-

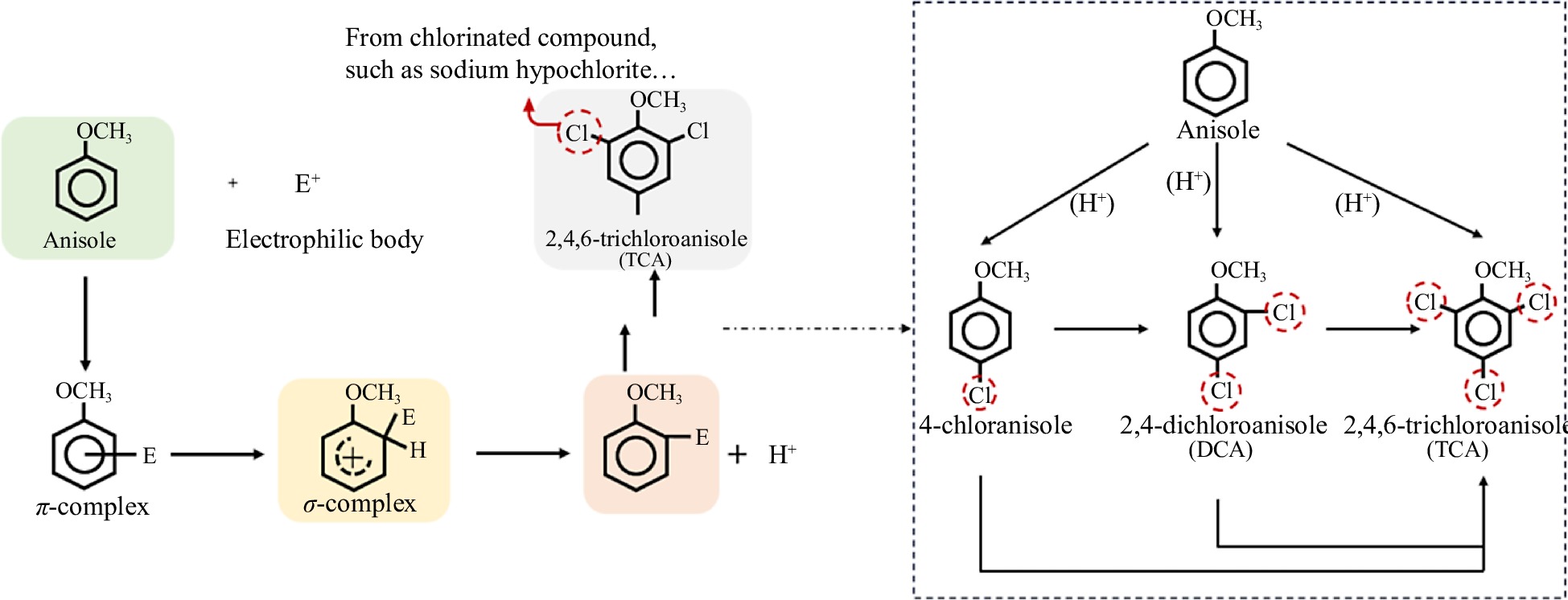

Figure 1.

Pathway of electrophilic substitution of anisole produces 2,4,6-TCA.

-

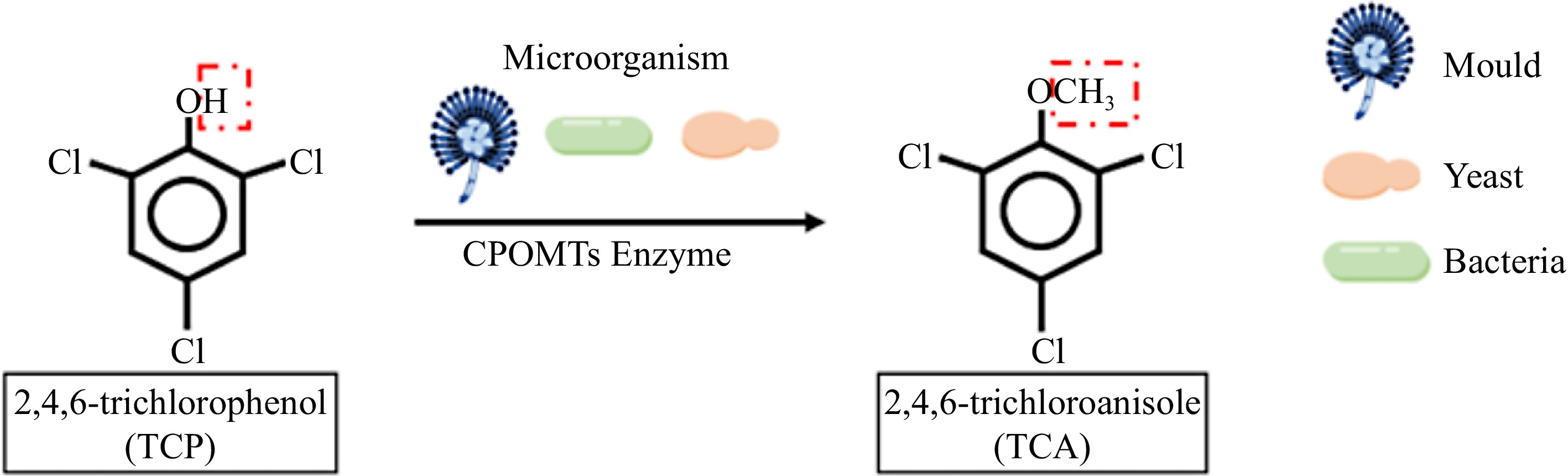

Figure 2.

Pathway of 2,4, 6-trichlorophenol biosynthesis catalyzed by O-methyltransferase.

-

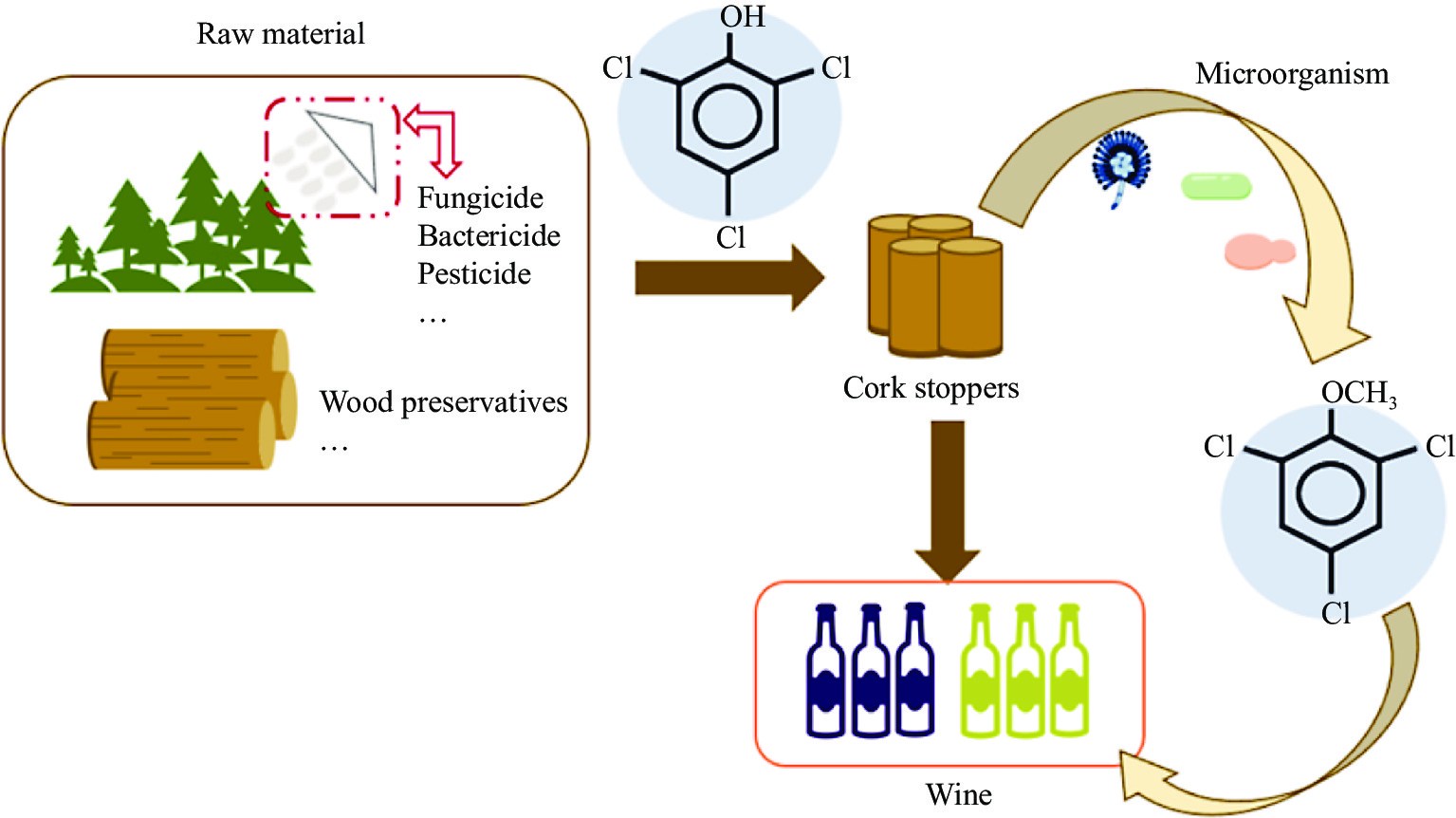

Figure 3.

2,4,6-TCA originates from cork stoppers.

-

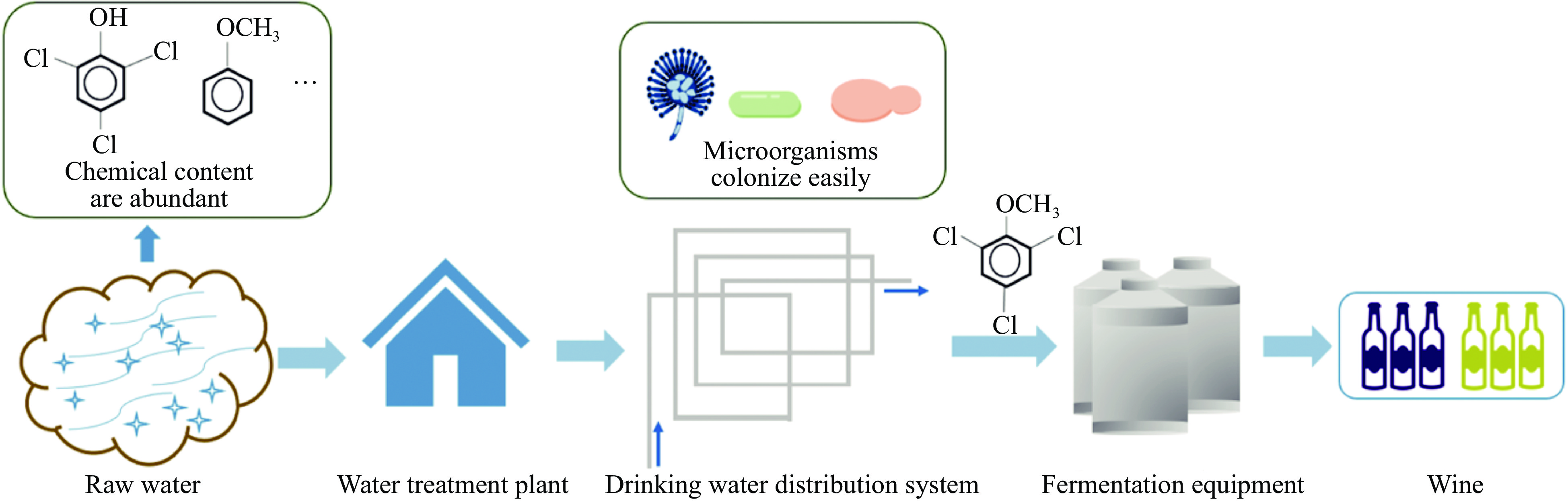

Figure 4.

2,4,6-TCA originates from water.

-

Figure 5.

2,4,6-TCA originates from others.

-

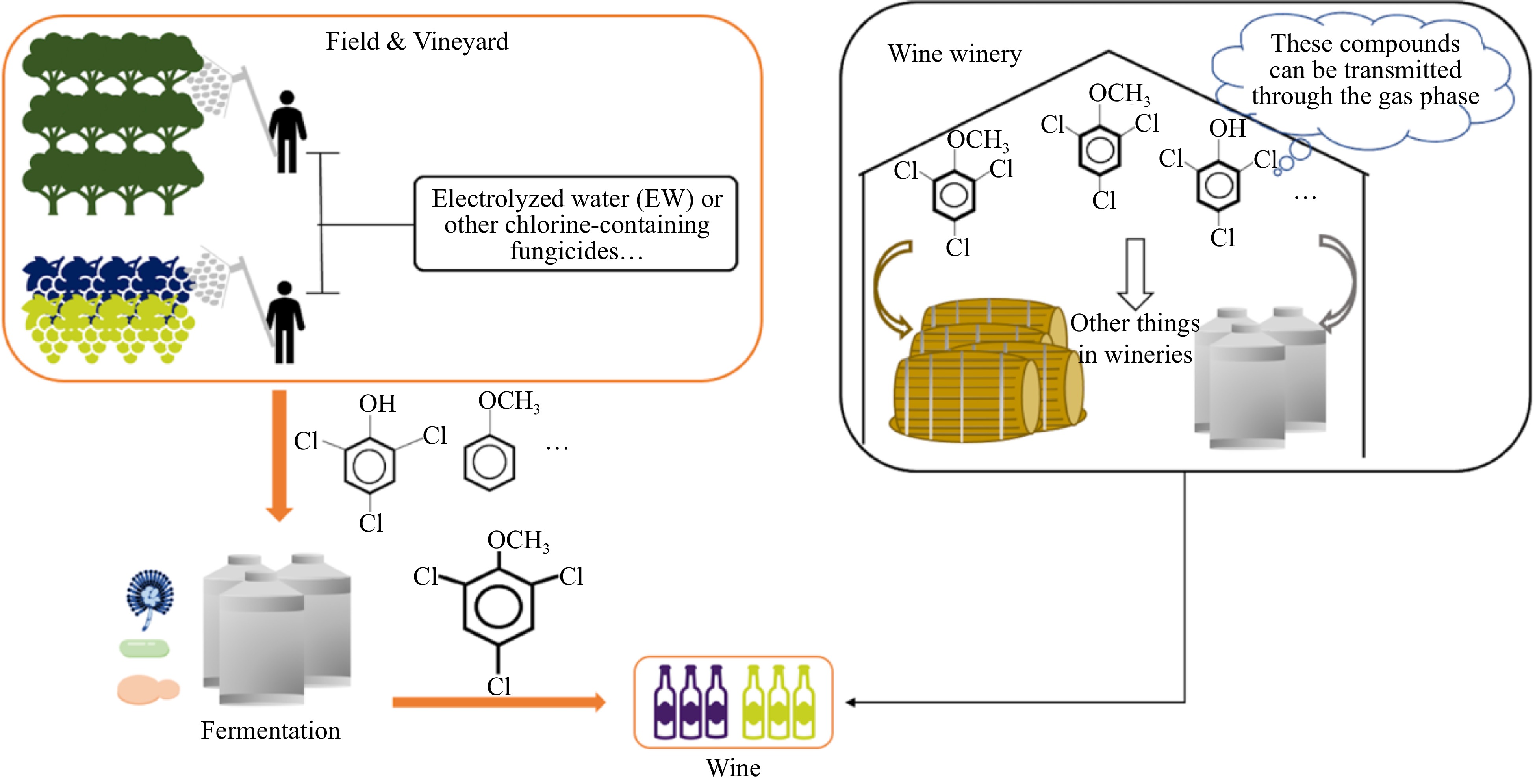

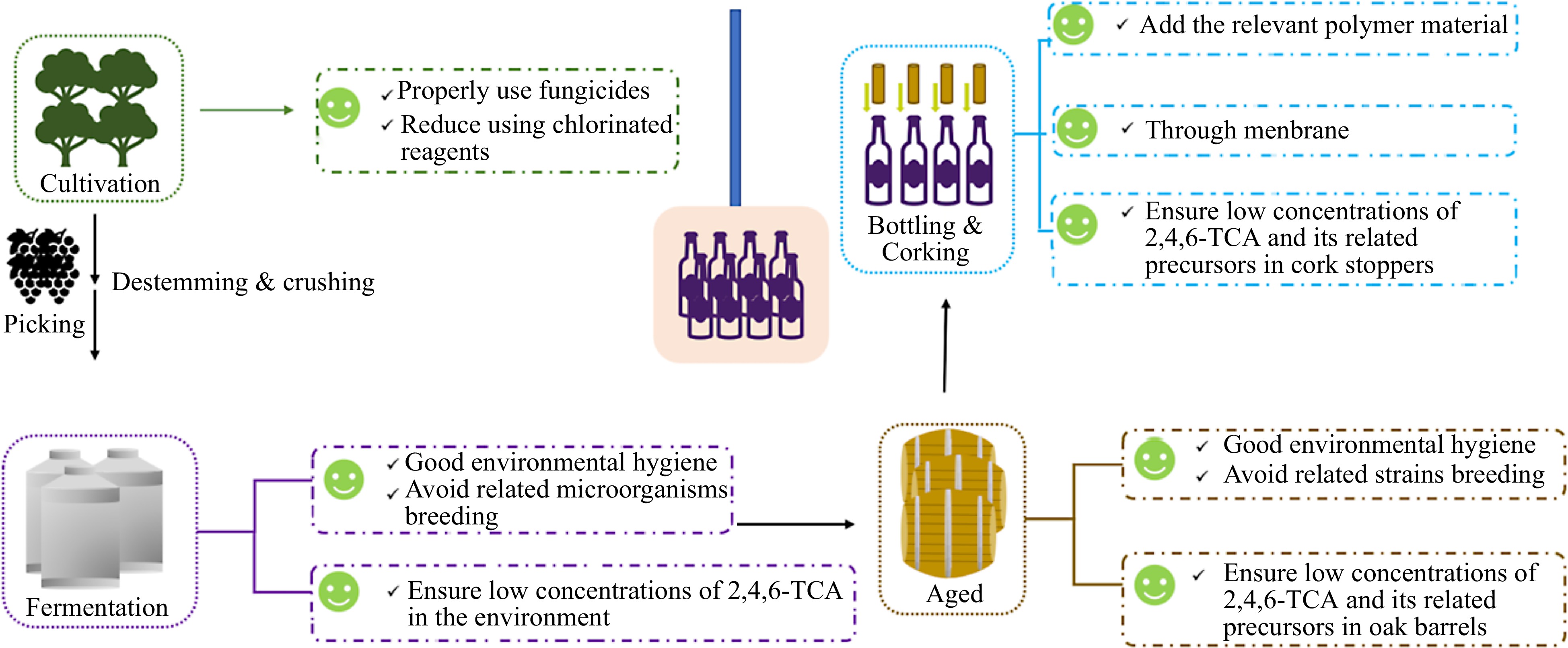

Figure 6.

Possible ways in which 2,4,6-TCA can contaminate wine, and recommendations for reducing the risk of 2,4,6-TCA contamination.

-

Genus Species Isolated from The rate/ability of converting

TCP to TCADetection methods Ref. Fungi Acremonium Strictum Settled water 3.3%−14.24% SPME-GC-MS [27] Fungi Aspergillus − Raw one-piece cork stoppers In MEA medium, 44.5%−54.9%

On the cork, 19.9%−21.5%GC-ECD [20] Fungi Aspergillus Niger Cork stoppers On solid cork medium, 0.16%

On liquid medium, 0.65%.HS-SPME-GC-MS [19] Fungi Aspergillus Oryzae Tap water; Stoppers On solid cork medium, 0.21%;

On liquid medium, 1.17%SPME-GC-MS;

HS-SPME-GC-MS[19,27,28] Fungi Aspergillus Versicolor Settled water 40.5% SPME-GC-MS [27] Fungi Bjerkandera Adusta Finished water 2.0 × 10−5%−0.18% SPME-GC-MS [27] Fungi Botrytis Cinerea Grapes In MEA medium, 34.1%;

On wood plugs, 28.4%GC-ECD [20] Fungi Chrysonilia Sitophila Raw one-piece cork stoppers In MEA medium, 64.6%;

On wood plugs, 4.3%GC-ECD [20] Fungi Cladosporium Cladosporioides Finished water 7.0 × 10−2% SPME-GC-MS [27] Fungi Cladosporium Oxysporum Cork stoppers 14.31% HPLC [21] Fungi Cyclotella Hebeiana Lake Initially 0.2 mg/L 2,4,6-TCP; eventually 4.08 ng/L 2,4,6-TCA can be produced SPME-GC-MS [13] Fungi Fusarium Asiaticum Finished water 0.28% SPME-GC-MS [27] Fungi Fusicolla Matuoi Finished water 2.6% SPME-GC-MS [27] Fungi Fusarium Oxysporum Cork stoppers 28.65% HPLC [21] Fungi Laccaria Amethystina Raw water;

Settled water;

Post filtration water; Finished water2.9 × 10−2% SPME-GC-MS [27] Fungi Mortierella Alpina Cork stoppers 0.11% HPLC [21] Fungi Mucor Plumbeus Cork stoppers 0.03% HPLC [21] Fungi Mucor Racemosus Cork stoppers On solid cork medium, 5.21%;

On liquid medium, 5.21%HS- SPME-GC-MS [19] Fungi Paecilomyces Variotii Fibreboard cartons 2%−65% HPLC; GC-MS [29] Fungi Paecilomyces Viridis Cork stoppers 7.88% HPLC [21] Fungi Paecilomyces − Cork stoppers On solid cork medium, 3.65%;

On liquid medium, 4.45%HS- SPME-GC-MS [19] Fungi Penicillium − Raw one-piece cork stoppers In MEA medium, 23.2-37%;

On cork, 1.3%−53.1%GC-ECD [20] Fungi Penicillium Chrysogenum Cork stoppers 3.29%−7.87% HS- SPME-GC-MS [19] Fungi Penicillium Citreonigrum Cork stoppers 13.28% HPLC [21] Fungi Penicillium Decumbens Cork stoppers 0.11% HPLC [21] Fungi Penicillium Glabrum Cork stoppers 2.18%−20.43% HS- SPME-GC-MS [19] Fungi Penicillium Purpurogenum Cork stoppers 11.02% HPLC [21] Fungi Phialemoniopsis Ocularis Post filtration water 0.13% SPME-GC-MS [27] Fungi Pseudomonas − Lake – SPME-GC-MS [13] Fungi Rhizopus Oryzae Broiler house litter < 1% Gas-Liquid Chromatography [30] Fungi Scopulariopsis Brevicaulis Broiler house litter 60% Gas-Liquid Chromatography [30] Fungi Sistotrema Brinkmannii Post filtration water; Finished water 2.3% SPME-GC-MS [27] Fungi Talaromyces Pinophilus Finished water 2.7% SPME-GC-MS [27] Fungi Trichoderma − Raw one-piece cork stoppers; Lake In MEA medium, 64.4%;

On cork, 13%GC-ECD; SPME-GC-MS [13,20] Fungi Trichoderma Longibrachiatum Cork 37.56% – [31] Fungi Trichoderma Viride Cork stoppers 3.37%−4.86% HS- SPME-GC-MS [19] Fungi Verticillium Psalliotae Cork stoppers 6.9% HPLC [21] Bacteria Acinetobacter − Water 2.4 × 10−10 ug*h (cell/mL) GC-MS [32] Bacteria Bacillus Australimaris Water OMPPC (1.31 × 10−9 ng/CFU) SPME-GC-ECD [33] Bacteria Brachybacterium Brachybacterium Cork – HS-SPME-GC-MS [32] Bacteria Brachybacterium Paraconglomeratum Cork – HS-SPME-GC-MS [32] Bacteria Bradyrhizobium Frederickii Water produce 2,4,6-TCA

(1.7 × 10−9 ng/CFU)SPME-GC-ECD [33] Bacteria Brevundimonas − Water – SPME-GC-ECD [33] Bacteria Caulobacter − Water – SPME-GC-ECD [33] Bacteria Chromobacterium − Water – SPME-GC-ECD [33] Bacteria Erythrobacter − Water – SPME-GC-ECD [33] Bacteria Escherichia Coli Lake Initial 0.2 mg/L 2,4,6-TCP;

generated 4.6 ng/L 2,4,6-TCASPME-GC-MS [13] Bacteria Flavobacterium − Cork – HS-SPME-GC-MS [32] Bacteria Microbacterium Oxydans Cork – HS-SPME-GC-MS [32] Bacteria Paenibacillus − Water – SPME-GC-ECD [33] Bacteria Pelomonas − Water – SPME-GC-ECD [33] Bacteria Ralstonia Mannitolilytica Water – SPME-GC-ECD [33] Bacteria Rhodoccoccus Acinetobacter Lake – SPME-GC-MS [13] Bacteria Rhodococcus − Water 5.5 × 10−8 ug*h (cell/mL) GC-MS [34] Bacteria Xanthobacter − Water – SPME-GC-ECD [33] Cyanobacteria Chlorella Vulgaris Lake Initial 0.2 mg/L 2,4,6-TCP;

generated 30.5 ng/L 2,4,6-TCASPME-GC-MS [13] Algae Anabaena Flos-aquae Lake Initially 0.2 mg/L 2,4,6-TCP;

generated 10.2 ng/L 2,4,6-TCASPME-GC-MS [13] Table 1.

Microorganisms associated with 2,4,6-TCA production.

-

Microextraction methodologies Detection methodologies LOD LOQ Analysis time per sample Ref. Instrument Sample type Analytes Fiber type Extraction condition Instrument Column type GC condition MS condition Internal standards HS-SPME Wine d5-TCA PDMS,

100 μmIncubation

temperature: 55 °C

Incubation time: 3 min

Sample extraction time: 11 min

Sample desorb time:

4 minQP-2010 Plus GC-MS (Shimadzu, Kyoto, Japan) RTX-5MS Gas flow 1.61 mL/min

Oven program:

90 °C for 0 min,

10 °C/min to 205 °C, and then 30 °C/min to 280 °CSIM d5-TBA 0.4 ng/L 1 ng/L 32 min [44] HS-SPME Wine TCA, TCP, 2,3,4,6-TeCA, TBA, 2,3,4,6-TeCP, 2,3,4,5-TeCA, PeCA, TBP, PeCP DVB/CAR/

PDMS,

50/30 µmIncubation

temperature: 60 °C

Incubation time: 5 min

Sample extraction time: 45 min

Sample desorb time:

5 minAgilent 7890A

GC-7000B triple quadrupole MSHP-5 Flow rate: 1.18 mL/min

Oven program:

50 °C for 1 min,

10 °C/min to 200 °C, and then 40 °C/min to 280 °C hold for 3 minMS/

MS-MRMTCA-d5 Haloanisoles:

3 ng/L

Halophenols:

10 ng/LHaloanisoles:

10 ng/L

Halophenols: 30−100 ng/L76 min [46] HS-SPME Wine TCA, TeCA, TBA, PCA PDMS,

100 μmIncubation

temperature: 40 °C

Incubation time: 5 min

Sample extraction time: 30 min

Sample desorb time:

15 minScionGC system (Bruker Corporation, Freemont, CA, USA) × Scion QqQ-MS/MS instrument (Bruker) VF-5ms Flow rate: 1 mL/min

Oven program:

90 °C for 5 min,

30 °C/min to 280 °C hold for 7 minSRM 4-iodoanisole TCA: 0.1 ng/L

TeCA: 0.2 ng/L

TBA: 0.3 ng/L

PCA: 0.1 ng/LTCA: 0.4 ng/L

TeCA: 0.6 ng/L

TBA: 0.9 ng/L

PCA: 0.3 ng/L68.33 min [47] HS-SPME Cider TCA, TeCA, TBA, PCA PDMS,

100 μmIncubation

temperature: 40 °C

Incubation time: 5 min

Sample extraction time: 30 min

Sample desorb time:

15 minScionGC system (Bruker Corporation, Freemont, CA, USA) × Scion QqQ-MS/MS instrument (Bruker) VF-5ms Flow rate: 1 mL/min

Oven program:

90 °C for 5 min,

30 °C/min to 280 °C hold for 7 minSRM 4-iodoanisole TCA: 0.2 ng/L

TeCA: 0.2 ng/L

TBA: 0.3 ng/L

PCA: 0.1 ng/LTCA: 0.5 ng/L

TeCA: 0.7 ng/L

TBA: 1.1 ng/L

PCA: 0.5 ng/L68.33 min [47] HS-SPME Cava TCA, TeCA, TBA, PCA PDMS,

100 μmIncubation

temperature: 40 °C

Incubation time: 5 min

Sample extraction time: 30 min

Sample desorb time:

15 minScionGC system (Bruker Corporation, Freemont, CA, USA) × Scion QqQ-MS/MS instrument (Bruker) VF-5ms Flow rate: 1 mL/min

Oven program:

90 °C for 5 min,

30 °C/min to 280 °C hold for 7 minSRM 4-iodoanisole TCA: 0.1 ng/L

TeCA: 0.2 ng/L

TBA: 0.4 ng/L

PCA: 0.2 ng/LTCA: 0.4 ng/L

TeCA: 0.6 ng/L

TBA: 1.3 ng/L

PCA: 0.7 ng/L68.33 min [47] HS-SPME Water TCA, TCP PDMS,

100 μm– GC-2010/parvum 2, Shimadzu, Kyoto, Japan 5MS/Sil Flow rate: 42 cm/s

Oven program:

40 °C for 3 min,

10 °C/min to 80 °C, and then 15 °C/min to

250 °C hold for 3 minSIM – – – > 21.3 min [74] HS-SPME Water 2-CP, 2-BP, 2,4-DCP, 2,4,6-TCP, 2,4-DBP, 2,4,6-TBP, 2,4,6-TCA, 2,4,6-TBA PDMS/DVB,

65 μmIncubation

temperature: 60 °C

Incubation time: 10 min

Sample extraction time: 30 min

Sample desorb time:

3 minAgilent 7890 GC × Agilent 5975 MS HP-5MS Flow rate: 1 mL/min

Oven program:

40 °C for 3 min,

15 °C/min to 235 °C hold for 1 minSIM 4-iodoanisole Haloanisoles: 0.23−0.29 ng/L

Halophenols: 0.24−0.91 ng/LHaloanisoles: 0.97−0.77 ng/L

Halophenols: 0.80−3.30 ng/L60 min [75] HS-SPME Garlic TCA, TBA CWR/PDMS, 120 µm Incubation

temperature: 80 °C

Sample extraction

time: 20 minShimadzu GC-2010 × Shimadzu TQ8050 Rxi-5 ms Flow rate: 35 cm/s

Oven program:

70 °C for 1 min,

10 °C/min to 300 °C hold for 3 min.MS/MS-MRM TCA-d5 – TCA:

0.02 μg/kg

TBA:

0.03 μg/kg47 min [76] SPME Water 2,4,6-TCA, 2,3,6-TCA, 2,3,4-TCA, 2,4,6-TBA PDMS/DVB/

CAB,

50/30 µmIncubation temperature: 70 °C

Incubation time: 10 min

Sample extraction time: 30 min

Sample desorb time:

10 minGC-MS HP-17MS Oven program:

45 °C for 4 min,

10 °C/min to 240 °C hold for 1 min,

30 °C/min to 280 °C

hold for 4 minSIM – 2,4,6-TCA:

0.098 ng/L

2,3,6-TCA:

0.127 ng/L

2,3,4-TCA:

0.109 ng/L

2,4,6-TBA:

0.086 ng/L– 79.8 min [77] Vacuum-assisted HSSPME Wine TCA, TeCA, PCA, TBA PDMS/DVB,

65 μmIncubation

temperature: 25 °C

Incubation time: 10 min

Sample extraction time: 30 min

Sample desorb time:

15 minShimadzu GC-17 A, GC-ECD DB-5MS Flow rate: 1 mL/min

Oven program:

90 °C for 5 min,

20 °C/min to 280 °C hold for 5 min– – TCA 0.16 ng/L

TeCA 0.18 ng/L

PCA 0.19 ng/L

TBA 0.13 ng/L– 74.5 min [78] LLE Wine TCA, TeCA, PCA, TBA, TCP, TeCP, PCP, TBP – – Agilent HP 5980 GC × ECD (Agilent Technologies, USA) CP-Sil 5CB Oven program:

40 °C for 0 min,

3 °C/min to 160 °C, and then 5 °C/min to

220 °C hold for 10 min– – – – >

38 min[79] Pressurized liquid extraction Cork MDMP, IPMP, IBMP, TCA, TCP, TeCA, TeCP, TBA, TBP, PCA – – Agilent 6890 N GC × Agilent 5973 N MS DB-5 Flow rate: 1 mL/min

Oven program:

40 °C for 10 min,

2 °C/min to 155 °C, and then 20 °C/min to

260 °C hold for 9 minSIM 2,3,6-trichloroanisole 0.10 ng/g – > 81.75 min [80] DLLME Wine 2-CA, 4-CA, 2-BA, 2,6-DCA, 2-CP, 4-BA, 4-CP, 2-BP, 2,4-DCA, 4-BP, 2,6-DCP, 2,4,6-TCA, 3M4CP, 2,4-DCP, 2,4,6-TCP, 2,4-DBA, 2,3,4,6-TeCA, 2,4-DBP, 2,4,6-TBA, 2,3,4,6-TeCP, 2,3,4,5-TeCA, PCA, 2,4,6-TBP, PCP – – Agilent 6890 N GC × Agilent 5973 MS HP-5MS Flow rate: 1 mL/min

Oven program:

40 °C for 5 min,

5 °C/min to 105 °C hold for 3.5 min,

5 °C/min to 120 °C hold for 3 min,

10 °C/min to 145 °C,

and then

5 °C/min to 185 °C,

10 °C/min to 200 °C

hold for 0.5 minSIM – 0.006–0.05 ng/mL – 40 min [81] – Cork TCA, TeCA, TBA, PCA – – Agilent 6890N GC × Agilent 5973 MS HP-5MS Flow rate: 1 mL/min

Oven program:

80 °C for 0.6 min,

25 °C/min to 180 °C hold for 0.6 min

25 °C/min to 210 °C

hold for 0.8 min,

50 °C/min to 300 °C

hold for 1.4 minSIM 5-Bromo-2-chloroanisole TCA: 1.6 ng/g

TeCA: 2.6 ng/g

TBA: 1.7 ng/g

PCA: 2.5 ng/gTCA: 5.4 ng/g

TeCA: 8.8 ng/g

TBA: 5.7 ng/g

PCA: 8.5 ng/g> 9.6 min [82] Table 2.

Analysis methodology regarding 2,4,6-TCA.

Figures

(6)

Tables

(2)