-

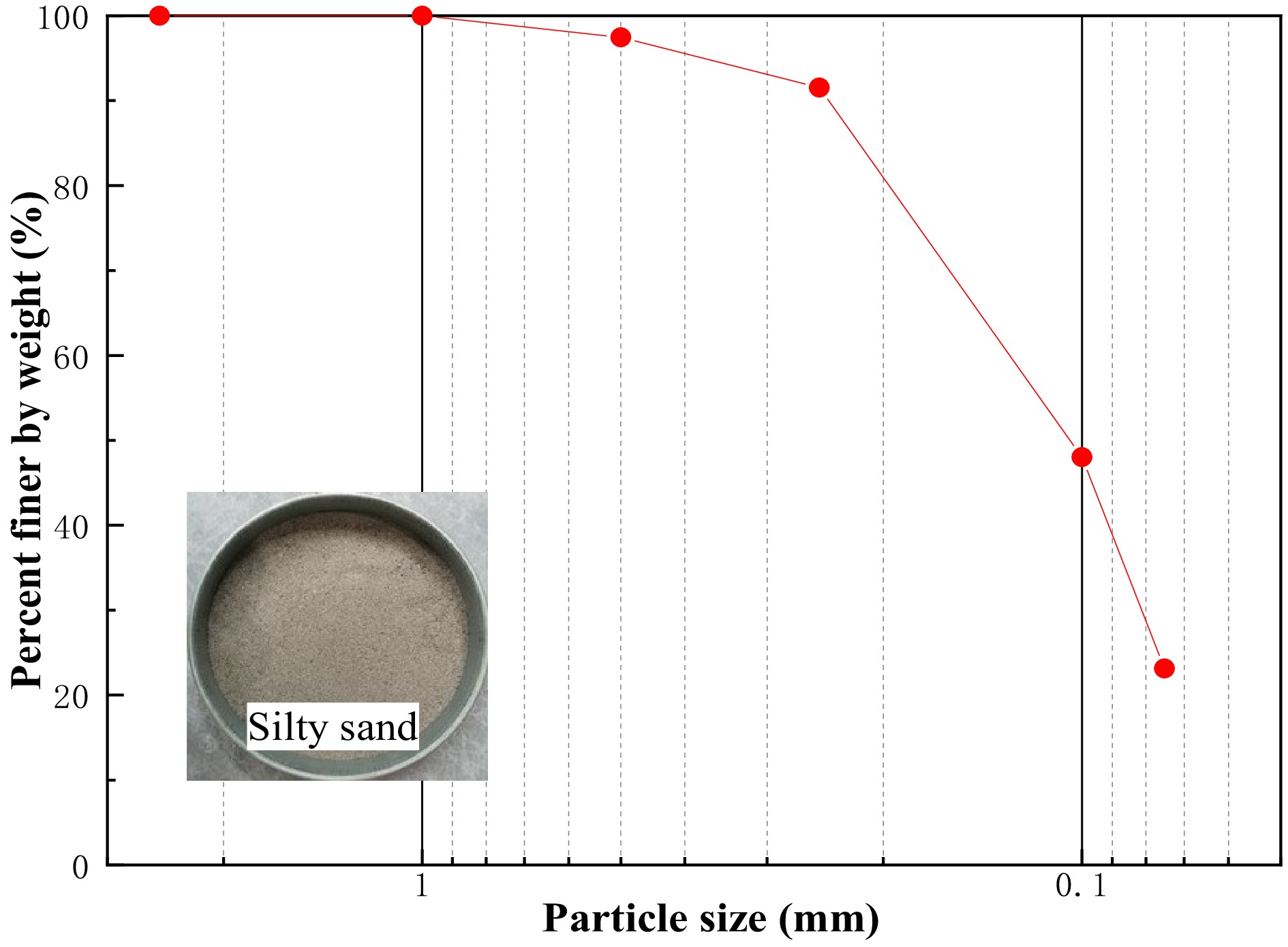

Figure 1.

Grading curve of silty sand.

-

Figure 2.

Samples of CaO and Na2SiO3.

-

Figure 3.

Experimental apparatus. (a) Universal testing machine, (b) JSM-6510 SEM.

-

Figure 4.

Systematic technique route for this study.

-

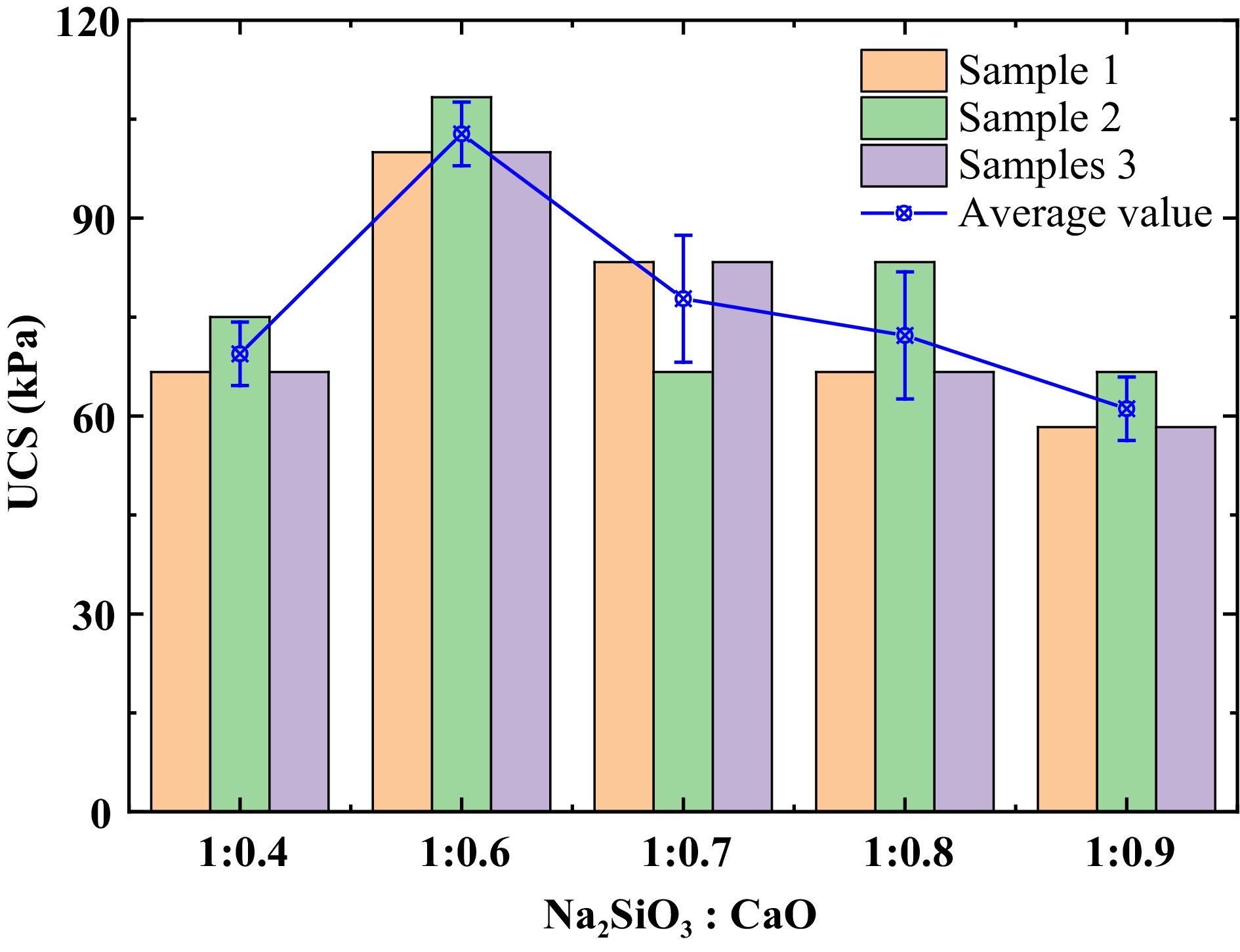

Figure 5.

Variation of unconfined compressive strength of geopolymer stabilized silty sands at different ratios of Na2SiO3 to CaO in the alkaline activator.

-

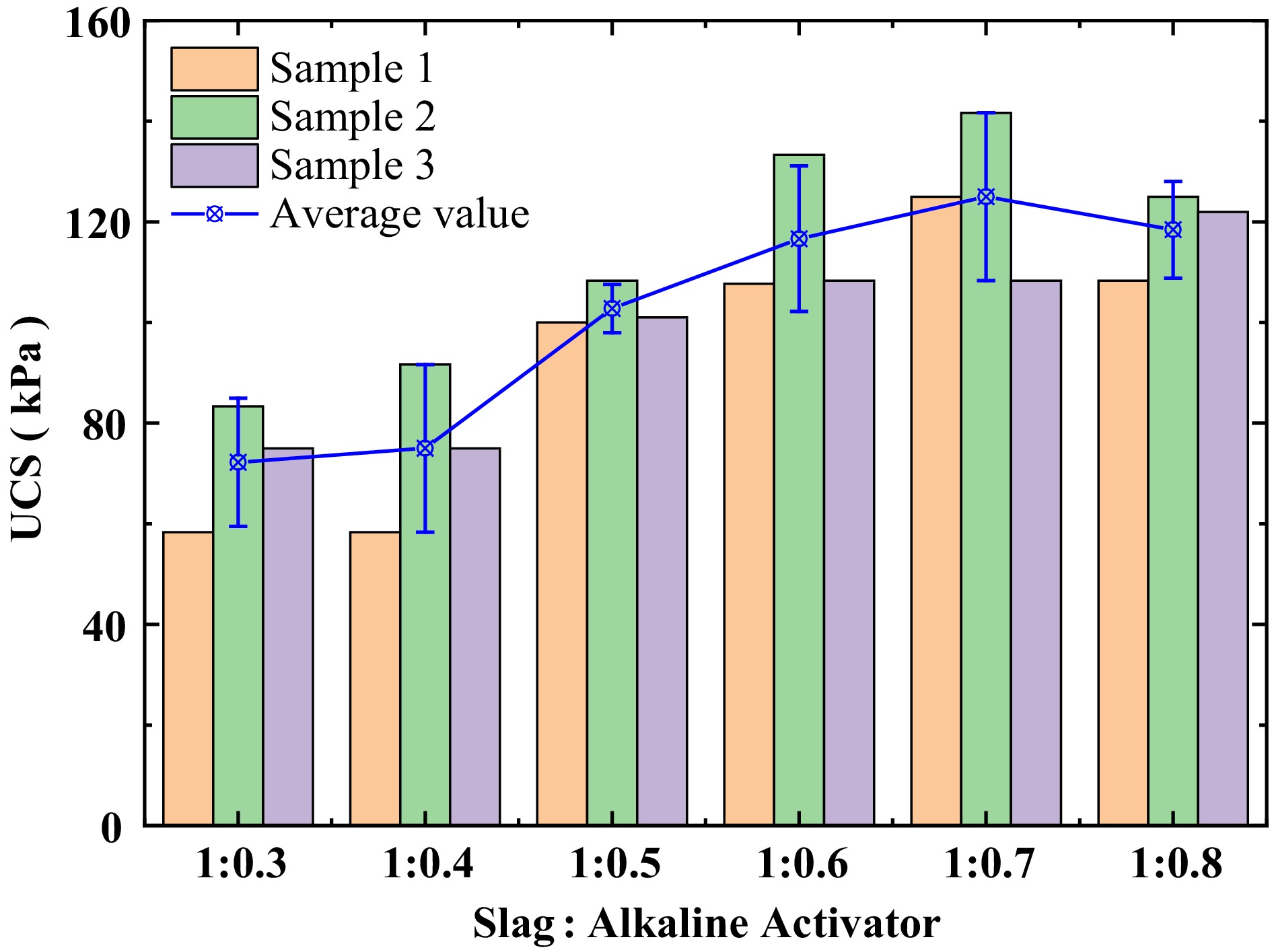

Figure 6.

Variation of unconfined compressive strength of geopolymer stabilized silty sands at different ratios of slag to alkaline activator.

-

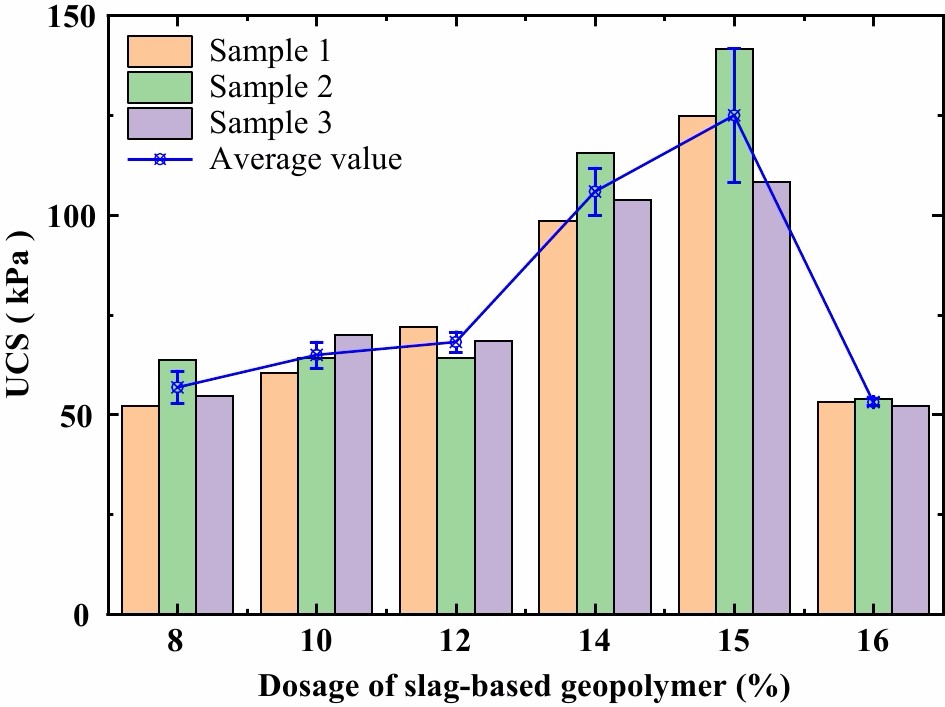

Figure 7.

Variation of unconfined compressive strength of silty sands stabilized with different dosages of steel slag-based geopolymer binder.

-

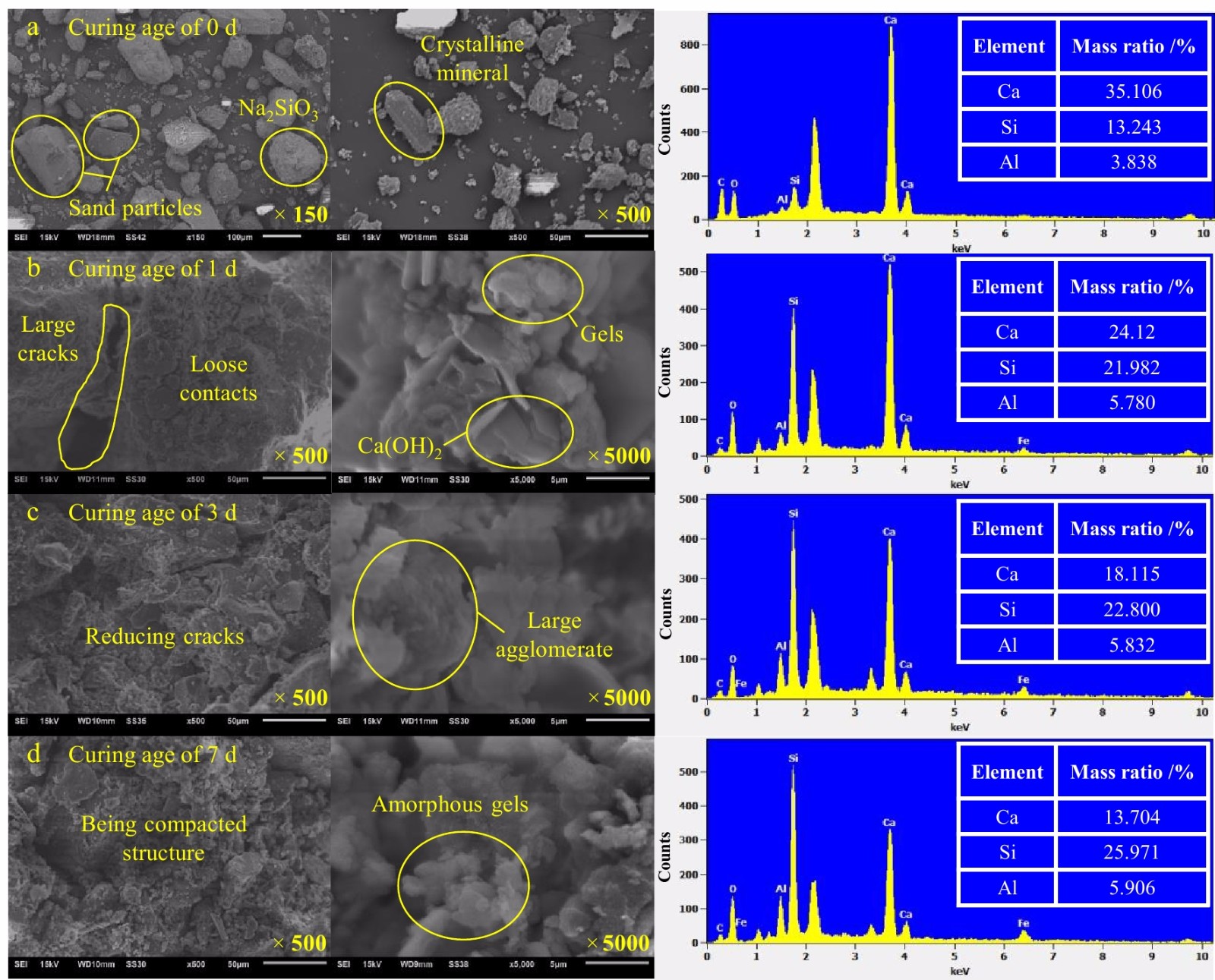

Figure 8.

Microstructural and chemical composition evolution of geopolymer stabilized silty sands at different curing ages.

-

Component CaO SiO2 MgO Al2O3 Fe2O3 Mass ratio (%) 59.23 29.02 3.89 1.40 6.46 Table 1.

The chemical compositions of slag.

Figures

(8)

Tables

(1)