-

Industrial hemp was first brought to North America in 1606, and its first colonial-era use was in 1632 in Virginia. Farmers were legally obligated to plant hemp as a staple crop throughout the 17th and 18th centuries[1]. Cannabis (including hemp) was taxed under the Marijuana Tax Act of 1937, resulting in a severe decline in hemp production. Also, concern over its psychotropic properties resulted in the crop's effective prohibition in 1970 under the controlled substance act. The decline in fiber needs along with competition from other fiber sources, drastically decreased hemp's demand during much of the 20th century[2]. The Agricultural Act of 2014 reestablished industrial hemp in the United States (US) after a gap of almost 45 years[3]. According to state pilot projects, the US planted 36,422 ha of industrial hemp in 2018, which is the largest since 1943 when 59,165 ha were planted[4]. The total hemp produced in open fields and protected structures in the US is valued at $824 million in 2021[5]. Although the US hemp industry has swiftly expanded in terms of participation and is now legal in nearly all states, the future of industrial hemp remains uncertain. Being a new crop in the US, there is a lack of production guidelines, good quality seeds, and cultivars. Additionally, factors such as competition from conventional crops and marijuana (in states where it is legal), international competitors, and continued market development are impacting the long-term economic feasibility of hemp in the US[3].

Cross-pollinating hemp is an annual crop that produces substantial biomass over the growing season[6]. In addition to agriculture, it has many agro-industrial applications in the field of construction, textiles, bio-composites, paper, automotive, biofuel, functional foods, biodiesel, cosmetics, personal care products, and pharmaceutical products[7]. It can serve as a natural insect repellent[8], a weed retardant[9,10], and a pathogen inhibitor[11]. It can reduce greenhouse gas emissions by binding approximately 2.5 tons of CO2 per ha[12]. Hemp cultivation has been reported to improve soil quality and have an intrinsic capacity for phytoremediation and remediating land polluted by heavy metals[13−15]. Hemp has a deep root system and the depth of the roots in the soil ranges from 45 to 90 cm. In comparison to plants with shallow root systems, deep-rooting plants like hemp are more effective in removing widespread contamination while simultaneously aerating the soil, creating soil aggregates, and reducing erosion.

Despite growing interest in hemp adoption, its production in the US remains restricted due to undefined agronomic specifications and inadequate fertilization recommendations[16]. Due to a lack of basic data for decision-making, farmers who were interested in growing hemp in 2020, had to work out several logistical challenges to overcome. These included finding a good quality seed and cultivars that will thrive in the area, finding a buyer before investing the acres, and trying to predict the weather conditions for ideal planting and harvesting of the crop[17].

Extending from South Dakota to Texas, the Ogallala aquifer is the primary source of water in the Southern High Plains (SHP) including west Texas. The most recent report from the US Geological Survey estimates that the water level in the Ogallala area decreased by approximately 4.6 m between predevelopment (often before 1950) and 2013[18]. Within 50 years, the entire aquifer is expected to be depleted by 70%[19]. The sustainability of this water resource is crucial to the economy of the region as about 95% of the pumped groundwater is used to irrigate agriculture[20]. Cotton (Gossypium herbaceum) is the main crop in Texas and its water requirement is 2.5 times higher than that of the water demand of hemp per growing season[21]. Notably, it needs 2,041 to 3,401 L of water to produce 1 kg of viable hemp fiber compared to 9,788 to 9,958 L of water to produce 1 kg of cotton fiber. As a result, compared to hemp, cotton uses roughly three times as much water to create 1 kg of finished fiber[21]. There is a need to develop sound and cost-effective remedial strategies and provide a possible substitute crop such as industrial hemp for west Texas that can complement cotton and assist in extending the life of the Ogallala aquifer.

This research aims to assess an alternative crop that could fit well in the declining water situation of the SHP and could be beneficial to growers, stakeholders, and industrialists. Hemp being a new crop requires intensive research to test its adaptability to new environmental conditions, and to determine the best cultivars and management practices for its profitable production. Therefore, multiple experiments were conducted to (1) evaluate the biomass (fiber) productivity potential of several imported hemp cultivars under different planting dates in the semi-arid west Texas, and (2) test the seed germination capacity of hemp cultivars in a range of temperatures using growth chamber.

-

To assess the productivity potentials of several imported hemp cultivars under different planting dates in field conditions.

Experimental site description

-

Field trials were conducted during the summers of 2020 and 2021 at the quaker research farm of Texas Tech University, Lubbock, Texas (latitude 33.6014° and longitude −101.9082°, 992 m above sea level). The study site is a semi-arid region with a mean annual precipitation of 350−550 mm and mean evapotranspiration of 1,500−1,750 mm[22]. The average maximum and minimum temperatures are 23.3 and 7.8 °C, respectively. The soil at the site is Amarillo sandy clay loam (fine-loamy, mixed, superactive, thermic Aridic Paleustoll) and Olton clay loam (fine, mixed, superactive, thermic Aridic Paleustolls)[23]. Soil physical and chemical properties of the study site are summarized in Table 1.

Table 1. Soil physical and chemical properties of the study site in Lubbock, TX, USA

Parameter nutrients and soil characteristics Concentration Organic matter (%) 0.6 Soil pH 7.9 Phosphorous P1 - weak bray (ppm) 26 Phosphorous P2 - strong bray (ppm) 39 Potassium (ppm) > 700 Calcium (ppm) 2,164 Magnesium (ppm) 599 Nitrate (ppm) 26 Cation exchange capacity 17.6 meq/100 g Particle distribution (0-10 cm) Clay (%) 16.72 Sand (%) 73.21 Silt (%) 10.07 Planting material, experimental design, and cultural practices

-

As an initial effort to evaluate the adaptive and productivity potential of some of the imported cultivars under west Texas conditions, we partnered with the Native AgPartners (NAP) in Lubbock, Texas to conduct a pilot study on three cultivars in 2020, and six cultivars in 2021 (Table 2). These cultivars were selected based on their known productivity under a similar agroecological regime as west Texas.

Table 2. List of hemp cultivars with their origin, type of flower and purpose in 2020 and 2021 field trials at Lubbock, TX, USA.

Year Cultivar Region Flower type Purpose 2020 Henola Poland Monoecious Grain Bialobrzeskie Poland Monoecious Fiber, grain Jinma China Dioecious Fiber 2021 Fibranova Italy Dioecious Fiber Carmagnola Selezionata Italy Dioecious Fiber, grain Eletta Campana Italy Dioecious Fiber Yuma China Dioecious Fiber, grain Jinma China Dioecious Fiber Anka Canada Monoecious Fiber, grain The first hemp growing season after its legalization in Texas was in 2020. Due to the COVID-19 pandemic in 2020, which affected the hemp research license process and hemp seed delivery, hemp was only planted on June 16 involving three hemp cultivars − Henola, Bialobrzeskie (B-lab), and Jinma (Table 2). The experiment was conducted using a randomized complete block design (RCBD) with four replications, resulting in a total of 12 plots. In 2021, a blocked split-plot design was used to randomize planting dates (April 26 and May 5) as the main-plot factor and six cultivars - Fibranova, Carmagnola Selezionata, Eletta Campana, Yuma, Jinma, Anka as the sub-plot factor. All treatment combinations were replicated four times, resulting in a total of 48 plots.

The seedbeds were prepared with a tractor-mounted disk plow. The hemp seeds were planted using a four-row planter maintaining a 100 cm spacing between the rows. In 2020, Henola, Jinma and B-Lab were planted using a seed rate of 1,503, 1,887 and 4,255 thousand seeds ha−1, respectively. While in 2021, Fibranova, Eletta campana, Yuma and Jinma had seed rate of 1,467, 1,574, 624 and 857 thousand seeds ha−1 (Table 3). Mechanical weeding was performed as needed. The field was irrigated using a subsurface drip irrigation system laid at a depth of 30 cm under each bed and 100 cm apart. The irrigation application was based on the crop evapotranspiration (ETc) requirement calculated as a product of reference evapotranspiration (ETo) and stage-specific crop coefficients (Kc)[24]. The ETo was computed from the weather data using the Penman-Monteith method[25]. The weather data were recorded by a weather station (Davis Instruments 6152, Wireless Vantage Pro2, Davis Instruments Corporation, Hayward, California, USA) installed near the experimental site. All experimental plots received equal amounts of fertilizer based on the soil test recommendations. The fertilizers were applied through a drip irrigation system at the rate of 27.2 kg N ha−1 and 15.8 kg P ha−1 at 4 weeks after planting in both years.

Table 3. Seed rate, 100-seed weight and stand count of hemp cultivars in 2020 and 2021 at Lubbock, TX, USA.

Year Cultivar Seed rate

(Kg ha−1)100 seed weight (g) Stand count

(plants ha−1)2020 Henola 22.4 1.49 776,000a Bialobrzeskie 61.7 1.45 685,000ab Jinma 61.7 3.27 638,500b 2021 Fibranova 28.02 1.91 158,750b Eletta Campana 28.02 1.78 310,000a Carmagnola Selezionata 28.02 − − Yuma 28.02 4.49 337,500a Jinma 28.02 3.27 361,250a Anka 28.02 − − Data collection

-

Stand count was recorded 21 d after planting (DAP) in 2020 and 2021 by counting plants per 2 m2 area in each plot, and the total plants per hectare were calculated. Plant height was measured at harvesting maturity using a measuring scale from the base to the tip of the plant in 2021 and no height data were collected in 2020. For biomass calculation in both years, a 2 m2 area was harvested from each plot and samples were oven-dried at 70 °C to a constant weight. In 2020, all cultivars were harvested on October 8 (114 DAP). In 2021, based on physiological maturity, Jinma and Yuma for planting 1 were harvested on September 30 (157 DAP), while Eletta Campana and Fibranova were harvested on August 31 (127 DAP). Alternatively for planting 2 in 2021, Jinma and Yuma were harvested on October 13 (161 DAP), and Eletta Campana and Fibranova were harvested on September 16 (134 DAP). Leaf samples were collected for Tetrahydrocannabinol (THC) analysis at the flowering stage from all plots. Growing degree days (GDD) was measured using Eqn. 1 with a base temperature of 1 °C[26]:

$\rm \left[\dfrac{{{T}}_{{max}}\;+\;{{T}}_{{min}}}{{2}}\right]-{{T}}_{{base}} $ (1) Irrigation water use efficiency (IWUE) was calculated using the formula in Eqn. 2:

$ \rm {IWUE}\;=\;\dfrac{{Final\; Biomass \; produced}}{{Total\; water\; usage \;of\; crop}} $ (2) Growth chamber experiment

-

To test seed germination capacity of hemp cultivars in a range of temperatures using a growth chamber.

A germination study was conducted in a growth chamber at Texas Tech University, Lubbock, TX, USA. The germination rate of four hemp cultivars (B-LAB, Carmagnola Selezionata, Henola, and Jinma) was evaluated at six temperatures: 10, 15, 20, 25, 30, and 35 °C during the day. The night temperature was maintained at 5 °C less than the day temperature. At each temperature, four petri plates of each cultivar represented four replications were placed in a split-plot design with temperature as the main-plot factor and cultivars as the sub-plot factor. In an individual petri plate, seed-germinating paper towels were cut according to the dimensions of square plates. A total of 50 seeds were placed between two layers of paper towels on each plate. Before placing seeds in petri plates, seeds were surface sterilized using commercially available Clorox® bleach (Clorox Company, Oakland, CA, USA)[27]. The number of seeds germinated in each petri plate was recorded every day starting 2 d after seed placement and continued until 14 d. A seed was considered germinated when there was a presence of a 2 mm radicle protrusion.

Germination percentage was calculated using Eqn. 3:

$ \rm {Germination }\;{\text %} \;=\;\dfrac{{Final\; number\; of\; seeds\; germinated}}{{Total\; number\; of\; seeds}} $ (3) Speed of germination index (SGI) was evaluated using Eqn. 4 as described by Wardie et al.[28] and mean germination time (MGT) was estimated using Eqn. 5, computed by Ranal & de Santana[29],

$ \text{SGI}=\displaystyle\sum _{\text{i=1}}^{\text{n}}\dfrac{{\text{N}}_{\text{i}}}{{\text{T}}_{\text{i}}} $ (4) $ \text{MGT}=\dfrac{\displaystyle\sum _{\text{i=1}}^{\text{n}}{\text{N}}_{\text{i}}{\text{T}}_{\text{i}}}{\displaystyle\sum _{\text{i=1}}^{\text{n}}{\text{N}}_{\text{i}}} $ (5) Where Ni is number of seeds germinated on the ith day (Ti) and n is the last day of germination observed. The SGI is an extensive measurement that emphasizes variability in germination among cultivars by combining both germination percentage and speed[30]. Mean germination time is the amount of time it takes for seeds in a sample lot to germinate. It has a great influence on determining the speed and uniformity of seedling emergence.

Statistical analysis

-

The field experiment data were analysed using analysis of variance with RCBD in 2020 and split-plot design in 2021 in R version 3.5.2 using Agricolae package version 1.2-8. The growth chamber experiment data were analysed with split-plot designs using the same statistical software. The least significant difference test was used to compare treatment means at a 5% significance level. The figures were prepared using Sigma-Plot software version 14 (Systat Software, San Jose, CA, USA).

-

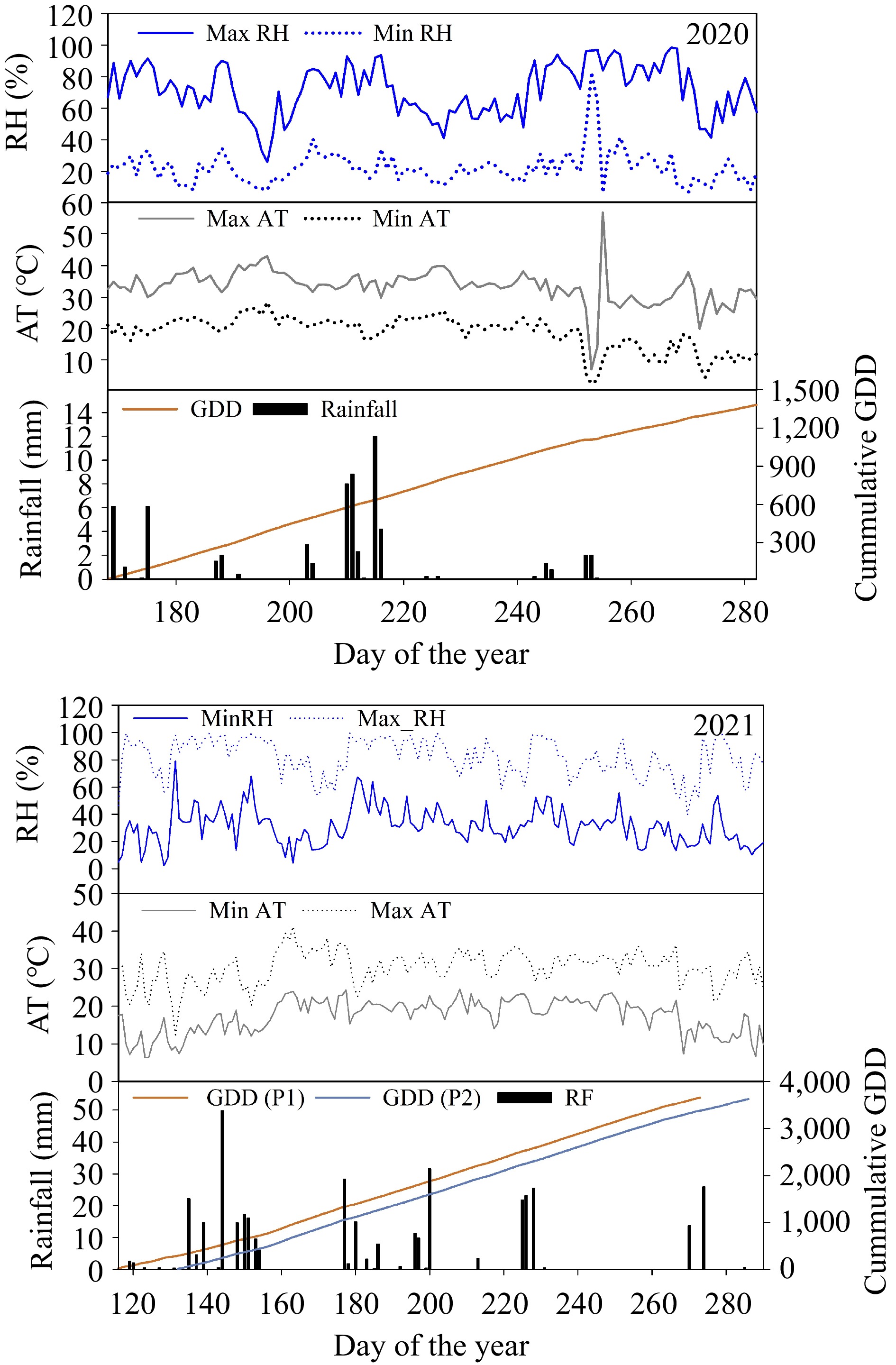

The prevailing weather conditions during the 2020 and 2021 growing seasons are illustrated in Fig. 1. The average relative humidity during 2020 and 2021 was 47% and 57%, respectively. The average temperature during the growing season was 26.0 °C in 2020 and 23.8 °C in 2021. The average maximum and minimum temperatures recorded during the growing seasons were 43 and 2.3 °C in 2020 and 41.2 and 6.3 °C in 2021, respectively. In 2020, the planting week was hotter (26.5 °C) than the planting week of 2021 (Planting 1 − 19.5 °C and Planting 2 − 18.6 °C). Overall, the 2020 growing season was hotter and drier than 2021. The total accumulated rainfall in the 2021 growing season (347.4 mm) was 82% greater than the 2020 growing season (63.6 mm). In 2020, less rainfall was received during the vegetative stage, but more rainfall received after flowering and very little was observed before harvest. The GDD accumulated for all hemp cultivars in 2020 from planting to harvest was 1,382. During 2021, Jinma and Yuma acquired 3,657 GDD during planting 1 and 3,628 GDD during planting 2 which were 697 units and 548 units higher than Eletta Campana and Fibranova, respectively.

Figure 1.

Daily maximum (max) and minimum (min) air temperature (AT), relative humidity (RH), rainfall and cumulative growing degree days (GDD) during the 2020 and 2021 growing seasons in Lubbock, TX, USA.

Stand count

-

In 2020, Henola recorded the highest stand count of 776 thousand plants ha−1, despite having the least seed rate as compared to other cultivars (Table 3). It showed 36% and 18% more survival rates in comparison to B-Lab and Jinma, respectively. Although, B-Lab and Jinma had similar seed rates, but differed in 100 seed weight, with B-Lab having a lighter seed weight of 1.45 g/100 seeds compared to Jinma’s 3.27 g/100 seeds. This resulted in a greater number of seeds for B-Lab and a lower stand count for Jinma, even though both cultivars had similar seed rates.

In 2021, mean stand count from both plantings was presented because of no significant interaction between planting times (Table 3). Jinma, Yuma, and Eletta Campana recorded statistically similar stand counts of 362, 337 and 310 thousand plants ha−1, but significantly greater than Fibranova (Table 3). Fibranova observed 56% fewer plants compared to Jinma. The lower survival rate of Eletta Campana and Fibranova can be explained by the occurrence of self-thinning as both had nearly 2.5 times more seeds planted than Yuma due to less seed weight. Amaducci et al.[31]reported a loss of initial stand by 50% and 60% at high plant density treatments of 180 and 270 plants m−2, respectively. Van der Werf et al.[32] found that self-thinning resulted in plant mortality at densities of 90 and 270 plants m−2 with reductions in stand count of 24% and 59%, respectively. It was determined that interplant competition caused mortality due to self-thinning[33]. Carmagnola Selezionata and Anka failed to germinate in 2021, which leads to further research for examining their correct planting time and density.

Plant height

-

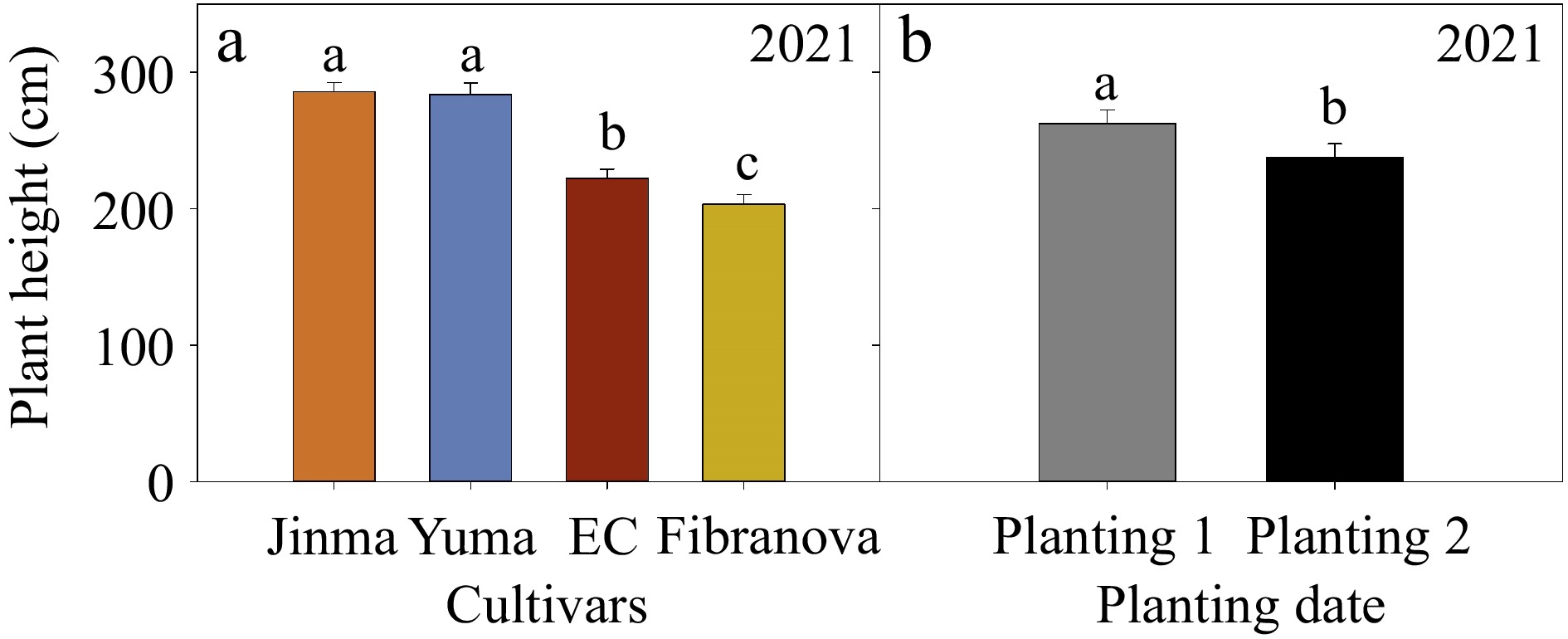

Plant height was not recorded in 2020 but through visual observation, Jinma had the highest height, followed by B-lab and Henola. The height difference was noticed due to different flowering times of July 8, July 10, and July 23 for Henola, B-lab, and Jinma, respectively. In 2021, plant height varied significantly among cultivars, ranging between 202 cm (Fibranova) and 286 cm (Jinma), despite having the same growing conditions (Fig. 2a). Jinma and Yuma recorded similar heights but significantly greater than other cultivars. On the other hand, Fibranova being the shortest among all was 29% shorter than Jinma. Eletta Campana was better than Fibranova and observed an average of 21 cm higher height than Fibranova. Between planting times, late planting demonstrated an average decrease of 28 cm in plant height (Fig. 2b). The reason could be that the shorter day length in late planting might have led to early flowering and reduced vegetative growth. Pre-flowering with corresponding gradual abatement in hemp stem elongation was also observed by Van der Werf[26] in late planting. Similar results were observed by Sengloung et al.[34] where earlier planting led to a longer vegetative growth period, resulted in a longer hemp plant stem, and late planting reduced plant height. Similarly, Sleiman et al.[35] reported that mid-April planting had 1.5 times taller hemp plants than the planting in mid-May. Zhang et al.[36] observed that in comparison to a 12-h day length, hemp plant height extension growth (after flowering) was 47%−102% higher under a 14-h day length in essential oil cultivars but photoperiod had no effect on fiber/grain cultivars for the growth after flowering. This is also found by Hoppner et al.[37] that the length of the vegetative phase has a positive relationship with hemp stem length.

Figure 2.

Plant height of hemp cultivars in 2021 at Lubbock, TX, USA. Bars with same letters indicate no significant differences between treatments according to the least significant difference test at p ≤ 0.05. EC: Eletta Campana.

Plant biomass and irrigation water use efficiency

-

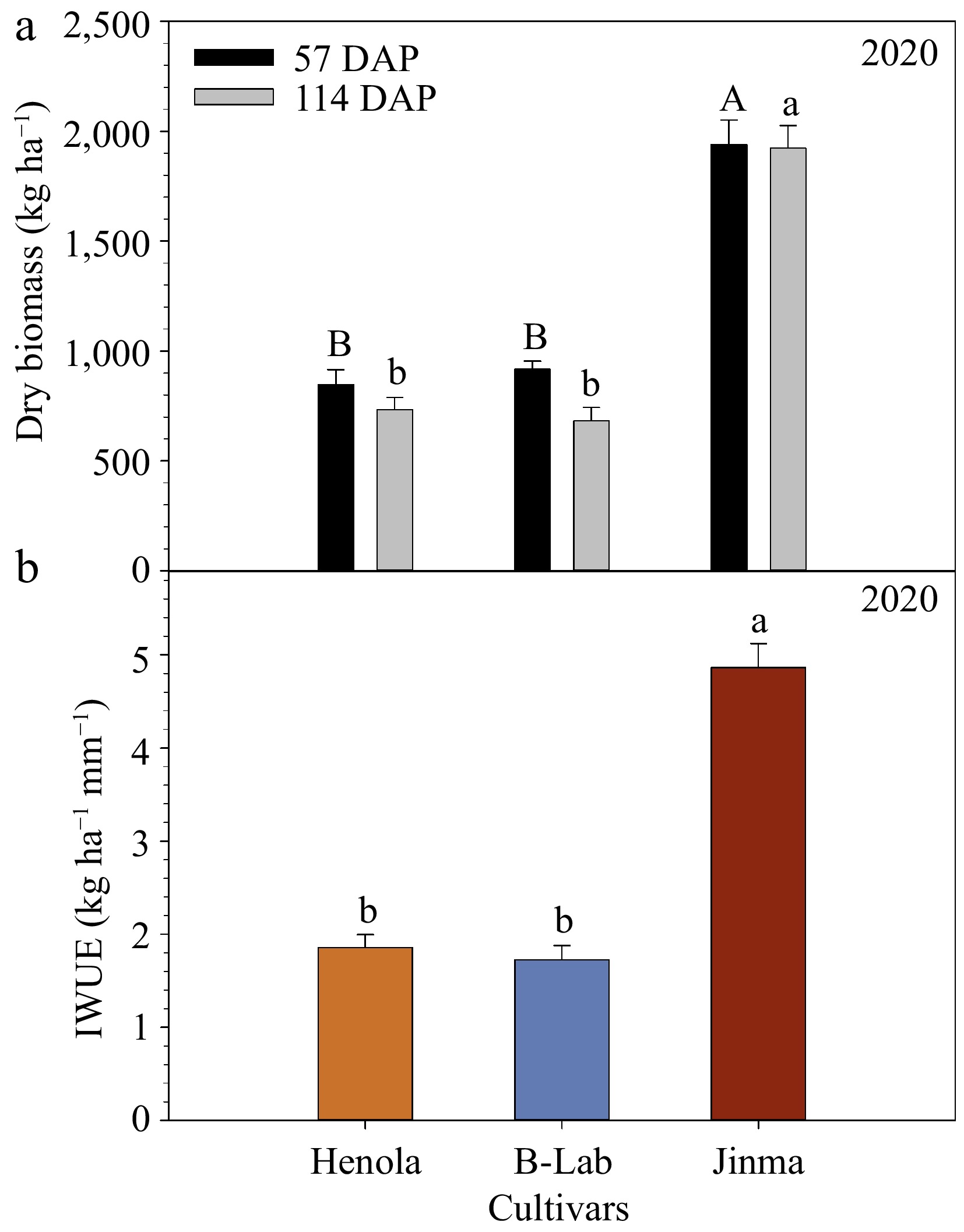

In 2020, plant biomass followed the opposite trend as of stand count. Jinma recorded the highest plant biomass which was 53% and 56% higher than the plant biomass observed for B-lab and Henola at 57 DAP (Fig. 3a). Due to senescence, a decrease in biomass was seen at 114 DAP compared to 57 DAP, and the highest reduction was noticed for B-lab which was 26%, followed by Henola (13%) and Jinma (0.88%). Genotypic variation and different flowering periods of cultivars could be the reason of discrepancy in biomass production among them. In particular, the onset of flowering was two weeks later in Jinma than in Henola and B-Lab. Compared to the other cultivars, Jinma's prolonged flowering period caused a longer vegetative growth phase, which ultimately resulted in a larger biomass accumulation. An early seasonal transition to flowering and reduced vegetative development as a result of relatively short days ultimately limit stem elongation and biomass yield[9,38]. Additional, hemp has a high level of heterogeneity. This is largely due to sexual dimorphism, which results in significant disparities in the rates of growth and development between male and female plants. Male plants blossom and senesce earlier than female plants. Intraspecific competition creates a size hierarchy and consequently increases diversity. This fluctuation may limit yields, diminish resource efficiency, and result in inconsistent quality[39]. While significant differences in biomass yield were detected across the three cultivars, none achieved their full potential as recorded under the conditions in China and Poland. The possible reason for the low biomass yield for all the cultivars could be the very late planting of hemp in 2020, which again supports the need for research to define the optimum planting time of hemp in west Texas.

Figure 3.

(a) Plant dry biomass [at 57 and 114 d after planting (DAP)] and (b) irrigation water use efficiency - IWUE of different hemp cultivars at Lubbock, TX, USA in 2020. Bars with same letters indicate no significant differences between treatments according to the least significant difference test at p ≤ 0.05. B-Lab: Bialobrzeskie.

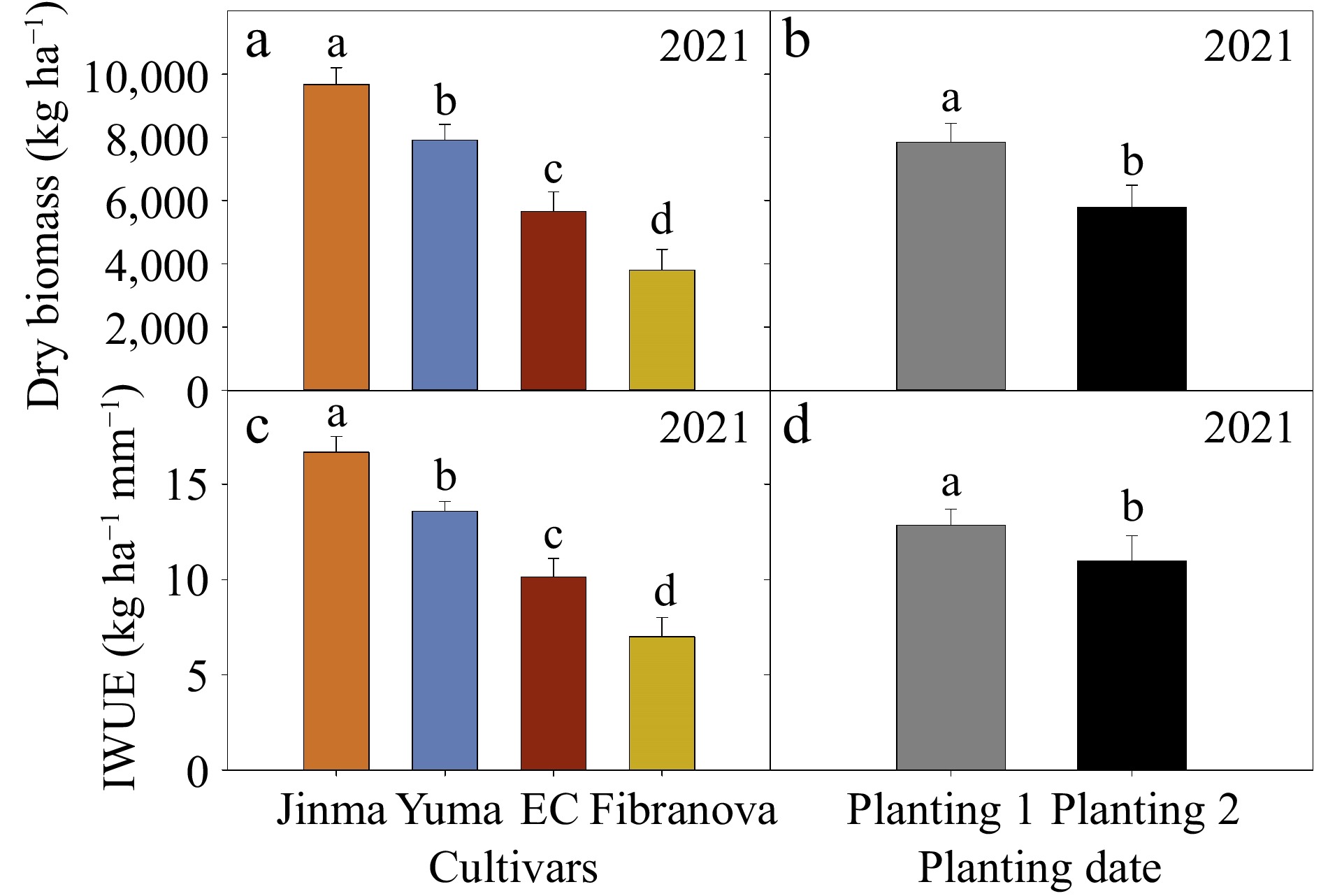

In 2021, the highest plant biomass was recorded for Jinma, followed by Yuma, Eletta Campana, and Fibranova (Fig. 4a). The plant biomass results corresponded with the stand count and plant height data, which followed the same decreasing trend as that of plant biomass. Jinma had the highest plant height as well as stand count against other cultivars, which ultimately led to higher biomass production. Jinma recorded 9,669 kg ha−1 of biomass which was 18% and 42% higher than Yuma and Eletta campana, respectively, and 2.5 times higher biomass production than Fibranova. The results show that planting 2 had seen an abatement of 2,060 kg ha−1 in biomass as compared to planting 1 (Fig. 4b).

Figure 4.

Plant dry biomass and irrigation water use efficiency (IWUE) of hemp cultivars in 2021 at Lubbock, TX, USA. Bars with same letters indicate no significant differences between treatments according to the least significant difference test at p ≤ 0.05.

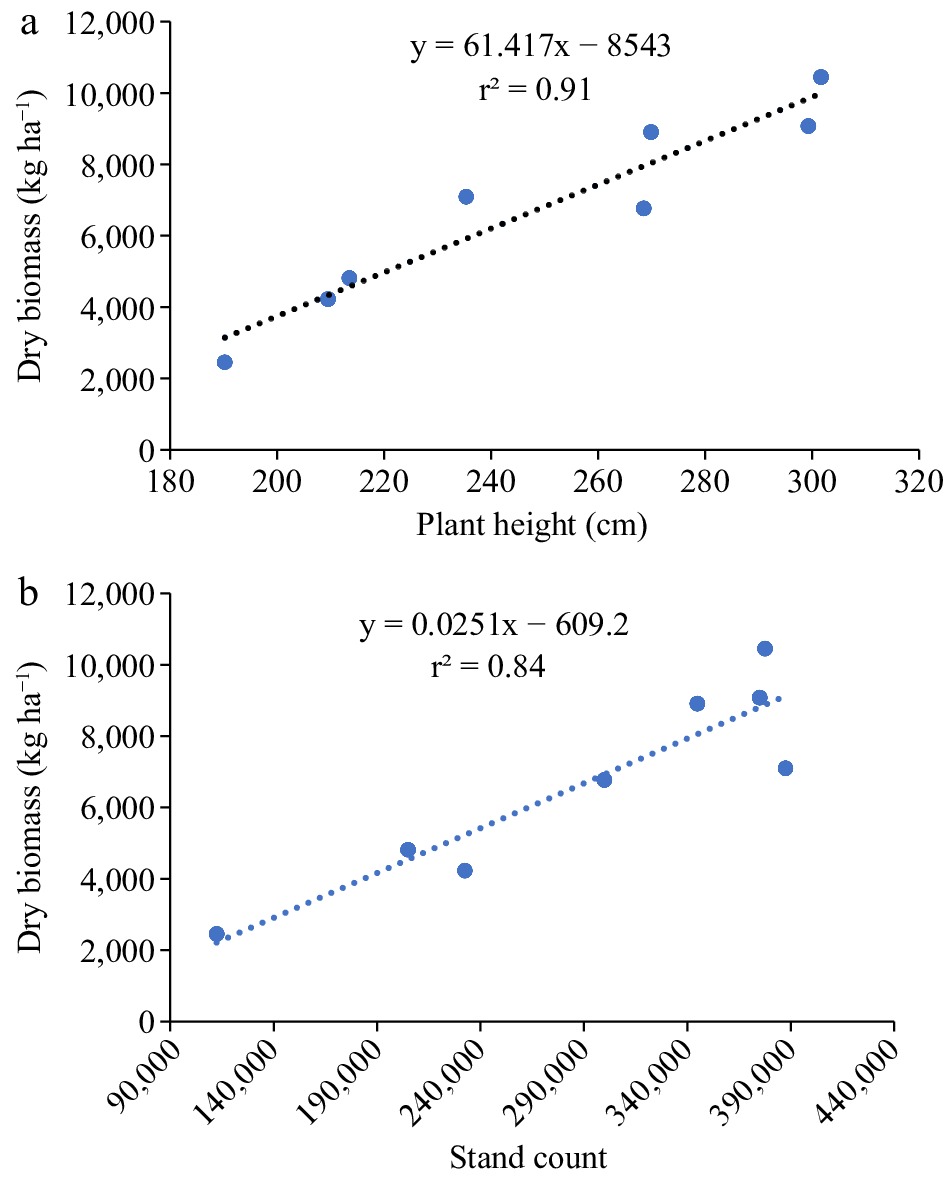

Despite having a 43% lower stand count in 2021 than in 2020, plant biomass for Jinma showed a five fold increase in 2021 compared to 2020. Early planting resulted in a large height in 2021 compensating for stand count and accounting for higher biomass accumulation. Jinma and Yuma had THC level greater than 0.3% of the dry weight, in contrast to observed THC level of other cultivars. Sandhu et al.[40] observed that in the tropical and subtropical regions, early planting (April) resulted in more hemp plant growth and biomass production than late planting (June). Darby et al.[41] also noted that early planting produced 22% higher plant weight than later planting. This decrease in biomass occurs due to photoperiodism as hemp is a short-day plant. This behaviour affects crop biomass yield because the efficiency with which absorbed radiation is converted to dry matter decreases significantly once flowering begins[26]. Zhang et al.[36] reported that certain cultivars' floral initiation can be affected by changes as minor as a 15-min photoperiod difference, highlighting the value of screening cultivars for photoperiod requirements before introducing them to any agroclimatic location. An analysis of the biomass with stand count and plant height showed that they are closely correlated (Fig. 5). The plant height contributes more than the stand count to the final biomass production, as shown by the comparison of the r2 = 0.91 for biomass and plant height (Fig. 5a) and r2 = 0.84 for biomass and stand count (Fig. 5b). This suggests that plant height could be used as an indicator of increased biomass production of industrial hemp. In contrast, Campbell et al.[42] found that biomass was more correlated to stand count (r = 0.63, p-value = 5.29 × 10−5) than plant height (r = 0.58, p-value = 2.48 × 10−4), reporting that biomass production increased in plots where more plants emerged and survived. Aubin et al.[43] also observed a positive correlation (r = 0.55; p < 0.001) between plant height and biomass yield.

Figure 5.

Relationship of biomass with (a) plant height and with (b) stand count during 2021 growing season in Lubbock, TX, USA.

Results for IWUE followed the same decreasing trend as of plant biomass among the cultivars in 2020 and 2021 as similar water was applied to all the cultivars. Jinma was the most water-efficient cultivar in both years. In 2020, Jinma consumed 2.6 times and 2.8 times less water per kg biomass produced in comparison with Henola and B-Lab (Fig. 3b). In 2021, Jinma was 19%, 36%, and 58% more water-efficient than Yuma, Eletta Campana, and Fibranova, respectively (Fig. 4c). Planting 1 recorded 22% higher IWUE than planting 2 (Fig. 4d). These outcomes are similar to research of Tejero et al.[44], which showed that cannabis cultivars cultivated in April had greater biometrics, productive traits, and water use efficiency (WUE) than later planting dates. Sleiman et al.[35] also reported that the highest values of WUE for hemp were recorded for early planting of mid-April which were 2.5 folds higher than mid-May planting.

Growth chamber experiment

Germination percentage

-

Germination results showed non-significant differences in germination percentage from 10 to 30 °C; however, a 20% decline in germination was observed at 35 °C in comparison to 30 °C (Table 4). This indicates that hemp seed germination is not as sensitive to low temperature as much as to high temperature. This finding is also supported by our field study where Jinma was the common cultivar in years 2020 and 2021. In 2020, the average day temperature for seven days after planting was 33.3 °C and the germination percentage of Jinma was 34% (based on seed rate and stand count – Table 3). In 2021, plantings had an average temperature of 25.6 °C that increased the germination of Jinma to 42%. The best temperature range (10−30 °C) for hemp seed germination tested in this growth chamber study is comparable to the April-May planting window in the High plains, which could be the optimum time of hemp planting in the region. Among cultivars, B-Lab, Carmagnola Selezionata, and Henola performed similar to each other at different temperature regimes. However, Jinma had the lowest germination, which was almost 50% lower than the other cultivars.

Table 4. Effect of temperature on germination percentage across four cultivars of industrial hemp at Lubbock, TX, USA.

Germination % Temperature (day/night) (T) 10/5 °C 64.8a 15/10 °C 64.4a 20/15 °C 66.0a 25/20 °C 66.9a 30/25 °C 66.7a 35/30 °C 47.8b Cultivar (C) BLAB 70.61a Carmagnola Selezionata 74.57a Henola 71.94a Jinma 33.91b T × C NS 'T × C' indicates temperature into cultivar interaction and 'NS' indicates non-significant at p ≤ 0.05. Mean values followed by the same letter in each column within a factor are not significantly different according to the least significant difference test at p ≤ 0.05. Geneve et al.[45] found that between 19 and 30 °C, the hemp seed germination rate and percentage were maximum. Similarly, Qin et al.[46] discovered that germination percentage and rate were the highest between 20 and 25 °C. In this study, the highest temperature was 35 °C, where germination decreased to 48%. Germination levels of less than 15% were recorded at 40 °C by Byrd[47]. On the contrary, Lisson et al.[48] reported good but declining germination (by 40%) at 40 °C and continued to see germination at 18% when the temperature was increased to 54 °C when working with 'Kompolti' hemp. The maximum high-temperature threshold in these studies was different from 35, 40, and > 50 °C. These discrepancies are difficult to explain except for the probability that hemp germination is cultivar-dependent[45]. According to Byrd's research[47], southern European hemp lines exhibited better germination at temperatures over 30 °C than northern European and Canadian hemp lines.

Speed of germination index (SGI)

-

The speed of germination index was significantly affected by temperature, cultivar, and temperature × cultivar interaction treatments (Table 5). Averaged over cultivars, SGI was the highest at 30 °C, which was 9% and 25% higher than what was noticed at 25 and 20 °C, respectively. The SGI was less at lower temperatures and increased with increasing temperature until 30 °C, and then further decreased by 43% at 35 °C. Heat stress from high temperatures might impair the viability and speed of germination of the seeds as it causes the moisture in the seed to evaporate more quickly, which could cause desiccation and have a negative impact on germination rates. This indicates that hemp seeds will germinate more quickly when there is a rise in temperature. A similar study was conducted by Singh et al.[30] and Hu et al.[49], who found that guar (Cyamopsis tetragonoloba [L.] Taub.) seeds germinate most rapidly at 27−28 °C. Overall, Henola and Carmagnola Selezionata observed the highest SGI across all the temperatures in comparison with other cultivars. Henola and B-Lab did not differ significantly in SGI. Jinma on the other hand, recorded three-fold lower germination rate than Carmagnola Selezionata. The germination rates of different hemp cultivars vary noticeably, according to this observation, pointing to clear distinctions between them. Breeders can make use of this insightful data to improve the quality of hemp germplasm through selective breeding.

Table 5. Interaction effects of temperature and cultivar on speed of germination index of four hemp cultivars grown in a growth chamber at temperature range of 10−35 °C at Lubbock, TX, USA.

Cultivars Speed of germination index (day−1) 10 °C 15 °C 20 °C 25 °C 30 °C 35 °C Average Jinma 1.96cA 1.82bA 3.74bA 3.08cA 3.97cA 2.17bA 2.82c Henola 5.91abC 6.50aBC 7.02abB 10.37aA 10.88aA 4.17abD 7.70ab B-Lab 4.81bC 6.85aABC 8.07aAB 8.18bAB 8.59bA 6.39aBC 7.16b CS 6.67aB 6.27aB 7.31aB 9.99abA 11.48aA 7.04aB 8.31a Average 4.84D 5.36D 6.54C 7.91B 8.73A 4.94D Values within a column followed by same lowercase letters are not significantly different at p ≤ 0.05. Values within a row followed by same uppercase letters are not significantly different at p ≤ 0.05. B-Lab: Bialobrzeskie, CS: Carmagnola Selezionata. Temperature and cultivar showed a strong interaction for SGI (p < 0.001). All cultivars performed better at 30 °C compared to other temperatures. Jinma had the lowest speed of germination among the cultivars at all temperatures studied and showed no significant difference at different temperature ranges. The temperature range for optimum germination rate in B-Lab ranged from 15−30 °C. Henola and Carmagnola Selezionata obtained higher SGI in a temperature range of 25−30 °C compared to other temperatures. Further 5 °C increase to 35 °C reduces the germination rate by 62% and 39% in Henola and Carmagnola Selezionata, respectively. Also lowering 5 °C below this temperature range (25−30 °C) led to a reduction in SGI by 1.5 times for the cultivars. Low temperatures may cause seed’s metabolic activity to slow down, delaying the germination process. Additionally, the enzyme processes that break down the stored nutrients in the seed may proceed more slowly at lower temperatures, delaying the germination process.

Mean germination time (MGT)

-

A gradual decrease in MGT with an increase in temperature was observed from 10 to 35 °C (Table 6), indicating that higher temperature promotes faster germination. Across different cultivars, the time required for hemp to reach maximum germination percentage at 10 °C extended beyond 5 d, whereas it significantly reduced to a mere 3 d at 35 °C. This temperature effect on the time for seed germination was also observed by Gresta et al.[50] in guar under Mediterranean conditions, where germination time was reduced with increase in temperature. Pooled over temperatures, the highest MGT was detected in Jinma which was nearly 5 d. This was followed by B-Lab, Henola, and Carmagnola Selezionata. This indicates the diversity in MGT among hemp cultivars, and it may be useful information given that a delay in germination increases the risk of damage from predators, diseases, etc., decreasing the uniformity of plant stand[51].

Table 6. Interaction effects of temperature and cultivar on mean germination time of four hemp cultivars grown in a growth chamber at temperature range of 10−35 °C at Lubbock, TX, USA.

Cultivars Mean germination time (d) 10 °C 15 °C 20 °C 25 °C 30 °C 35 °C Average Jinma 7.10aA 7.15aA 5.18aB 5.07aB 3.20aC 2.92aC 5.10a Henola 4.73bA 4.78bA 3.61bB 2.78bC 2.57aC 2.62aC 3.49bc B-Lab 5.78abA 4.03cB 3.89bBC 3.75bBC 2.83aC 2.89aBC 3.90b CS 4.46bA 4.15bcA 3.71bAB 2.91bBC 2.66aC 2.73aC 3.42c Average 5.52A 5.02A 4.09B 3.63B 2.82C 2.79C Values within a column followed by same lowercase letters are not significantly different at p ≤ 0.05. Values within a row followed by same uppercase letters are not significantly different at p ≤ 0.05. B-Lab: Bialobrzeskie, CS: Carmagnola Selezionata. Jinma recorded the highest MGT among all cultivars at all temperatures ranging from 10 to 35 °C. At 20 and 25 °C, Henola, B-Lab, and Carmagnola Selezionata showed no significant difference in their germination time. In contrast, at higher temperatures (30 and 35 °C), all cultivars took a similar time for their germination. The largest difference in MGT at 10 and 30 °C was observed in Jinma for about 4 d and the least was noted of 2 d for Carmagnola Selezionata. At 10 and 15 °C, the highest MGT was recorded for Jinma, Henola, and Carmagnola Selezionata, while B-Lab reduced germination time by 30% at 15 °C as compared to 10 °C. For the cultivation of industrial hemp, it is essential to optimize temperature management during the germination stage. These findings can be used by farmers to modify their germination procedures, ensuring the provision of suitable temperature conditions for quick and effective seedling emergence.

-

Jinma, Yuma, and Eletta Campana performed substantially better in field compared to other cultivars. However, Jinma and Yuma resulted in high THC content when the flowers were measured at harvesting. Therefore, Eletta Campana has the potential to emerge as the adaptable variety for the west Texas region. Early planting (April) outperformed over late planting (May) in terms of biomass, plant height, and IWUE, demonstrating the importance of timely planting as a crucial factor for optimal crop growth and development. The germination experiment suggests that the optimal conditions for germination were observed at 30 °C, demonstrating maximum germination percentage, faster germination speed, and reduced mean germination time. The findings imply that cultivar choice and planting time can significantly affect industrial hemp productivity.

-

The authors confirm contribution to the paper as follows: conceptualization: Singh S, Saini R; methodology: Singh M, Kafle A, Parkash V; analysis: Bajwa P, Singh M, Parkash V; resources: Saini R, Singh S; data collection and curation: Singh M, Parkash V, Bajwa P, Kafle A; writing - original draft preparation: Bajwa P; review and editing: Singh M, Saini R, Singh S, Bajwa P; Supervision: Singh S. All authors reviewed the results and approved the final version of the manuscript.

-

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Partial funding for this project from Native AgPartners (Escondido Minerals LP) and Texas Hemp Growers Association is much appreciated. We would like to thank Department of Plant and Soil Science, Texas Tech University for their assistance in this study. The authors also acknowledge Gary Pelletier, Nelson Mora, and Lelton Howell and his crew for their assistance in the fieldwork.

-

The authors declare that they have no conflict of interest.

- Copyright: © 2023 by the author(s). Published by Maximum Academic Press, Fayetteville, GA. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Bajwa P, Singh S, Singh M, Kafle A, Parkash V, et al. 2023. Assessing the production potential of industrial hemp in the semi-arid west Texas. Technology in Agronomy 3:17 doi: 10.48130/TIA-2023-0017

Assessing the production potential of industrial hemp in the semi-arid west Texas

- Received: 08 October 2023

- Accepted: 20 November 2023

- Published online: 08 December 2023

Abstract: Industrial hemp (Cannabis sativa L.) is a water-efficient crop that could fit in the declining water situation of West Texas. However, being a new crop, there is a lack of knowledge about hemp cultivation practices. Therefore, multiple experiments were conducted at Quaker Research Farm of Texas Tech University to (1) evaluate the biomass productivity potential of several imported hemp cultivars under different planting dates in field conditions, and (2) test the seed germination capacity of hemp cultivars in a range of temperatures using a growth chamber. In the field, the highest biomass yield was recorded for Jinma in 2020, which was almost 180% higher than the average biomass of two other cultivars. In 2021, early planting observed higher plant biomass, plant height, and irrigation water use efficiency compared to late planting. The highest biomass was recorded for Jinma, followed by Yuma, Eletta Campana, and Fibranova in 2021. Jinma and Yuma resulted in high Tetrahydrocannabinol content at harvesting. In the growth chamber study, percentage germination remained similar from 10 to 30 °C, but it decreased by 28% at 35 °C compared to 30 °C. The speed of germination was higher at 30 °C compared to other temperatures. The mean germination time was recorded the highest at 10−15 °C, and in Jinma among cultivars. Results indicate that Eletta campana with early planting could be more productive in West Texas. Overall, hemp germination was more sensitive to high temperatures compared to low temperatures.