-

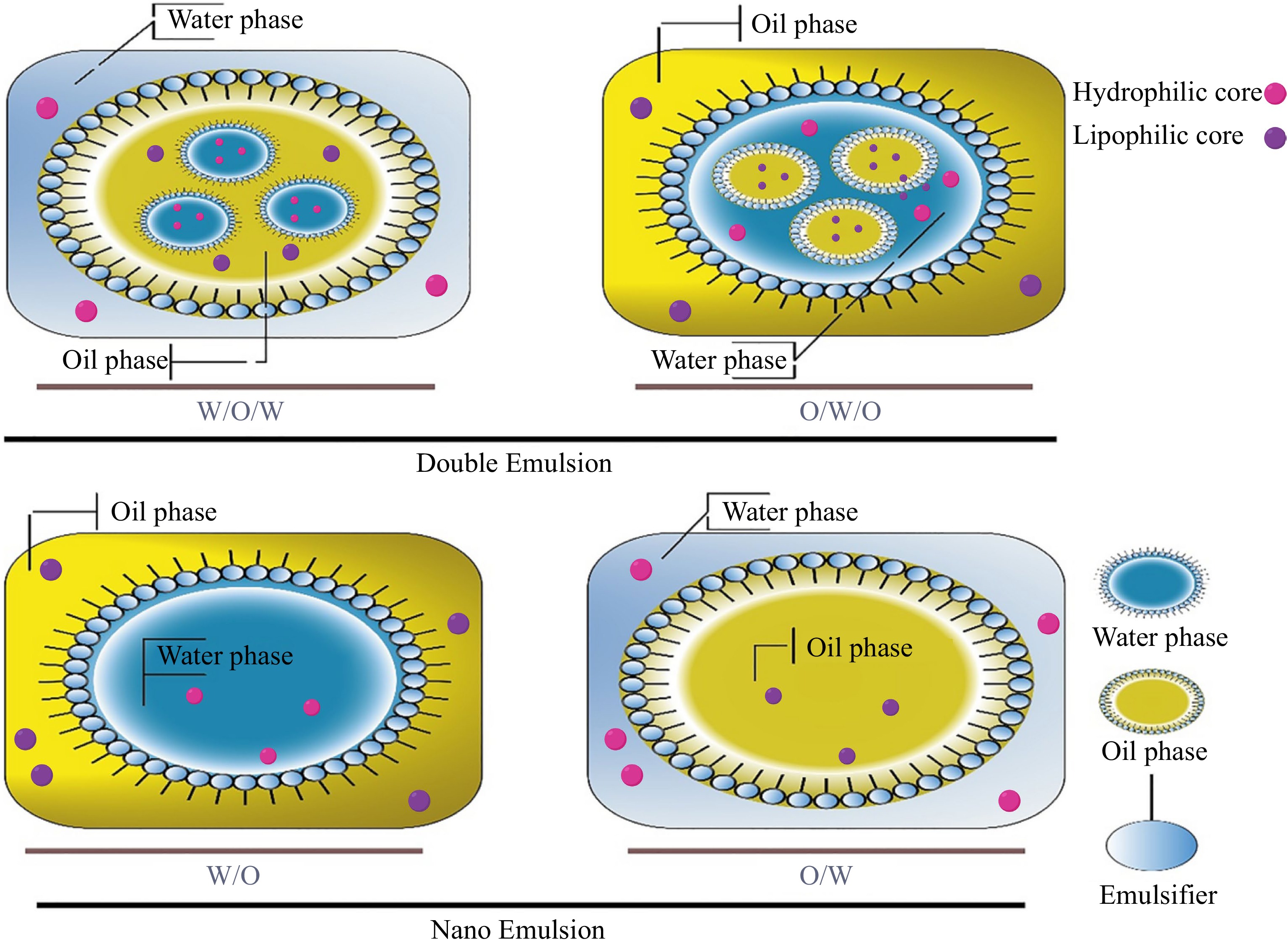

Figure 1.

Schematic diagram representing different forms of emulsion (single and double emulsion).

-

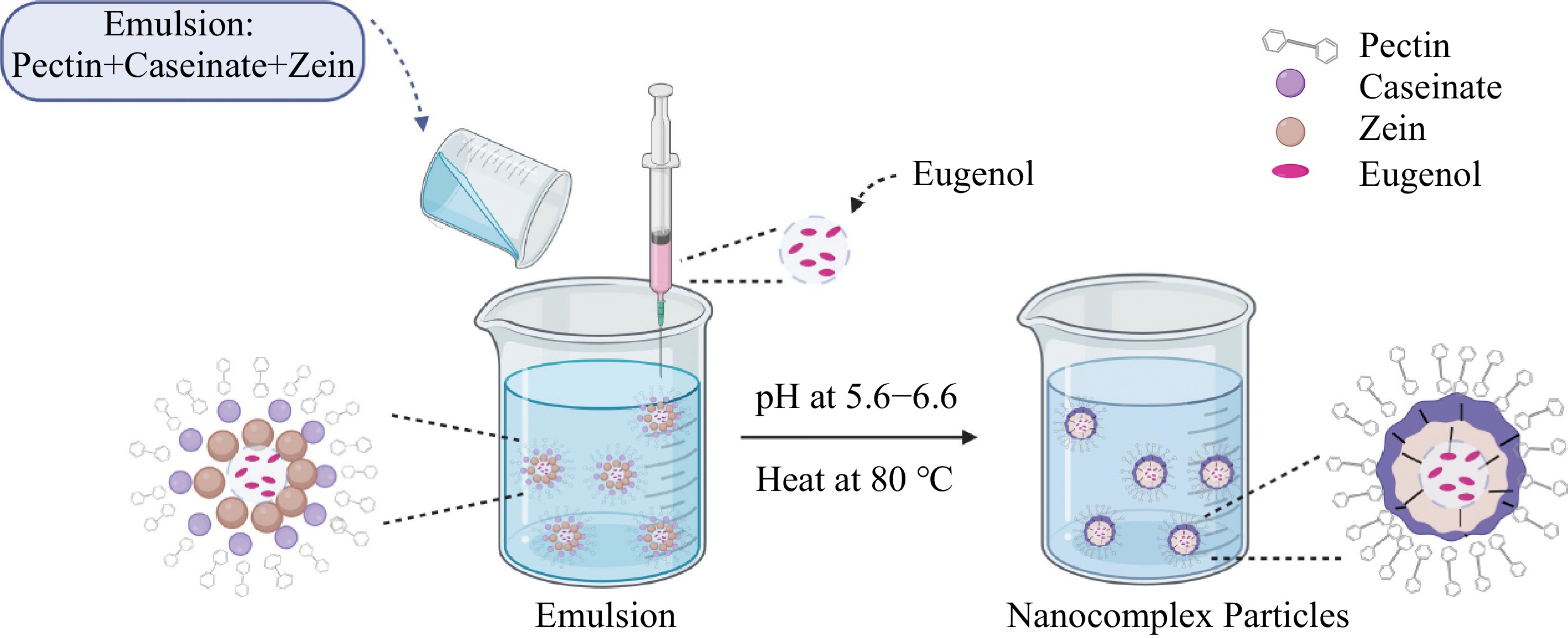

Figure 2.

Formation of nano-complex particles using zein/casein/pectin system.

-

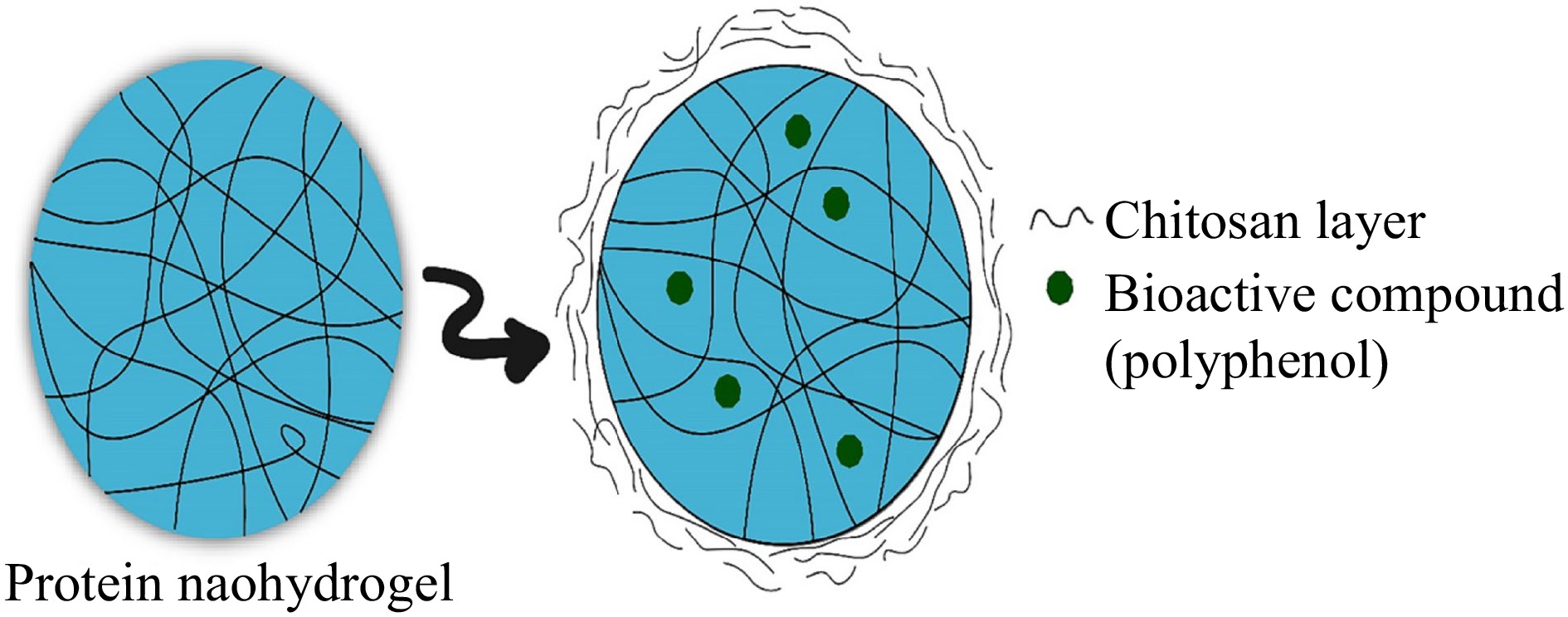

Figure 3.

Formation of nanocomplex particles using zein/casein/pectin system.

-

Nanoencapsulation techniques Carrier compound Polyphenolic compound Particle size

distribution (nm)Key discoveries Utilizations Citations Nanoemulsion WPC and pectin Olive leaf phenolic extract − Emulsion stability with controlled release of the encapsulated substance Food product fortification Mohammadi et al. (2015)[12] Nanoemulsion WPC and pectin Gallic acid 100−200 emulsion from the WPC-pectin complex had the same resistance (against creaming and sedimentation) as a synthetic emulsifier (Tween-80) Food, pharmaceutical and cosmetic industry Gharehbeglou et al. (2019a)[8] Nanoemulsion WPC and pectin Oleuropein 191 Successful encapsulation with an encapsulation efficiency of 91% Food, pharmaceutical and cosmetic industry Gharehbeglou et al. (2019b)[40] Nanoemulsion WPC Curcumin 141 This method was effective to increase the bioaccessibility of compounds Food and pharmaceutical industry Sari et al. (2015)[41] Nanoemulsion BSA Curcumin 18−30 Stable and controlled drug release was achieved Food and pharmaceutical industry Kaur et al. (2015)[42] Nanoemulsion Chitosan and soy protein Grape and apple pomace phenolic extract 5−300 Successfully encapsulation of encapsulant Food, pharmaceutical and cosmetic industry Gaber Ahmed et al. (2020)[43] Biopolymer nanocomplex formation WPC and pectin D-limonene 100 4% WPC and 1% pectin yielded superior results in complex formation Food products like cakes, muffins, juices and biscuits Food products such as cakes, muffins, juices, and biscuits Ghasemi et al. (2018)[44] Biopolymer nanocomplex formation Complexation of zein, sodium caseinate, and pectin Eugenol 140 Provide better stability to eugenol Food industry Veneranda et al. (2018)[13] Biopolymer nanocomplex formation Protein isolate and Peet pectin Anthocyanin < 200 Ineffective in enhancing antioxidant activity and color stability Application of natural colorants and nutraceuticals Arroyo-Maya & McClements (2015)[45] Biopolymer nanocomplex formation lactoferrin and pectin Curcumin 208 This complex resulted in high encapsulation efficiency (85%) with a 13.4% loading capacity Food, pharmaceutical, and cosmetic sectors Dai et al. (2017)[5] Biopolymer nanocomplex formation Zein and pectin Curcumin 250 More than 86% encapsulation efficiency was achieved Food, pharmaceutical, and cosmetic sectors Hu et al. (2015)[46] Biopolymer nanocomplex formation Zein and pectin Resveratrol 235 Successful encapsulation Bioactive food and beverage items, as well as their integration into nutraceuticals and medicinal preparations Huang et al. (2017)[5] Biopolymer nanocomplex formation Chitosan and β-lactoglobulin Quercetin 170−350 Increased encapsulation efficiency Food industry Ha et al. (2013)[47] Biopolymer nanocomplex formation Zein/sodium caseinate complex Quercetin 130−161 Encapsulated quercetin was stable when exposed to UV light and alkaline pH Food, pharmaceutical, and cosmetic sectors Patel et al. (2012)[48] Biopolymer nanocomplex formation Whey protein isolate and pectin Quercetin 200−500 The encapsulated phenolic compound showed better stability (4 times better) against UV irradiation as compared to free quercetin Food products like beverages Wijaya et al. (2019)[49] Biopolymer nanocomplex formation Casein and pectin Rutin 199−697 Successful encapsulation Food and pharmaceutical industry Luo et al. (2015)[50] Nanoydrogel 'LDL' and 'pectic substances' Curcumin <60 Successful creation, outstanding stability in simulated gastrointestinal conditions, and regulated release of curcumin. Food and pharmaceutical industry Zhou et al. (2016)[51] Nanoydrogel Lactoferrin-glycomacropeptide and chitosan Curcumin and caffeine Bioaccessibility of encapsulants was increased Food and pharmaceutical industry, Drug delivery Bourbon et al. (2018)[52] Nanoydrogel Lactoferrin Curcumin 89.4 Successful encapsulation Food and pharmaceutical industry de Araújo Lopes et al. (2018)[53] BSA = Bovine Serum Albumin, WPC = Whey protein concentrate. Table 1.

Use of protein as the carrier for various polyphenols.

Figures

(3)

Tables

(1)