-

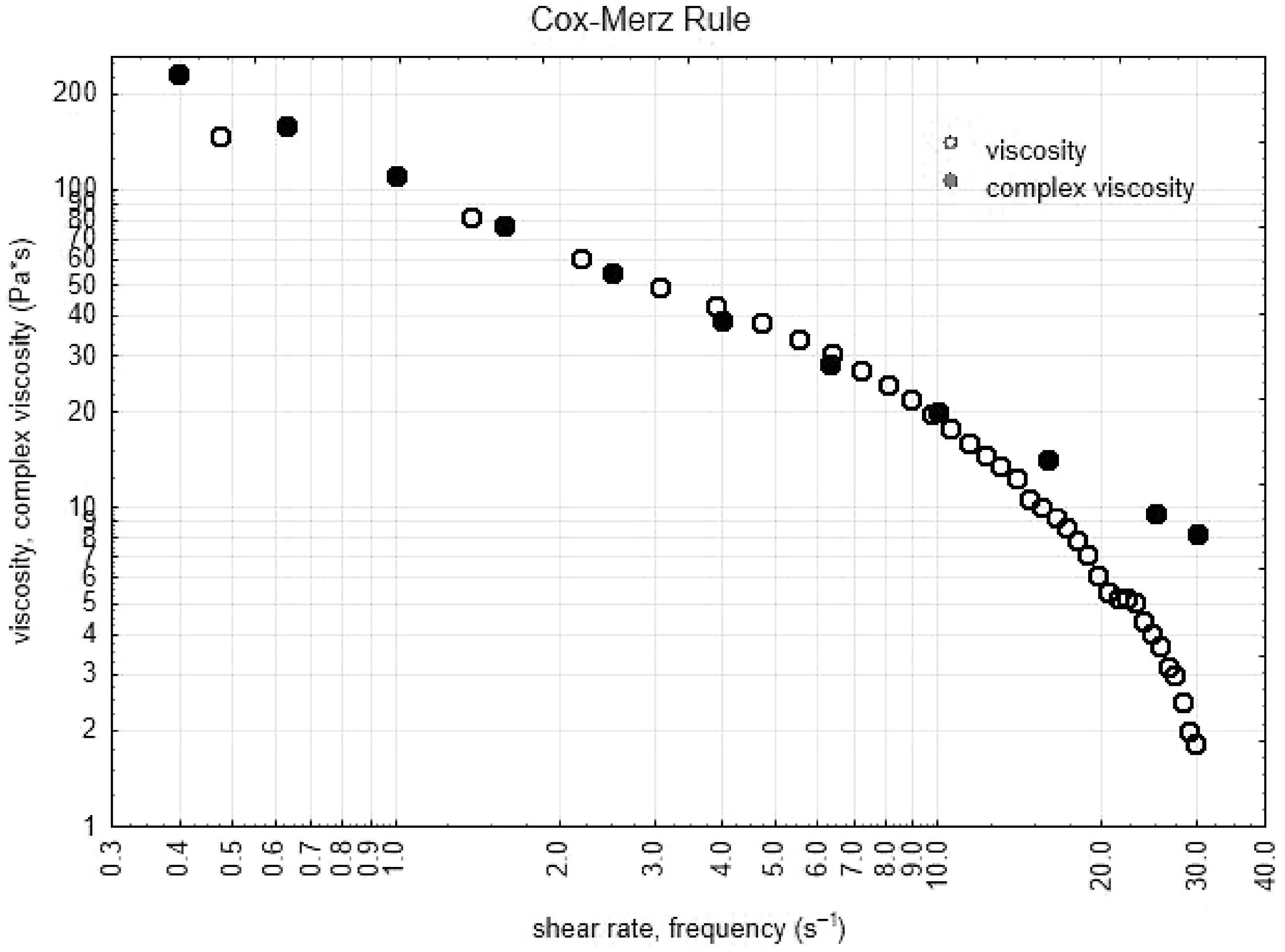

Figure 1.

Cox–Merz rule applied to bigels obtained with oleogels and hydrogels at all experimental condition used in the experimental work.

-

Hydrocolloid/

oleogelAgitation

(rpm)Mixing

time (min)Firmness

(N)Cohesiveness

(N)67:33 11,200 5 1.19 ± 0.10ab −0.66 ± 0.001ab 67:33 11,200 7 1.48 ± 0.10ab −0.73 ± 0.030ab 67:33 15,600 5 1.60 ± 0.03b −0.76 ± 0.010b 67:33 15,600 7 1.55 ± 0.18ab −0.69 ± 0.120ab 83:17 11,200 5 0.88 ± 0.04ª −0.43 ± 0.020ab 83:17 11,200 7 0.92 ± 0.16ab −0.42 ± 0.090ª 83:17 15,600 5 1.02 ± 0.12ab −0.48 ± 0.010ab 83:17 15,600 7 1.03 ± 0.11ab −0.48 ± 0.040ab Data shown are the mean of three replicates ± standard deviation; different literals in the same column indicates statistical differences (p < 0.05, Tukey test). Table 1.

Firmness and cohesiveness values of the bigels obtained at the different `proportions of hydrocolloid/oleogel at different agitation rates and mixing time.

-

Hydrocolloid/

oleogelAgitation

(rpm)Mixing time

(min)Melting point

(Tm) (°C)Melting enthalphy

(Kcal/mol)Crystallization point

(°C)Crystallization enthalphy

(Kcal/mol)67:33 11,200 5 0.9 ± 0.1 66.32 ± 17.43 −20.1 ± 0.3 75.99 ± 15.41 67:33 11,200 7 1.5 ± 0.2 133.15 ± 19.15 −16.6 ± 0.7 128.06 ± 11.74 67:33 15,600 5 1.9 ± 0.2 141.85 ± 13.35 −14.5 ± 0.2 129.40 ± 12.30 67:33 15,600 7 2.2 ± 0.6 164.05 ± 17.25 −13.8 ± 0.3 143.70 ± 13.80 83:17 11,200 5 1.5 ± 0.2 192.70 ± 23.80 −16.8 ± 0.1 163.40 ± 18.90 83:17 11,200 7 1.4 ± 0.1 201.10 ± 28.40 −17.0 ± 0.7 174.80 ± 17.40 83:17 15,600 5 0.9 ± 0.1 59.34 ± 15.75 −18.3 ± 0.2 86.50 ± 15.81 83:17 15,600 7 1.4 ± 0.3 195.6 ± 11.00 −15.7 ± 0.7 151.25 ± 20.15 Data shown are the mean of three replicates ± standard deviation; different literals in the same column indicates statistical differences (p < 0.05, Tukey test). Table 2.

Calorimetric behavior (melting, crystallization) of the bigels obtained at the different proportions of hydrocolloid/oleogel at different agitation rates and mixing time.

-

Ratio H/O Rate (rpm) Time (min) Recovery (%) G0 Pa μ0 Pa s G1 Pa μ1 Pa s λ s R2 67:33 11,200 5 47.63 10.54 978.55 8.85 18.51 2.09 0.96 67:33 11,200 7 48.06 6.65 709.00 7.62 15.69 2.06 0.94 67:33 15,600 5 33.00 6.78 919.13 8.78 11.13 1.27 0.93 67:33 15,600 7 60.04 18.91 852.74 7.79 33.29 4.27 0.98 83:17 11,200 5 48.41 5.03 575.48 5.71 7.65 1.34 0.92 83:17 11,200 7 76.11 29.82 581.34 6.48 41.06 6.34 0.99 83:17 15,600 5 67.33 53.11 577.18 6.63 50.40 7.60 0.99 83:17 15,600 7 66.08 71.22 1402.51 20.12 174.16 8.65 0.99 Data shown are the mean of three replicates ± standard deviation. Table 3.

Parameters of Burgers model of bigels at the different conditions of ratio hydrogel (H)/Oleogel (O), mixing rate, time of agitation.

Figures

(1)

Tables

(3)