-

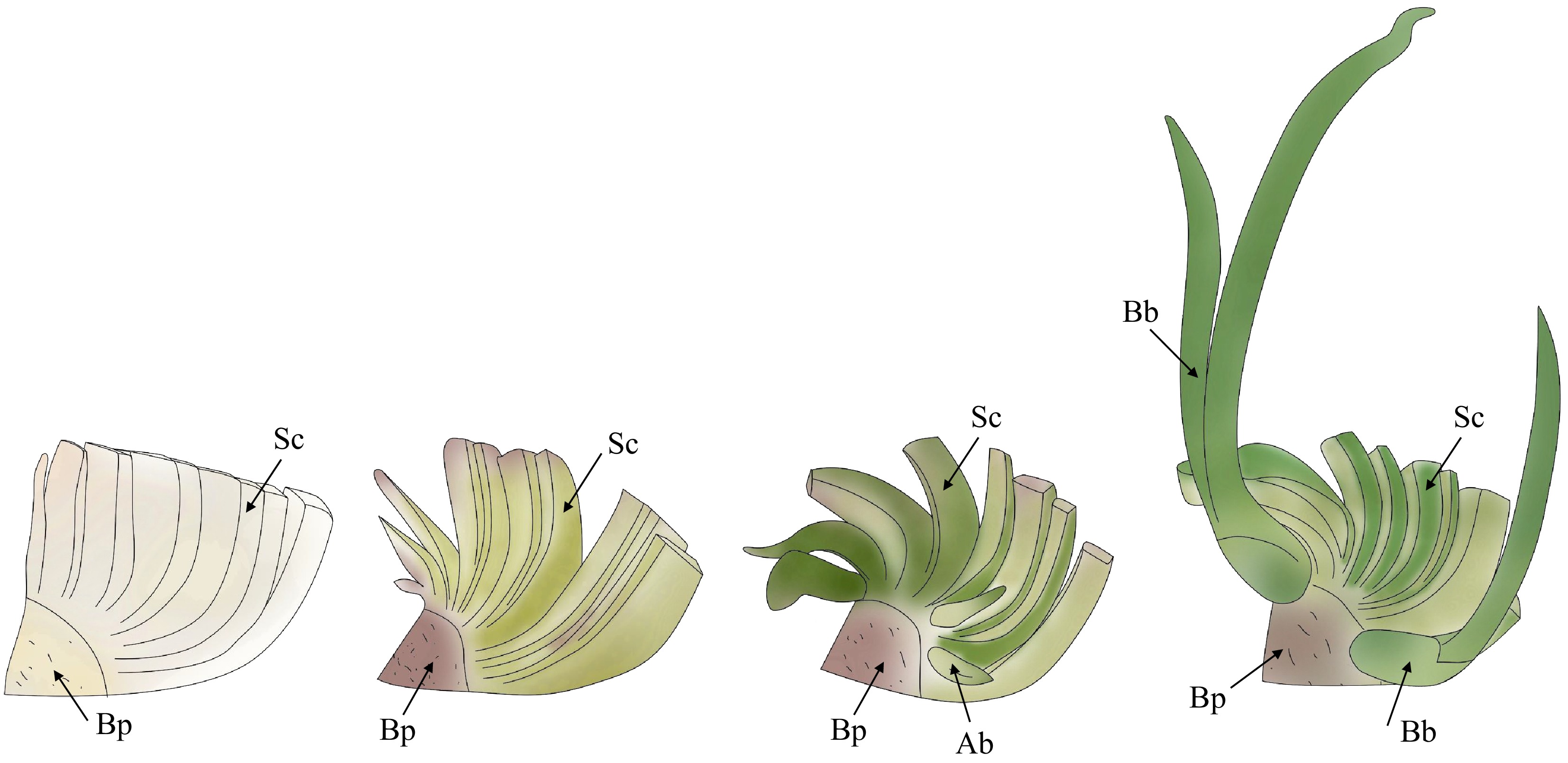

Figure 1.

Schematic illustration of bulblet formation through scale cutting in Hippeastrum. Sc: scales; Bp: basal plate; Ab: axillary bud; Bb: bulblet.

-

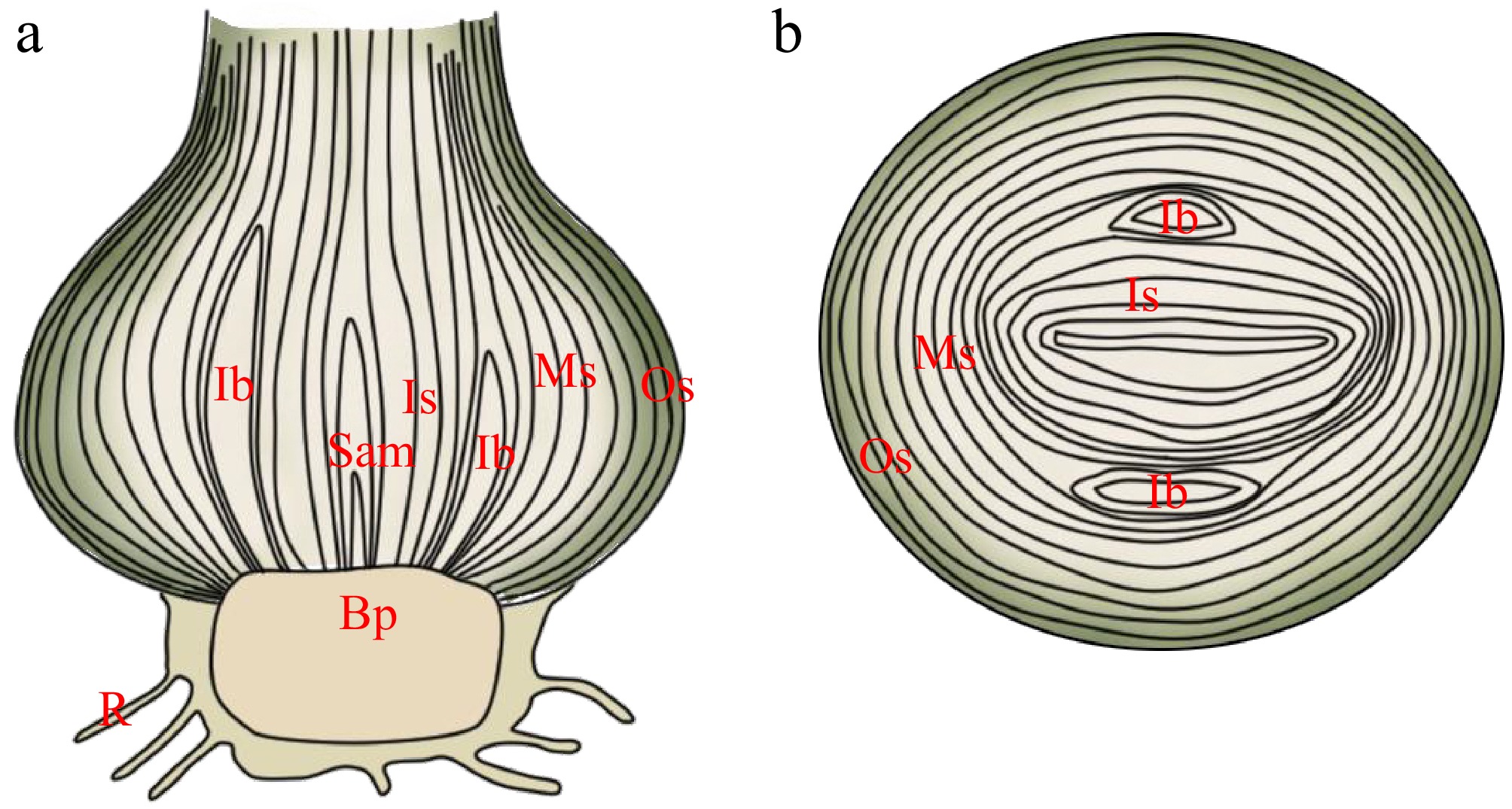

Figure 2.

Schematic diagram of Hippeastrum bulb structure. (a) Longitudinal section of Hippeastrum bulb. (b) Cross-section of Hippeastrum bulb. Based on the classification of Lycoris bulb scales into three layers[15], Hippeastrum bulb scales are similarly divided into outer scales (Os), middle scales (Ms), inner scales (Is), and the basal plate (Bp). Sam: shoot apical meristem; Ib: inflorescence bud; R: root.

-

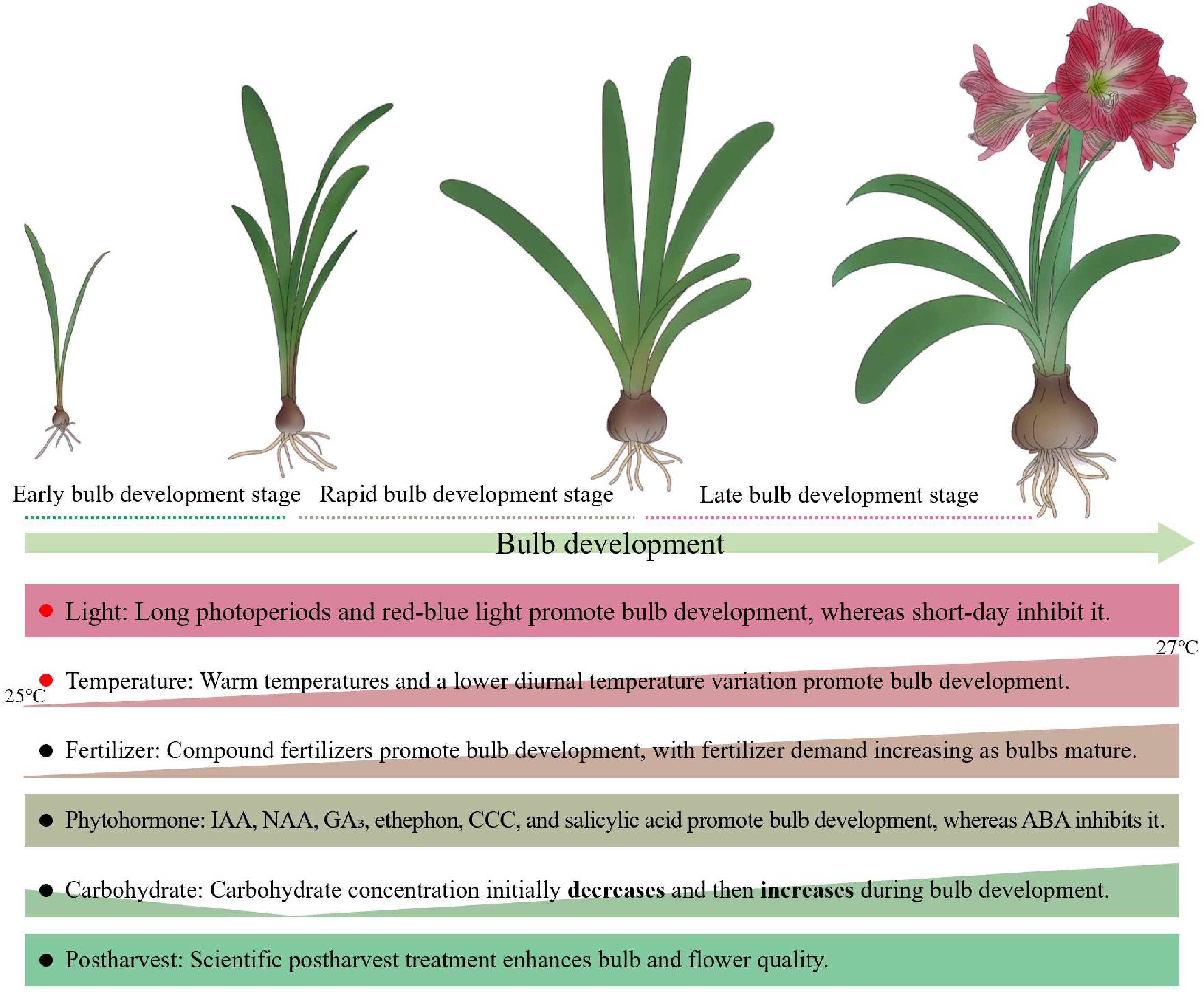

Figure 3.

Diagram of factors affecting Hippeastrum bulb development. The classification of bulb developmental stages is based on current research on bulbous plants[17,18]. Rectangles indicate that regulatory factors (e.g., light and postharvest treatment) that may exert consistent effects across different developmental stages of Hippeastrum bulbs, or whose stage-specific effects remain insufficiently investigated (e.g., phytohormones). Right triangles indicate that the demand for certain factors (e.g., temperature, fertilizers, and carbohydrates) varies across different developmental stages of Hippeastrum bulbs. Red solid dots highlight factors that may serve as critical determinants of Hippeastrum bulb development. IAA, indole-3-acetic acid; NAA, naphthaleneacetic acid; GA3, gibberellin; CCC, chlormequat chloride; ABA, abscisic acid.

-

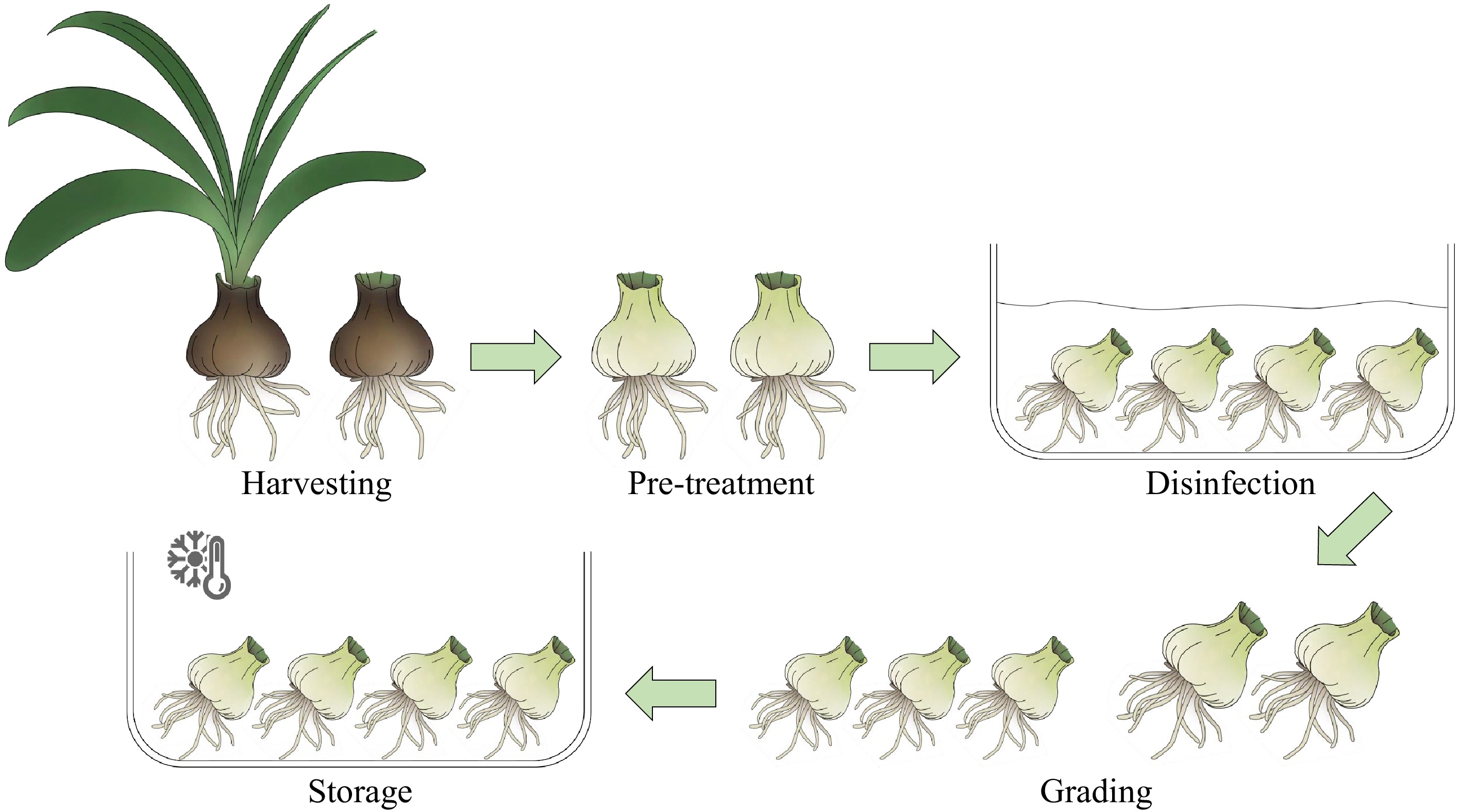

Figure 4.

Diagram of postharvest treatment process for Hippeastrum bulbs. During this process, all leaves should be removed, while the decision to retain or remove the roots should be based on subsequent industry needs, postharvest objectives, storage conditions, and cultivation plans.

-

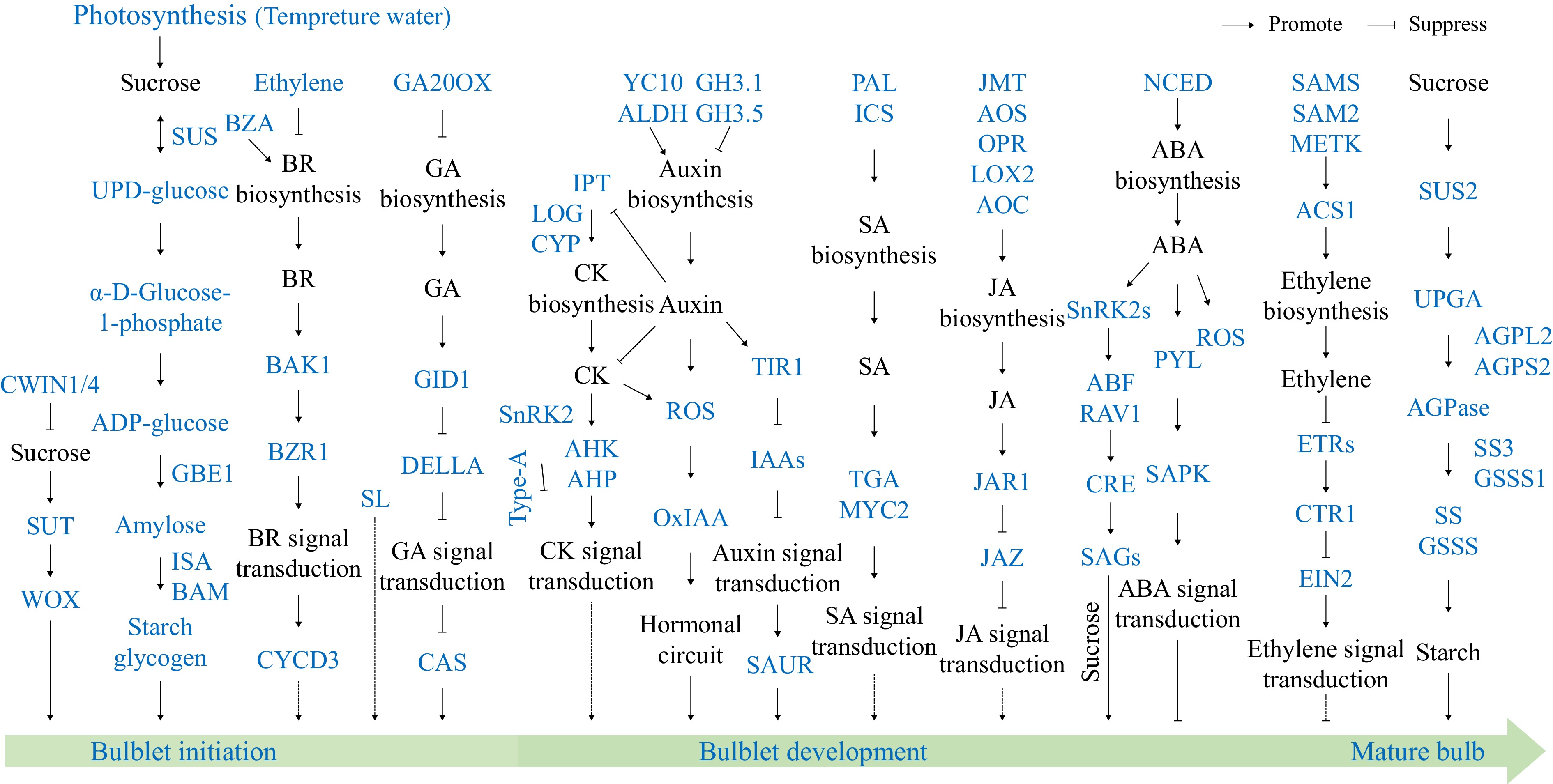

Figure 5.

Integrative regulatory network of bulbil initiation and subsequent development: hormonal, carbohydrate, and environmental mediation. A referenced framework for future research on Hippeastrum (adapted from Fig. 6 of Shu et al.[87]).

-

Processing Detailed approach Purpose/Reason Ref. Harvesting 1. Harvest 30−50 d after flowering.

2. Adjust harvesting time flexibly according to cultivation goals, avoiding overly late harvesting.

3. Harvesting under clear, sunny conditions.1. Bulbs are fully developed, with sufficient nutrient reallocation, which supports the formation of small bulbs.

2. Minimizing the risk of fungal or bacterial infections.[76,79,80] Pre-treatment 1. Remove inactive scales, decayed roots, dead leaves, and surface dirt, and select full, healthy bulbs free of pests and diseases for grading.

2. Retain or remove roots.Eliminate potential disease risks to ensure safe storage and future cultivation. [9,82,83] Bulb disinfection 1. Common disinfectants: Soak bulbs in 700x diluted 70% carbendazim for 40−60 min or soak in 800x diluted 75% chlorothalonil for 20 min.

2. Avoid using copper-based chemicals.Prevent pest and disease infections. [74,83,85] Temperature control 1. Phased treatment: short-term treatment at around 27 °C to remove excess moisture; store at 9−10 °C for 30−60 d.

2. Flexibly arrange the cooling period.1. Promote synchronized sprouting of flower buds and leaf buds, unify flowering time, and improve flowering rate and quality.

2. Extend the storage life of bulbs.[74,77,86] Other treatments Soak the bulb base in a solution containing 150 mg/L GA at room temperature for 1−2 h. Rehydrate and promote root development. [78] Planting or forcing cultivation 1. Plant 60−70 d before desired flowering.

2. Select appropriate varieties and bulb sizes: larger bulbs

(≥ 8 cm in diameter) have higher flowering rates.Table 1.

Postharvest treatment process and key technical points for Hippeastrum bulbs.

-

Treatment category Method Mechanism Detailed approach Physical treatment Optimization of harvest

timingRegulates bulb maturity and ensures adequate nutrient accumulation Harvest 30–50 d after flowering Mechanical pre-treatment Controls pathogens and reduces infection risks Remove dead roots, withered leaves, inactive scales, and surface dirt Cold storage Regulates moisture, suppresses respiration, and delays sprouting Gradual temperature adjustment: (1) Short-term treatment at 27 °C; (2) Storage at 9–10 °C for 30–60 d Chemical treatment Disinfection treatment Inhibits pathogens and reduces fungal/bacterial infections Use carbendazim and chlorothalonil; avoid copper-based chemicals (e.g., Kocide) GA treatment Promotes root development Soak bulbs in a 150 mg/L GA solution for 1–2 h Biological treatment (To be explored) (To be explored) (To be explored) Table 2.

Summary of postharvest treatment techniques for Hippeastrum bulbs.

Figures

(5)

Tables

(2)