-

Chicken meat has long been a favorite animal protein source because it is more affordable and nutritious[1]. Broiler meat accounts for more than 90% of the consumer market for chicken meat, about 28.15% of total global meat consumption[2]. As the living standards improved continuously, people’s dietary consumption has shifted from the demand for quantity to the pursuit of quality. Particularly the demand for high quality broiler meat is increasing. Owing to a growing supply of pre-cut poultry meat products, rapid growth of broiler meat has become a primary screening criterion for breeding in the modern broiler industry[3]. Although the rapid growth raises the yield of broiler breast, meat quality problems appear to emerge concurrently. In the 1980s, when people paid more attention to the growth rate and yield of broiler, muscle myopathy and meat abnormality problems related to broiler breast began to occur[4,5]. The problems are worsening in the 21st century.

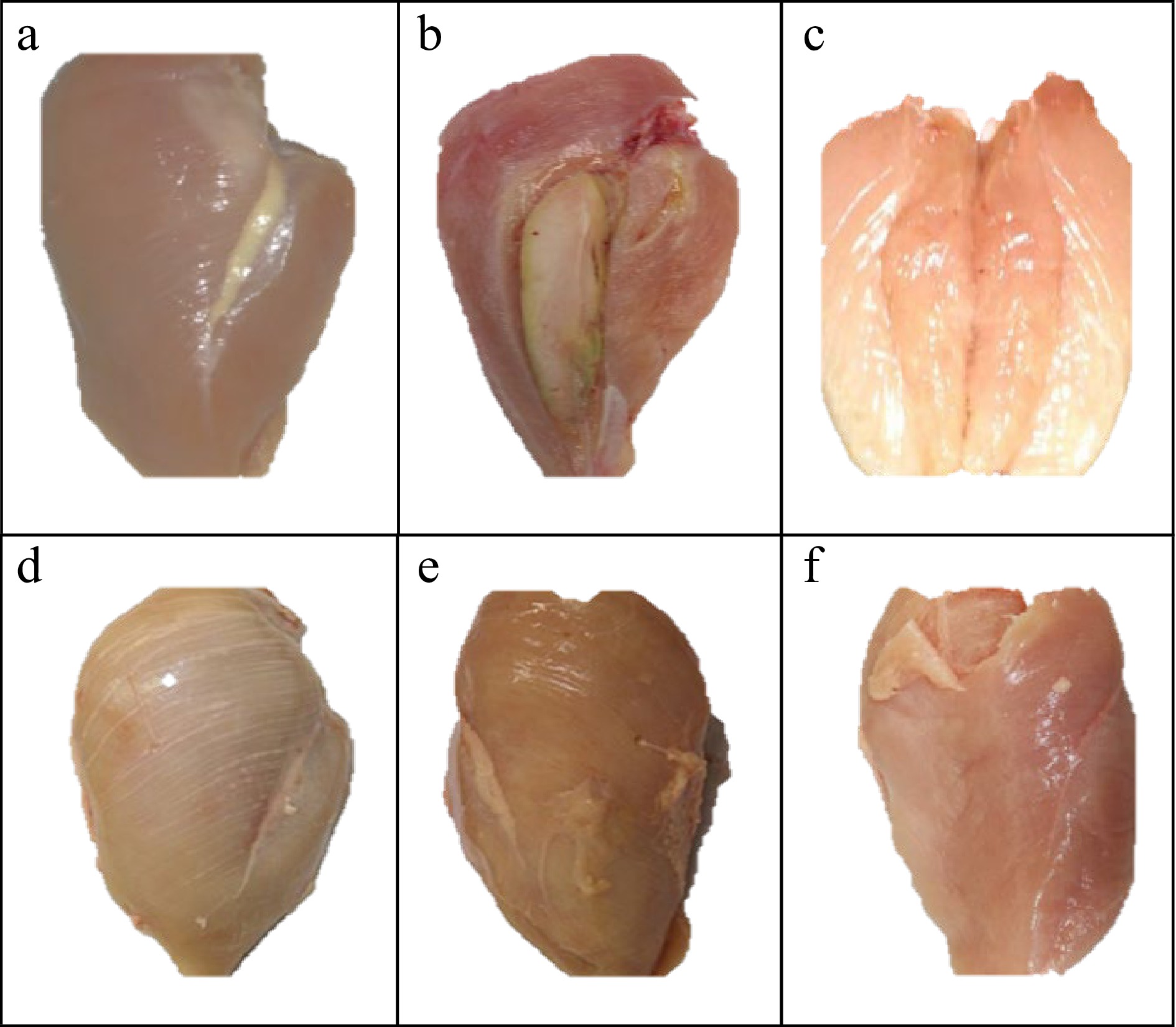

As shown in Table 1, among these emerging muscle abnormalities of broiler breast, deep pectoral muscle (DPM)[5], PSE (pale, soft, exudative)-like broiler meat, wooden breast (WB), white-striping (WS) meat and spaghetti meat (SM) are widely-acknowledged representatives (Fig. 1)[6]. Besides, pink chicken meat (commonly referred to as pinking) in cooked broiler is also a common meat abnormality. It is often found in unmarinated broiler products, even though the end-point temperature exceeds the minimum temperature required by the food safety regulations for poultry meat[7]. Pink color meat abnormality does not really affect meat quality of broiler, and it happens intermittently and randomly. Research has shown that it can be significantly reduced by adding metal chelators, dairy proteins, citric acid, calcium chloride and phosphates[8]. Therefore, in this review the above three less influential abnormal broiler meat problems are not discussed.

Table 1. Impacts of broiler muscle myopathies/abnormalities on organoleptic and functional properties of muscles and proteins.

Item Appearance Quality characteristics Meat gel quality Reference DPM (deep pectoral muscle) The muscles color turns green Z-line disintegration; actin filaments decomposition; nuclear and organelle destruction Not investigated Lilburn et al. (2019);

Barbut et al. (2019)PSE (pale, soft and exudative) -like broiler meat Pale, soft and exudative Proteins solubility declines; myosin thermal stability and pH decline Gel structure and WHC (Water holding capacity) of salt soluble protein decreased Grashorn (2010);

Chen et al. (2018);

Dong et al. (2020)WB (wooden breast) Texture hardness, the caudal area has a ridge protrusion Protein content and water holding capacity (WHC) declines; hardness, pH, water content and crude fat content increased Gel microstructure loose; have a higher α-helix content, lower β-sheet and β-turn content

Same as WBBaldi et al. (2019);

Soglia et al. (2020);

Liu et al. (2011)WS (white-striping) White fat deposits Same as WB Same as WB Kuttappan et al. (2016) SM (spaghetti meat) Impaired muscular integrity, connective tissue sparse Muscle pH, WHC, and protein solubility declined; emulsion stability impaired Not investigated Baldi et al. (2017);

Tasoniero et al. (2020)

Figure 1.

Normal and different abnormal types of broiler breast meat. (a) Normal meat, (b) deep pectoral muscle, (c) PSE-like meat, (d) white-striping, (e) wooden breast, (f) spaghetti meat.

Abnormal meat problems have been also found in turkeys and broiler thighs. However, compared with broiler breast meat, the abnormal meat problems either have little or marginal effect on quality traits. Among all breeds of broilers, white feather broiler is the most important consumptive in the industry[9]. In recent decades, abnormalities of broiler breast meat did not appeared at the same time in. With changes in human consumption habits, the characteristics of abnormal broiler meat are difficult to be accepted by consumers[10,11]. Broiler breast abnormalities affect not only the color and texture of meat surfaces, but also the functional properties of muscle proteins. Table 1 shows the impact of meat abnormalities on meat quality. Any abnormality is accompanied with a certain degree of damage to the meat functionality[12]. Owing to huge economic impacts, abnormal broiler meat condition has a relevance to poultry industrial development.

In recent years, many studies have been conducted to elucidate the causes of broiler breast meat abnormalities and/or myopathies[13]. The origin of these myopathy may arise from an inherited metabolic disorder[14,15]. This conclusion is enough to show that the problem of abnormal meat cannot be solved overnight, and the control of its source is the key factor. To detect these myopathies and/or abnormalities rapidly and effectively in a large flock of broilers, researchers have established classification levels and standards for abnormal meat based on new spectroscopical techniques[16,17]. These detection technologies can enable producers to screen out abnormal meat for further processing[18,19]. To reduce the impact, many studies have been conducted to reduce the incidence of abnormal meat. The research focuses include changing feed formulation and limiting feed intake[20]. To date, it is difficult to reduce growth-related abnormalities or muscle myopathies in broilers, without affecting feed efficiency and slaughter performances[21]. Because of the continuous increase in demand of poultry meat, breeders and producers will most likely continue to increase the growth rate and meat yield of broilers. In other words, solving the problem of abnormal meat from the source is still a big challenge, and improving the utilization of existing abnormal meat maybe the key choice.

Therefore, processing and utilization of abnormal meat become crucial for sustainability and availability of protein supplies. The quality issues caused by muscle abnormalities and/or myopathies are not food safety concerns or do not harm human health. However, current research on the abnormal meat has focused predominately on their etiology. Studies on their processing and utilization are very much limited. Moreover, there is a lack of systematic investigation of validated processing technologies. Therefore, it is difficult to provide efficient guidance for utilization of the abnormal meat. In this review, we discuss the latest findings in studies on the processing and utilization of abnormal broiler breast meat and provide an insight into the comprehensive utilization of abnormal meat. Overall, the review provides reference to broiler research and processes and helps industry, to recover the economic losses due to the abnormalities.

-

PSE-like broiler meat has become an intractable issue for poultry processors in recent decades. The unusual characteristics of PSE-like broiler meat are pale, soft, and easy to lose juice or unable to retain moisture[3]. The surface of raw broiler breast meat looks pale, which decreases sensory quality of fresh meat and reduces consumers' wish to buy[22]. At present, research is focussed on the exploration of the formation reasons and improvement of PSE-like meat.

Formation mechanism of PSE-like meat

-

PSE-like meat is associated with the changes of water holding capacity (WHC), pH, color, and microstructure. Compared with normal meat, space between PSE-like broiler muscle cells is much greater[23]. The lower pH of muscles reduces WHC. This is due to the more moisture migration from the muscles to extracellular space. Similar to WHC, the color of broiler meat is also altered by the change of muscle cell space. Carvalho et al. testified that with the expansion of muscle cell space, the specific surface area of muscle cells increases, the reflection of light increases on the surface of meat appearing pale and shallow[24]. Therefore, the color measurement is mainly used to perform rapid non-destructive testing and classification of PSE-like broiler meat.

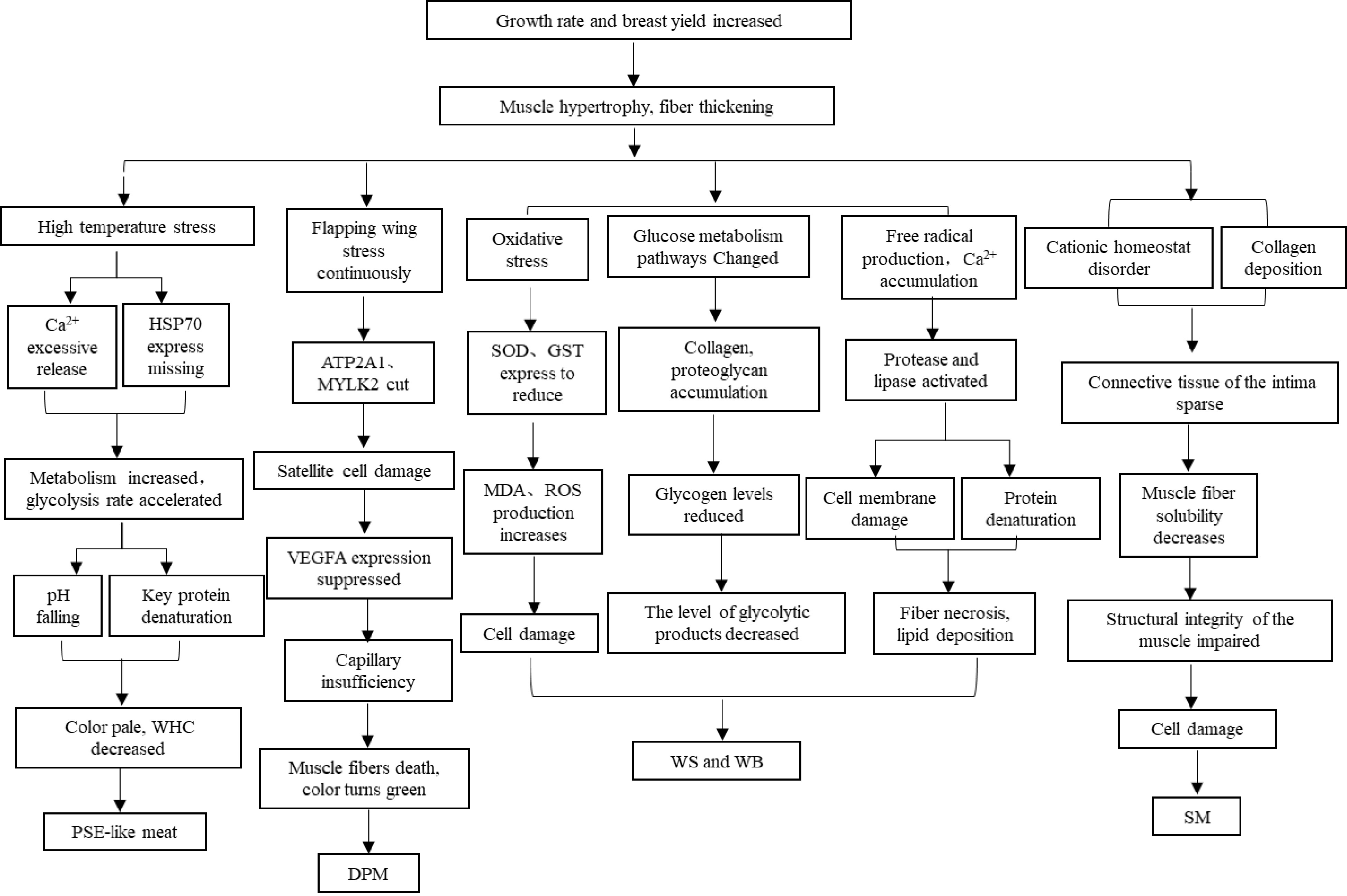

The rapid growth and muscular hyperplasia in broiler breast increase muscle sensitivity to stress, leading to the appearance of some spontaneous or idiopathic abnormal broiler breast meat. The formation mechanism of PSE-like meat and other abnormal meat are shown in Fig. 2. Stress (such as physical stimulation and high temperature) is widely known as the primary cause of PSE-like broiler meat[25]. Stress can stimulate the neuro-endocrine system of animals, influence their immunity, physiological and metabolic functions. In the early postmortem period, stress further caused muscle changes in physiological and biochemical[23]. Stress results in a different extent of damage in a variety of animals, and birds are more susceptible to the impact of heat stress[13]. For broilers, stress causes the imbalance of energy state, accelerates the initial glycolysis rate after slaughter, and leads to the rapid decomposition of glycogen and the accumulation of lactic acid. Stress arouses the transformation in the activity of calcium-activated enzymes and cathepsin, affects the degradation of key skeleton proteins, and leads to changes in muscle tenderness and WHC. Stress altered some key proteins posttranslational modifications, such as phosphorylation, oxidation, nitrification and acetylation[26]. Stress also leads to a disturbance of calcium ions and redox balance, causing cell apoptosis, and thus affecting meat quality[27]. The combination of these above-mentioned may promote the formation of PSE-like broiler meat.

The influence on quality of PSE-like broiler meat

-

Compared with normal meat, the protein solubility and the thermal stability of myosins and sarcoplasmic proteins declined in PSE-like broiler breast meat[25]. The low solubility of PSE-like broiler breast meat protein limits the extraction of proteins, and the denaturation of myosin will have adverse influences on deep processing (product processing) of PSE-like broiler meat[3]. PSE-like broiler meat has a weak gel forming ability. The gel is softer than that made from normal poultry meat[8]. The comminuted products with PSE-like broiler meat form aggregated gel matrix after heating, while normal meat formed a good gel network structure with many protein filaments[13]. PSE-like broiler meat proteins have less α-helix and β-fold structures and reduced exposure of hydrophobic groups and tyrosine residues[28]. Thus, the solubility, gel texture (reduced hardness and elasticity), and WHC of salt soluble proteins are affected. The porous gel microstructures of PSE-like meat weaken the ability to trap water and impair the textural properties. The less β-fold content indicates that PSE-like meat hindered the cross-linking interactions during the formation of the network, leading to inferior meat gels with a lower WHC and poor textural properties[29]. Overall, PSE-like broiler meat should not be used for gel products.

Detection and grading of PSE-like broiler meat

-

The quality impact of PSE-like broiler meat leads to research interest in detecting and classifying it[30,31]. A preferred method is to use both pH and brightness (L*) values to categorize meat showing PSE-like meat characteristics[32]. Bowker et al. reported that there were high correlations among L*, pH, and WHC[33]. However, conventional methods (pH and colour) are destructive, time-consuming and unsuitable for commercial application. It is necessary to develop a rapid and non-destructive method for the identification of PSE-like broiler meat.

Optical techniques have many advantages, such as fast and non-invasive, and can simultaneously detect multiple traits[34]. For this purpose, dielectric spectra in radiofrequency and microwave ranges were evaluated in the detection. Victoria et al. tested the Traffano-Schiffo model classification for poultry meat. This model produces classification through different characters of abnormal meat[35]. Besides, multivariate statistical methods have also been adopted for detection of meat abnormalities. Principal component analysis (PCA) with Visible/Near-Infrared (Vis/NIR) spectra showed feasibility in classification of broiler breast meat into different quality grades[36]. Hyperspectral imaging (HSI) technology is also very promising for the detection and classification of PSE-like meat[37]. HSI in the spectral range of Vis-NIR and NIR was evaluated for predicting quality traits and grades of intact broiler breast meat[38]. Table 2 summarizes research progress in PSE-like meat detection and classification technology. Although great progress has been made in the detection/classification, the feasibility remains to be validated in practice and new technologies remain to be explored.

Table 2. Detection and grading of PSE-like broiler meat, WS and WB in recent years.

Item Detection and grading Comment References PSE-like broiler meat pH and L* values Destructive, time-consuming and unsuitable Li et al. (2014);

Bowker et al. (2014)Dielectric spectra in radiofrequency and microwave ranges Depending on the level of protein degradation to grade meat Victoria et al. (2018) PCA with Vis/NIR Classification of intact broiler breast fillets into different quality grades Yang et al. (2018) Hyperspectral imaging (HSI) A rapid and impactive method to predict quality

traits and grades of broiler meatYang et al. (2020) WS/WB Artificial ratings (Finger pressing) Poor stability, low repeatability and non-uniform evaluation system Cai et al. (2018) Frequency-radiometric spectrometry (FRS) Detection and grading of WS Traffano-Schiffo et al. (2017) Near-infrared spectroscopy (NIS) Rapid online detection and grading of the WB Wold et al. (2017) Computer vision system (CVS) Based on vision system for WB classification Geronimo et al. (2019) Bioelectrical impedance analysis (BIA) Based on outer, inner, and tail areas for WB classification Morey et al. (2020) Near infrared with linear discriminant analysis method Portable and nondestructive de Carvalho et al.

(2020)Time-domain nuclear magnetic resonance

(TD-NMR)Predicting the severity of the WB condition Pang et al. (2020) Air deformation Identify severity of WB Sun et al. (2021) Methods for improving PSE-like broiler meat

-

There have been numerous studies on the formation mechanism of PSE-like meat, but the current incidence of PSE-like meat is still high[32]. Therefore, the most urgent task is to reduce the quality damage from existing PSE-like meat. Several techniques have been evaluated to change the adverse properties of PSE-like broiler meat such as adding auxiliary ingredients (starch or edible gum), processing with innovative technologies and chemical modifications[39]. As summarized in Table 3, ameliorative strategies for PSE-like broiler meat include adding non-meat ingredients (starch, soy protein isolate, carrageenan and transglutaminase), marination and tumbling, high-pressure processing, high-intensity ultrasound, glycosylation, pulsed electric field, isoelectric solubilization/precipitation, pH shifting and low-speed shearing.

Table 3. Evaluation of processing techniques for PSE-like broiler meat, WS, and/or WB meat.

Item Processing technique Effect References PSE-like broiler meat Adding non-meat ingredients (starch, soy protein isolate, carrageenan, transglutaminase, collagen) Reduce cooking loss, improve protein binding,

and increase gel propertiesLee & Chin (2020);

Daigle et al. (2005);

Lesiow et al. (2017)Marination and tumbling The pale color and shelf life of PSE-like meat improve; yield loss reduced Haddad et al. (2017);

Paula et al. (2019)High-pressure processing (HPP) The surface hydrophobicity of the protein

increased; WHC improvedChan et al. (2011a) High-intensity ultrasound (HIU) The function of meat protein affected; muscle tension, WHC and gel strength improved Xue et al. (2017) Pulsed electric field (PEF) The rheological property of PSE-like meat protein changed; protein solubility, surface hydrophobicity and active sulfhydryl group increased Dong et al. (2020) pH shifting and low-speed shearing

Glycosylation

Isoelectric solubilization/precipitation (ISP)Partially deteriorating protein conformations and dispersibility recovered Yang et al. (2020) Glycosylation The conformation of proteins modified; solubility and emulsifying properties increased Rannou et al. (2016) Isoelectric solubilization/precipitation (ISP) The oxidation stability of muscle protein, the uniformity of gel network, and the gel ability improved Zhao et al. (2019) WS/WB Blade tenderization (BT) The cooked meat texture of WB meat improved Tasoniero et al. (2019) Marination and tumbling The hardness and chewability of WB meat reduced; the WHC of WS meat improved Maxwell et al. (2018);

U-Chupaj et al. (2021)Ultrasound Economic losses of WB meat reduced Li et al. (2021) Non-meat ingredients added

Starch

-

Different types of starch have been added to regulate and control the undesirable properties of PSE-like broiler meat[40]. Adding starches increases the cooking yield of PSE-like meat[41]. Other types of starch have also been tested, showing that starch can ameliorate PSE-like broiler meat[42]. The above results indicate that adding starch can increase the WHC and gel properties of PSE-like broiler meat. However, in actual production, the product quality is closely related to the amount of starch added, so it is difficult for consumers to accept this move.

Soy protein isolate

-

Soy protein isolate (SPI) is helpful for improving PSE-like broiler meat[43]. It was reported that adding 1.5% SPI declined the cooking loss, and storage loss and reconstructed the protein complex of PSE-like turkey breast meat[44]. Compared with ordinary starch, SPI guarantees the excellent properties of protein. However, the unique smell of SPI needs to be covered up in another way.

Collagen

-

Collagen can also be used as an auxiliary material for PSE-like broiler meat. Schilling et al. noted that introducing 1.5% collagen reduced cooking loss during heat processing and enhanced protein binding, which is conducive to reconstruct functionality of PSE-like broiler meat[45]. Collagen, as a material derived from animals, can fit well with meat products, and raw materials are relatively easy to obtain. So, it is a promising ingredient for improvement of PSE-like meat in the future. However, an important problem is that the denaturation temperature of collagen and muscle protein is different, so it is necessary to consider the unity of both in the common deep processing process.

Carrageenan

-

Similarly, colloidal polysaccharides and their derivatives were also evaluated for improvement of PSE-like broiler meat. Carrageenan (CG) is a hydrophilic polysaccharide macromolecule extracted from red seaweed[46]. Daigle et al. revealed that CG inclusion at 0.3% lowered the storage loss in PSE-like meat[44]. The key point is to pay attention to the taste change caused by colloidal polysaccharide when improving abnormal meat, and should not have too much adverse effect on the taste of raw meat.

Transglutaminase

-

Transglutaminase (TG) is an enzyme recently isolated from microorganisms[47]. Sun and Arntfield found that myofibrillar proteins (MPs) supplemented with appropriate amounts of TG formed a stronger and more elastic gel than that without TG[48]. Adding TG enzyme could remarkably increase the hardness of PSE-like broiler meat[49]. Compared with other exogenous substances, these new substances can produce significant effects in a small amount, and are more suitable for reducing the normal characteristics of chicken breast meat. However, the selection of such enzymes should be considered on the premise of cheaper prices to avoid excessive costs.

Physical technologies

-

Although it has been demonstrated that adding non-meat ingredients is useful for improving functionality of PSE-like broiler meat, food additives could cause consumer health concerns[50]. Physical technologies are a better option for meat processors, and achieve good impacts under non-destructive conditions.

Marination and tumbling

-

In traditional processing techniques, marination is an effective method to improve product quality such as WHC, texture, and yield[51,5]. During marination, tumbling could be applied to speed up penetration of marinade into the meat products[52,53]. Haddad et al. found that adding 0.8% salt was enough to improve the quality characteristics of the PSE-like meat product[54]. Paula et al. concluded that salt addition at 1.2% was beneficial to the quality of PSE-like meat[39]. Overall, marinating and tumbling can help to improve the texture of PSE-like broiler meat, but the high concentration of salt may conflict with the modern low-salt healthy dietary requirements.

High-pressure processing

-

High-pressure processing (HPP) is a food processing method[55]. HPP is widely used in meat processing. When subjected to 200 MPa pressure for 5 min, the protein conformation of PSE-like broiler meat increases the WHC through enhancing protein surface hydrophobicity and improving exposure of sulfhydryl groups[56]. As a non-destructive processing method, HPP has an advantage in the improvement of PSE-like meat. However, if it is practical or not still needs to be investigated.

High-intensity ultrasound

-

High-intensity ultrasound (HIU) can also improving PSE-like broiler meat[57]. Li et al. showed that ultrasound treatment (frequency 20 kHz and amplitude 60%) had an evident impact on PSE-like meat[58]. In comparison to ultrasound treatment for 0 and 3 min, the secondary structure content in proteins showed lower α-helix content and higher β-sheet, β-turn and random coil contents. However, HIU still has some technical problems that need to be addressed. Typically, it is difficult to process in large quantities, and the high price of the equipment is also an obstacle to further development[59].

Pulsed electric field

-

Pulsed electric field (PEF) is a new type of non-thermal food sterilization technology. It can process liquid and semi-solid food with higher electric field intensity (10−50 kV/cm), shorter pulse width (0−100 μs), and higher pulse frequency (0−2,000 Hz). In a recent study, Dong et al. found the solubility, surface hydrophobicity, and reactive sulfhydryl groups of MPs from PSE-like broiler meat steadily strengthen with increasing PEF intensity and pulse frequency[60]. However, when the intensity exceeded 18 kV/cm, these quality measurements declined. Attention should be paid to the control of intensity and reasonable use of PEF. Overall, PEF is effective in improving PSE-like broiler meat, and needs further research[61].

Joint physical processing technologies

-

In addition, the combined use of various technologies provides the possibility for the further improvement of PSE-like broiler meat in the future. For instance, physical methods, as mentioned above, include combinations of tumbling and marination, HPP, and HIU treatment. Vacuum treatment of whole PSE-like meat on the basis of marination can effectively improve the efficiency. HPP treatment after HIU of PSE-like comminuted meat will have a better-quality performance. The combination of multiple technologies allows PSE-like meat to improve dramatically and multiply its profits[39]. However, there is also some disadvantages, such as the need for specialized equipment maintenance, the price of equipment is generally very expensive, mass processing is difficult to carry out[61].

Chemical modification

-

Compared with the addition of non-meat ingredients mentioned above, physical processing technologies have shown some advantages. Therefore, certain chemical methods might be a good option for overcoming the disadvantages. From the perspective of protein structure and function, glycosylation, isoelectric solubilization/precipitation, and pH shifting showed great potential.

Glycosylation

-

Glycosylation has been used in research to modify proteins[62]. The glycosylated modified protein presents good protein function and high-quality gel quality. Nonetheless, the nonenzymatic browning reaction also results in a brown appearance and/or forming potentially harmful compounds such as acrylamide[63]. These disadvantages can be overcome through enzymatic modifications, for example enzymatic glycosylation[59]. The above research reports indicated that the MPs in PSE-like meat after glycosylation had better functional properties (gel and emulsification). The MPs after glycosylation can form a better gel, offsetting the issue that PSE-like meat is difficult to be processed into meat emulsion products.

Isoelectric solubilization/precipitation

-

Isoelectric solubilization/precipitation (ISP) is also a potential chemical modification method. Mainly by adjusting the isoelectric point to increase the quality of meat. For ISP-treated PSE-like broiler meat proteins, solubilization at pH 11.0 or 3.5 was proven to have a positive impact on the gel properties[64]. Treatment with precipitation at pH 6.2 noticeably endowed PSE-like broiler meat quality[65]. Overall, ISP could be applied to improve PSE-like meat.

pH shifting and low-speed shearing

-

A rapid postmortem pH decline causes the alteration/denaturation of meat proteins, forming the PSE-like meat which has impaired protein functionality[66]. Based on the robustness of proteins, the PSE-like meat protein solubility and conformation were recovered partly by modifying the surface charge of the PSE-like meat protein and inputting energy[67]. After pH adjustment and low-speed shearing are combined, the structure and various capabilities of the protein have been improved. This method can further improve product quality and reduce economic losses in the food industry.

-

WS and WB are also representatives in terms of abnormal meat problems and could occur simultaneously due to rapid growth of broilers[4]. WB shows obvious hardness on the upper part of pectoralis major muscles and rigidity on the caudal area, often accompanied by stripes and bleeding spots. WS is a fat white deposit on the surface of the muscle parallel to the muscle fibers. These two myopathies exhibit a similar histological feature[9]. WS was first reported in 2009[68], which is defined upon appearing white streak-like fat deposits parallel to the muscle fibers on the breast and leg muscles. WB was formally proposed in 2014[69]. This defect causes significant elevation in the hardness of broiler breast meat, and the surface of severe WB major shows a wood-like texture with even petechial hemorrhaging and sticky secretions.

Some studies suggest that WS and WB are the same heterogeneous meat. WS occurs in the early stage and gradually deteriorates into WB[70]. The current incidence of severe WS and WB in fast- growing, large white-feather broiler breeds is about 40%, respectively, and there is an upward trend year on year[71]. The economic loss caused by these myopathies is incalculable (the incidence of these conditions can result in an excess of USD $200 million per year lost)[9]. The main reasons for the formation of WB and WS are high growth rate and increased breast meat yield. There were great and positive relationships between the increase in growth rate and body weight and the occurrence rate of WB and WS[72]. Broilers with fast growth rate and high breast meat yield are often accompanied by changes in muscle fiber structure, such as muscle fiber diameter, incidence of giant fiber, and content of glycolysis muscle fiber[73]. In addition, the muscle fibers and the capillary density decline, result in an insufficient supply of oxygen and nutrients, affecting the excretion of metabolic waste. This results in oxidative stress and triggers inflammation and fibrosis, thereafter, causing WB and WS conditions[69].

Formation mechanism of WS and WB

-

The formation mechanism of WB and WS is mainly reflected in three aspects. Firstly, oxidative stress reduces the gene expression and antioxidant enzyme activity of superoxide dismutase (SOD), glutathione transferase (GST), and increases production of malondialdehyde (MDA), reactive oxygen species (ROS), leading to oxidative damage of cells[14]. In the muscles, blood circulation insufficiency and oxidative stress destroy protein structure integrity and induce the production of WB. Due to the decline in activity of antioxidant enzymes, ROS cannot be removed in time[15]. Oxidative stress continues to damage cell proteins and plasma membranes, leading to changes in the morphological structure of muscle fibers[11]. Secondly, the changes of sugar metabolic pathways induce accumulation of collagen and proteoglycan, resulting in increases in the connective tissue in WS and WB meat[72]. At the same time, fructose-6-phosphate, glucose-6-phosphate, lactic acid and pyruvic acid drop, suggesting that glycolysis pathway is restrained[74]. Thirdly, research showed that sodium and calcium content in WB and WS were remarkably elevated[75]. WS and WB might promote the accumulation of calcium ion in muscle fibers[76]. It was speculated that the accumulation of free radicals and calcium ions in cells might activate protease and lipase, leading to the destruction of the cell membrane integrity and protein denaturation[77]. This damage might exceed the muscle ability to regenerate, leading to necrosis of the fibers, as well as fibrosis and fat deposition, as shown with histological changes in WS and WB[71].

Influence on broiler meat quality of WS and WB

-

WB and WS influence meat quality, such as pH, protein content, water content, crude fat content, WHC, and texture[78]. There is a strong correlation between pH and meat color or WHC, which is an important index to measure meat quality. Studies have shown that the pH values in WS and WB meat are significantly higher than those in normal meat[79]. The pH of postmortem muscles declines due to glycogen conversion to lactic acid during anaerobic fermentation. The increase in pH in WS and WB meat is not caused by the abnormal metabolism of broiler breast after slaughter, but it is due to low glycogen content and insufficient glycolysis potential in muscles[80]. Generally, the L* of WB and WS will decrease, but some brightness will increase[9]. In terms of meat color, there are no significant discrepancies in lightness value (L*) between WB and WS meat[81]. However, it is impossible to differentiate WB and WS just based on meat color.

Broiler breast hardness or texture quality can be measured with extrusion and shear force. Texture measurements of WS and WB meat showed that WB shear force is remarkably higher than normal broiler breast meat, and extrusion pressure increases with a severity of WB[82]. Through measurements of sarcomere length, Soglia et al. verified hardness of WB meat may not result from excessive contraction of muscle fibers, while it is related to broiler breast thickness and connective tissue accumulation[83]. Zhang et al. observed the protein degradation after slaughter and found that the degradation of heat shock protein 27 (HSP27 protein, a small molecular chaperone) was closely related to the tenderness of meat[84]. It was found that HSP27 protein content was very high in WB meat, and the hardness of WB meat was closely related to it[85]. Decorin protein (a proteoglycan that binds to collagen fibrils) is a regulator of the collagen cross-linking process. Several studies have pointed out that an abnormally high expression of Decorin protein leads to an increased cross-linking interaction in collagen, causing an accumulation of collagen fibers and an increase in muscle hardness[86].

Compared with normal broiler breast, the proportion of free water in WS and WB meat were remarkably increased, while the proportions of bound water and immobilized water in WB meat are remarkably decreased[87]. The free water in muscles is the main source of drip loss, and the increase of free water leads to the decline of measured WHC[88]. Composition analyses showed that, content of water, crude fat, and collagen in WS and WB meat remarkably increased[9]. The accumulations in fat and connective tissues are mainly caused by the replacement of myofibrillar fibers due to the necrosis. This reduces nutritional value of chicken meat and could affect consumers’ predilection.

WB and WS seriously affect the processing performance of broiler meat. Tijare et al.[89] assessed the differences in quality measurements between the non-marinated and marinated abnormal meat, such as sarcomere length, marination uptake, cooking loss, and Meullenet-Owens razor shear energy (MORSE). The same measurements were also taken after the samples were cooked at 78 °C. Regardless of freshness (fresh vs frozen-thawed), cooking (raw vs cooked), and degree of WBC, both MORS force and energy of the WBC samples were higher than that of the normal samples (P < 0.05). For TPA adhesiveness and resilience, there were no differences between normal and WBC samples (P > 0.05). However, average TPA hardness and chewiness measurements of the fillets with WBC were higher than the normal fillets (P < 0.05)[71]. Compared with the normal broiler breast gel, the microstructure of the gel made from WB meat was loose[90]. In addition, the gel had higher helix content, lower sheet and turn content in protein secondary structure. It has been reported that higher sheet content is conducive to the formation of high-quality gels, and the quality of gels processed with WB/WS meat is seriously affected.

Detection and grading of WS and WB

-

According to the appearance of broiler breast[22], WS can be rated and classified to normal (score 0) representing broiler breast meat with no white stripes; medium (score 1) showing that thickness of white stripes parallel to the direction of muscle fibers on broiler breast meat is < 1 mm; severe (score 2) showing that more white stripes are parallel to the direction of muscle fiber and stripe thickness is > 1 mm; and extremely severe (score 3) showing that a lot of white stripes are parallel to the direction of muscle fibers and stripe thickness is > 3 mm. Grading and classification of the WB according to the appearance and hardness of the broiler breast[71]: normal (score 0) the whole broiler breast is soft and elastic, without any stiffness characteristics; mild (score 1) the cranial portion and caudal area of broiler breast meat appears slightly changed and the cranial portion is harder; medium (score 2) the broiler breast meat shows a large proportion of hardening, but elastic from middle to the caudal area; and severe (score 3) the broiler breast meat is overall hardened and the surface is accompanied by bleeding[17].

At present, WS and WB conditions mainly rely on human classification. This is too subjective to be consistent across research institutes and broiler processors. The classification of WB mainly adopts the palpable hardness pressure method, which has poor stability, low repeatability and a non-uniform evaluation system[91]. A fast and convenient method, like spectroscopy for PSE-like meat assessment, could be very helpful for the detection and classification of WS and WB. Table 2 summarizes research progress in WS and WB meat detection and classification technologies. Traffano-Schiffo et al. used the sensors equipped with a spectrophotometer to detect the abnormal broiler breast, demonstrating the feasibility of using frequency-radiometric spectrometry (FRS) for the determination of WS meat[92]. Wold et al. developed a regression model by using near-infrared spectroscopy (NIS) based on the protein content in the chicken breast and established a rapid online system for detection and grading of the WB[93]. Computer vision system (CVS) and near infrared (NIR) spectra can be jointly used for the identification and classification of WB in slaughterhouses. It also included physicochemical and technical parameters and supported decision tree modeling. Geronimo et al. used CVS and linear and nonlinear algorithms to obtain information from the NIR spectra for identifying and classifying the broilers of WB[94]. Morey et al. applied bioelectrical impedance analysis (BIA) to detect breast meat with WB in modern broiler broilers[16]. Based on the WB severity, BIA could be used to separate the outer, inner, and caudal areas of WB meat. Recently, the near infrared technology has made new progress in detecting abnormal meat. de Carvalho et al. used a portable NIR spectrometer to obtain spectral information[95]. It uses the continuous projection algorithm, linear discriminant analysis (SPA-LDA) and analogy method of soft independent modeling (SIMCA) classification model. As an alternative of the conventional recognition classification method, the technology is portable and nondestructive, making its application in industrial production line possible. The time-domain nuclear magnetic resonance (TD-NMR) also showed potential as a non-destructive method for predicting WHC in intact broiler breast fillets with the WB condition[96]. Recently, Bekhit et al. tested air deformation on raw meat surfaces to identify severity of WB in broiler fillets[97]. The results indicated that WB could be identified by compression force and the air deformation on raw breast meat surfaces. These studies provide instrumental methods for the objective detection and grading of WS and WB, which could be useful in the future study of these two types of abnormal meat.

Strategies for improving the functional characteristics of WB and WS

Technology improvement

-

The quality abnormalities of WB and PSE-like meat are quite different. The WB shows greater hardness and is crunchy, which is the main reason why it is unacceptable[17]. Therefore, reducing its hardness with processing technologies is the interest for its utilization. However, compared with PSE-like meat, there are limited technologies that can be used to improve WS and WB meat. As shown in Table 3, three methods, blade tenderization (BT), marination and/or tumbling, and ultrasound, were evaluated for improvement of WB.

Blade tenderization

-

In terms of texture, WB meat shows greater hardness, which limits their utilization as an end-use product. Blade tenderization (BT) weakens the meat toughness by severing the MPs network and the connective tissue[97]. Therefore, it has been evaluated to lower WB meat hardness. Tasoniero et al. treats WB meat with BT and compares it with normal broiler breast meat[98]. In the maximum range, the shear force of WB raw meat treated with BT was still harder than normal breast meat, although it was significantly lower than the untreated WB control. BT demonstrated potential for improving cooked meat texture in WB fillets.

Marination and tumbling

-

Since marination technology helps improve PSE-like broiler meat, some studies have combined it with tumbling technology to improve the quality of WB meat[99]. Mudalal et al. concluded that vacuum tumbling marination could be used to improve the sensory attributes of WB fillets[100]. Due to discrepancies in cooked texture characteristics predominantly in the ventral portion of the fillet, WB was still detectable in marinated broiler breast meat. Similarly, U-Chupaj et al. investigated the effects of non-phosphate and low-sodium (NPLS) marination on properties of WS meat[101]. The findings suggest that the NPLS marination was a promising method for improving WHC of the WS meat.

Ultrasound

-

Ultrasound significantly improves quality/functionality of abnormal meat. Thus, some researchers have applied it to improve qualities of WB meat. Li et al. used ultrasound technology to treat WB meat[102]. Stress relaxation and creep showed that the hardness of the WB treated samples decreased with 600 W ultrasound. Analysis of shear force indicated that the 600 W (5 min) ultrasonic power could significantly tenderize WB as shown by the results of the decreased shear force valve. However, the meat became hard at treatments higher than 600 W because the heating effect caused water loss, connective shrinkage and even protein oxidation. In summary, the 600 W ultrasound treatment was an effective strategy to improve texture properties of WB.

WS and WB meat utilization

-

Chen et al. affirmed that WB meat might not be appropriate to produce gel-type meat products because WB meat showed inferior functional properties through processing[28]. Their research highlighted quality defects caused by the WB condition, such as declining ability to bind water, increased water purge during gelation, and impaired textural properties in meatballs prepared from WB meat. These findings are consistent with those reported by Xing et al., who also demonstrated that WB meat could not be suitable to produce gel-type meat products with low salt levels[101]. Therefore, utilization of WB meat could be related to several factors, such as the replacement rate of normal broiler meat in the formulation, the meat particle size (whole muscle, ground, and coarsely or finely chopped), and the use of nonmeat ingredients, particularly the concentration of salt[102]. Table 4 shows that comminuted meat products, sausages, hamburger, and ground meat are better choices in utilization of WB meat[103,104]. The cooked surface of WB meat is darker, redder and more yellow than meat without the WB condition[105]. The detrimental impact of WB on the surface color and appearance of cooked breast fillets was noticeable and not eliminated by marination or frozen storage[82]. In addition, the latest studies agree that overall manifestation of muscle abnormalities mainly affects the superficial section of pectoralis major muscle, while the deep section was less affected[78].

Table 4. Evaluation of the utilization of WS and/or WB meat in ground meat products.

Strategies for utilization Findings References WB broiler sausages No differences in sensory quality and purchase intention between WB and normal products Madruga et al. (2019) WS chitosan sausages Enhancement of stability and preservation of WS sausage Larissa et al. (2020) WB frozen sausages No impact of WB condition on odor and color liking of frozen and stored products Santos et al. (2019) WB broiler hamburger No difference in sensory quality and oxidative stability de Oliveira et al. (2020);

Caldas-Cueva et al. (2021);

Brambila et al. (2017)Ground meat of WB and WS No undesirable sensory characteristics that are noted with intact WB and/or WS meat Garner et al. (2020) WB broiler sausages

-

WB meat was evaluated for meat sausage products. Three types of broiler sausages were made: 100% normal broiler meat, 100% of WB broiler meat and 50% of normal meat/50% of WB meat. Sensory evaluation indicated no sensory differences between the three-sausage formulations, as did the acceptability and purchase intention[106].

Likewise, sausages can also be made from WS meat. The researchers found that the addition of chitosan to cooked turkey meat sausages affected by the WS caused changes in some of the evaluated technological and quality parameters[107]. When quantifying the lipid-derived volatiles, a clear antioxidant activity of chitosan was observed, which limits the release of these compounds, mainly aldehydes (hexanal and nonanal). Reformulated sausages presented better nutritional characteristics (lower fat content) and oxidative stability (lower aldehydes) than the control samples. Additionally, chitosan improved both emulsion stability (lower weight losses) and texture parameters. In contrast, lower redness value was observed in the reformulated sausages. Therefore, low-fat sausages containing chitosan may represent an interesting alternative for adding value to turkey meat affected by WS. The use of chitosan in the sausage formulation has great potential for enhancement of stability and preservation of this product. However, further studies are needed to evaluate the influence of chitosan addition on the microbial stability of cooked turkey sausages.

WB for the manufacture of broiler sausages subjected to freezing is a viable option[108]. Although WB exhibits the advantages of processed sausage products at the sensory level, nutritional value is not yet known. Other scholars have found that incorporation of WB into products does not influence sensory acceptability[109]. There was no impact of storage time on odor and color of WB sausages in experiment. Furthermore, it may be required to investigate the nutritional value. As a large class of cheap consumables, frozen sausage can help the utilization of WS, and consumers usually ignore some shortcomings with its high cost performance ratio. However, this is only a temporary measure to solve the problem. We still need to consider how to solve the WS problem from the source.

Ground meat of WB and WS

-

Previous studies showed grinding WB meat could avoid the undesirable sensory characteristics of intact WB meat[107]. However, grinding is not able to overcome high drip-loss, lower WHC, and higher cooking loss due to these myopathy conditions. In addition, the undesirable meat properties of ground WA meat can be further exacerbated by freezing[109]. Therefore, addressing the adverse effects of freezing is critical. Garner et al. have demonstrated that the addition of phosphates can help the utilization of ground WB meat even after frozen storage[110].

Broiler breast hamburgers with WB are a viable alternative for the poultry industry[111]. Researchers found that hamburgers produced with broiler breast affected by WB showed regular oxidative stability, and had a greater lightness, redness, yellowness, and pH. The authors did not detect differences in the sensory characteristics of these products made with normal broiler breasts and the moderate and severe degrees of WB. In European and American countries, hamburgers have a large market, indicating that the hamburger has a good potential for WB utilization.

In addition, the effect of using broiler breast fillets affected by WB condition on quality characteristics of chicken patties is related to the degree of WB severity and the proportion to be incorporated into the formulation[112]. Thus, these data suggest that the combinations of breast fillets of normal quality with those affected by WB myopathy at relatively low proportions could be considered by processors as an alternative in commercial chicken patty recipes. However, further research is needed to optimize the incorporation of WB meat into chicken patty formulations for industrial applications considering the meat particle size and including suitable food additives accompanied by technological, sensorial, and nutritional profile assessments[104].

-

Among abnormal meat, PSE-like broiler meat, WB, and WS are three types of myopathies with high incidence. But WS/WB improvements methods are few, including meat tenderization, marination, grinding for comminuted products. They are not able to overcome all the quality abnormalities. Chinese sauce brine meat products prefer raw materials with high fat content and collagen content for their flavor and taste. Beef tendon is commonly used. Therefore, the changes in WB and WS meat might be a good fit for such value-added products. The comprehensive performance is still worse than normal meat.

Ultrafine comminution

-

Ultrafine comminution is less common in food applications[113]. Recent research also showed that through ultra-fine pulverization (UFP) can improve the chicken myofibrillar protein gel WHC and strength[114]. The reduced protein size allows meat products to dissolve and disperse better, avoiding the defects of the abnormal meat as a whole. This technology could not only improve the abnormal meat, but also foster molecular biology of meat. However, these inferences have not been further studied, so practice is needed to prove their usefulness.

Protein-based beverages

-

Protein-based beverages have a fluidic texture and can be maintained stable. It can also be stored in a powder state. After rehydration, it will show a stable liquid state. Compared with solid meat, the surface area of protein-based beverages is enlarged owing to the transformation of its own state, which can be more convenient for digestion and absorption[115]. This benefit is also extremely friendly to people with impaired gastrointestinal digestion functions. In addition to the basic nutritional elements contained in meat, traditional meat products cannot provide total nutrient needs[1]. Liquid state of protein-based beverages can be added with different edible gums and other types of nutritional elements, and provide humans with total nutrition. Abnormal meat is not a food safety concern, therefore it can be considered as an ingredient or additive[106]. Although abnormal meat exhibits poor sensory quality, it might be used for extraction of myofibrillar protein and as a raw material for liquid protein[116]. However, such animal derived protein drinks are still in the exploration stage. Further experiments are needed to ensure its large-scale application.

Fermentation of meat

-

Fermentation of meat is a traditional energy efficient preservation method widely used for improving quality, functionality, and shelf life of meat[117]. WB and WS meat display a high pH, while fermentation produces lactic acid, which reduces pH and ensures safety, stability, and shelf life of meat products[118]. Therefore, we conclude that the ability of fermentation to enhance the quality of WB/WS meat may overcome the defects of abnormal meat, such as hardness, poor WHC, and unacceptable appearance. This could be a good alternative for the processing and utilization of abnormal broiler breast in the future.

-

In recent years, the poultry breeding industry has been very successful in meeting the supply of the global poultry meat for human consumption. However, emerging broiler breast meat abnormalities indicate to not only to focus on the growth rate and muscle yield of broilers, but also to improve the quality of the broiler meat in breeding. The global broiler industry is facing the need for reducing the occurrence of abnormal meat problems and thus reducing economic losses, providing consumers with better meat products, while producing adequate supplies of meat. This review found that currently, the research mainly focuses on improvement of functionality for PSE-like meat, with an emphasis on the utilization for WS and/or WB meat. Therefore, in order to determine multiple developments, it is necessary to fill the gaps in these two aspects to fully reduce the adverse effects of abnormal broiler meat. We will need new technologies to improve the quality and utilization of abnormal meat, avoid waste of raw materials, and maximize the recovery of economic losses.

This work was financially supported by the Shandong Modern Agricultural Technology and Industry System, China (SDAIT-11-11), China Agricultural Research System (CARS-41-Z06). Natural Science Foundation of Shandong Province (ZR2022MC087).

-

The authors declare that they have no conflict of interest.

- Copyright: © 2023 by the author(s). Published by Maximum Academic Press on behalf of Nanjing Agricultural University. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Wang K, Li Y, Sun J. 2023. Quality improvement and comprehensive utilization of abnormal broiler breast meat: A review. Food Materials Research 3:1 doi: 10.48130/FMR-2023-0001

Quality improvement and comprehensive utilization of abnormal broiler breast meat: A review

- Received: 21 October 2022

- Accepted: 09 February 2023

- Published online: 28 February 2023

Abstract: During the past few decades, there has been a notable increase in the demand for poultry meat due to its low cost and good nutritional profile. Rapid growth of chicken breast has become a primary screening criterion in the modern broiler industry. However, the rapid growth causes many abnormal meat quality problems. Wooden breast (WB), PSE (pale, soft, exudative)-like broiler meat, and white-striping (WS) meat are the representative features reflecting serious chicken myopathy. The high incidence of these myopathies leads to a range of questions, increasing concerns of producers and retailers. There are many studies involved in the formation mechanism and detection grading of abnormal broiler meat, but there are few reports on the use of abnormal broiler. Several abnormal broiler types and the improvement strategies are reviewed through enhancing its processing properties or alleviating its degenerated functionalities. The improving approaches, include adding non-meat ingredients, marination, vacuum tumbling, high-pressure processing, high-intensity ultrasound, pulsed electric field, pH-shifting and low-speed shearing, glycosylation, isoelectric solubilization/precipitation, blade tenderization, and using them as ingredients in further-processed products. The combined use of various physical and chemical technologies provides the possibility for improvement in utilization of abnormal broiler meat in the future.

-

Key words:

- Broiler breast meat /

- Abnormal meat /

- PSE-like broiler meat /

- Wooden breast /

- White-striping meat /

- Improvement /

- Utilization