-

Recently, prepared foods have received attention due to the consumers' demand for convenient, health-promoting, and nutritious foods. It is well established that prepared food refers to ready-to-eat, heated, ready-to-cook, and paired food derived from agricultural, meat, and aquatic products, which are stored at room temperature, refrigerated, or under frozen conditions[1,2]. In recent years, high-quality and nutritious prefabricated aquatic products are one of the important categories of prepared foods in the market[3]. A satisfying flavor is a crucial factor regulating the consumption of prepared aquatic products. The flavor components from aquatic products can be categorized as aldehydes, ketones, acids, alcohols, esters, amines, hydrocarbons, and sulfides, etc[4,5]. These substances can produce not only flavors but also off-flavors during preparing and storage of prepared aquatic products. Typical off-flavors include hexanal, heptanal, nonanal, 1-octen-3-ol, 2-octen-1-ol, trimethylamine, and sulfur-containing substances[6]. The existence of unacceptable off-flavors can also weaken consumer inclination and restrict demand for prepared aquatic products. Therefore, maintaining the flavor compounds and preventing off-flavor generation is vital to improving the quality of prepared aquatic products.

Suitable packaging materials and methods contribute to maintaining the flavor and inhibit flavor deterioration of aquatic products[7]. Oxidation, microorganisms, and enzymes mainly affect flavor changes of prepared aquatic products during processing and storage. Oxidation of proteins and lipids and the growth of microorganisms could be inhibited by typical packaging. Vacuum packaging and modified atmosphere packaging (MAP) have been applied in the flavor control of prepared aquatic products[8]. For instance, vacuum packaging plays an active role in retaining the flavor of freshwater crawfish[9], fish balls prepared from Capoeta trutta[10], tuna-like fillets[11], and traditional fish-smoked products[12]. MAP has a positive effect on the flavor regulation of cold-smoked salmon[13], dried fermented catfish[14], and deep-water rose shrimp[15] by different gas ratios. However, vacuum packaging has the drawback of leading to structural changes in products and difficulty in material degradation[16]. Meanwhile, the disadvantage of high input costs and relatively high maintenance costs is the limitation of MAP. Furthermore, MAP must be adapted to refrigeration conditions, restricting its freshness preservation effect. These shortcomings of traditional packaging have inspired researchers to develop new environmentally friendly and smart packaging methods. Innovative packaging has advantages in flavor retention and off-flavor control of aquatic products due to degradable, edible, antibacterial, and sensitive characteristics in packaging[17]. Edible packaging is rapidly developing in which proteins, lipids, polysaccharides, etc., and other edible components extracted from unconventional sources, such as microorganisms, are used alone or combined. The application of biodegradable materials, such as polylactic acid biopolymer films[18] and cellulose nanocrystals[19], promotes flavor regulation in aquatic packaging. For instance, citral, carvacrol, and alpha-terpineol essential oil showed advantages in the application of pacific white shrimp[20]. Furthermore, intelligent packaging systems, including colorimetric indicator labels, bio/chemical sensors, time-temperature indicators (TTIs), and radio frequency identification labels (RFID), receive certain interests in packaging. The choice of packaging methods and materials is critical to the flavor of prepared products. And the packaging applicability and advantages of various prepared aquatic products are different.

It has been observed that these typical and innovative packaging methods and materials positively impact the flavor of aquatic products. However, the summary of aquatic product flavor changes associated with packaging materials and methods is rare, especially for prepared aquatic products. Therefore, this article aims to describe the mechanisms of flavor change in package-associated products and summarize the effects of typical and innovative packaging methods and materials on the flavor regulation of prepared aquatic products. This review is expected to provide a basis for the packaging-regulated flavor of prepared aquatic products.

-

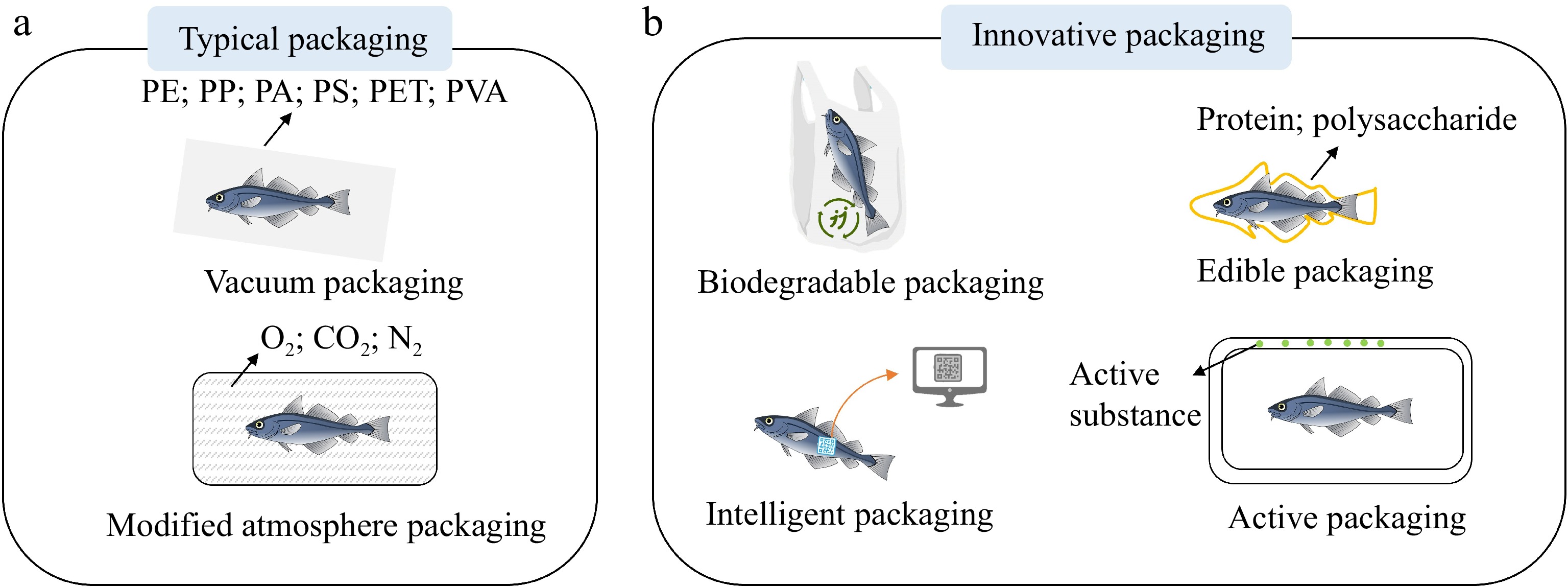

Flavors play a primary role in the quality evaluation of prepared aquatic products. Applying different packaging materials and packaging techniques with various internal environment gas and moisture composition, directly impacts the flavor of prepared aquatic products. Traditional air packaging of aquatic products cannot exclude oxygen interference, so lipid oxidation and hydrolysis, protein oxidation and degradation, microbial growth, and enzyme action will still occur during storage and transportation[21]. The typical and innovative packaging materials and methods for prepared aquatic products are shown in Fig. 1. Prepared aquatic products in various packaging methods may still come into contact with air or small molecules that promote oxidation and degradation, causing flavor changes. The direct interaction between packaging materials and aquatic products may also impact the flavor of prepared aquatic products. Many diverse pathways can generate flavor and off-flavor compounds. Generally, chemical and biological reactions are critical pathways for the formation of flavors in aquatic products.

Figure 1.

(a) Typical packaging materials and methods and (b) innovative packaging materials and methods for prepared aquatic products (PE: Polyethylene; PP: polypropylene; PA: polyamide; PS: polystyrene; PET: polyethylene terephthalate; PVA: polyvinyl alcohol).

Mechanism of flavor change in prepared aquatic products by chemical reactions

Lipid oxidation and hydrolysis

-

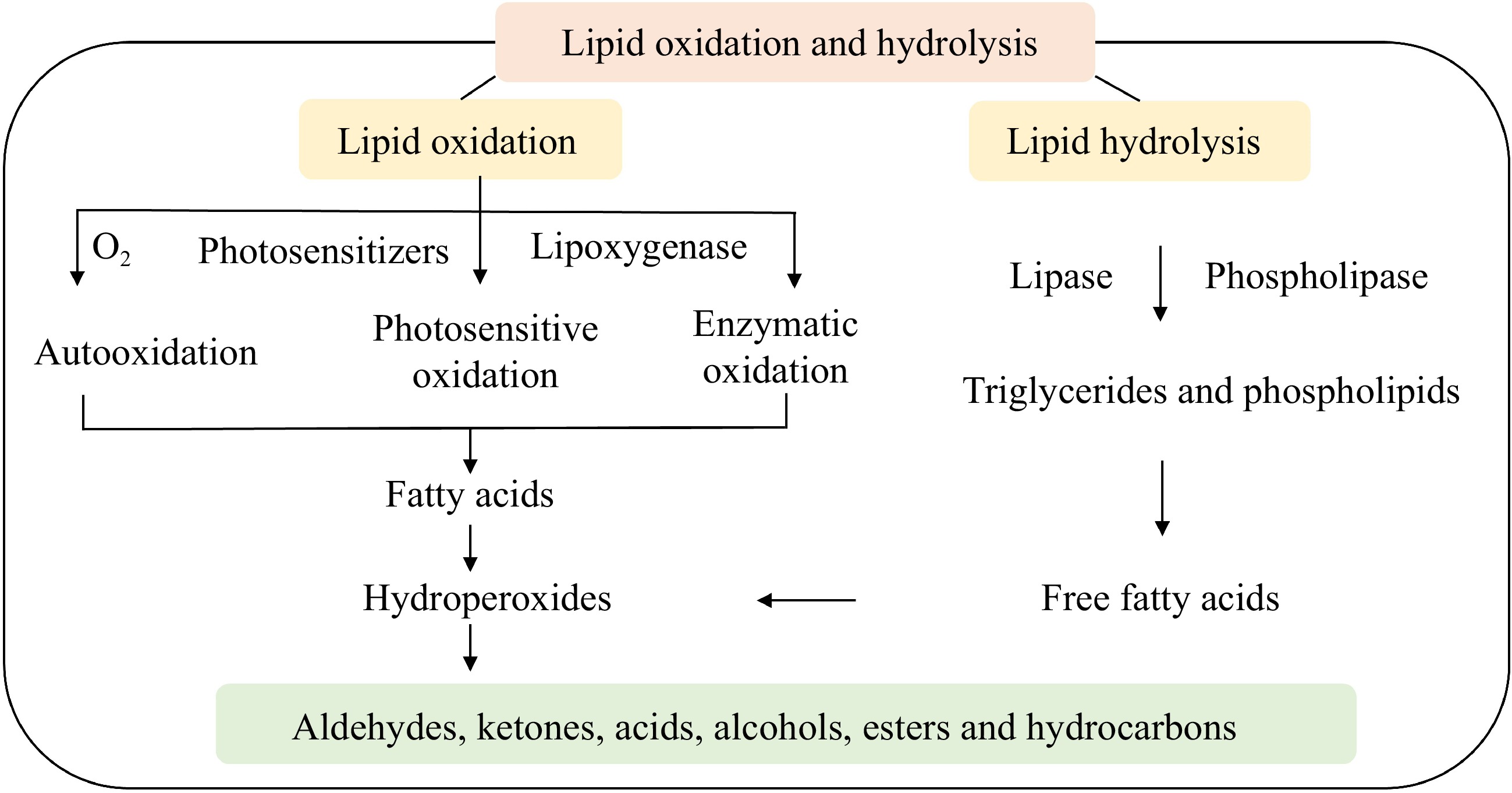

Lipids are accessible to oxidate and hydrolyze during the preparation and storage stages, which is confirmed to perform a crucial character in the flavor and off-flavor changes of prepared aquatic products. The mechanism of flavor change in prepared aquatic products under lipid oxidation and hydrolysis is shown in Fig. 2. Autooxidation, photosensitive oxidation, and enzymatic oxidation are the primary pathways of lipid oxidation. The primary oxidation products are a result of the reaction of fatty acids with molecular oxygen, photosensitizers, or lipoxygenase[22]. Hydroperoxides are unstable and susceptible to breaking up into aldehydes, ketones, acids, alcohols, esters, and hydrocarbons causing the production of flavors or off-flavors. Among these compounds, aldehydes are the significant compounds contributing to flavor development owing to low odor threshold and high concentration. Hidalgo & Zamora[23] indicated that chemical lipid oxidation pathways could generate benzaldehyde and phenylacetic acid. The study by Zhang et al.[24] on dry-cured black carp represented that the variation of microbial community diversity in black carp correlated with lipid oxidation products during storage.

Figure 2.

Mechanism of flavor change in prepared aquatic products under lipid oxidation and hydrolysis.

Lipid hydrolysis is mainly due to the function of lipase and phospholipase. Lipase and phospholipase act on triglycerides and phospholipids, releasing free fatty acids, which are the precursors of fat oxidation[25]. Aldehydes, alcohols, esters, hydrocarbons, and other substances formed by the hydrolysis of lipids affect the flavor of prepared aquatic products. In addition, microbial lipases also contribute to lipolysis, particularly in dried and fermented aquatic products[26]. Proper hydrolysis and oxidation of lipids are conducive to improving the flavor of prepared aquatic products. However, rancidity and flavor deterioration of products can also be found from excessive hydrolysis and oxidation[27]. It has been shown that the flavor deterioration under lipid oxidation and hydrolysis of prepared aquatic products can be regulated by changing the packaging methods[28]. Packaging materials loaded with antioxidants have attracted attention in recent years. For instance, as a natural functional component, rosemary extract has been used as a material for film packaging and has been shown to exhibit significant antioxidant features[29]. Hence, the oxidation and hydrolysis process of the fish can be altered by diverse packaging materials and methods, affecting the flavor of prepared aquatic products.

Protein oxidation and degradation

-

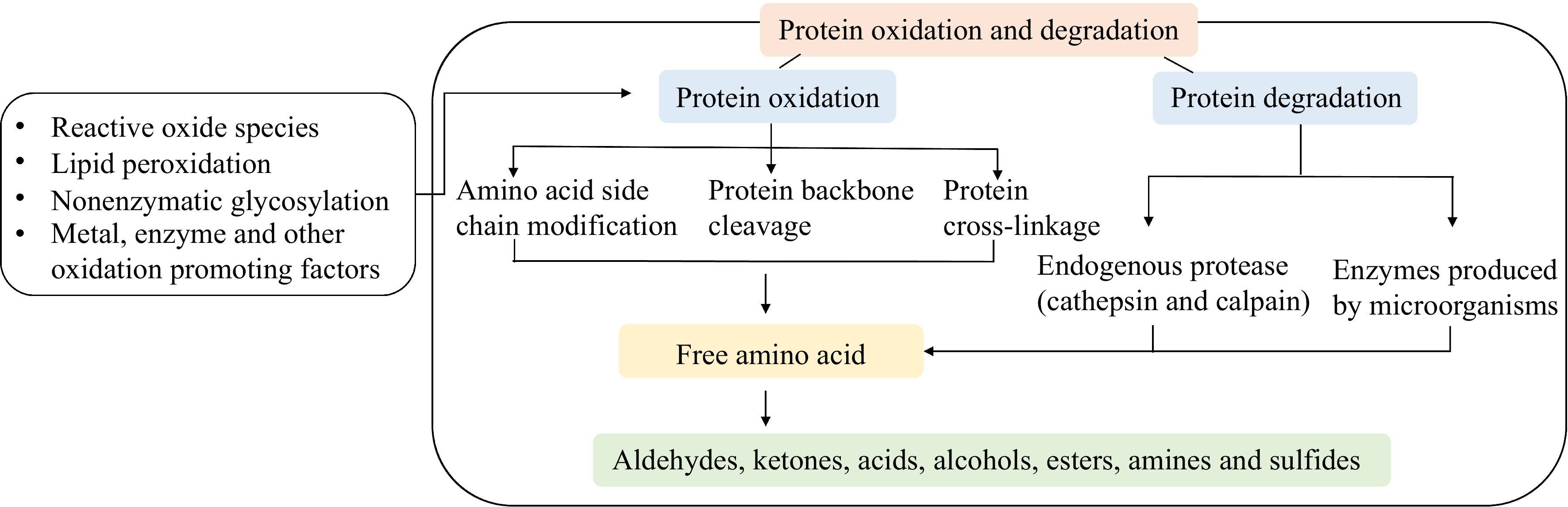

Most aquatic products are rich in protein, making prepared aquatic products tend to be degraded and oxidized during processing and storage[30]. The mechanism of flavor change in prepared aquatic products under protein oxidation and degradation is depicted in Fig. 3. Protein oxidation, a reaction that results in the covalent modification of proteins, can result in irreversible changes to protein structure, including the modification of amino acid side chains, cleavage of the protein backbone, and protein cross-linkage[31]. The free amino acids generated during protein oxidation can decompose to aldehydes, ketones, acids, alcohols, and esters as flavor or off-flavor components. Liu et al.[32] studied the connection between Russian sturgeon protein and changes in flavor under low-temperature vacuum heating and found that protein oxidation was closely related to odor production.

Figure 3.

Mechanism of flavor change in prepared aquatic products under protein oxidation and degradation.

Protein degradation by endogenous proteases plays an essential role in flavor formation while preparing aquatic products for storage. The production of aldehydes, ketones, acids, amines, and sulfur by protein degradation under the function of endogenous protein enzymes and microorganisms can accelerate pleasant flavors and may result in flavor deterioration of prepared aquatic products[33]. Long-term anaerobic fish storage leads to high ammonia production due to the deterioration of amino acids and the cumulation of low fatty acids including acetic acid, butyric acid, and propionic acid[34]. Moderate oxidation and hydrolysis of proteins are beneficial for the formation of flavor. The packaging process of prepared aquatic products can regulate off-flavor through protein oxidation and degradation. Hence, the focus of attention has shifted to how to avoid excessive oxidation to maintain flavor and improve off-flavor deterioration through innovative packaging during the packaging process. Innovative packaging materials and methods could prevent prepared aquatic products from coming into contact with pro-oxidative factors. In addition, it is feasible to regulate the protein oxidation and degradation of prepared aquatic products by inhibiting enzyme activity under innovative packaging.

Mechanism of flavor change in prepared aquatic products with biological regulation

Microbial action

-

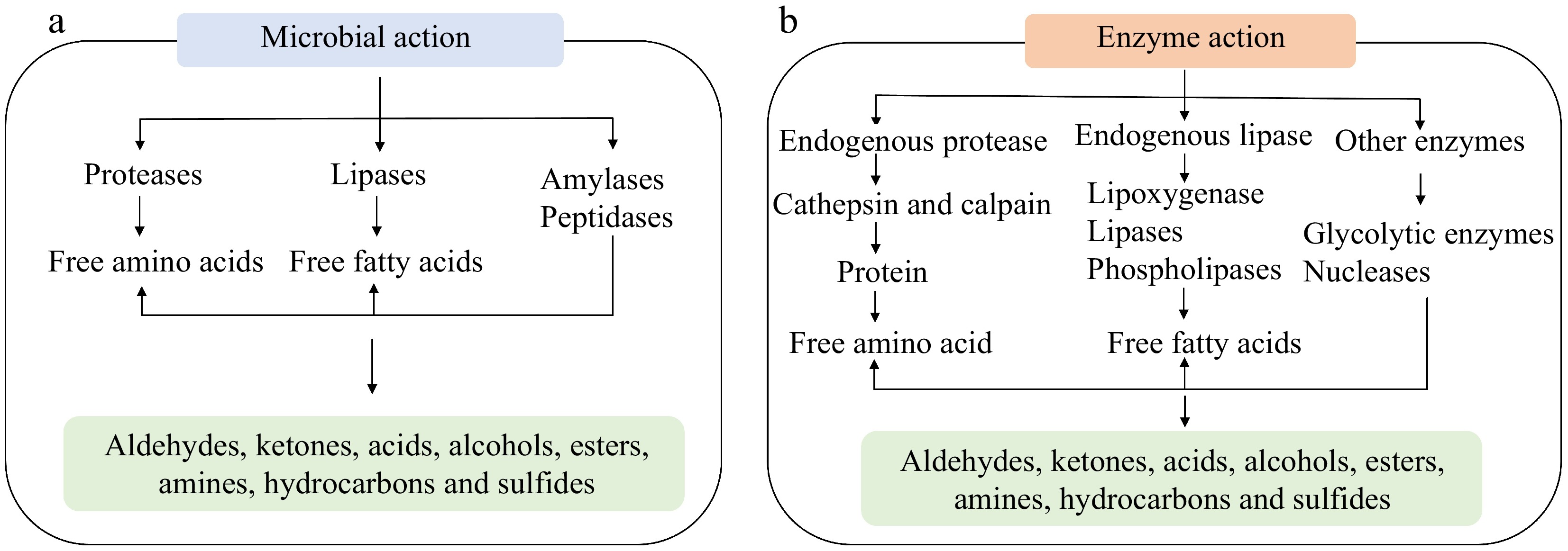

Microbial action is essential in causing flavor deterioration and spoilage of fresh, refrigerated, and frozen prepared aquatic products. The mechanism of flavor change in prepared aquatic products under microbial action is shown in Fig. 4a. Proteases, lipases, amylases, peptidases, and various hydrolytic enzymes generated by the growth and reproduction of microorganisms could accelerate the degradation rate of proteins, lipids, and other nutrients. For instance, proteases secreted by microorganisms cause the oxidation and degradation of proteins to produce free amino acids, further decomposed to volatile amines, biogenic amines, and sulfides. Similarly, microorganisms release lipases that promote lipid hydrolysis and oxidation. Free fatty acids could further break down into alcohols, aldehydes, and ketones. Some microorganisms and metabolites, such as bacteriocins, have antibacterial effects and can be used in film-coated packaging. The spoilage of refrigerated shrimp could be delayed under Lactobacillus plantarum as reported by Tang et al.[35]. Lactobacillus plantarum has excellent antibacterial activity and could be used as a biological preservative. Innovative packaging materials and methods could significantly inhibit microbial activity by lowering water activity, isolating oxygen, and releasing antibacterial compounds, which in turn regulate the flavor of aquatic products.

Figure 4.

Mechanism of flavor change in prepared aquatic products under (a) microbial action and (b) enzyme action.

Enzyme action

-

The mechanism of flavor change in prepared aquatic products under enzyme action is shown in Fig. 4b. The endogenous enzymes involved in the flavor formation processes of prepared aquatic products include lipid oxidation, lipid hydrolysis, and protein degradation[36]. Muscle lipases and phospholipases usually stand for lipolysis in prepared aquatic products. Likewise, microbial lipases also impact lipolysis, particularly in dried and fermented aquatic products[27]. However, the free fatty acids produced by lipid degradation via endogenous lipases are prone to oxidation to generate carbonyl compounds[37]. Lipoxygenase can catalyze the oxidization of polyunsaturated fatty acids to produce hydroperoxides[38]. Endogenous proteases such as cathepsin and calpain act on proteins leading to protein degradation[39]. A series of hydrolysis products including small molecule peptides and free amino acids could be further generated. Inosine and hypoxanthine, produced by adenosine triphosphate, adenosine diphosphate, and hypoxanthine nucleotides under nucleases, are bitter[40]. The overall flavor of aquatic products is negatively impacted by inosine and hypoxanthine. Lactic acid is produced by glycolytic enzymes acting on glycogen, causing a decrease in muscle tissue pH, and affecting the flavor of prepared aquatic products. Flavor regulation by optimizing packaging materials and methods has shown outstanding effects in aquatic products. It is expected that using the enzyme inhibitors in cutting-edge packaging materials and techniques to control enzyme activities like lipase and protease can control off-flavor from the perspective of regulating free amino acid and fatty acid reactions.

-

Vacuum packaging and MAP are now widely used for prepared aquatic product packaging, as depicted in Fig. 1a. Food-grade, highly temperature-resistant, and mechanically strong materials are typically chosen for vacuum packaging. The growth and reproduction of aerobic microorganisms have been suppressed due to the low oxygen content. In addition, the flavor of prepared aquatic products is preserved by slowing down the rate of protein and lipid oxidation, as shown in Table 1. Vacuum packaging materials are generally plastics made from petrochemical-based resources because of their affordability, outstanding mechanical qualities, and quick production. Packaging materials are divided into single, composite materials according to the type of raw materials used. Polyethylene (PE), polypropylene (PP), polyamide (PA), polystyrene (PS), polyethylene terephthalate (PET), and polyvinyl alcohol (PVA) are the most prevalent polymers in plastic packaging[41]. Most plastic is nonbiodegradable, and only about 9% of plastic waste could be recycled[42]. Microplastics and potentially hazardous plasticizers can cause severe concerns to food safety along the food chain[43]. Moreover, the plastic packaging may react with the contents, affecting the product's flavor. Liu et al.[44] concentrated on the effect of container materials on the degradation of Sichuan pickles. They found that plastic packaging promoted the production of butyric acid and lactic acid in pickles. Thus, the environmentally friendly materials that could be degraded and replenished are needed to retain the flavor of prepared aquatic products.

Table 1. Flavor regulation of prepared aquatic products associated with typical packaging.

Typical packaging Packaging methods Aquatic products Response effect of packaging References Vacuum packaging Vacuum packaging Tuna Vacuum packaging was adequate to postpone the lipid oxidation of tuna fillets at 4 °C. [11] Frozen and vacuum-packed Lethrinus atkinsoni fillets Frozen and vacuum-packed samples were a suitable strategy for preventing lipid oxidation in Lethrinus atkinsoni fillets, prolonging shelf-life of the samples. [45] Vacuum packaging (PE, polyester, and other packaging materials) Smoked salmon Polyester and PE had superior water vapor barrier qualities and inhibited the formation of total volatile base nitrogen (TVBN) in smoked salmon. [12] Vacuum packaging (PA

and PET plastic)Surimi The sensory evaluation of surimi packed in PA was the least acceptable to consumers. [46] Modified atmosphere packaging 80% CO2 and 20% N2 Rainbow trout fillets When compared to aerobic packaging, MAP with 80% CO2 and 20% N2 reduced the total production of ammonia, TVBN, and putrescine of rainbow trout fillets. The shelf-life of rainbow trout was prolonged by at lowest two times owing to MAP, which slowed down microbial activity and biochemical alterations. [47] CO2 to N2 volume ratio

of 3:2Salmon The growth of spoiling bacteria was suppressed, and the shelf-life of fish fillets was prolonged for salmon under modified atmosphere packaging. [48] 30% N2, 40% CO2, and

30% O2Gray triggerfish MAP delayed the acceleration of TVB-N content in fish fillets and extended the shelf life of fish in comparison with air and vacuum packaging. [49] Super chilling in combination with 40% CO2 and 60% N2 Atlantic cod During storage, the association of super chilling and MAP suppressed microbial growth and TVBN generation. [50] Modified atmosphere packaging and ambient gas

-

It is well known that MAP is an effective preservation technology for inhibiting microbial growth, retaining quality, and prolonging the shelf life of aquatic products. MAP technology generally alters the aquatic products' gas environment by using various amounts of N2, CO2, and O2[51]. N2, as an inert gas, could inhibit the oxidative spoilage of aquatic products. The growth of specific spoilage organisms can be hindered by CO2. It could generate H2CO3 in the aqueous medium to reduce the pH of aquatic products during storage to lengthen the shelf-life. The proportion of each component in the gas mixture of the MAP depends on the sensitivity of marine fish products to O2 and CO2 and the growth habit of specific spoilage microorganisms[52]. By changing the environment of the product, MAP impedes the entry of outside air. And the accumulation of off-flavors, for instance, biogenic amines, could be restrained by MAP. In addition, MAP effectively slows down the flavor degradation caused by microbial action, lipid oxidation, and protein degradation. The flavor variation of prepared aquatic products associated with modified atmosphere packaging is shown in Table 1. Although air conditioning packaging can be used to counteract the texture changes caused by vacuum packaging on the extrusion of aquatic products, its packaging materials and equipment are more expensive. They typically require refrigeration to achieve the best effect in aquatic product preservation. MAP can also be associated with other physical technologies, such as ultrasonic processing, low-temperature plasma, electrostatic field, and coating technology to upgrade product safety, retain flavor, and prolong shelf life.

-

Innovative packaging materials and methods, including biodegradable, edible, active, and intelligent packaging (Fig. 1b), have received attention in prepared aquatic products' flavor regulation. Table 2 shows the advantages and disadvantages of typical and innovative packaging for flavor regulation. It can be seen that innovative packaging avoids the drawbacks of typical packaging and has better effects on flavor retention. The innovative packaging however has defects that can be improved.

Table 2. Advantages and disadvantages of typical and innovative packaging for flavor regulation of prepared aquatic products.

Packaging types Packaging methods Advantages Disadvantages References Typical packaging Vacuum packaging Low oxygen content; suppresses the action of

aerobic microorganismsNonbiodegradable; hazards of microplastics; migration of plasticizers; texture deterioration [42, 43] Modified atmosphere packaging Inhibiting microbial growth; alters the gas environment High input costs; typically require refrigeration [48, 50] Innovative packaging Biodegradable packaging Renewable; degradable Weaken in physical, mechanical, and thermal properties [53, 54] Edible packaging Edible; good resistance to

lipids and oxygen; economicalMechanical properties, thermal properties, and air/moisture barriers need further improvement [55] Active packaging Antibacterial activity; delays lipid oxidation The active substance may be sensitive to temperature or humidity; the release velocity of the active substance [56] Intelligent packaging TTIs and colorimetric indicator labels have low cost and fast detection; bio/chemical sensors and RFID are responsive and sensitive in detecting TTIs are not easy to control; colorimetric indicator labels are easily affected by sample humidity; bio/chemical sensors and RFID reaction materials for food safety are unclear [3] Biodegradable packaging and materials

-

Biodegradable packaging has recently obtained focussed attention owing to the difficulty of degrading plastic packaging and the safety of microplastics. Terms like bioplastics, biobased plastics, biodegradable plastics, and recycling plastics are frequently used[53]. High temperature resistant molding is employed for the exterior packaging of prepared food such as edible, semi-finished, cooked, and convenience products. Plant fiber packaging is also used for packaging trays of frozen products. Cellulose, chitosan, and starch have attracted widespread attention as biodegradable packaging components. Cellulose is gaining interest as a renewable and degradable polymer for degradable packaging. For instance, carboxymethyl and hydroxypropyl cellulose act as a barrier to hydrophobic substances and perform effectively in packaging[57]. Chang et al.[58] developed a high throughput packaging using biodegradable antimicrobial pullulan fibers and found that the coating significantly prolonged the shelf-life of fruits. Furthermore, the chitosan nanoparticles are non-toxic, friendly, and biodegradable, which could be applied as biodegradable composites for food packaging[59]. In addition, starch is being investigated for packaging material owing to its thermoplasticity.

Compared to commonly used petro-based polymers, most biopolymers are intrinsically poor in terms of physical, mechanical, and thermal properties when used alone in packaging[54]. Biodegradable packaging could be created by combining different biopolymers. Meanwhile, biopolymer chain crosslinkers and nano-fillers are typical biodegradable packaging fillers[60]. As shown in Table 3, biodegradable packaging has been developed for the flavor regulation of aquatic products. Biodegradable packaging could slow down the flavor deterioration caused by aldehydes and biological amines by regulating oxidation and microorganisms. Improving the biodegradability, mechanics, and barrier properties of biodegradable packaging materials and reducing their costs to expand the application potential are crucial directions for biodegradable packaging development. In addition, biodegradable packaging materials combined with natural pigments and antimicrobial ingredients have great potential as active packaging or intelligent packaging for prepared aquatic products.

Table 3. Flavor regulation of prepared aquatic products associated with innovative packaging.

Innovative packaging Packaging methods Aquatic products Response effect of packaging References Biodegradable packaging Starch/

carboxymethylcellulose/

gelatin/cellulose/green tea groundsSalmon This innovative packaging is readily biodegradable, inhibits the growth of specific spoilage organisms in salmon fillets, and delays the formation of biogenic amines. [63] Carboxymethyl-cellulose/starch/ purple sweet potato anthocyanins Grass crap The coating can degrade and be used as intelligent packaging to monitor fish quality by changing color when exposed to ammonia or varying pH levels from red to blue and green. [64] Polylactic acid (PLA)/tilapia fish gelatin-sodium alginate bilayer films Sea bass Compared to PLA and edible gelatin-based monolayer films, this combination enhanced the films’ ability to act as an oxygen and water vapor barrier. The films were highly antioxidant and antibacterial. [65] Sodium alginate films with Clitoria ternatea extract (CTE) Freshwater shrimp Owing to intermolecular interactions and crosslinking of polymeric networks, the addition of CTE to alginate coatings increased the heat stability of materials. The films showed outstanding colorimetric capabilities and could be applied as a biodegradable freshness indicator. [66] Edible packaging Ethyl lauroyl arginate and lemon essential oil added to edible chitosan film coating Mackerel The film-treated mackerel could store at 2 °C for 9 days, and its biogenic amine content was 30%−40% lower than that of the uncoated group. [67] Pectin combined with plant essential oils Large yellow croaker The coating technology can effectively slow water migration, inhibit endogenous enzyme activity, and slow the oxidation process of large yellow croaker rhubarb protein during storage. [68] Chitosan film incorporated with thinned young apple polyphenols Grass carp The accumulation of peroxide, thiobarbituric acid values, and TVBN content have been decreased in grass carp and the shelf life of fillets has been extended for 4 days. [69] Rice starch films with oregano essential oil Genidens genidens During chilled storage, fish fillets wrapped in oregano essential oil and rice starch film had lower malondialdehyde content. The packaging components can be used as active packaging. [70] Active packaging Chitosan-nisin (CS-nisin) microcapsules Small yellow croaker CS-nisin microcapsules observably inhibited microbial growth, lipid oxidation, and protein degradation. This active packaging extended the shelf-life of the small yellow croaker for 6−9 days. [71] Polyhydroxy butyrate-co-valerate (PHBV) with gallic acid/sodium carbonate Fatty food simulants Gallic acid was released into food simulants during contact with fatty food simulants. The PHBV active packaging offers significant potential for protecting food quality by combining anti-free radicals and oxygen scavenger functions. [72] Starch-based films with potato peel phenolic extracts Smoked fish The newly created starch/0.5% phenolics-based coatings enable the dehydration of smoked fish fillets. [73] Bacteriocin GP1 of Lactobacillus rhamnosus GP1 Cod Applying bacteriocin GP1 in stored fish could effectively control the growth of spoilage organisms. Bacteriocin treatment inhibited spoiling by reducing the formation of volatile amines during storage. [74] Intelligent packaging Colorimetric indicator labels Shrimp The colorimetric film of polyvinyl alcohol/okra mucilage polysaccharide/ rose anthocyanins was sensitive to volatile ammonia. The indicator label had color variations between pH 2−12. [75] Shrimp The film consisted of starch/polyvinyl alcohol/ betalains-rich red pitaya peel extract. The formation of volatile nitrogen during the shrimp spoilage process caused color changes in the film. [76] Bio/chemical sensors Squid and large yellow croaker Xanthine oxidase was immobilized onto a biocompatible copper-based metal-organic framework nanofibers film. When applied to detecting frozen squid and large yellow croaker, the electrochemical biosensor for xanthine and hypoxanthine shows good recovery. [77] TTIs Oysters TTIs can both identify the growth of psychrotrophic spoiling microorganisms and monitor the shelf life of refrigerated oysters. [78] RFID Sea bass RFID can detect temperature changes in fish in styrofoam boxes. [79] Edible packaging and materials

-

Food can be packaged and transported using edible packaging, which is cutting-edge and valuable. The creation of edible packaging of protein-based and polysaccharide-based films was motivated by a study into the drawbacks of plastic materials and the excellent coating-forming capabilities of proteins and polysaccharides. Plant-based proteins, like maize gluten, wheat gluten, and peanuts, are frequently used in food packaging[61]. In contrast, gelatin, casein, myofibrillar protein, and collagen are examples of animal-based film formers[62]. The advantageous properties of proteins can be used for flavor carriers to deliver and hold onto flavors[80]. Polysaccharides have received much attention as potential essential components for biobased/biodegradable polymers for packaging. Polysaccharides can build good films, exhibit strong resistance to lipids, and even exhibit antimicrobial capabilities[81]. Moreover, lipid films are frequently utilized as coatings, such as monoacylglycerols, phospholipids, and free fatty acids[82].

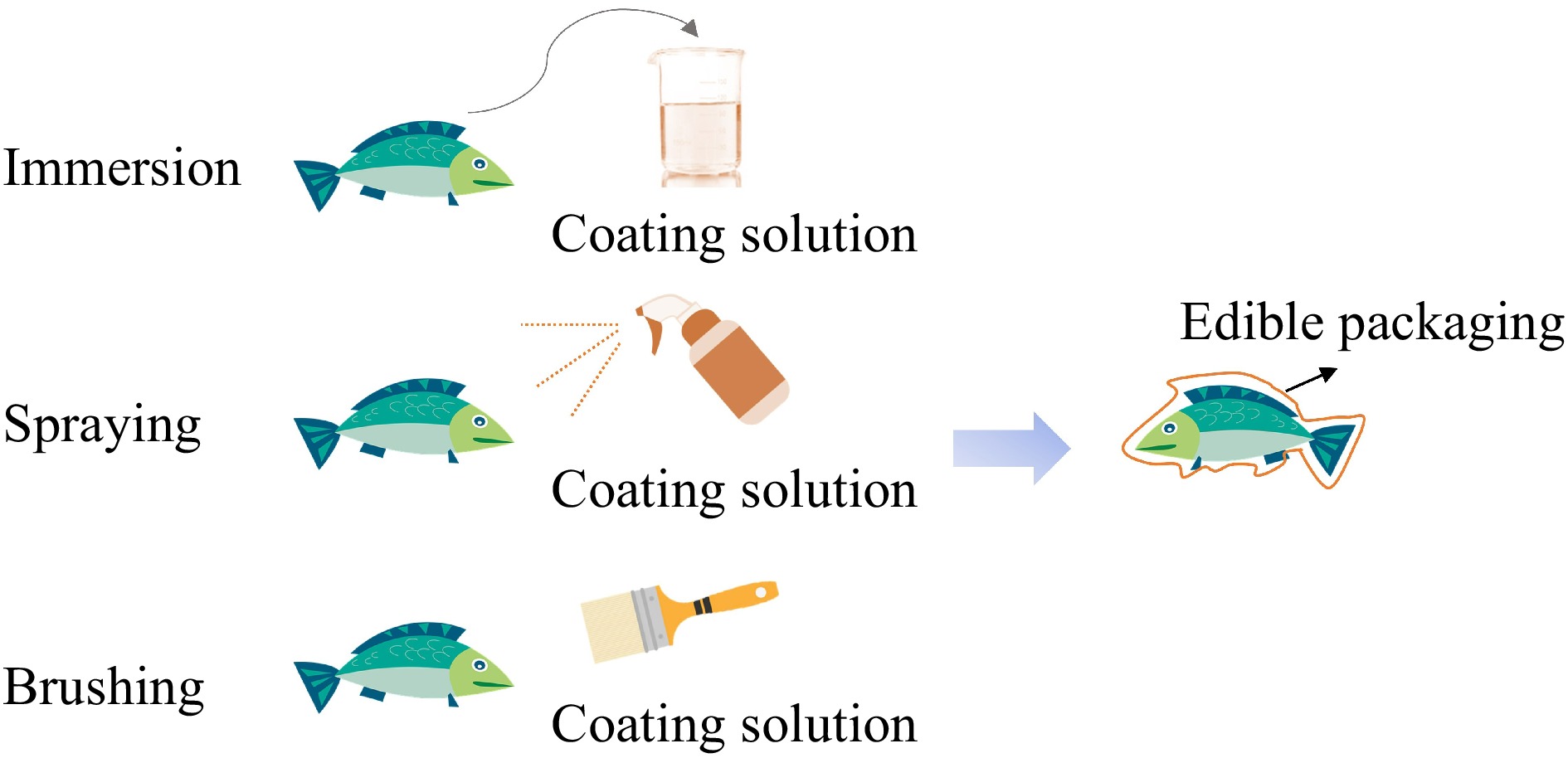

Edible packaging of aquatic products is a premade coating solution wrapped in the surface of the products, which can retain the flavor and extend the shelf-life of prepared aquatic products[83]. The film solution is a more effective and economical viable strategy[84] and can be used in multiple methods, including immersion, spraying, and brushing, as shown in Fig. 5. The immersion mode, or coating or dipping, involves dipping whole slices of samples in a film solution before draining and drying them at a particular temperature[85]. Spraying delivers a thinner but less uniform coverage[86]. In brushing edible packaging, the coating solution is transported to the samples' surfaces using a brush[87]. The flavor variation of prepared aquatic products associated with edible packaging is shown in Table 3. The flavor of aquatic products could be regulated by reducing oxygen exposure and inhibiting endogenous enzyme activity under edible packaging[55]. Slowing down the accumulation of off-flavor metabolites is also an important way to preserve the flavor of prepared aquatic products in edible packaging. In general, edible coating films have excellent coating-forming properties, outstanding resistance to lipids, oxygen, and even antibacterial activity. However, the mechanical capacity, thermal properties, and air/moisture barriers still need to be improved in the packaging of prepared aquatic products.

Figure 5.

Preparation method of edible packaging for prepared aquatic products (adapted from Jafarzadeh et al.[88]).

Active packaging and materials

-

Active packaging is a cutting-edge food preservation system that interacts food with the packaging and the environment. This packaging method can be classified as an active scavenger and release system[56]. The former removes undesirable substances from products or the environment, such as moisture, oxygen, carbon dioxide, and other off-flavors. At the same time, in the latter, elements such as antimicrobial components, antioxidants, or plant essential oils could be added to packaged foods or the headspace of packaging. Packaging with decreased remanent oxygen is feasible for active scavenger systems with the aid of oxygen scavengers[89]. A nonferrous oxygen scavenger consisting of activated carbon and sodium l-ascorbate was invented by Lee et al.[90] to improve the preservation efficiency of raw meatloaves. Superabsorbents such as carboxymethylcellulose, starch copolymers, and silicates could be utilized as active moisture scavengers[91]. In active packaging materials, natural antioxidants, for example, polyphenols, plant extracts, and essential oils are becoming widely attractive[92]. Lončarić et al.[38] found excellent lipoxygenase inhibitory activities from extracts.

Aldehydes, ketones, sulfides, and biogenic amines are the main undesirable off-flavor components in aquatic products[93]. Active packaging for aquatic products can effectively maintain the flavor and quality of the aquatic product, as shown in Table 3. Active packaging could inhibit lipid oxidation, protein degradation, and microbial growth. It is possible to prevent the accumulation of volatile amines in prepared aquatic products. However, the variety of preparation methods and the structural complexity of aquatic products may impact active components' release, absorption, and diffusion rates. Further, the components of aquatic products may interact with the active ingredient, limiting the intended activity. Additionally, it is critical to investigate the mechanisms of microbial, enzymatic, and oxidative effects of active packaging components on prepared aquatic products and the relationship between packaging components and flavor.

Intelligent packaging and materials

-

Conventional packaging is designed to shield aquatic products from the environment. In contrast, intelligent packaging uses indicator labels, sensors, and other devices to reveal information concerning the quality of aquatic products, including freshness, microorganisms, and flavor. Correspondingly, it monitors changes in the external environment, including temperature, humidity, and carbon dioxide, which decreases aquatic product losses and raises utilization value[94]. For prepared aquatic products, the primary flavor-indicating compounds are aldehydes, ketones, acids, alcohols, esters, and amines caused by the action of oxidation, microorganisms, and enzymes. Intelligent packaging systems are designed to confirm the changes in flavor by detecting these substances[95]. According to the study of Shao et al.[96], aldehyde colorimetry showed great sensitivity and favorable humidity stability in intelligent packaging for flavor monitoring.

Intelligent packaging systems, including colorimetric indicator labels, bio/chemical sensors, TTIs, and RFID, can monitor changes in the quality and flavor of aquatic products in real time[97], as shown in Table 3. Intelligent packaging is typically applied as labels to the interior or headspace of packages to determine the flavor and quality of products. This packaging not only demonstrates changes in the quality and flavor of the products but also tracks the records of the product from manufacturing, packaging, logistics and distribution, and sales[98]. Intelligent packaging, such as TTIs and colorimetric indicator labels, has low cost and fast detection. Moreover, bio/chemical sensors and RFID are responsive and sensitive in detecting aquatic products. However, TTIs are not easy to control, and colorimetric indicator labels are easily affected by sample humidity. Bio/chemical sensors and RFID reaction materials for food safety are unclear. It is still necessary to thoroughly investigate the parameters of the intelligent packaging systems, mechanisms of action, and safety for various prepared aquatic products, establishing the basics for further intelligent packaging applications.

-

Packaging methods and packaging materials can regulate the flavor of prepared aquatic products under the action of protein, lipids, enzymes, and microorganisms. Active packaging and intelligent packaging provide the direction of regulation and detection of off-flavor in prepared aquatic products. Meanwhile, edible packaging and biodegradable packaging offer guidelines for environment-friendly packaging materials. Large-scale application of innovative packaging materials and methods has significant commercialization potential. Further research towards innovative packaging materials and methods for flavor regulation in prepared aquatic products should focus on the following aspects:

(1) Future innovative packaging should be based on the mechanism to regulate the flavor of aquatic products. Further, it is essential to focus on enhancing packaging coating preparation technology and improving the mechanical properties of degradable packaging. Moreover, raising the detection stability of active packaging and determining the detection sensitivity of intelligent packaging is equally important.

(2) According to the various types and processing methods of prepared aquatic products, flavor regulation associated with packaging methods should take the condition of storage and transportation into account.

(3) Modern information technology is a crucial mode that could be applied to the flavor regulation of prepared aquatic products, such as machine learning-based, digital twins, and computer-aided food engineering.

This study was supported by the National Natural Science Foundation of China (32072290), the Zhejiang Provincial Natural Science Foundation of China (LZ22C200003, LGN21C200014), and the Zhejiang Provincial Sannongjiufang Program (2022SNJF069).

-

The authors declare that they have no conflict of interest.

- Copyright: © 2023 by the author(s). Published by Maximum Academic Press on behalf of China Agricultural University, Zhejiang University and Shenyang Agricultural University. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Zhao X, Chen J, Li H, Chen Y, Lian R, et al. 2023. Innovative packaging materials and methods for flavor regulation of prepared aquatic products: Mechanism, classification and future prospective. Food Innovation and Advances 2(2):145−155 doi: 10.48130/FIA-2023-0017

Innovative packaging materials and methods for flavor regulation of prepared aquatic products: Mechanism, classification and future prospective

- Received: 02 February 2023

- Accepted: 29 March 2023

- Published online: 20 June 2023

Abstract: Prepared aquatic products refer to ready-to-eat, heated, ready-to-cook, and paired food derived from marine products, which are growing as attractive convenience food. Flavor is a vital factor for consumers in choosing prepared aquatic products. Suitable packaging materials and methods are the crucial pathways used to maintain the flavor and control the off-flavor of prepared aquatic products. Compared to vacuum packaging and modified atmosphere packaging, innovative packaging, including biodegradable, edible, active, and intelligent packaging, has received attention due to the potential advantages of flavor regulation. The mechanism of flavor change in package-associated prepared aquatic products is surveyed in this paper according to the reaction of lipids, proteins, microorganisms, and enzymes. Further, the effects of innovative packaging materials and methods on the flavor regulation of prepared aquatic products are summarized under the investigation of typical packaging. Moreover, prospects for innovative packaging materials and methods for flavor regulation in prepared aquatic products are proposed. This review provides references and bases for developing innovative packaging that maintain the flavor and wipes off-flavor.

-

Key words:

- Innovative packaging /

- Prepared aquatic products /

- Flavor /

- Packaging materials /

- Packaging methods