-

The sensory profile of European pears is changing as new postharvest treatments and storage methods are introduced in the supply chain. Pears are usually harvested at a mature-green stage and cold-stored before they are allowed to ripen to a soft and juicy texture[1,2]. The exposure to chilling temperatures is required for most pear cultivars to start or hasten the ripening process but can be replaced by exogenous ethylene application[1]. These fruit ripening requirements are likely to interfere with pear responses to the technological attempts to inhibit the effects of ethylene.

The inhibition of ethylene action by the postharvest treatment with 1-methylcyclopropene (1-MCP) is used to prevent superficial scald and to delay the ripening process of pears during storage and post-storage shelf life. 1-MCP is very effective in reducing or preventing superficial scald, slowing softening, and delaying skin yellowing in pears[3,4]. However, an undesirable ripening blockage is sometimes reported in pears treated with 1-MCP[5]. In extreme instances, 1-MCP-treated pears do not soften, a condition described as evergreen fruit[5], a phenomenon that was earlier observed in 'Conference' pear[6].

A consistent effect of 1-MCP in pears is the retention of firmness during storage and slower softening during subsequent shelf life[7,8] and a reduction in respiration rate[9,10], not always associated with a loss of fruit acidity[10,11]. Due to these effects on mechanical properties and on fruit composition, 1-MCP alters the sensory profile of pears. However, conflicting effects of 1-MCP on sensory profile and consumer acceptance are reported. Cluster analyses of sensory scores clearly discriminate 1-MCP-treated 'Abbé Fétel' pear from the untreated control fruit preferred by assessors[12]. In contrast, ripe 'Bartlett' pear that had been treated with 1-MCP were preferred to ethylene-treated or untreated pear; this preference was attributed to the higher sweetness, juiciness, typical pear aroma, lower emission of fermentation-related volatiles, gritty texture, and tart taste of 1-MCP-treated pears[13].

Addressing the effect of 1-MCP on the fruit sensory perception of pears is challenging. As ripening is blocked or delayed by the inhibition of ethylene action, a comparison between 1-MCP treated and untreated fruit on the same sampling date implies different ripening stages. In kiwifruit it was resorted to temperature conditioning to uncouple the effect of 1-MCP from that of the ripening stage per se[14]. These authors showed that kiwifruit treated with 1-MCP and conditioned in a way that hastened the ripening process were perceived as indistinct from untreated fruit, indicating that kiwifruit consumers respond to differences in the ripening stage, not the 1-MCP treatment per se[14].

Instrumental analyses provide a fast and objective means to assess pear quality on a commercial scale. Despite their usefulness, the data from instrumental analysis do not always correlate with those from sensory assessments of acceptance or preference[15]. Therefore, an adequate quality management of pear in the supply chain require a better understanding of the changes in the sensory profiles as affected by postharvest technologies and a better interpretation of the instrumental data from the perspective of consumer acceptance and preference.

The aim of this study was to differentiate the effect of 1-MCP and that of temperature on ripening of 'Rocha' pear and to assess whether the sensory profile during ripening was adequately described by the instrumental measurements commonly used in fruit quality control.

-

Pear (Pyrus communis L. 'Rocha') fruit with an average weight of 190 ± 25 g were harvested at physiological maturity, determined by the skin color, flesh firmness, soluble solids (SS) and titratable acidity (TA), from an orchard located in Cadaval, Oeste Region of Portugal. At harvest, fruit had a hue angle of 106 º (green hue), flesh firmness of 52 N, SS of 110 g·kg−1 and TA of 2 g·kg−1. Fruit were hand sorted for uniform size, absence of disease and external defects or mechanical damages and packed into plastic crates.

Immediately after harvest, fruit were cooled and stored for 30 d in air at –0.5 °C (± 0.3 °C) and relative humidity of 88 to 91%. This time under air at −0.5 °C before treatment was either to simulate a delay in purchasing the 1-MCP by the industry and storage managers, and also to adapt fruit in air before treatments were applied. After 30 d in air at −0.5 °C, sets of 300 fruits were placed inside 250 L plastic containers equipped with a small ventilator and treated with 1-MCP at 150 or 300 nL·L−1 generated from SmartFreshTM (Agrofresh, Inc., Springhouse, PA, USA). The decision in using these two doses of 1-MCP was based on our early experiences in storing pears treated with 1-MCP. Pears are not like apples that have an overall optimal dose around 600 nL·L−1 1-MCP for many apple cultivars. Pears, when treated with higher doses, show the risk of developing the evergreen process in ripening (ripening blockage). The containers remained sealed for 24 h at −0.5 °C, after which time they were vented to the outside of the storage facility and fruit were transferred to a room in air at 20 °C (± 0.3 °C) to ripen. Control fruit were placed under the same conditions inside the containers, but without the 1-MCP treatment. An additional set of fruit untreated with 1-MCP was ripened in air at 10 °C (± 0.3 °C). The ripening temperature of the treatments was monitored with digital thermometers (Hanna Instruments, Woonsocket, RI, USA) inserted inside sample fruits.

Ethylene production rate was measured in three replications of four fruits, each kept in a closed system at ripening temperature of 20 or 10 °C. The temperature of 20 °C was used to simulate the traditional shelf-life period with pome fruits, and the 10 °C to verify the effect of half temperature effect on fruit metabolism during the shelf-life in supermarket where fruits are exposed in refrigerated counters. Ethylene in the headspace of 2.15 L glass jars was separated by gas chromatography (GC Trace 1300, Thermo Fisher Scientific, Waltham, MA, USA) with a capillary column TG bond alumina (Na2SO4) and detected in a flame ionization detector as described by Saquet & Almeida[10].

Respiration rate of pear fruit was expressed by the release of CO2 into the headspace of the glass jars (the same samples that were measured the ethylene production rate). Immediately after ethylene analysis, the CO2 concentration in the glass jars at 20 or 10 °C was measured with an Oxycarb 6 gas analyzer (Isolcell Italia, Laives, Italy) fitted with an infrared sensor and a continuous flow at a rate of 0.1 L·min−1.

Fruit skin color was measured in the CIE L*a*b* color space with a tri-stimulus colorimeter (CR-400, Konica Minolta, Tokyo, Japan) with the C illuminant. The measurements were made on the widest part of each fruit in three replicated samples of 15 fruits each. The a* and b* coordinates were converted to hue angle (hº) as described by McGuire[16].

Flesh firmness was measured after skin removal on two opposite sides of the equatorial region of fruit, with a handheld penetrometer TR Turoni (FT 327, Forlì, Italy) equipped with an 8-mm diameter curved tip. The maximum force required to penetrate the probe 6 mm into the fruit flesh was registered in three replications of 15 fruits each.

Juice was extracted from three replicated samples of 15 fruits each and used for SS and TA. Juice was obtained from 10 mm diameter discs excised from the widest region of each fruit. SS was measured directly in the juice with a refractometer (HI 96801, Hanna Instruments, Woonsocket, RI, USA). TA was calculated after titration with 0.1 M NaOH solution required to increase the pH of 10 mL juice diluted in 90 mL distilled water to a final value of 8.1 and expressed as malic acid equivalents.

Sensory evaluation was performed after 2, 8 and 14 d of ripening at 10 and 20 °C. Fruit were equilibrated at room temperature and cut into slices of 10 mm thick along the axis. Three slices of pears containing the skin were presented to each panelist inside a lidded transparent polypropylene box of 500 mL volume and coded with a random three-digit number.

A panel of 30 assessors was asked to score the samples for the following attributes: skin color, aroma intensity, hardness, sweetness, acidity, juiciness, flavor intensity, off-flavor and overall appreciation, using a numerical scale from 1 to 9. Skin color was scored from greener (1) to yellower (9), aroma intensity from lower (1) to higher (9); hardness from softer (1) to harder (9); sweetness, acidity, juiciness, and flavor intensity from lower (1) to higher (9); off-flavor from absent (1) to intense (9); and overall appreciation from dislike extremely (1) to like extremely (9). The panelists were instructed to first score the skin color, then to open the box and score the aroma, and subsequently to taste the slices and evaluate the remaining quality attributes.

The trial was conducted in a completely randomized design with three replications. Data were subjected to analysis of variance (ANOVA) using the software Action Stat (2014, São Carlos, SP, Brazil). When appropriate, means were separated by Fisher's protected LSD test at α = 0.05. Correlations among the instrumentally measured physicochemical parameters and sensory traits were analyzed using Spearman's rank correlation coefficients and the one-sided null hypothesis tested at α = 0.05.

-

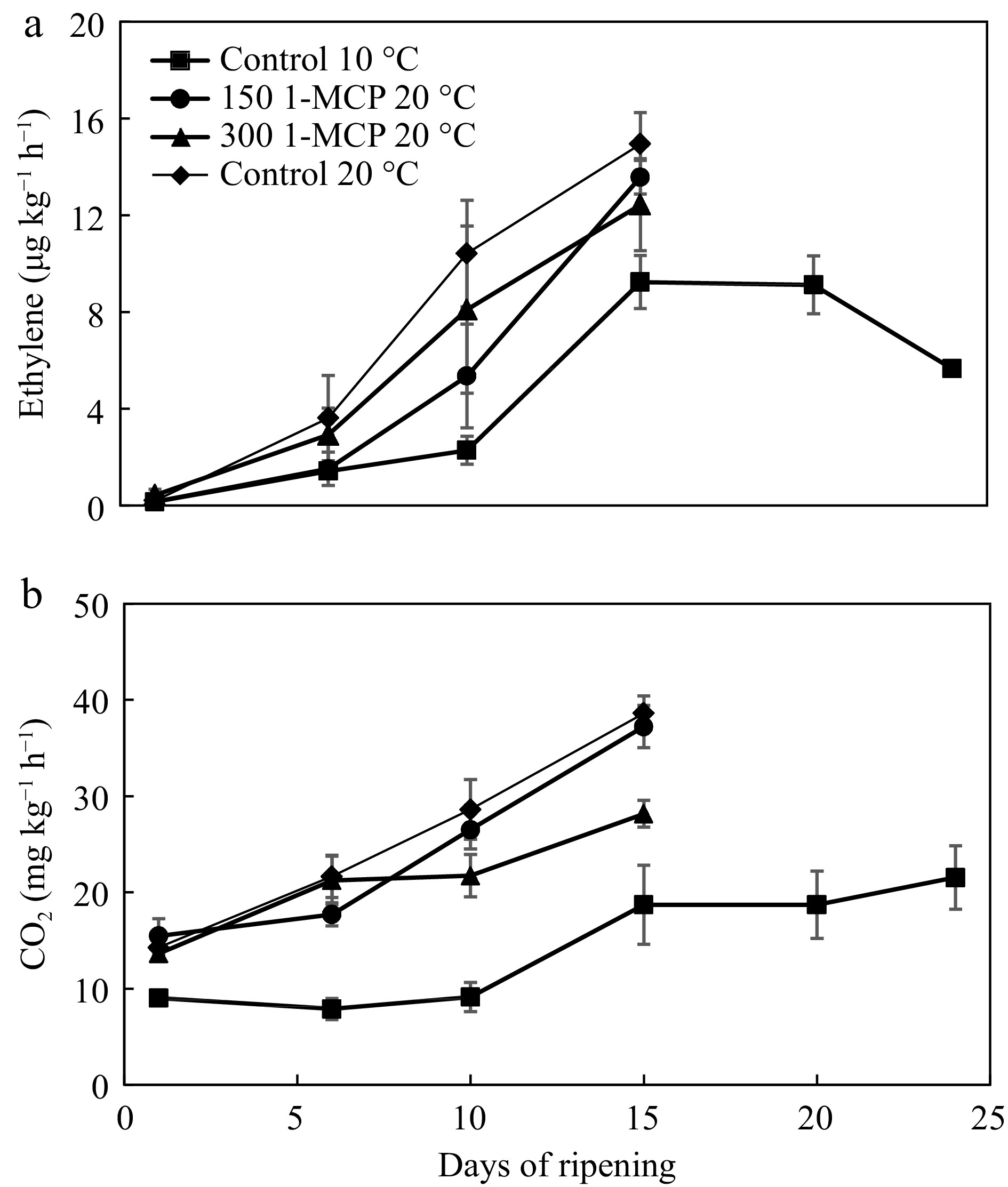

The ethylene production of 'Rocha' pear immediately after harvest was below the detection limit of the method. After transfer from −0.5 to 10 or 20 °C the ethylene production remained very low irrespective of the 1-MCP treatment (Fig. 1a) and increased during ripening to a maximum of 14.9 µg C2H4 kg−1·h−1 in control fruit after 15 d in air at 20 °C (Fig. 1a). In fruit treated with 1-MCP, the rate of ethylene production at 20 °C was slightly lower than that of control fruit but followed the same trend with no significant dose effect (Fig. 1a). Untreated fruit ripened at 10 °C produced ethylene at a lower rate than 1-MCP-treated fruit at 20 °C. Ethylene production by pear fruit at 10 °C increased at a low rate during the first 10 d, reached a peak of 11.3 µg C2H4 kg−1·h−1 at day 15 and decreased thereafter (Fig. 1a).

Figure 1.

(a) Ethylene production and (b) respiration rate of 'Rocha' pear during ripening of untreated fruit at 10 °C and untreated or 1-MCP-treated fruit at 20 °C. Bars are SD (n = 3).

The respiration rate, expressed by the CO2 release, in control fruit at 20 °C increased from 14.2 to 38.6 mg CO2 kg−1·h−1 during the first 15 d of ripening (Fig. 1b). 1-MCP at 150 nL·L−1 did not affect the respiration rate in relation to control fruit, but the treatment with 300 nL·L−1 reduced the peak respiration rate by 27% (Fig. 1b). The control fruit kept at 10 °C respired at an average rate 55% lower than that of fruit maintained at 20 °C (Fig. 1b). The Q10 of respiration rate between 10 and 20 °C ranged between 1.6 at the beginning of shelf life to 3.1 by day 10 and decreased to 2.1 by day 15 (Fig. 1c). On average, the Q10 was 2.4 in control fruit, 2.2 and 2.0 in 1-MCP-treated fruit at 150 and 300 nL·L−1, respectively.

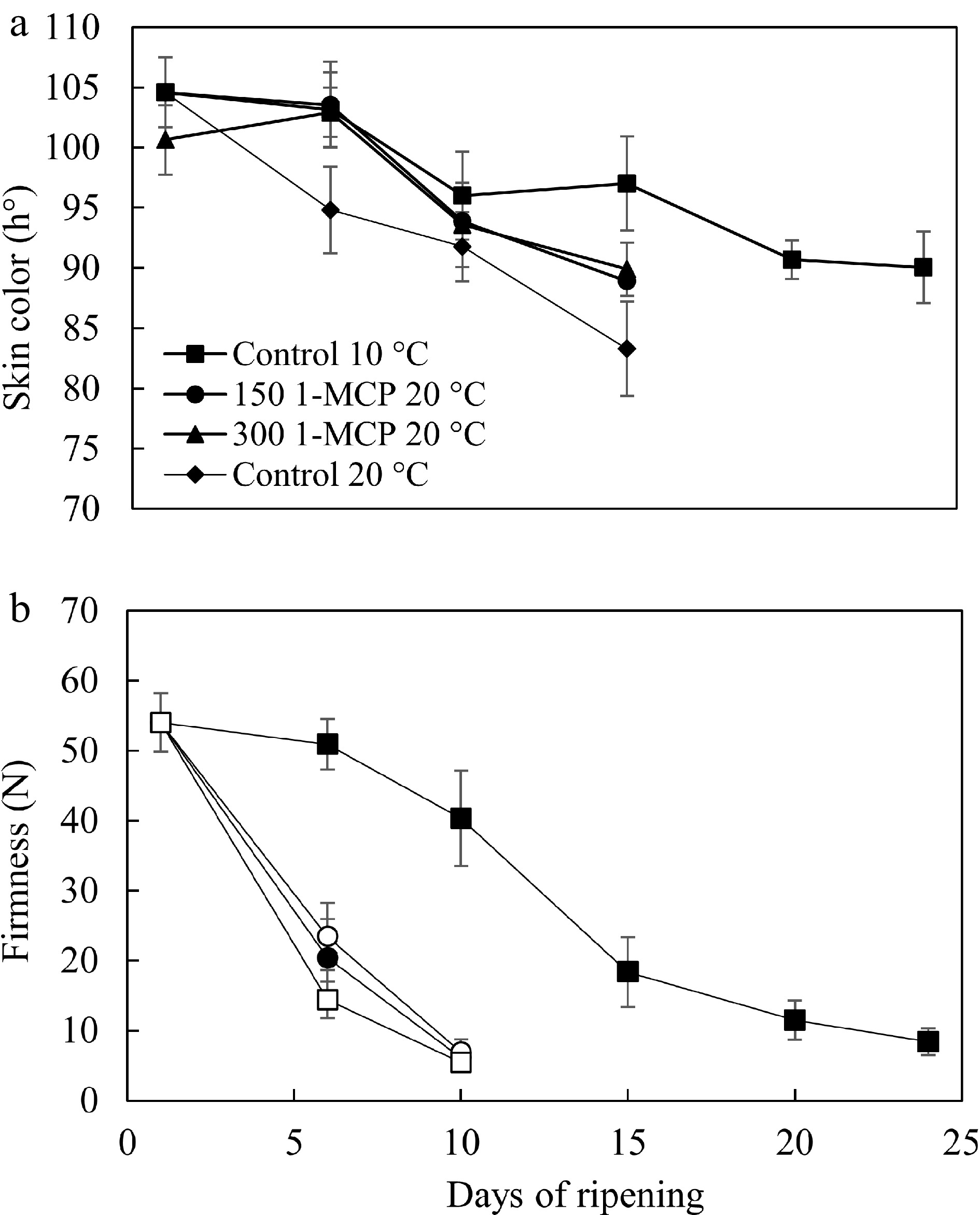

The hue angle is a coordinate suitable to track color changes in 'Rocha' pear from the green hue of mature fruit to the yellow hue of ripe fruit[8]. At the beginning of shelf life, fruit skin had a hue angle of 104° (Fig. 2a). Hue angle decreased faster in control than in 1-MCP-treated fruit during the first 6 d at 20 °C but the difference in hue was reduced after 15 d in yellow fruit (h = 83° to 90°). During ripening at 10 °C, the skin hue angle was significantly higher and after 10 d yellowed at a slower rate than those at 20 °C even than the 1-MCP treated ones (Fig. 2a).

Figure 2.

Changes in (a) skin color and (b) flesh firmness during ripening of 'Rocha' pear during ripening of untreated fruit at 10 °C and untreated or 1-MCP-treated fruit at 20 °C. Bars are SD (n = 3).

At 20 °C, fruit softened at an average rate of 4.7 N d−1 from 54 N to 7 N in 10 d (Fig. 2b). The softening rates during the initial 5 d were 8.5, 7.4, and 6.9 N·d−1 for control fruit and those treated with 1-MCP at 150 and 300 nL·L−1, respectively (Fig. 2b). The final firmness of ripe fruit, however, was similar in both 1-MCP treated and control fruit. At 10 °C, the softening rate was of 1.4 N·d−1, about 70 % lower than that of control fruit ripened at 20 °C; at 10 °C pears required 24 d to reach 8.4 N (Fig. 2b).

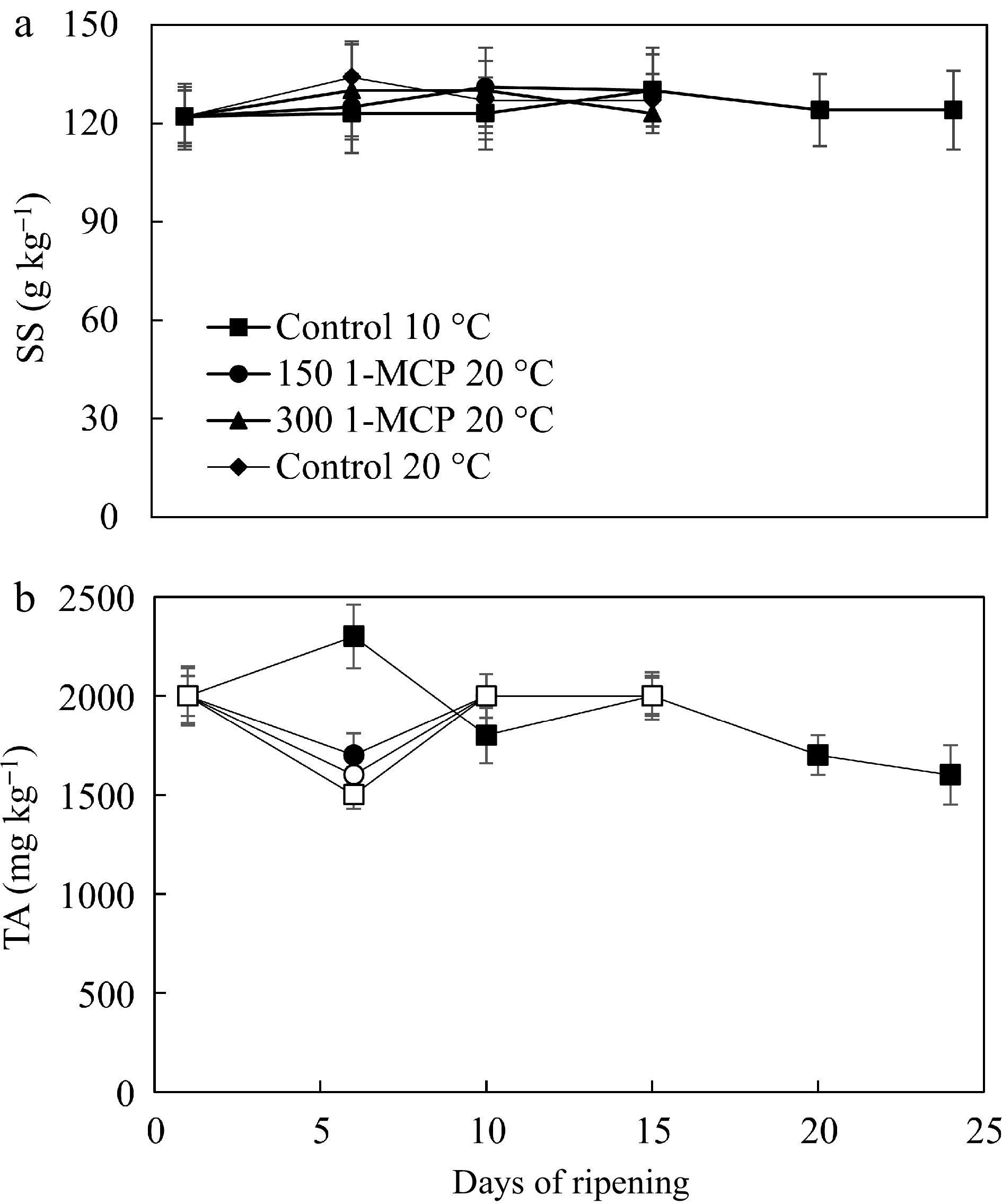

The SS ranged from 122 to 134 g·kg−1 during ripening and was not significantly affected by 1-MCP treatments or temperature (Fig. 3a). TA varied from 2.0 to 1.6 g·kg−1 during ripening with no clear effect of temperature or 1-MCP dose (Fig. 3b).

Figure 3.

(a) Soluble solids and (b) titratable acidity during ripening of 'Rocha' pear during ripening of untreated fruit at 10 °C and untreated or 1-MCP-treated fruit at 20 °C. Bars are SD (n = 3).

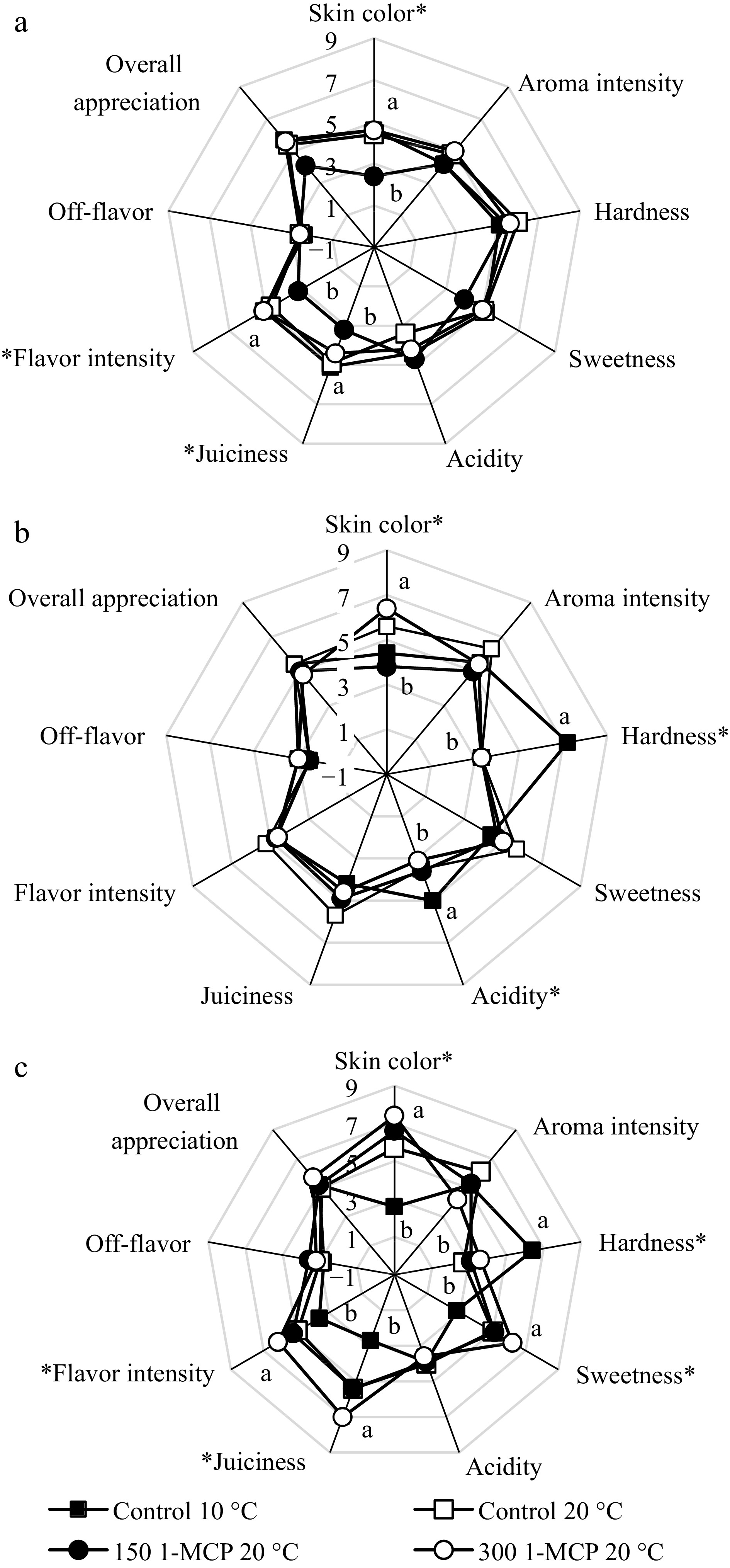

The sensory profiles of pear fruit sampled 2, 8, and 14 d after the beginning of ripening at 10 and 20 °C are shown in Fig. 4. After 2 d, fruit treated with 150 nL·L−1 1-MCP were perceived by panelists as significantly greener, with lower juiciness and lower flavor intensity than the remaining fruit (Fig. 4a).

Figure 4.

Sensory evaluation of 'Rocha' pear after (a) 2, (b) 8 and (c) 14 d of ripening of untreated fruit at 10 °C and untreated or 1-MCP-treated fruit at 20 °C. Values are mean scores (n = 25). *, Significant at the 0.05 level.

After 8 d, fruit ripened at 20 °C, irrespective of the treatment with 1-MCP, were perceived as significantly yellower, softer, than at day 2. Between day 2 and day 8, the average score of aroma increased much less in fruit treated with 1-MCP than in untreated fruit, either at 20 or 10 °C, and the acidity score actually decreased in both 1-MCP treatments but not in untreated fruit (Fig. 4a & b). In the same period, the sensory scores of juiciness and flavor intensity increased more in fruit treated with 1-MCP at nL·L−1 than in any other conditions. After 8 d, fruit ripened at 10 °C were judged by panelists as harder, more acidic, and greener than those ripened at 20 °C, although the skin color of these fruit was similar to fruit treated with 150 nL·L−1 1-MCP (Fig. 4b). This is consistent with the instrumental measurement of firmness (Fig. 2b), but not with the actual acidity (Fig. 2d).

As ripening progressed further, the sensory profiles became more differentiated. After 14 d, significant differences were perceived in skin color, hardness, sweetness, juiciness, and flavor intensity (Fig. 4c). Panelists perceived pears ripened at 10 °C as harder, greener, with lower sweetness, juiciness, and flavor intensity than all other samples. Fruit treated with 300 nL·L−1 1-MCP were classified as the sweetest, juiciest and with the better flavor intensity (Fig. 4c). Between day 8 and 14, the scores of fruits treated with 1-MCP at 150 and 300 nL·L−1 1-MCP significantly increased for color (yellower), juiciness, and flavor intensity (Fig. 4b & c).

The closeness of the relationship between the instrumentally measured hue angle, flesh firmness, SS, and TA and the sensory attributes skin color, hardness, sweetness, and acidity was evaluated using the Spearman's rank correlation coefficients (Table 1). Significant correlations were observed between hue angle and perceived skin color, and between firmness and sensory perceived hardness, but not between SS and sweetness or between TA and perceived acidity.

Table 1. Spearman's rank correlation coefficients between instrumentally measured and sensory assessed characteristics of 'Rocha' pear (n = 12).

Instrumental variable Sensory attribute Spearman's rho1 Hue angle (º) Skin color −0.654* Firmness (N) Hardness 0.661* SS (%) Sweetness 0.224n.s. Titratable acidity (%) Acidity 0.510n.s. 1*, significant at the 0.05 level; n.s., non-significant. -

Pears respond differently to 1-MCP treatment depending on cultivar, maturity stage, dose of 1-MCP, and time of application[17]. 'Rocha' pear is able to ripen immediately after harvest without exposure to chilling temperature or exogenous ethylene application[10]. Additionally, the inhibition of ethylene action by a treatment with 1-MCP immediately after harvest delays, but does not impair the ripening of 'Rocha' pear[10]. In the current study, fruit were treated with 1-MCP after 30 d in air at −0.5 °C, a chilling exposure that promotes ethylene biosynthesis in pear[18].

The effect of 1-MCP on climacteric ethylene production and respiration rate is small or absent when the treatment is applied to pear after initiation of ripening process[19]. The results reported herein show that 1-MCP at 300 nL·L−1 slowed the ripening metabolism as indicated by the decrease in ethylene production and respiration rate (Fig. 1). However, the ripening temperature had a stronger effect on the metabolic rate of 'Rocha' pear; the ripening of untreated fruit at 10 °C was slower than fruit treated with 150 or 300 nL·L−1 1-MCP at 20 °C (Figs 1 & 2).

The change in metabolic rate induced by 1-MCP and by temperature had differential effects on the ripening-related changes in skin color, flesh firmness, soluble solids and acidity, characteristics that, taken together, are considered as reliable indicators of the eating quality of pears[20].

Skin color is the major determinant of the visual appraisal of pears[20]. The treatment with 1-MCP retained the green hue angle during 5 d at 20 °C and subsequent yellowing occurred at a similar rate to that of untreated fruit at the same temperature. Fruit ripened at 10 °C remained greener that those ripened at 20 °C for 24 d indicating that lower ripening temperature was more effective in keeping the green skin color than the treatments of cold-exposed fruit with 1-MCP.

In contrast to color, the softening rate was not affected by 1-MCP during ripening at 20 °C. Under these conditions, all pears reached a firmness of 7 N after 10 d. However, the ripening temperature had a stronger effect on softening and the fruit at 10 °C reached 10 N after 24 d.

Clearly, color and firmness are the two physical properties whose change during ripening could be decoupled by a treatment with 1-MCP or by ripening temperature. The differential modulation of color and firmness allowed a range of values at each sampling date to allow the assessment of possible correlations between instrumental measurement and sensory perception (see below).

The chemical properties SS and TA are strong determinants of pear flavor and consumer experience. It has been suggested that a minimum SS of 113 g·kg−1 is required for consumer acceptance of pears[21]. However, SS alone is not always a reliable indicator of flavor quality. The ratio between SS and TA provides a better indicator of pear flavor quality and can clarify a decision during the sensory evaluation[20,22]. Neither 1-MCP nor ripening temperature affected SS contents, but fruit ripened at 10 °C kept higher TA during the first 5 d than fruit ripened at 20 °C.

Skin color, juiciness, flavor intensity, hardness, sweetness and acidity, were the sensory attributes perceived as different during ripening of 'Rocha' pear under the various conditions and evaluation times (Fig. 4). Off-flavor was consistently scored as low, and the aroma intensity and the overall appreciation were similar in pears subjected to the different treatments, with the latter indicating the different preference among the panelists.

The sensory profile evolved during the 14 d of ripening and the effect of temperature and ethylene inhibition become more evident over time. 1-MCP applied at 300 nL·L−1 after 30 d in air storage at −0.5 °C slightly delayed the ripening of 'Rocha' pear at 20 °C without impairment. Pears treated with 300 nL·L−1 1-MCP were scored as significantly sweeter, juicier and with higher flavor intensity. Hardness of these fruit was similar to the other treatments. Flavor maintenance or enhancement by the treatment with 1-MCP was reported in 'Packham's Triumph'[11] and 'Conference'[23] and 'Spadona'[24] pears stored in air. 'Packham´s Triumph' pear, treated with 200 nL·L−1 1-MCP at harvest, were perceived as better in firmness, color, aroma, sweetness, and a better overall acceptance after six months of air storage[11]. Similarly, 'Bartlett' pear treated with 600 nL·L−1 1-MCP had more desirable sensory traits, as compared with ethylene-treated and untreated pear: Higher sweetness, juiciness and typical pear aroma, reduced fermented aroma, gritty texture and tart taste[13].

However, the preference for 1-MCP treated pear is not always reported. 'Abbé Fétel' pear treated with 300 nL·L−1 1-MCP, perceived as firmer with grainy texture, were less preferred by panelists compared to control fruit[12]. Additionally, 1-MCP-treated 'Conference' pear were described by panelists as hard and poor in flavor after six months storage followed by a 10 d shelf life in relation to fruit ripened with a combination of 1-MCP and ethylene[25].

The temperature conditioning of 1-MCP-treated pears are likely to play a role in the sensory perception. In kiwifruit, consumers perceived 1-MCP-treated fruit as firmer, less juicy, less sweet and less flavorful than control fruit. However, altering the ripening rate by temperature conditioning to hasten ripening of 1-MCP-treated in relation to untreated fruit made it impossible for panelists to distinguish between treatments[14]. Similarly, differences in the sensory evaluation of 'Rocha' pear treated with 1-MCP may be associated to different ripening stages induced by treatments, and in this case, mainly due to ripening during shelf life at 20 °C.

The Spearman's rank correlation coefficients apply to variables that are not normally distributed and/or linearly related necessarily as long as the relationship among variables is monotonic[26]. Hue angle and flesh firmness, the two physical variables that were significantly associated to their sensory counterparts, skin color and hardness, respectively, were also the two variables that had the widest range of measurements.

The hue angle of the pear skin within the interval 104.6° (green) to 83.3° (yellow) was correlated with the sensory perception of skin color (Table 1). The negative correlation is due to the definition of the sensory scale from green (low value) to yellow (high value); this direction of color change, related to the progression of ripening, is opposed to the variation of the hue angle from green (higher values) to yellow (lower values). The use of the sensory scale resulted in a coefficient of variation of color scores of 30%, much higher than the 7% associated with the hue angles.

Flesh firmness of pears between 54.0 and 5.5 N was correlated with the sensory perception of hardness (Table 1). The large changes in flesh firmness associated with ripening-related softening (Fig. 2b) had a coefficient of variation of 63%. The coefficient of variation of sensory hardness scores was 32%, lower than that of flesh firmness measured with a penetrometer. Texture is a key factor in fruit quality assessment but a reliable relationship between objective measurements and subjective sensory methods is not always feasible[15]. It has been argued, that no instrumental analyses are currently adequate to replace the human sensory perception[27]. However, practical considerations related to the time, the expertise, and the costs associated to sensory evaluations, instrumental analyses are frequently used in quality control[27]. On the other hand, the correlation between SS and the perception of sweetness was not significant (Table 1). This is likely due to the narrow interval of SS in the sampled pears, ranging from 122 and 134 g·kg−1. SS measurements in the pear samples were much less variable that the sensory scores of sweetness, with coefficients of variation of 3% and 17%, respectively.

The correlation between titratable acidity and the sensory perceived acidity by the sensory taste panel was also non-significant at the 0.05 level although moderately positive (Table 1), likely due to the narrow range found (1.5 to 2.3 mg·kg−1). The variation of titratable acidity among pears was similar to that of the sensory acidity scores, with coefficients of variation of 10% and 14%, respectively.

-

The ripening of 'Rocha' pear at 10 °C progressed at a rate of 1.7 fold slower than that of 1-MCP-treated fruit at 20 °C. The temperature during ripening was more important to the rate of ripening changes than 1-MCP. The treatment of 1-MCP at 150 and 300 nL·L−1 after 30 d in air at −0.5 °C reduced the metabolic rate without impairing fruit ripening. Fruit ripened at 10 °C for 14 d were perceived as harder, less sweet, less juicy, and with lower flavor intensity that fruit treated 1-MCP and ripened at 20 °C for the same period. Instrumentally measured hue angle and flesh firmness correlated to sensory scores of skin color and hardness. Soluble solids and titratable acidity were not associated to the sensory scores of sweetness or acidity.

-

The authors confirm contribution to the paper as follows: study conception and design: Saquet AA, Almeida DA; data collection: Saquet AA, Almeida DA; analysis and interpretation of results: Saquet AA, Almeida, DA; draft manuscript preparation: Saquet AA, Almeida DA. Both authors, Saquet AA and Almeida DA, reviewed the results and approved the final version of the manuscript.

-

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

-

The authors are grateful to Prof. Dr. I. Recasens (Universitat de Lleida, Lleida, Spain) and Prof. Dr. E. Tsantilli (Agricultural University of Athens, Athens, Greece) for reading this manuscript and helpful suggestions.

-

The authors declare that they have no conflict of interest. Adriano Arriel Saquet is the Editorial Board member of Technology in Horticulture who was blinded from reviewing or making decisions on the manuscript. The article was subject to the journal's standard procedures, with peer-review handled independently of this Editorial Board member and his research groups.

- Copyright: © 2023 by the author(s). Published by Maximum Academic Press, Fayetteville, GA. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Saquet AA, Almeida D. 2023. Sensory and instrumental assessments during ripening of 'Rocha' pear: the role of temperature and the inhibition of ethylene action on fruit quality. Technology in Horticulture 3:23 doi: 10.48130/TIH-2023-0023

Sensory and instrumental assessments during ripening of 'Rocha' pear: the role of temperature and the inhibition of ethylene action on fruit quality

- Received: 14 July 2023

- Accepted: 21 September 2023

- Published online: 06 November 2023

Abstract: The aim of this research was to differentiate the effect of 1-methylcyclopropene (1-MCP) from that of temperature on ripening of 'Rocha' pear and to assess whether the sensory profile during ripening was adequately described by the instrumental measurements commonly used in fruit quality control. Fruit of 'Rocha' pear from an orchard located in Cadaval, Oeste Region of Portugal were stored in air at −0.5 °C for 30 d subsequently treated with 1-MCP at 150 or 300 nL·L−1. Untreated control fruit were ripened at 10 or 20 °C and 1-MCP-treated pears ripened at 20 °C. Sensory and instrumental assessments were carried out on ripening fruit. A detailed taste panel was carried out to check the quality of the fruit. At the end of the experiment, untreated fruit at 10 °C ripened at about half the rate of all fruit at 20 °C, untreated or even 1-MCP treated. Fruit ripened at 10 °C were sensory perceived as harder, greener, less juicy and less sweet than all the others. After 14 d ripening at 20 °C, fruit treated with 300 nL·L−1 1-MCP were juicier, sweetest and showed higher flavor intensity. Instrumentally measured skin color and firmness correlated with the sensory scores of color and hardness. The temperature had a stronger effect on the sensory profile and ripening of pear, than the 1-MCP treatment.

-

Key words:

- Flavor /

- Fruit quality /

- 1-methylcyclopropene /

- Pyrus communis /

- Sensory profile.