-

Edible mushrooms have been popular food items for centuries due to their flavor and texture. Nutritionally, mushrooms are low in calories and fats well as high in fiber and protein. Beneficial bioactive compounds have been reported from edible and medicinal mushrooms; thus, mushrooms have the potential to prevent urgent health concerns such as obesity, cancer and diabetes[1−4]. Flavor, a balanced nutritional profile, and pharmacological potential have increased demand for mushrooms. As a result, global production of cultivated edible mushrooms has increased more than 30-fold from 1978 to 2013, and the industry was valued at approximately $63 billion in 2013[5]. Therefore, the burgeoning mushroom industry has enormous economic potential, which can be used to develop rural livelihoods.

Despite the fact that mushrooms generate billions of dollars in revenue, rural communities receive limited benefits. Wild mushrooms are recognized as important non-timber forest products (NTFP), and gathering wild mushrooms generates income for rural communities. However wild mushrooms account for 8% of total global mushroom production[5]. Wild mushroom production depends on climatic conditions, which are highly unpredictable; hence, a consistent supply is unattainable[6, 7]. In addition, habitat destruction has occurred at alarming rates in South and Southeast Asia due to intensive agricultural schemes and deforestation, posing a serious threat to wild mushroom growth[8−10]. At the same time, foraging for wild mushrooms is complicated by conservation regulations and resource management policies[11]. Consequently, wild mushrooms are insufficient to ensure local food security and community economic resilience.

Cultivation of edible and medicinal mushrooms creates a gateway to enter the emerging mushroom market for rural communities[12]. Mushroom cultivation is an alternative source of income and offers more nutritional diets while also securing a new food supply and establishing a sustainable agriculture system[12]. However, mushroom cultivation is a technical process. Limited education and lack of technical skills in rural communities are major obstacles to production. Though resources are typically available for basic mushroom cultivation, there are many challenges for rural communities to practice mushroom cultivation[13]. We implemented targeted strategies to develop mushroom cultivation in selected areas of Myanmar.

The Chin State, in the northwestern hilly area of Myanmar is one of the least developed states of Myanmar, where schools and healthcare facilities are largely inadequate. According to UNDP, the Chin State is one of the poorest regions in Myanmar, with 73% of the Chin people falling below the poverty line[14]. Chin communities lag in agriculture techniques more than other parts of Myanmar, e.g., they still practice slash-and-burn cultivation along mountain ranges to maintain livelihoods, resulting in insufficient food for the whole year and low family income[15]. Shifting cultivation in 7–15-year cycles is common in the Chin State, which is destructive to natural forests, causing rapid deforestation, and subsequent climate change further affects food production. Farmers find it difficult to sustain themselves for even half a year through their own staple food production in both northern and southern parts of the Chin State, where maize is the staple crop for most subsistence farmers[15]. When there is insufficient food, they employ various coping strategies, which are more or less the same in northern and southern regions of the Chin State. While labor migration is common for better-off households, most subsistence farmers who constitute the majority of the population in Chin State depend on forest products either for direct consumption or as income sources. However, the means used in utilizing forest products are not sustainable, leading to the current condition in which there are dramatic decreases in forest products while deforestation has doubled. Even worse, widespread extinctions of rare species is occuring for which no conservation measures have been taken. Due to limited knowledge in mushroom edibility, people often suffer from mushroom poisonings and are admitted to hospitals every year, especially during the rainy season[16]. To minimize the above problems faced by the Chin people, edible mushroom cultivation was introduced as a pilot project in the two selected communities.

Previous market and social surveys showed that Pleurotus species are quite popular mushrooms among locals. In addition, Pleurotus spp. can easily and successfully be cultivated on lignocellulosic wastes, such as woodchips, rice straw, maize cobs and rice bran, which are readily available in the region. Cultivation techniques of Pleurotus using saw dust and rice straw as the main substrates were demonstrated.

-

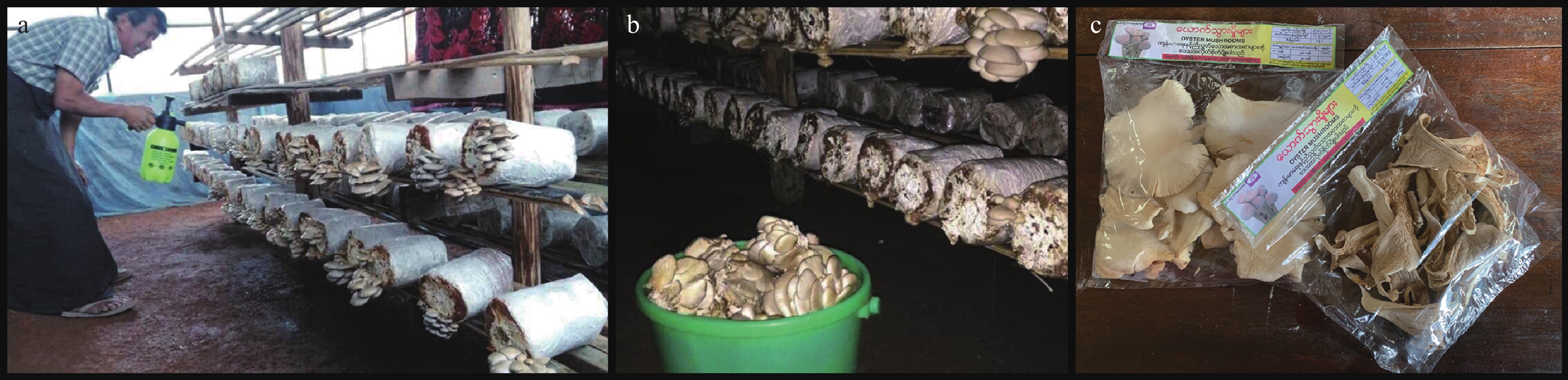

After a 20–35-day-incubation period, the fruiting period began (Fig. 1). Yield from 100 bags of each substrate, biological efficiency and expected monthly income of the Pleurotus sp. harvested from sawdust and rice straw were recorded in table 1.

Figure 1.

Harvesting and packing of Pleurotus sp.: a Spraying water to the bags to maintained relative humidity; b Harvested Pleurotus from sawdust substrate; c Fresh and dried packs of Pleurotus.

Table 1. Pleurotus sp. production on sawdust and rice strew. Expected monthly income was estimated by selling 200 g of fresh mushroom for $0.3 USD in the Chin state.

Date Number of bags harvest Weight of the fresh mushroom /g Date Number of bags harvest Weight of the fresh mushroom /g 26.7.2019 1 213 16.7.2019 1 73 29.7.2019 9 1,395 19.7.2019 7 459 31.7.2019 13 2,080 22.7.2019 11 820 2.8.2019 22 3,350 24.7.2019 12 1,064 3.8.2019 23 3,660 26.7.2019 13 1,140 6.8.2019 24 3,850 29.7.2019 12 1,046 10.8.2019 23 3,700 1.8.2019 14 1,000 15.8.2019 24 3,560 4.8.2019 10 600 23.8.2019 22 3,250 6.8.2019 6 385 26.8.2019 23 3,460 10.8.2019 5 253 Total 184 28,518 91 6,840 Biological efficiency (%) — 23.84 — 11.56 Expected monthly income ($) — 42.77 — 10.26 -

Pleurotus sp. can be cultivated successfully by proposed substrate recipes in this study, which include lingo-cellulose raw materials such as sawdust, rice straw, and rice bran, all of which are plentiful in the Chin state. Presently, sawdust is the most commonly used lingo-cellulosic substrate at the commercial scale for Pleurotus cultivation[17, 18], and the majority of Chin farmers prefer sawdust to rice straw due to its high biological efficiency[19]. A sustainable source of sawdust supply for Pleurotus cultivation in the Chin state is therefore required. Sustainable multipurpose use of local alder tree (Alnus nepalensis) has been practiced by swidden communities in Khonoma, Nagaland in northeast India[20, 21], providing a model that can be applied to the Chin state, where communities face similar living conditions.

Certain crop residues, such as maize plant residues or rice straw, can act as alternatives to sawdust, but are not always available or cannot be sustainably sourced. This is, though, a practically and economically feasible way of sourcing raw materials for the cultivation of Pleurotus and other commercial species (e.g., Auricularia, Lentinula) due to its simplicity of preparation and availability throughout the region. Paddy fields have been cultivated in 8.5% of the total cultivated land in the Chin state and are sustainable sources of straw for Pleurotus cultivation[15]. However, on rice straw substrates, the yield and biological efficiency are lower than those cultivated on sawdust. Similar findings were reported for Pleurotus eringii[19]. Past studies have found that maize plant residues are suitable alternatives for Pleurotus sp. cultivation[17, 22]. Maize plant residues, widely available lingo-cellulosic raw materials in the Chin state[15], are only available after late October due to its seasonal availability and were thus unable to be used in this experiment[23].

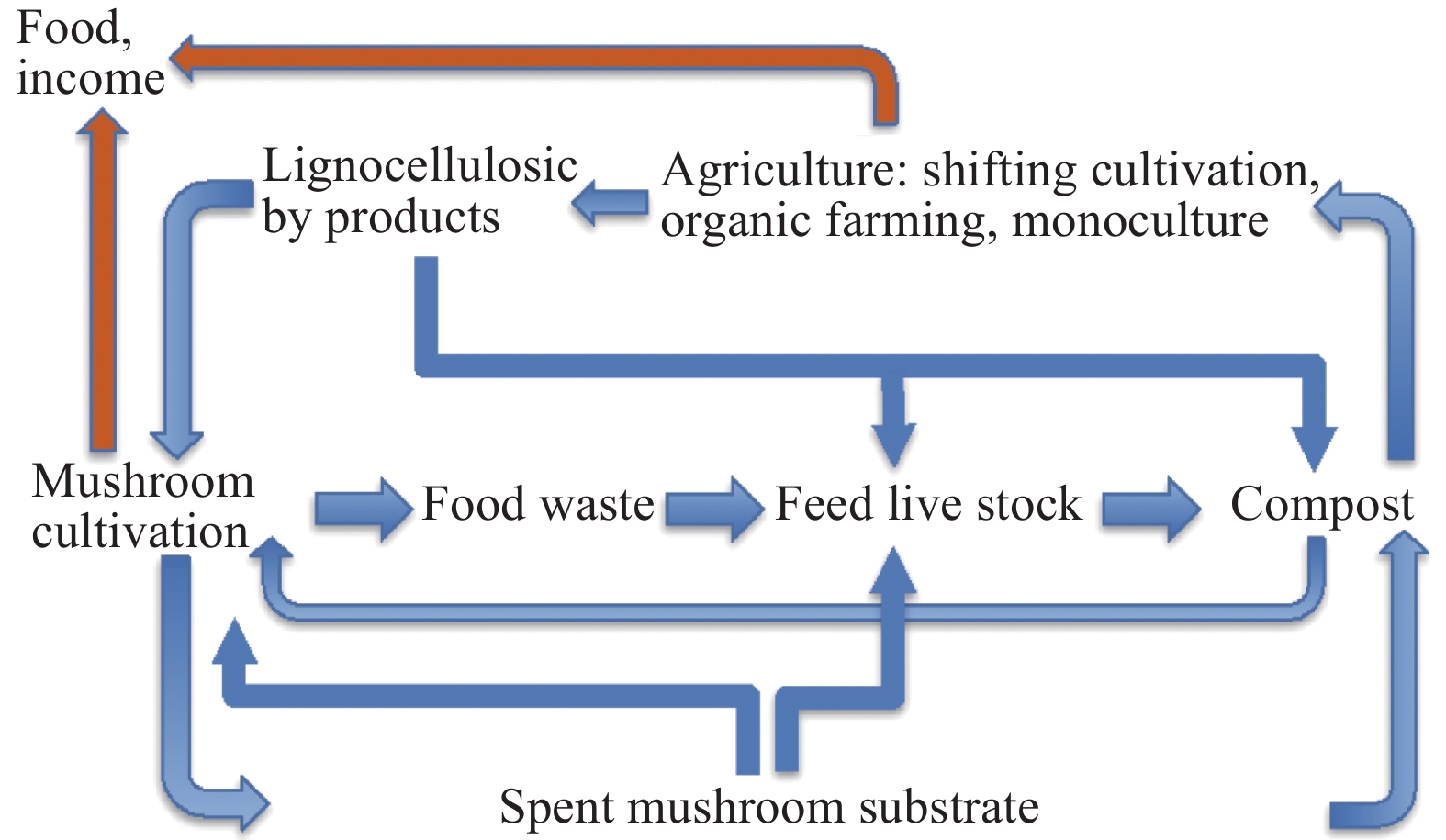

Agricultural crop residues such as straw, bran disposed as waste or field burning is the common practice in rural areas, which has been created serious environmental issues[24, 25]. In Myanmar, 49% agricultural crop residues were burnt in the field[24]. Since crop residues are rich in lignocellulose, cultivating wood-inhabiting mushrooms including Pleurotus spp. can play an important role in managing agricultural wastes[26]. Therefore, mushroom cultivation is a sustainable solution to transform agricultural crop residue biomass into nutritious food and additional income[26] (Fig. 2).

During harvesting, stems were trimmed, and this by product might be a useful alternative to antibiotic growth stimulators in poultry nutrition[27]. Pleurotus stem waste has antifungal, antimicrobial, antioxidant, and prebiotic properties[27]. Over 60% of livestock in the Chin state are poultry [23], and Pleurotus stem waste is a sustainable nutritional supplement for chickens (Fig. 2).

After the cropping cycle is completed, Pleurotus ostreatus results in 20% spent mushroom substrate[28]. The spent Pleurotus substrate can be recovered and used to cultivate Pleurotus spp. and other saprobic mushrooms, such as Agaricus, Agrocybe, Auricularia and Stropharia[29]. Furthermore, spent Pleurotus substrates can be used to produce compost and as organic fertilizer for crops or even a potential food source for humans and animals (Fig. 2)[30, 31].

Construction cost of the mushroom grow house is the main non-recurring expenditure of this study. The low-cost grow house is designed to control mushroom growth factors (e.g., light, humidity, temperature, and ventilation) efficiently and provide a decent environment during mushroom fruiting. The grow house costs 400–500 USD. The cost can be reduced to 300–350 USD if bricks and cement are not used for the walls and the floor. Instead of bricks and cement, clay can be used. Clay walls need to be strengthened by concealed bamboo lattice and mixed with a binding agent such as cement or lime to increase the plasticity to avoid cracking[32].

Challenges and solutions

-

Production and supply of quality spawns is a major bottleneck for rural mushroom producers. Rural mushroom producers have to wait long queues to acquire spawns and lack low temperature facilities (2–4 °C) for storage until inoculation, which affects viability. Mushroom growers are discouraged by the slow supply of spawn and the yield of mushrooms is limited by the low viability of spawns. Therefore, it is necessary to establish a fast, reliable supply of spawn in order to sustain the industry. It has been observed elsewhere in South and Southeast Asia that erratic spawn supply is a reoccurring problem for production systems, and new programmes aiming at mushroom cultivation should include a means of consistent spawn supply. This could be developed as a separate small to medium business enterprise to support rural households.

Many remote parts of the Chin state have limited market access, affecting the sales of fresh products such as mushrooms due to their limited shelf life. Drying mushrooms is a simple way to preserve them for long-term storage and trade. However, if not dried properly, the mushroom quality will deteriorate and often entire batches will be lost, ruining income for farmers and damaging the reputation of the farmers owning to selling substandard products. Sun-drying is an economical way to preserve mushrooms; however, this is not always an option in the wet season. Therefore, it is necessary to introduce low-cost drying facilities for preserving mushrooms, and there are numerous options and designs available that can be implemented at the village level.

Green mold disease was reported due to poor management of the growing house in Tuivial. However, this issue was successfully resolved, and participants learned pest and disease management in Pleurotus cultivation[33, 34].

Pleurotus spp. are the most popular mushroom species among the cultivators in the region. Edible and medicinal mushroom species other than the Pleurotus spp., (e.g., Hymenopellis raphanipes, Ganoderma lucidum) can be introduced to mushroom growers to achieve short-term goals. It is necessary to provide technical knowledge and further demonstrations about other mushroom species with higher market value. In order to ensure the production of high-quality mushrooms and to maintain high-yielding crops, a certain amount of follow-up training for rural farmers is required along with regular monitoring/extension work.

-

Two sites in Chin state of Myanmar were selected to introduce Pleurotus sp. cultivation. Among them, Tonzang Township is located in the northernmost part of Chin State. Tuivial village is located in the eastern part of Tedim Township in Chin State. Tonzang and Tuivial are at

1600 m above sea level. The weather conditions of both villages feature mist year-round, and the temperature varies between 10–25 °C.Training and capacity development

-

30 unemployed adults experienced in mushroom cultivation were selected from 30 households at each site. The programme was conducted across three practical sessions; 1) construction of mushroom grow house; 2) preparation of mushroom growing substrate and spawn inoculation; and 3) harvesting and packing, with six-week gaps between each two sessions. Progress, challenges, and solutions were discussed with participants at the end of the programme.

Construction of mushroom grow house

-

The grow house is a 5 m × 3 m × 3 m rectangular structure with low walls and a roof (Fig. 3a).

Figure 3.

Low-cost mushroom grow house: a, b measurements of the grow house in cm; c wooden frame covered by insect-proof net and wire mesh.

Six lumber posts (10–15 cm in diameter) locally harvested were buried 75 cm in depth in the soil on clear and level ground. 60 cm wide door frame (jamb) was placed along the wind direction in order to prevent contaminants entering to the room. Clay or brick walls covered the rest of the four sides up to 90 cm from the foundation (Fig. 3a and b). In the walls, rectangular wooden frames were vertically erected up to 240 cm on all four sides (Fig. 3a and 3b). Another wooden frame was placed horizontally in the four vertical wooden frames. Insect-proof net with 0.5–0.6 mm mesh was mounted on the all-wooden frames from the outside of the frame. The entire wooden frame was covered again by wire mesh traditionally used to cover poultry houses (Fig. 3c). Gable roof sticking out 60 cm on each side was built using opaque polycarbonate sheets on the lumber posts across the 60 cm gap between rooftop and horizontal wooden frame. A metal outswing door was connected to the jamb. Finally, the interior of the walls and floor were rendered with cement. Slightly inclined cemented floor provided a smooth surface that can easily be cleaned and facilitate drainage.

Preparation of mushroom growing substrate

-

Two kinds of media (saw dust or rice straw) can be used for Pleurotus cultivation.

The sawdust medium was prepared using sawdust 77.8%, rice bran 20%, lime (CaO) 1%, gypsum (CaSO4) 1%, and Epsom salt (MgSO4) 0.2% on the dry weight basis of the substrate and were mixed thoroughly using a shovel or a hoe (Fig. 4a). Water was added to the mixture gradually to adjust moisture content at 65% using a watering can (Fig. 4a). Crumpling the medium by hand and releasing without breaking the dough is the simple test to determine correct moisture content of the medium. The medium was filled into polypropylene bags (10 cm in diameter) and pressed by hand. About 1 kg of medium was packed into each bag (Fig. 4b). A piece (1/2 inch long) of PVC pipe (3/4 inch in diameter) was put on top of the bag through the neck, and plastic was folded backwards and tied with a rubber band. Sawdust bags were closed by cotton plugs or breathable plastic caps and steamed for 4 hours in a drum (Fig. 4c).

Figure 4.

Substrate preparation and spawn inoculation: a mixing ingredients while adding water; b bags packed with the sawdust medium; c steaming drum; d inoculating spawn to sawdust medium.

The rice straw medium was prepared by soaking dry rice straw in water about 8–10 hours and left to drain on a rack until the moisture content reached 65%. Damp rice straw was filled into polysack bags and steamed for 4 hours in a drum. Alternatively, dry rice straw was soaked in boiling water for 2 hours in a closed container and left to drain until the moisture content reached 65%. Pressing the damp rice straw by hand without water dripping through the fingers was the method to check for correct moisture content.

Sterilized sawdust bags or damp rice straw were placed on sterilized plastic sheets in a cleaned closed room for 12 hours.

Spawn inoculation

-

After cooling down to room temperature, the sterilized sawdust bags and rice straw were inoculated with the spawn, i.e., grain seeds with the mother culture. The cotton plug of the sawdust bag was opened in a sterile environment, and approximately 10 g of spawn was inoculated into the bag with a sterilized spoon. The bag was closed immediately after this procedure (Fig. 4d). Spawn was pre-prepared in a laboratory at the Kunming Institute of Botany, Chinese Academy of Science, using cooked (40–50 minutes) and autoclaved (121 °C/15 psi/90 minutes) rye grain.

Sterilized rice straw (1.5 kg) was put into polypropylene bags (45/30 cm) in small quantities, and grain spawn was scattered along the perimeter during bagging. Holes (80–100) were punched with a sterilized needle around the rice straw bag to facilitate air circulation.

Inoculated sawdust or rice straw bags were placed upright in a low-light room with ventilation. Bags were checked every three days for diseases. After bags were fully colonized by mycelia, they were transferred into the grow house. Sawdust bags were cut just below the neck and opened with a a sterilized knife. Sawdust bags were placed horizontally on bamboo racks and water was misted onto the opened surface of the bags using a hand sprayer to maintained relative humidity (80–90%). Rice straw bags were tied to the racks and suspended. Holes were poked in the surface of the rice straw bags (1 cm long) in 10–12 places randomly using a sterilized blade and water was sprayed.

Harvesting and packing

-

Mushrooms were manually picked by hand (Fig. 1b). Stipes of mushrooms were trimmed to remove substrate remnants. Harvest dates, number of bags harvested, and the total weight of daily yield was recorded. The biological efficiencies of the two substrates were calculated using the following equation:

${\rm{Biological\;efficiency }}({\text{%}}) = \dfrac{{\rm{Yield\;of\;fresh\;basidiome (g)}}}{{\rm{Substrate\;dry\;weight (g)}}} \times 100$ Fresh (250 g) and dry mushrooms (50 g) were packed in transparent plastic bags before being sent to local markets (Fig. 1c).

We thank to Ar Yone Oo for their support in successfully completing the mushroom cultivation project in two villages in the Chin state. Asanka R. Bandara would also like to thank the China Postdoctoral Science Foundation for funding his postdoctoral project.

-

The authors declare that they have no conflict of interest.

- Copyright: © 2021 by the author(s). Published by Maximum Academic Press, Fayetteville, GA. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Bandara AR, Lian CK, Xu J, Mortimer PE. 2021. Mushroom as a means of sustainable rural development in the Chin State, Myanmar. Circular Agricultural Systems 1: 4 doi: 10.48130/CAS-2021-0004

Mushroom as a means of sustainable rural development in the Chin State, Myanmar

- Received: 07 November 2020

- Accepted: 07 January 2021

- Published online: 01 March 2021

Abstract: Restricted access to quality crops and markets limits the capacity of rural communities to generate income in the mountainous regions of South and Southeast Asia, often resulting in the exploitation of forest systems, a subsequent decline in forest health, and the need for alternative means of income generation as well as forest restoration programmes. Cultivation of edible and medicinal mushrooms has been shown to be a feasible alternative source of income and also contributes to the household nutrition of rural and impoverished communities. There are a number of ongoing programmes in South and Southeast Asia currently implementing trainings and demonstrative practices for the cultivation of mushrooms at the village level. In this context, we implemented different cultivation strategies in selected rural areas in the Chin State, Myanmar. The cultivation strategies were to 1) introduce mushroom cultivation using locally sourced raw materials as substrates for rural communities unfamiliar with mushroom cultivation; and 2) improve the technical knowledge of those already experienced in mushroom cultivation in order to increase yield and minimize challenges in production systems. We introduced Pleurotus sp. cultivation to mushroom growers in the Chin state, Myanmar. These cultivation strategies will help further improve and develop mushroom industries in rural areas and contribute to rural development. In addition, we focused on cultivation systems that incorporate the use of crop residues and woody substrates in order to ensure a sustainable, integrated approach.

-

Key words:

- circular agriculture /

- crop residues /

- mushroom cultivation /

- Pleurotus