-

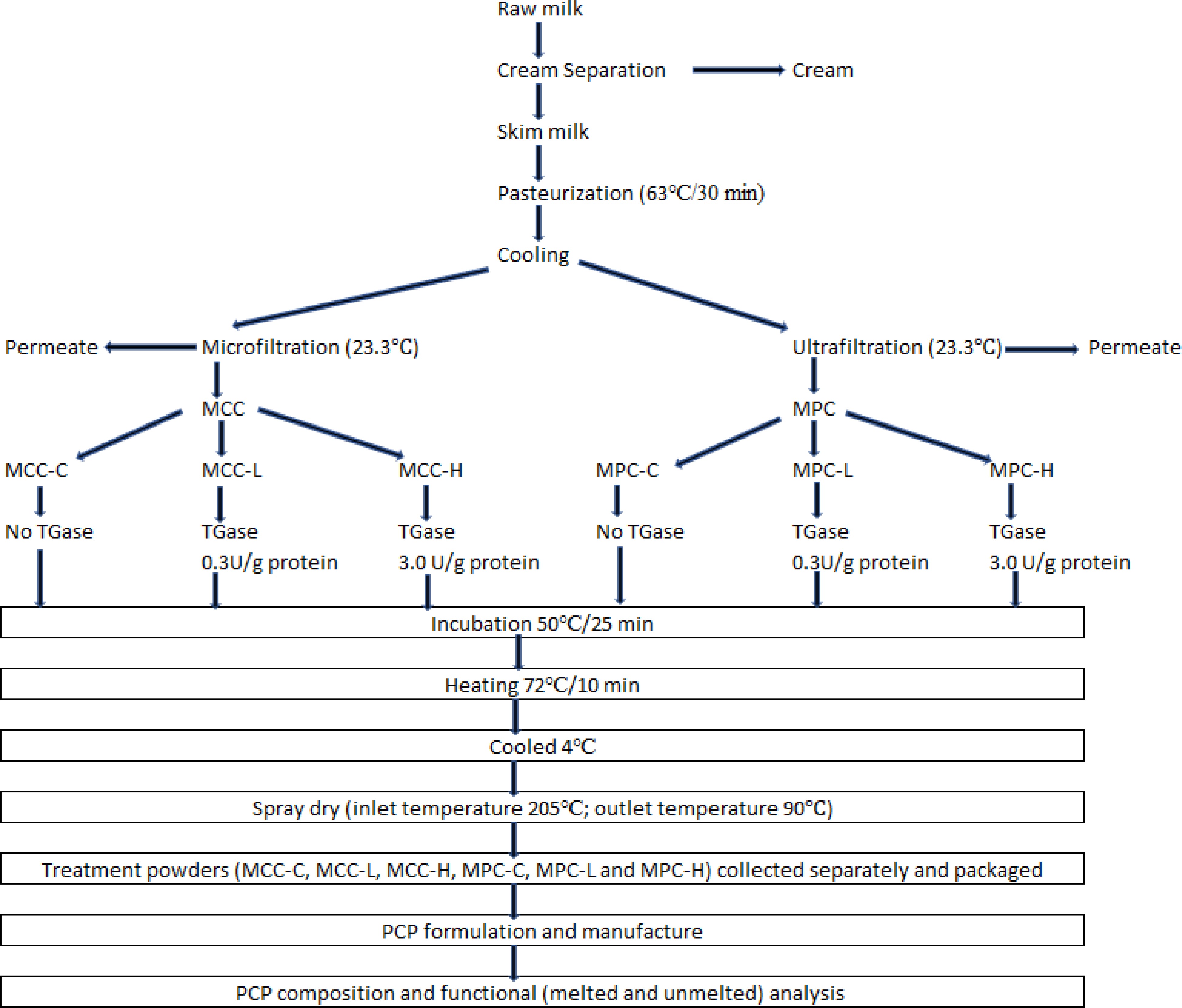

Figure 1.

Experimental design for the manufacture of treatment powders. Processed cheese product (slice) treatment: MCC-C = micellar casein concentrate powder, control; MCC-L = micellar casein concentrate powder, low TGase level; MCC-H = micellar casein concentrate powder, high TGase level; MPC-C = milk protein concentrate powder, control; MPC-L = milk protein concentrate powder, low TGase level; MPC-H = milk protein concentrate powder, high TGase level.

-

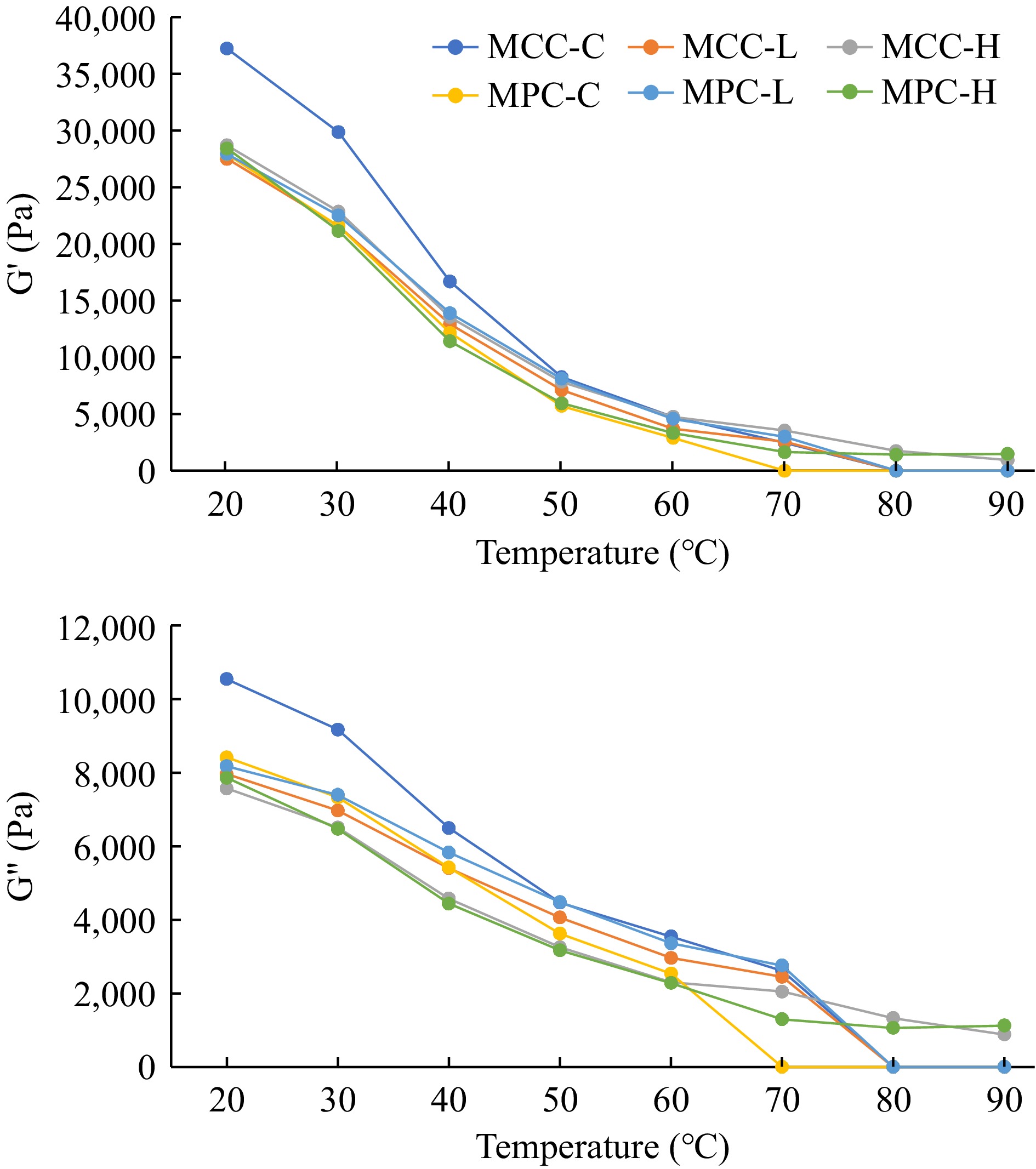

Figure 2.

Rheological characteristics of PCP (G' and G") of process cheese samples. Processed cheese product (slice) treatment: MCC-C = micellar casein concentrate powder, control; MCC-L = micellar casein concentrate powder, low TGase level; MCC-H = micellar casein concentrate powder, high TGase level; MPC-C = milk protein concentrate powder, control; MPC-L = milk protein concentrate powder, low TGase level; MPC-H = milk protein concentrate powder, high TGase level.

-

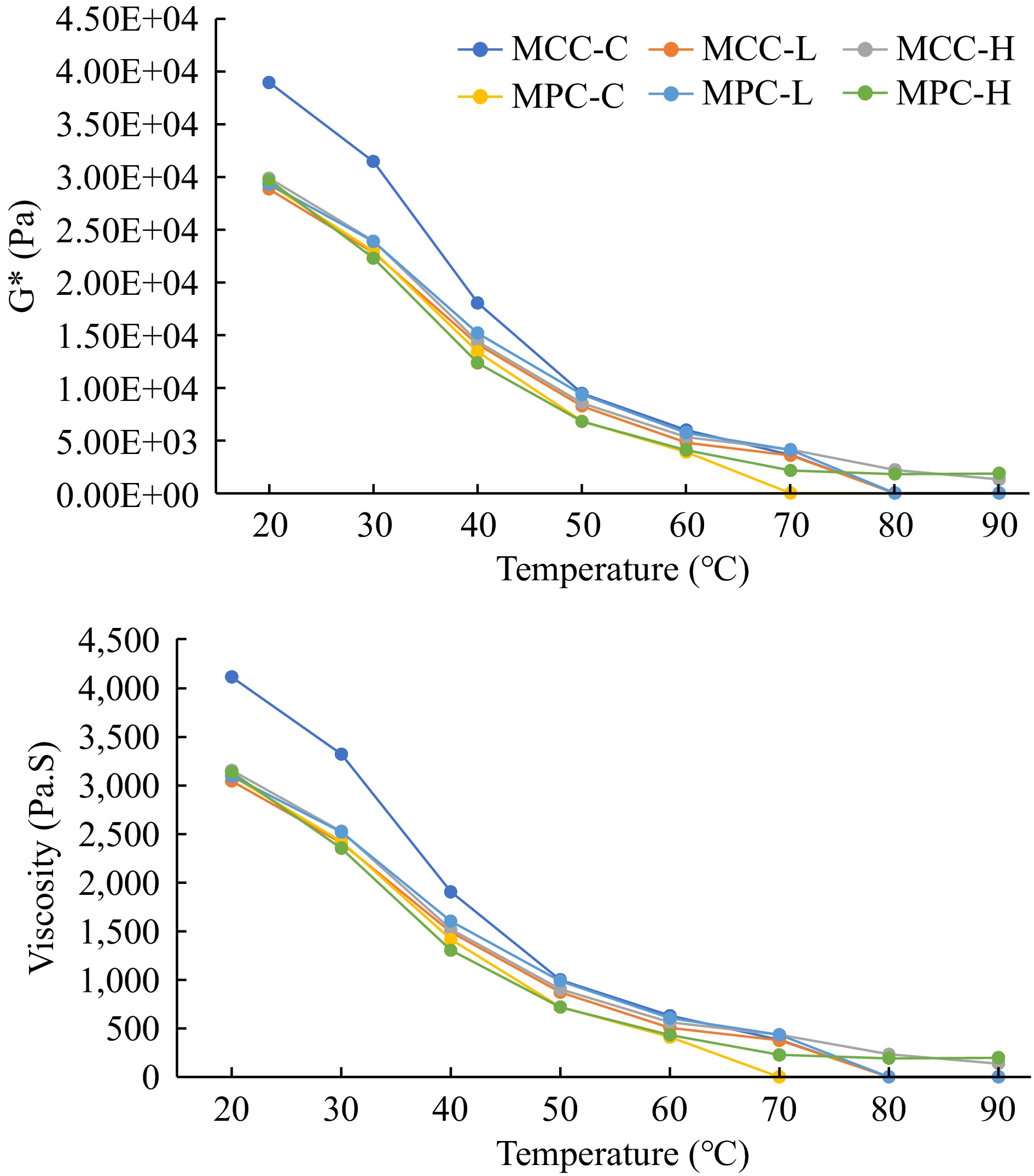

Figure 3.

Rheological characteristics of PCP (G* and viscosity) of process cheese samples. Process cheese product (slice) treatment: MCC-C = micellar casein concentrate powder, control; MCC-L = micellar casein concentrate powder, low TGase level; MCC-H = micellar casein concentrate powder, high TGase level; MPC-C = milk protein concentrate powder, control; MPC-L = milk protein concentrate powder, low TGase level; MPC-H = milk protein concentrate powder, high TGase level.

-

Ingredient MCC-C MCC-L MCC-H MPC-C MPC-L MPC-H % (Wt./Wt.) Water 40.63 40.55 40.62 40.50 40.45 40.72 Salt 1.25 1.25 1.25 1.25 1.25 1.25 Tri sodium citrate 2.00 2.00 2.00 2.00 2.00 2.00 Whey deproteinized 6.98 7.07 6.86 6.02 6.08 5.75 Lactic acid 1.00 1.00 1.00 1.00 1.00 1.00 Butter (salted) 21.49 21.48 21.55 21.66 21.64 21.65 Sodium phosphate, Dibasic 0.50 0.50 0.50 0.50 0.50 0.50 EMC paste 0.75 0.75 0.75 0.75 0.75 0.75 Sorbic acid 0.20 0.20 0.20 0.20 0.20 0.20 Cheddar cheese 5.00 5.00 5.00 5.00 5.00 5.00 Treatment powder 20.21 20.20 20.27 21.13 21.12 21.18 Total 100.00 100.00 100.00 100.00 100.00 100.00 1 Processed cheese product (slice) treatment: MCC-C = micellar casein concentrate powder, control; MCC-L = micellar casein concentrate powder, low TGase level; MCC-H = micellar casein concentrate powder, high TGase level; MPC-C = milk protein concentrate powder, control; MPC-L = milk protein concentrate powder, low TGase level; MPC-H = milk protein concentrate powder, high TGase level. Table 1.

Ingredient blend formulations utilized to manufacture the six Process cheese product (slice) treatment.1

-

Parameters MCC-C MCC-L MCC-H MPC-C MPC-L MPC-H pH 5.70 5.64 5.69 5.70 5.74 5.66 Fat (%) 19.93 19.94 19.97 19.99 19.95 19.97 Protein (%) 17.52 17.49 17.49 17.49 17.51 17.55 Moisture (%) 47.95 47.96 47.94 47.96 47.95 47.98 1 Processed cheese product (slice) treatment: MCC-C = micellar casein concentrate powder, control; MCC-L = micellar casein concentrate powder, low TGase level; MCC-H = micellar casein concentrate powder, high TGase level; MPC-C = milk protein concentrate powder, control; MPC-L = milk protein concentrate powder, low TGase level; MPC-H = milk protein concentrate powder, high TGase level. Table 2.

Mean (n = 3) composition of Processed cheese product (slice) treatments.1

-

Factors Df RVA viscosity Change in area Hardness Tan delta Replication 2 771,444.57 (0.085) 56,935.00 (0.089) 5,511.35 (0.002)* 16.71 (0.328) Product type 1 308,265.16 (0.005)* 405,215.28 (0.0008)* 22,552.99 (<0.0001)* 317.24 (<0.0001)* Enzyme level 2 14,197,912.72 (<0.0001)* 565,898.42 (<0.0001)* 2,740.38 (0.021)* 417.53 (<0.0001)* Product type x Enzyme level 2 139,446.25 (0.022)* 262,920.46 (0.001)* 775.23 (0.239) 142.79 (0.003)* Error 10 24,246.61 18,276.87 466.97 13.37 * Statistically significant at p < 0.05. Table 3.

Mean squares and p values (in parentheses) of RVA viscosity, melt area, hardness, and tan delta of the PCP manufactured from treatment powders.

-

Parameter MCC-C MCC-L MCC-H MPC-C MPC-L MPC-H RVA viscosity (cP, n = 36) 728.7c ± 47.2 725.5c ± 72.5 3653.1a ± 143.3 1204.3b ± 269.8 1122.4b ± 144.7 3565.7a ± 276.9 Change in area (mm, n = 12) 1081.9a ± 203.4 708.4b ± 29.3 61.3e ± 26.7 412.0c ± 44.8 323.4cd ± 104.4 215.8d ± 241.0 Hardness (g, n = 12) 402.1b ± 33.4 456.5a ± 54.3 398.0b ± 50.4 340.7c ± 35.1 359.8c ± 21.9 343.8c ± 14.7 Tan delta (°C, n = 9) 65.97c ± 3.77 69.60b ± 3.78 90.00a ± 0.00 61.97d ± 2.94 67.99bc ± 4.88 70.42b ± 4.75 a–e Means in a row with common superscripts do not differ (p ≥ 0.05). Processed cheese product (slice) treatment: MCC-C = micellar casein concentrate powder, control; MCC-L = micellar casein concentrate powder, low TGase level; MCC-H = micellar casein concentrate powder, high TGase level; MPC-C = milk protein concentrate powder, control; MPC-L = milk protein concentrate powder, low TGase level; MPC-H = milk protein concentrate powder, high TGase level. Table 4.

Mean (n = 3) RVA viscosity, melt area, hardness, and tan delta of the PCP manufactured from treatment powders at 3 levels (C, L, and H).

Figures

(3)

Tables

(4)