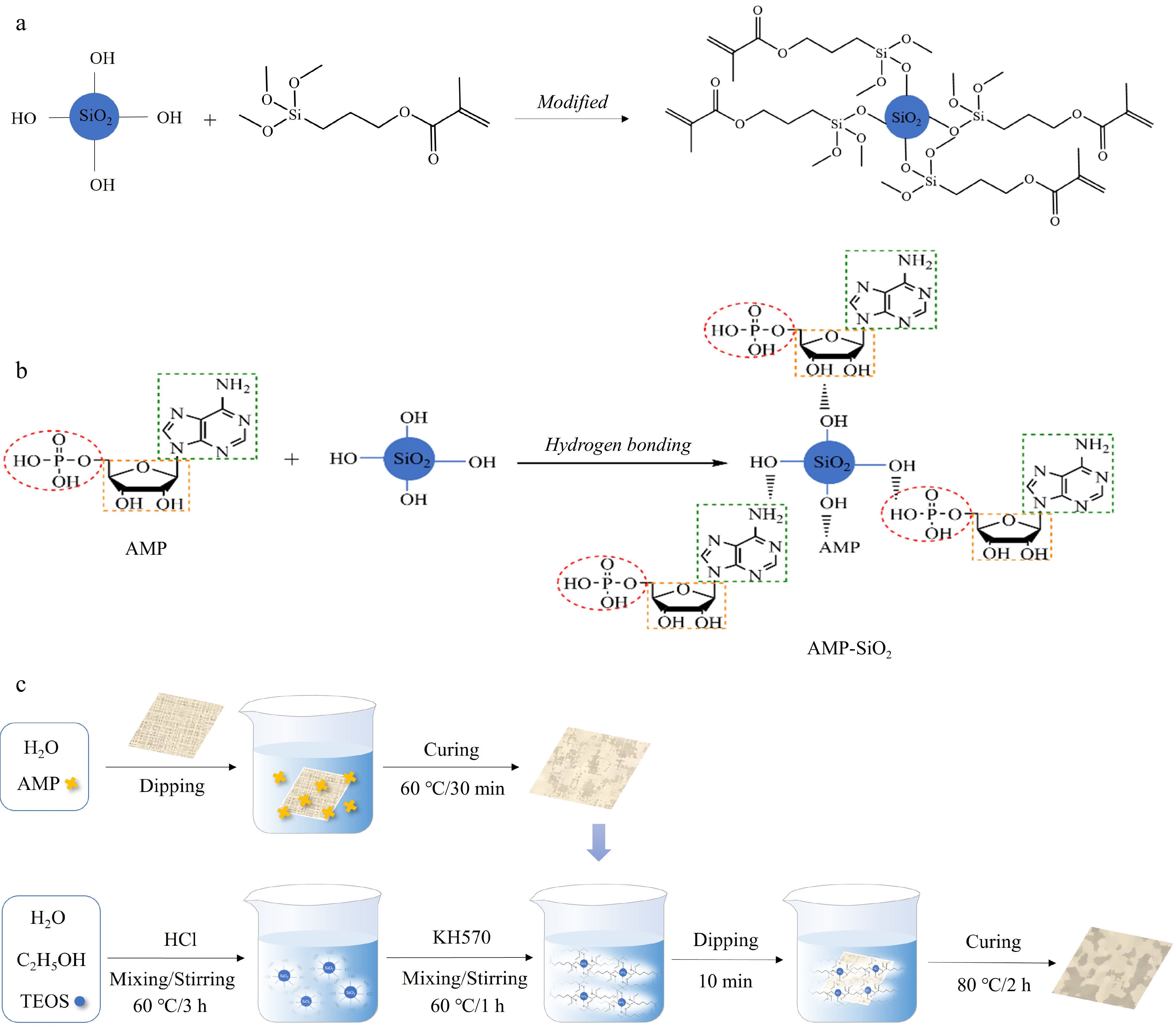

Figure 1.

(a) Path diagram of SiO2-KH570, (b) synthetic route of an AMP-SiO2 sol, (c) preparation process of AMP-SiO2-KH570@COT.

-

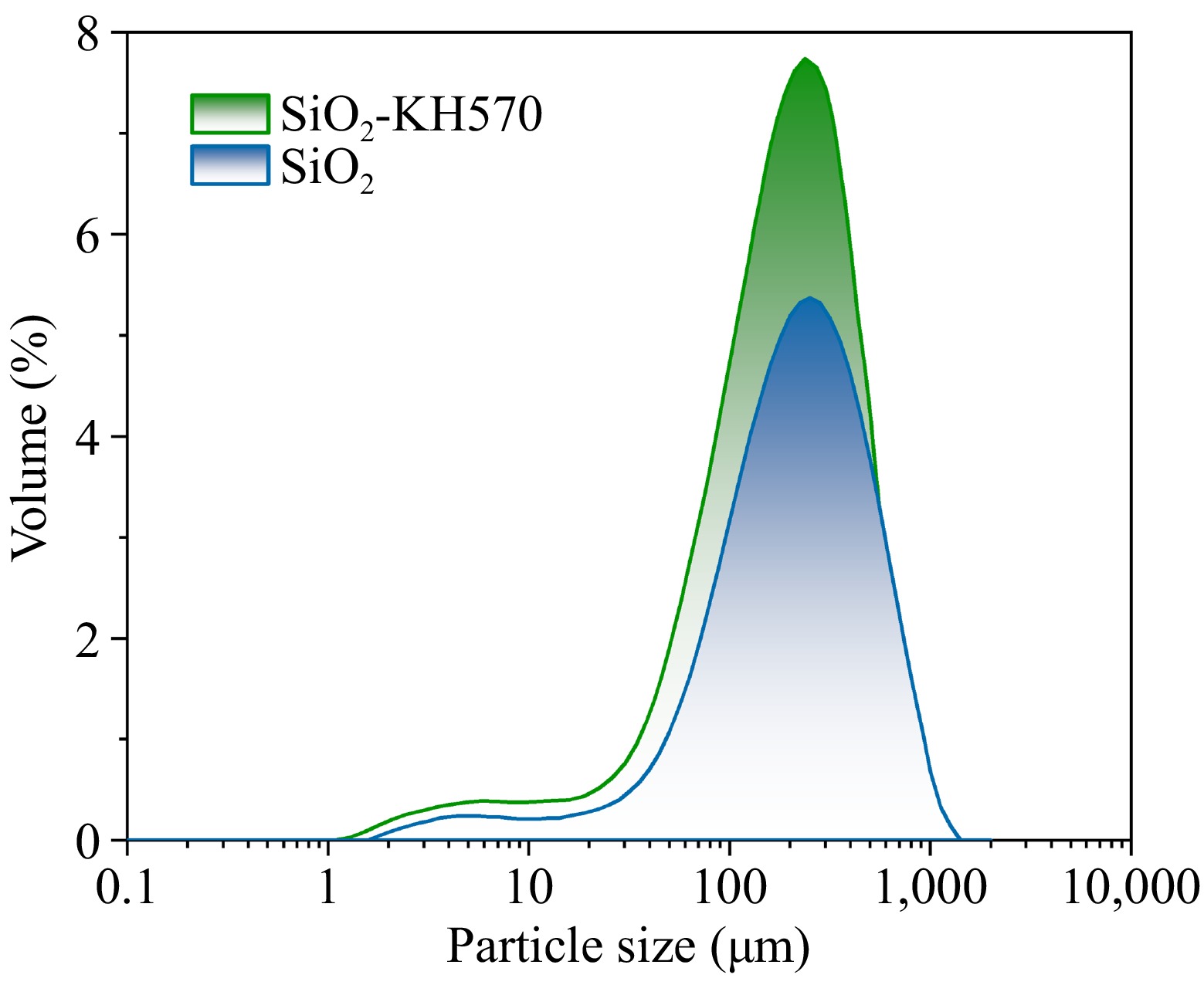

Figure 2.

Particle size distribution of SiO2 sol and SiO2-KH570 sol.

-

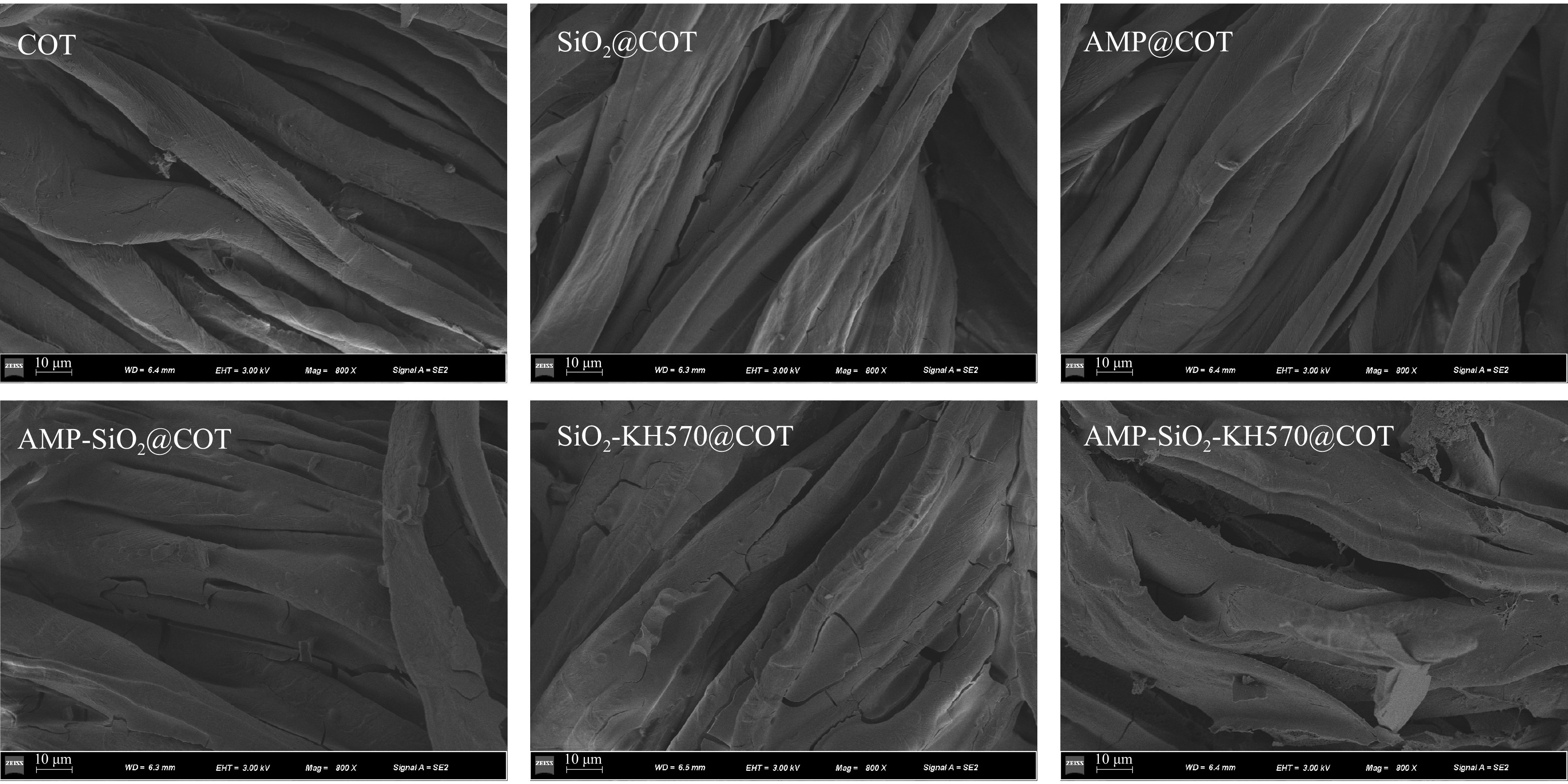

Figure 3.

SEM images of raw and treated cotton fabrics.

-

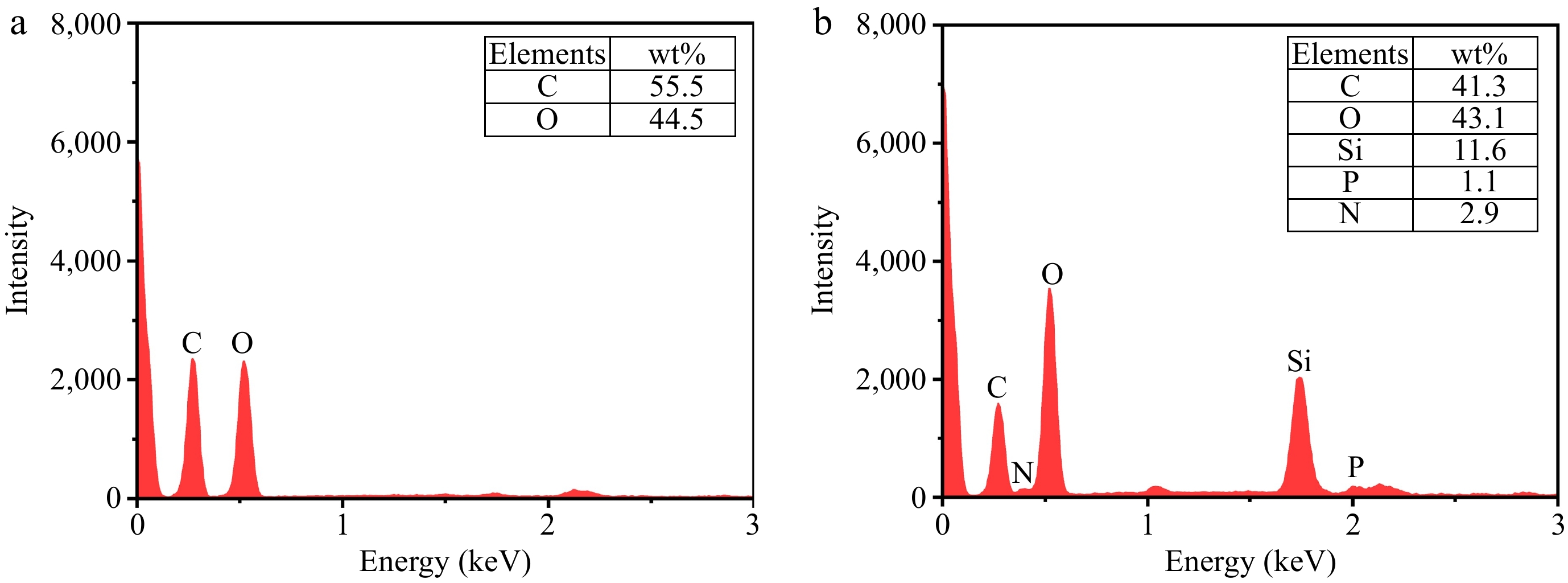

Figure 4.

(a) EDX spectra of COT, and (b) AMP-SiO2-KH570@COT.

-

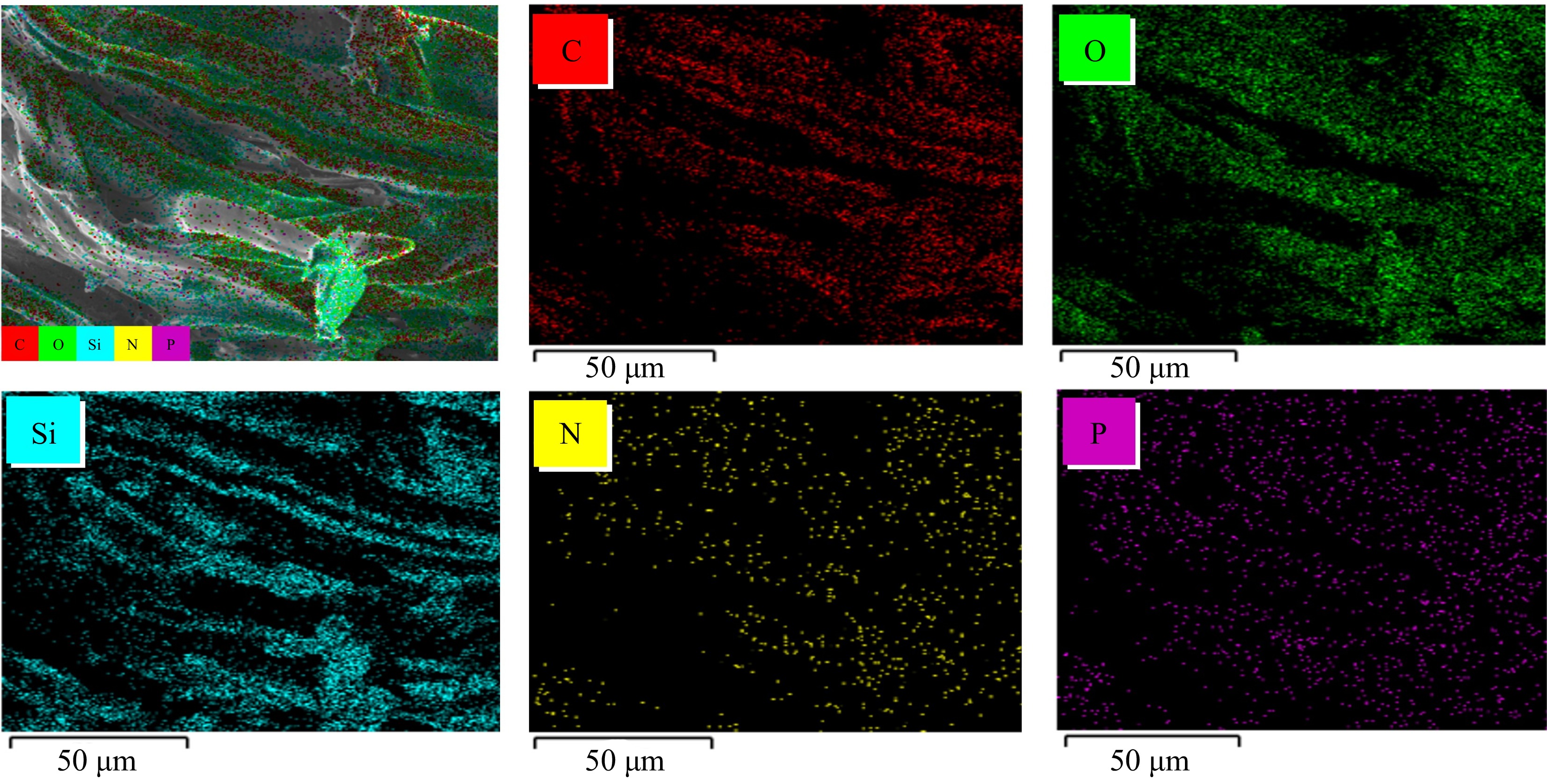

Figure 5.

Elements distribution images of AMP-SiO2-KH570@COT (depicting the mapping of carbon (C), oxygen (O), silicon (Si), nitrogen (N), and phosphorus (P) elements).

-

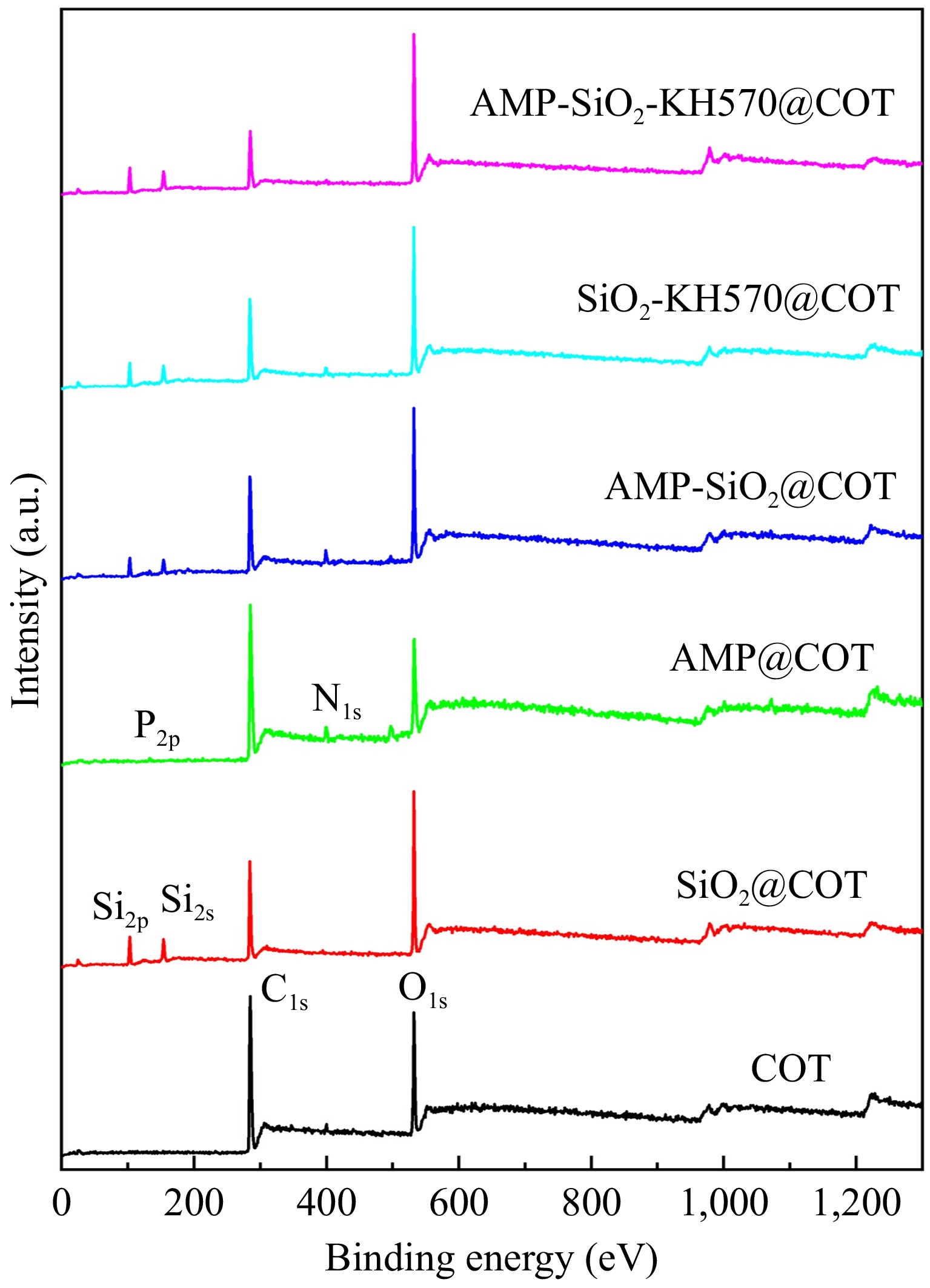

Figure 6.

XPS spectra of raw and treated cotton fabrics.

-

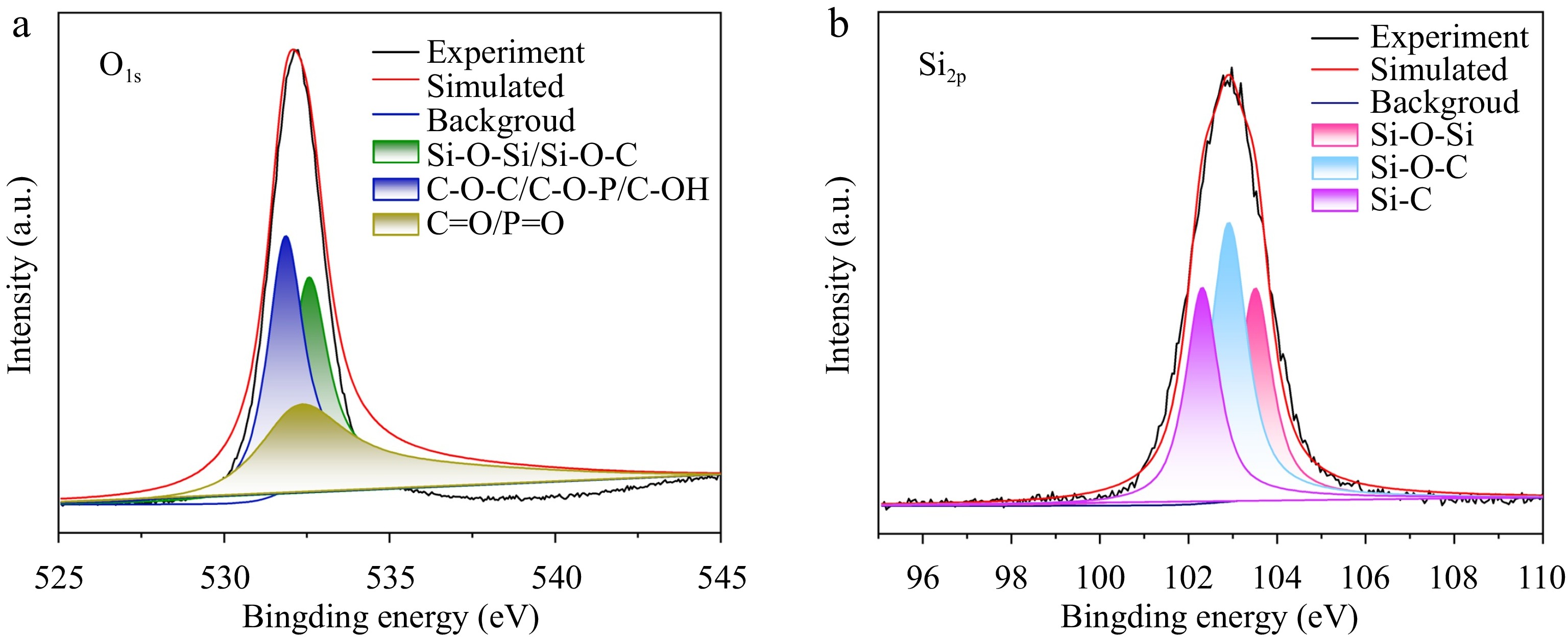

Figure 7.

High resolution XPS spectra for (a) O1s, and (b) Si2p of AMP-SiO2-KH570@COT.

-

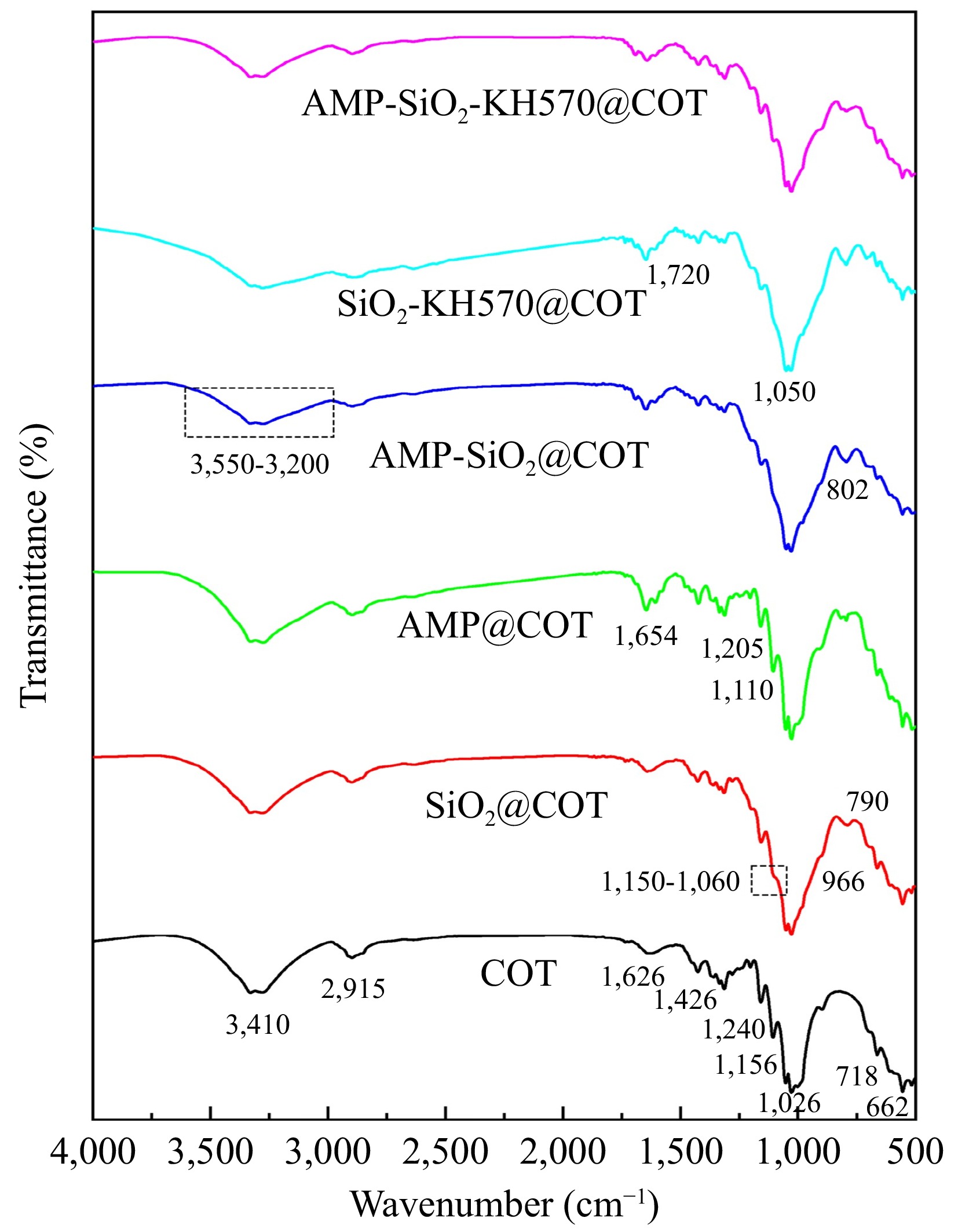

Figure 8.

FTIR spectra of raw and treated cotton fabrics.

-

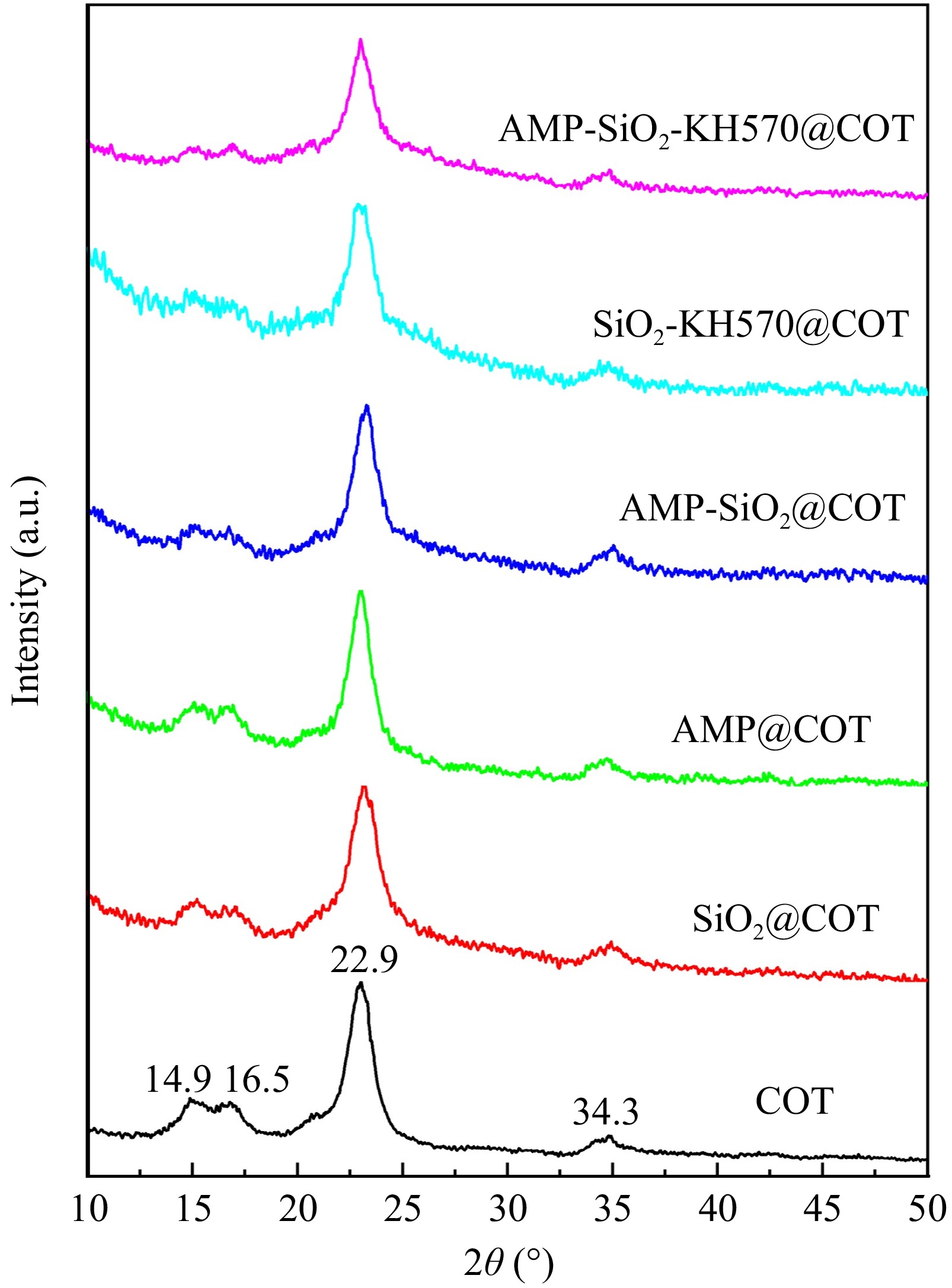

Figure 9.

XRD patterns of raw and treated cotton fabrics.

-

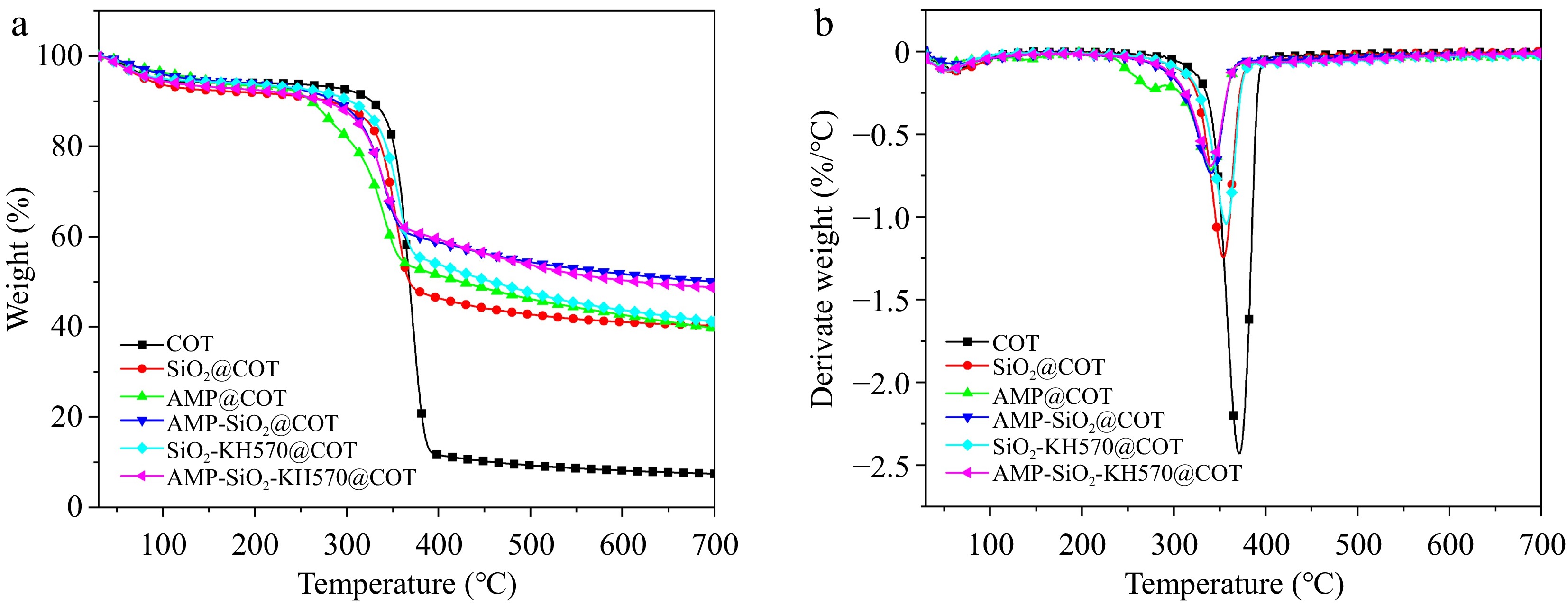

Figure 10.

(a) TG, and (b) DTG curves of raw and treated cotton fabrics (10 K/min, N2).

-

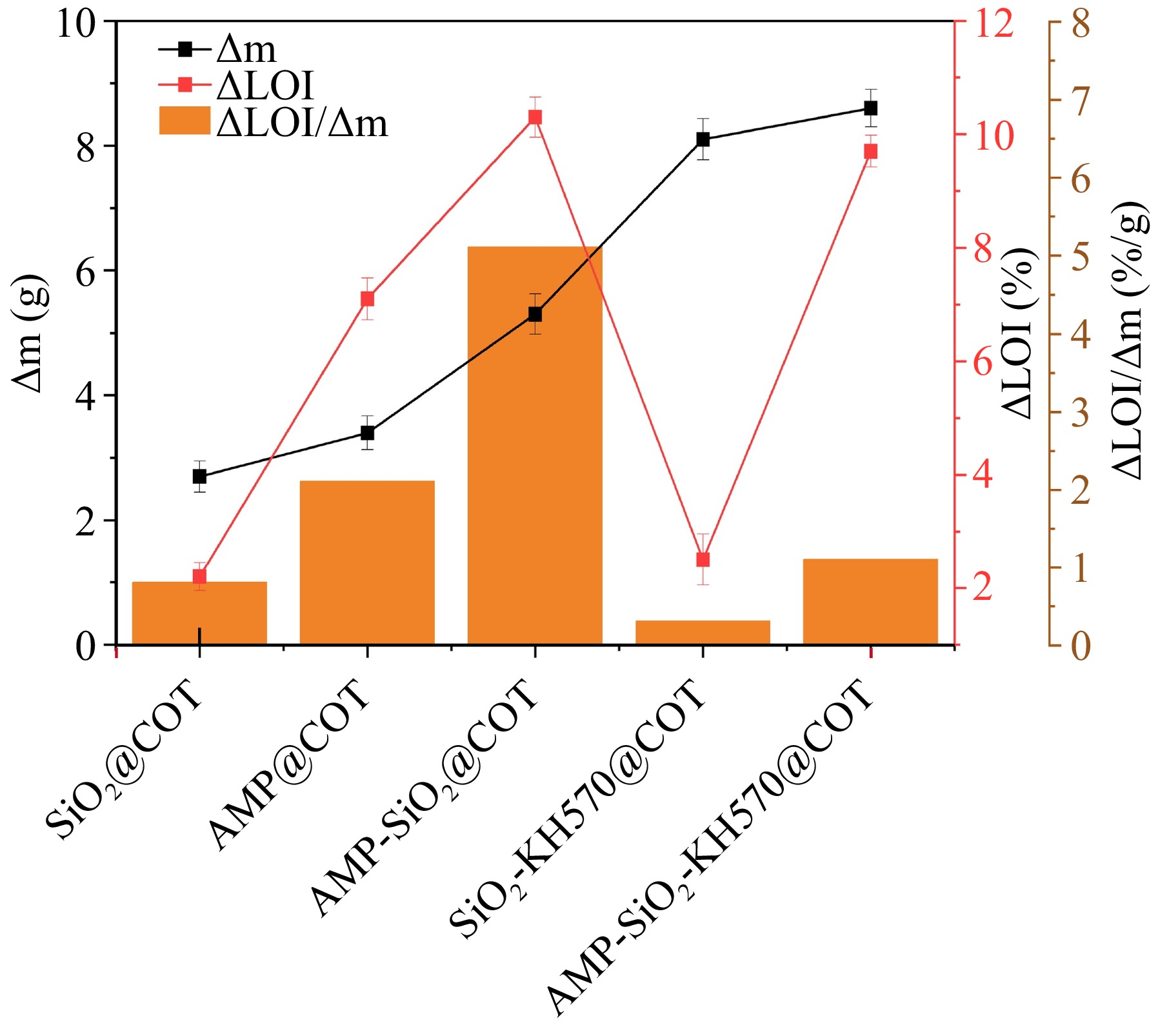

Figure 11.

Δm, ΔLOI, and the ratio ΔLOI/Δm of raw and treated cotton fabrics.

-

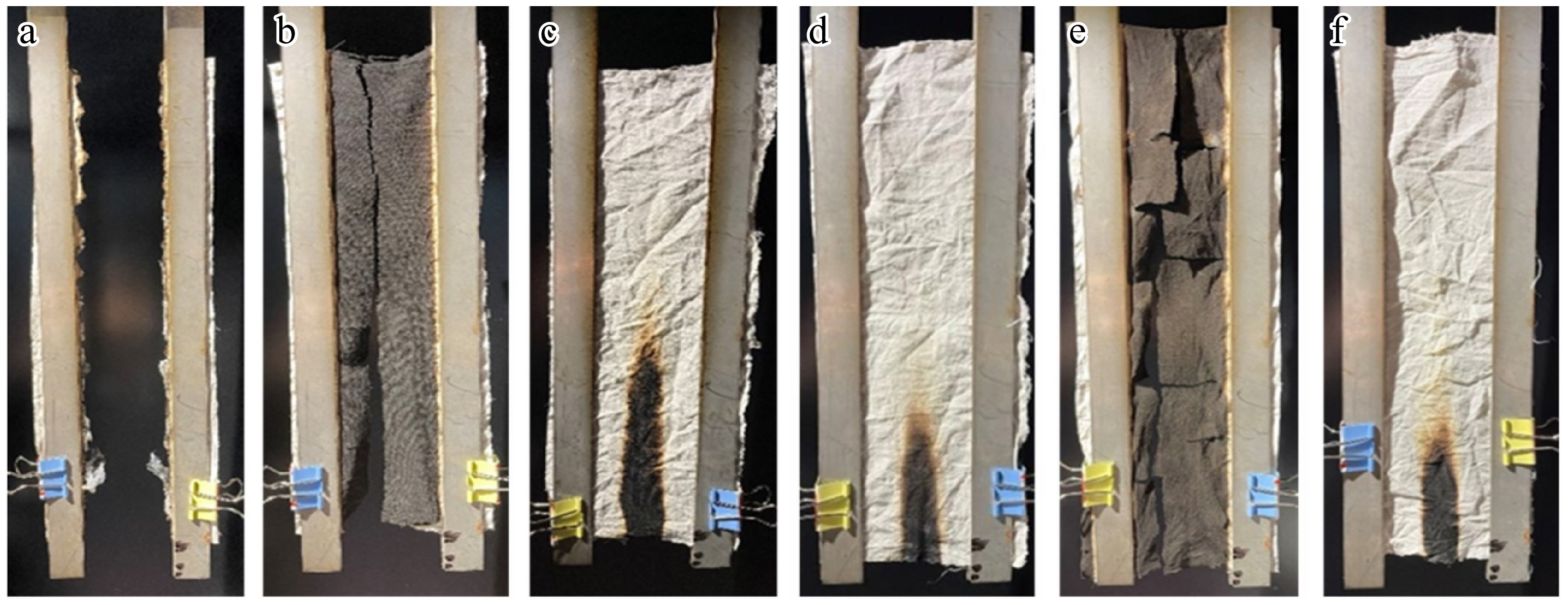

Figure 12.

VFT results of (a) COT, (b) SiO2@COT, (c) AMP@COT, (d) AMP-SiO2@COT, (e) SiO2-KH570@COT, (f) AMP-SiO2-KH570@COT.

-

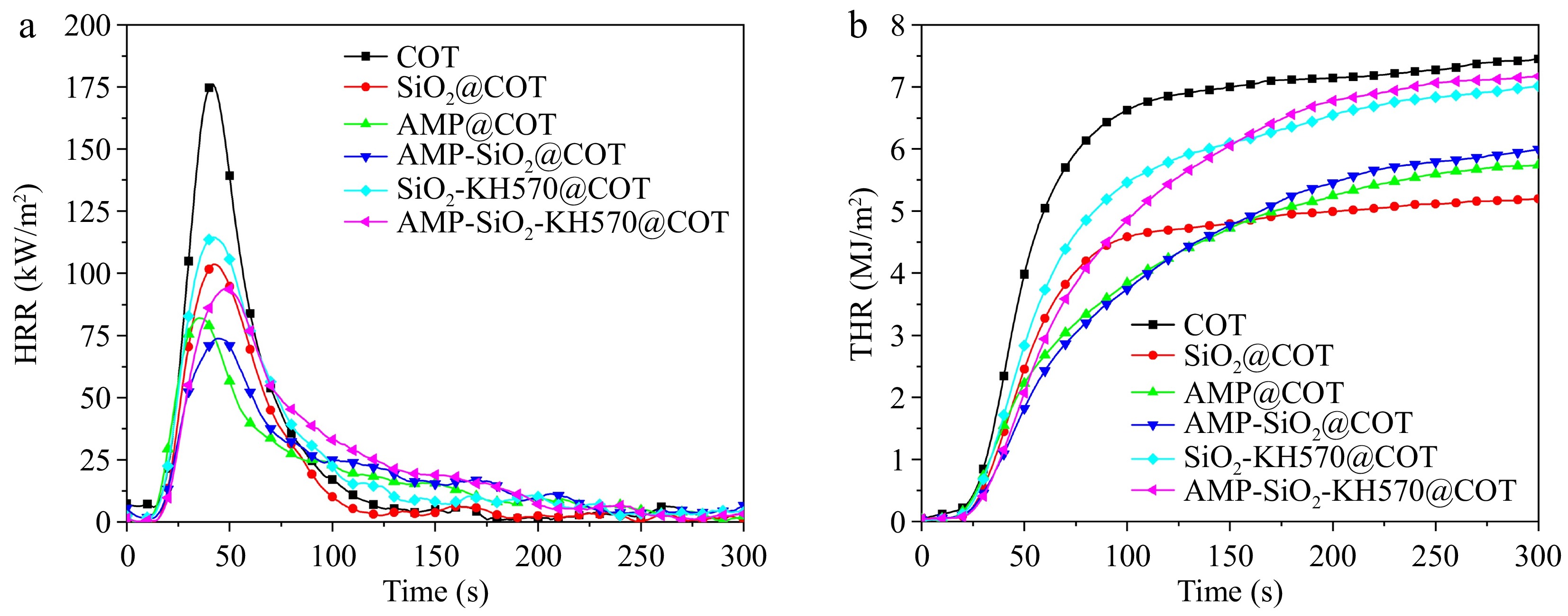

Figure 13.

Relationship between (a) HRR, (b) THR, and time for raw and treated cotton fabrics.

-

Figure 14.

CCT photos of raw and treated cotton fabrics. (a) COT, (b) SiO2@COT, (c) AMP@COT, (d) AMP-SiO2@COT, (e) SiO2-KH570@COT, (f) AMP-SiO2-KH570@COT.

-

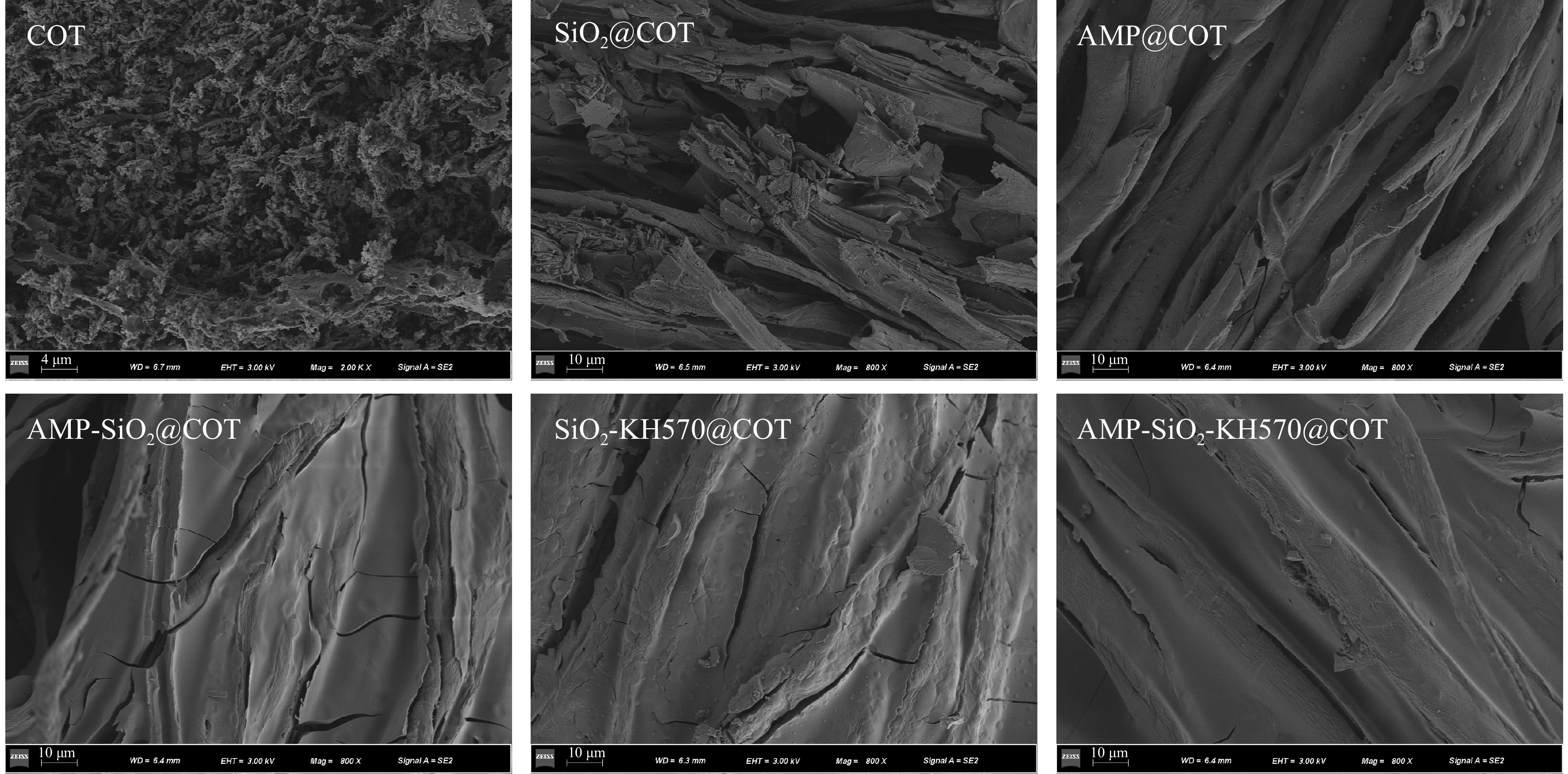

Figure 15.

SEM images of char residues after VFT.

-

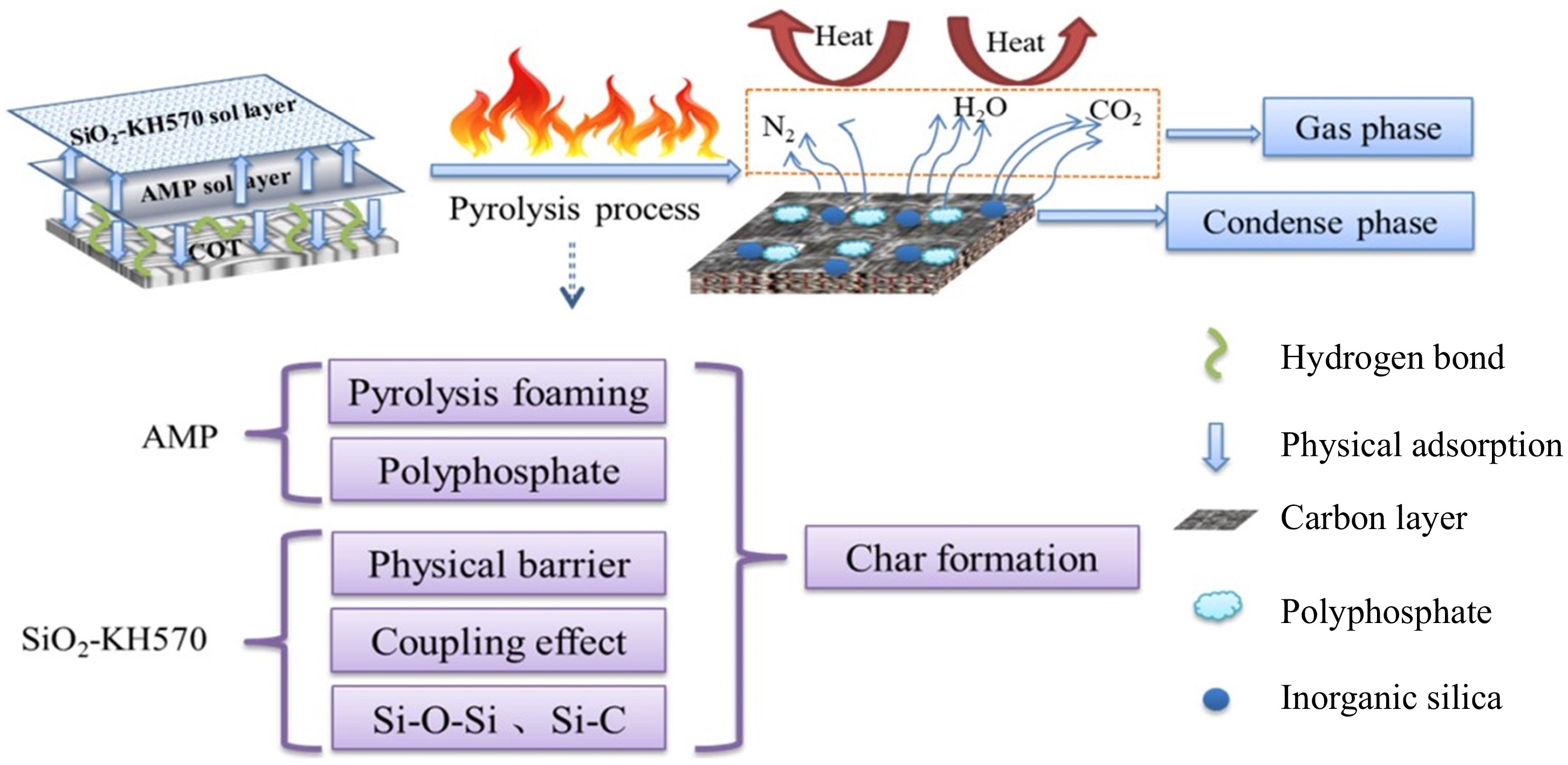

Figure 16.

The flame retardancy mechanism of AMP-SiO2-KH570@COT.

-

Substance TEOS KH570 AMP Structure

Table 1.

The molecular structures: TEOS, KH570, and AMP.

-

Sample WGR

(%)T10%

(°C)Tmax

(°C)Rmax

(%/°C)Char residue rate (%) COT − 327.5 371.2 2.4 7.5 SiO2@COT 28.3 284.3 353.3 1.3 40.3 AMP@COT 35.0 262.1 339.6 0.7 39.7 AMP-SiO2@COT 54.4 288.2 340.7 0.7 49.8 SiO2−KH570@COT 83.8 304.7 357.2 1.0 41.1 AMP-SiO2−KH570@COT 89.5 277.2 340.6 0.6 49.1 Table 2.

Main pyrolysis data of raw and treated cotton fabrics.

-

Sample LOI (%) ΔLOI (%) Δm (g) ΔLOI/Δm (%/g) Flammability level T1 (s) T2 (s) CL (cm) COT 18.0 − − − Inflammable 7.5 15.0 30.0 SiO2@COT 20.2 2.2 2.7 0.8 Inflammable 23.0 0.7 30.0 AMP@COT 25.1 7.1 3.4 2.1 Combustible 3.8 0 14.6 AMP-SiO2@COT 28.3 10.3 5.3 5.1 Non-flammable 3.0 0 8.9 SiO2−KH570@COT 20.5 2.5 8.1 0.3 Inflammable 14.7 1.2 30.0 AMP-SiO2−KH570@COT 27.7 9.7 8.6 1.1 Non-flammable 2.2 0 8.2 Table 3.

LOI and VFT data of raw and treated cotton fabrics.

-

Sample TTI

(s)PHRR

(kW/m2)TPHRR

(s)THR

(MJ/m2)FGR

(kW/(m2s)COT 7.0 183.1 36.0 7.5 5.1 SiO2@COT 8.0 104.2 36.0 5.2 2.9 AMP@COT 6.0 83.6 30.0 5.7 2.8 AMP-SiO2@COT 8.0 75.2 37.0 6.0 2.0 SiO2-KH570@COT 7.0 115.4 36.0 7.0 3.2 AMP-SiO2-KH570@COT 8.0 94.3 43.0 7.2 2.2 Table 4.

CCT data of raw and treated cotton fabrics.

Figures

(16)

Tables

(4)