-

Nowadays, science and technology are more concerned about nano-scale materials because of their numerous benefits. They have great potential for many health benefits and significant medical and food applications. Many attributes and capabilities of nanomaterials have been acknowledged, such as favorable substitutes for biological research, medical research, and fluorescent materials[1]. Nano-science or nano-technology is a rapidly developing versatile research area that deals with nanoparticle production, physical and chemical categorization, and application[2]. Generally, nanoparticles are smaller than 500 nm[3]. Due to their utmost nanoscale properties, increased surface area, and enhanced chemical reactiveness compared to bulk particles, nano-particles have extensive applications in energy, medicine, physicochemical attributes, materials, the food industry, and the synthesis of nano-particles[4]. Nanomaterials are potential alternatives for producing high-performance membranes of nanofibers for purification and ultrafiltration[5]. These materials are flexible, biocompatible, and have desirable aggregation-induced emission properties and critical visual technologies features[6].

Gas-filled nanoscopic bubbles are called nanobubbles (NBs) and have a diameter of less than < 500 nm[7]. There are two kinds of nano-bubbles one is surface nano-bubbles and the other is bulk nano-bubbles. Surface NBs exist in solid and liquid interfaces, while bulk nano-bubbles exist in solutions[8]. There is increasing concern about the mass production of bulk NBs because they can increase the surface area, modify the medium's physicochemical properties and promote mass transfer in a medium[9]. The presence and solidity of NBs have been authenticated in various fields. According to research, nano-baubles could remove tumors when they subside in the ultrasound field[10]. NBs have gained immense attention in the past few years due to their diversity of physicochemical attributes[11]. According to other research, nano-bubbles have been employed in different research areas to accomplish different goals, such as the nitrogen NBs for extraction purposes[12], air and oxygen NBs for plant growth[13], hydrogen NBs for drug provision and high-efficacy fuel[14], surface cleaning[15], bio-surfactant NBs for phytochemical extraction from Camellia Oleifera Shells[16], ozone NBs for removing dental bacteria[17], NBs were intended for coffee foam stability[18], and NBs used alone or in combination for the removal of harmful microorganisms from stainless steel and plastic materials[19]. In the food industry, gaseous bubbles in the micron range can soothe foam and improve the micro-level structure and effectiveness of commodities such as baked items, fizzy beverages, dairy products, confectionery, and chocolate-containing products[20].

Among many advanced extractions, freezing, and foam production technologies, nanobubble (NB) production via ultrasonication has become one of the most promising alternatives to conventionally used techniques[15]. Ultrasound induced chemical, mechanical, and biochemical changes in liquids via the production and following collapse of cavitation bubbles. The introduction of NBs to ultrasonic applications has attracted much interest during the past decades, as their benefits for modulating ultrasonic cavitation have been proven worldwide[16]. Researchers are constantly exploring new and green methods in the food processing industry. Applying ultrasonication associated with NBs can enhance food quality, improve the food structure and useful in removing the food pathogenic bacteria[17,18]. However, there have been few analyses on nanoscale bubbles regarding their application in the food industry. Also, there is still a need for a thorough investigation into the stability of NBs and production in food-liquid solutions[19,20].

This review focuses on the latest NBs research progress in food-related applications: the first section includes an introduction, characterization, and methods for NBs for a generation. The second section includes literature about the potential application of NBs in the food industry and the effect of NBs on food's different attributes. Lastly, the last segment summarizes some significant matters of NBs concerning their future perspectives, and finally, we provide some suggestions and future recommendations to conclude the paper.

-

There is no fixed definition for NBs, this term is constantly evolving, but generally, they are tremendously tiny gas molecules with a diameter of about 10 to 500 nm[21]; some researchers defined them as ultra-bubbles with a diameter range of 1−1,000 nm[22]. NBs showed some remarkable characteristics in aqueous solutions, which include higher solubility, high zeta potential, formation of free radicals, extraordinary stability against amalgamation, great surface area, and release of high energy by the disintegration of bubbles[23].

Persistence and stability

-

According to the conventional thermodynamic theory, the potential existence and the ability of NBs to remain stable in liquids under ambient conditions has been a contentious question for a long time[24]. According to Henry's law, the core pressure of NBs would be significantly more sophisticated than the outward pressure of a solution, allowing for the bubble's quick breakdown and disappearance within microseconds[25]. Because of their size, NBs can't exist or be stable[26]. Despite this, many studies showed that NBs could retain extraordinary stagnation properties in liquid solutions with measurable lifespan lasting hours, days, weeks, or even months under the right circumstances[27]. According to a theory, the durability of NBs may be influenced by the anion surface assimilation at their interface. Ions adsorbing to the NBs interface at the nanoscale may provide electrostatic repulsive forces that will counteract the constrictive force from an exterior pressure. The equilibrium of these forces would have consequence in either a long-lasting stability of NBs diameter or a non-contiguity of the air particles inside NBs with liquid. Additionally, because of their micro-scale diameter NBs have a higher particular apex than macro bubbles of the equivalent volume and a better bulk transference capability, considerably increasing the solvability of gases[28].

Zeta potential

-

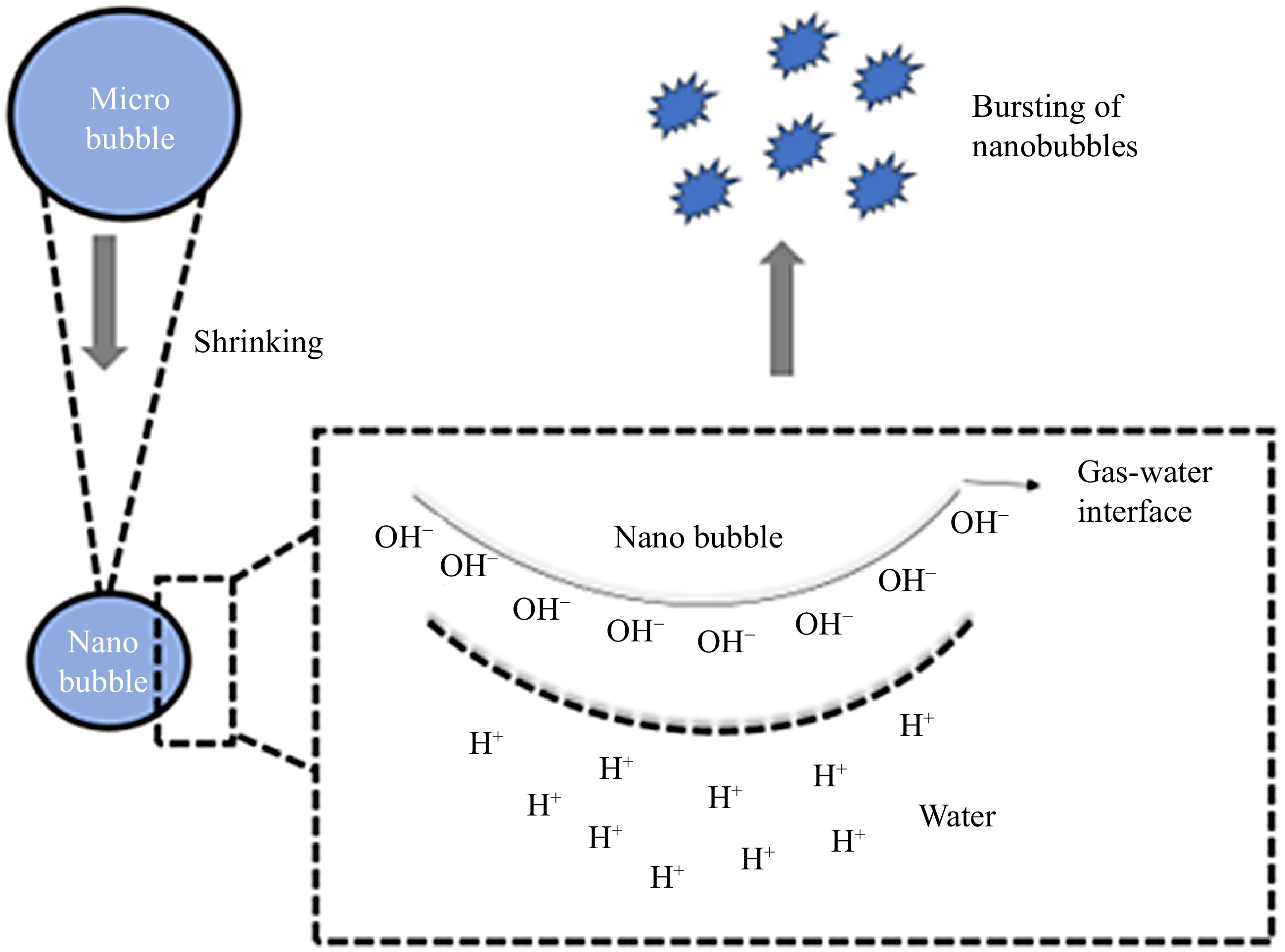

The downhill plane divides the dual layer of counterions generated before the bubble interphase and the bulk solution and is believed to represent a physical characteristic of NBs in suspension[29]. Zeta potential (ZP) is a crucial signal to predict the NBs constancy in an aqueous solution by examining the electrical perspective or interactions between bubbles and other droplets or elements[30]. Every bubble or particle in a suspension structure has a constant ZP at a high absolute value[29]. When compared to NBs with absolute ZP values below 30 mV, it was discovered that the former was significantly more stable. As shown in Fig. 1, more hydroxyl groups (−OH) made the NBs surface more negative. According to studies, positive ion surfactants can produce cationic charged bubbles, while counter ionic surfactants promote the production of negative (−) charged bubbles[31,32].

Free radical's generation by bubbles collapsing

-

The potential for NBs to produce reactive oxygen species (ROS) gives them a potentially effective cleaning ability[33]. The equation of Young-Laplace has described that NBs have an internal pressure that is significantly higher than the air pressure; when they explode, more surface energy is released, which enables the conversion of O2 molecules into ROS. It also has been reported that oxygen NBs can constantly generate ROS for up to or more than 24 h[34]. A study proved that microbubbles have the potential to produce hydroxyl radicals during ozonation[35]. These radicals react highly with organic matter waste and water chemicals that can be used in numerous sanitizing applications[36]. The mechanism of formation of reactive oxygen species (ROS) is based upon the collapse of NBs because the collapse of NBs releases an enormous amount of surface energy which drives the electrons to the excited state, facilitating the formation of ROS by splitting water molecules[37].

-

Several essential techniques have been employed to generate NBs like electrolysis techniques, membrane, and cavitation methods (Fig. 2). NBs generation techniques require unique and essential features for integrating NBs generators at an industrialized level like greater efficacy, permanency, and simplicity[38]. Many different types of NBs generators are available at the experimental scale in the marketplace. The goal of producing gaseous NBs using low-cost, straightforward, practical, stable, and scalable processes is essential for industrialization and for discovering uses for NBs in the broader market. Many methods are used to create NBs in the circumstances of surface and bulk NBs[39]. Different techniques for NBs generation include cavitation, membrane, and electrolysis methods.

Hydrodynamic cavitation

-

One of the most well-known methods used to create microscopic gas-filled bubbles is cavitation. Commonly, cavities develop when a standardized liquid phase goes through a phase transition due to a sudden drop in pressure below a specific critical threshold[24]. Hydrodynamics cavitation relates to two diverse approaches to reducing pressure in a fluid flow and an acoustic environment. Bubbles can be generated when vaporization occurs due to pressure drop by moving fluid. Generated bubbles collapse when there is an increase in pressure, and this condition leads to a phenomenon called hydrodynamic cavities[40]. Different system geometrics help achieve hydrodynamic cavitation, including throttling valves and venturi tubes[30]. The Venturi system has some important components, including tubes and inflow and outflow tubules[41]. High-intensity batch agitation can create NBs with a diameter of fewer than 500 nm. Another research reported that bubbles with a diameter of not more than 1,000 nm could be produced by employing hydrodynamic cavitation[42]. One of the least expensive and energy-efficient ways to manufacture NBs is by hydrodynamic cavitation, which has benefits like simple equipment and low maintenance costs[43]. Because it is simple to scale up, run, and control, the venturi-type generator has been frequently used.

Acoustic cavitation

-

A study reported that the propagation of ultrasonic waves through a liquid medium by pressure variations could create acoustic cavitation[40]. It has been reported that ultrasonic waves can produce bubbles if we lower the pressure to lower than normal vapor pressure[21]. By ultrasonically processing CO2 gas, NBs with an average size of 300–500 nm were created in an aqueous solution. Using ultrasonic at a 50% amplitude, CO2 gas bubbles of nano- to micron-scale were also produced in the lactose solution[44]. According to a study, carbon dioxide NBs can use low-intensity ultrasonic waves in a gel medium[45]. The heterogeneous systems in both systems likely prevented the measurement of the gas bubble size because they also contained additional particle elements.

Electrolysis method

-

A study reported that electrolysis could generate NBs with a diameter of about 100 nm and were stable for 1 d[28]. When water is electrolyzed, the electric potential causes water to break down into hydrogen and oxygen gases. Gas is created at the electrodes. NBs can be formed if the concentration of the produced gas in the anode and cathode mediums of the bulk water approaches the super-saturation level. Another study reported that oxygen NBs have more stability for up to 72 h with a bubble diameter of about 250 nm[46].

Membrane method

-

Using a membrane as the medium for liquid and gas dispersion, where the gas phase is forced through the pores of the applied membrane into a flowing aqueous phase, is another common technique for producing NBs[47]. A study revealed that NBs could be generated by injecting gases that have been pressurized through the membranes of nano-pore porcelain; this study shows the decreased size of NBs to 340 nm with elevated pressure up to 400 kPa[38].

-

NBs generation is a complex process. Several factors influence the generation of NBs with the complexity of diameter[48].

Temperature and pressure

-

Temperature and pressure have a great influence on the generation of NBs. Pressure greatly impacts the diameter of the generated NBs[49,50]. Many studies have supported that an increase in the pressure during the process leads to a rise in the density of gas which results in the formation of NBs of smaller size[51]. Temperature also has a prime influence on NBs creation affecting different properties of fluid that have been used for the generation of NBs. These properties include surface tension, vapor pressure, and the ability of fluid to dissolve gases. Temperature increases produce low gas solubility[52]. The cavitation rate also decreases with an increase in temperature.

Gas type and concentration

-

The type of gas employed to produce NBs is also thought to be a crucial factor in controlling how NBs form and behave. The amount of diffused gas in the aqueous system and the bubble nucleation rate are related. As a result, more bubbles can be produced by using more soluble gases in liquids, which also have better bubble nucleation rates due to reduced surface tension value. An increase in the solubility of gas results in the diminution of shape stability and interfacial tension[53]. The high dissolved oxygen concentration could keep the gas gradient between the bubble boundary and the liquid medium at a low concentration. Because of this, the permanency and high denseness of NBs in liquid may be supported[41].

Surfactants or electrolytes

-

A study reported that a protective barrier of hydration character might be provided by surfactant molecules adhering to the air and water interface of NBs, making the NBs extra stable[24]. Conferring to research, adding ionic liquid to distilled water, followed by sonication, results in the size reduction of NBs. The change in ZP values is caused by adding ionized surfactant to a liquid structure comprising NBs or by the captivation of ionic elements in the bubble membrane[23]. Electric ions may be taken up on the NBs boundary in the electrolyte solution, creating electrostatic revulsion that can prevent the amalgamation of bubbles. Additionally, the existence of electric ions can decrease the electronic dual layer's thickness, which allows interfacial tension's power to reduce bubble dimension[54]. It was reported that adding minute quantities of sodium chloride results in the stabilization of NBs because of ion shielding[55]. The effect of different individual electrolytes (NaCl and CaCl2) and surfactants on gas bubbles was investigated. The results showed that the NBs exhibited (p ≤ 0.05) lower size range (150–350 nm) significantly in surfactant solutions.

-

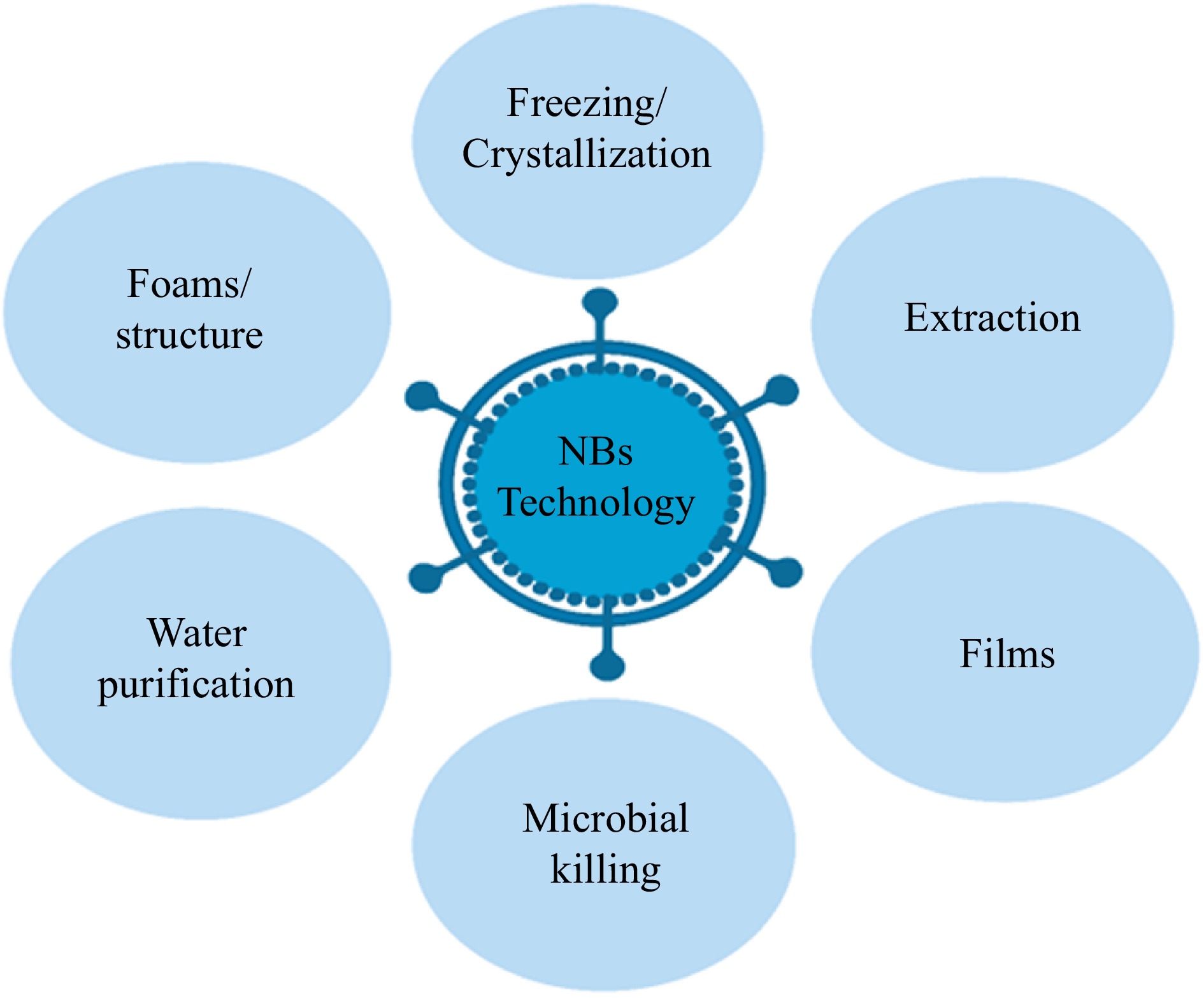

Extraction is the most common approach used in the food industry for various purposes. Figure 3, displayed the application of nanobubble technology in food and beverages. Whereas, Fig. 4 showed the nanobubbles mechainsm of action. Nanobubble-assisted extraction is a new and innovative approach supporting the extraction technology along ultrasound. Compared to conventional extraction methods, using NBs has many benefits, including the NBs gentle agitation does not harm the matrix or the target compounds[56]. The use of NBs can speed up the extraction process; this is one of the prime benefits for commercial applications. NBs are also compatible with various matrices and solvents, making the technique flexible and adaptable to various extraction scenarios[57]. The interest in producing bulk nanobubbles is rising since they can increase surface area, promote mass transfer and modify the physicochemical characteristics of the medium[12]. Researchers are moving to green extraction technologies with lesser organic solvents and low temperatures for phenolic compounds extraction[16]. A recent study investigated the extraction of phytochemicals from the shells of Camellia oleifera by employing carbon dioxide NBs during this research NBs solution was prepared from biosurfactant rhamnolipid[16]. The results of this study indicated that extracted compound exhibited better antioxidant potential with the NBs solution than with the conventional solution[12]. They explored the extraction of polyphenols from Carya cathayensis Sarg using nitrogen gas NBs in an ionic liquid. This study showed that extracting polyphenols by applying ionic liquid NBs coupled with ultrasound proved effective and exhibited extraordinary antioxidant potential. The collapse of NBs produced nano jets and caused permanent nanopores in a membrane, thus contributing to cell damage. Another study deals with polyphenol's extraction from the shells of Camellia oleifera by using carbon dioxide NBs. This study uses NBs generated by different compression and decompression techniques with dimensions ranging from 40-90 nm. This study claims that if CO2 NBs stabilized using a surfactant, then followed by ultra-sonication improved the phenolic compounds extraction[58]. A promising method that has the potential to completely change the extraction industry is NBs-assisted extraction. More research is necessary to fully comprehend the mechanism of action and improve the procedure for various applications.

Nano bubble assisted freezing/crystallization

-

Freezing is a food preservation method with many applications in food industries. A recent advancement in this field is NBs-assisted freezing[59]. The combined effect of NBs and ultrasound on the freezing manner of different foods was investigated[60]. Pre-introducing stable NBs and executing variable ultrasound frequency significantly increased the effectiveness of freezing dense foods, demonstrating significant potential for the food business[60]. Another research was conducted to investigate the influence of micro and nanobubbles on the crystal proliferation of different solutions, including sucrose, during freezing assisted by ultrasound technique. Results showed that adding micro and nanobubbles (MNBs) increased the freezing rate when combined with ultrasound-assisted freezing, proving that this approach was workable[61]. Research demonstrates that using gas infusion on liquid food could be a straightforward yet efficient way to regulate the freezing process of foods[62]. NBs-assisted crystallization is also a novel technique in the food sector. These sophisticated methods can reduce accumulation on the surface of frozen food and produce smaller ice crystals[63,64] described that the freezing rate could be effectively increased via cavitation. Existing bubbles may provide a nucleation effect comparable to that which ultrasound produces[65]. A study reported that adding gas NBs can positively change lactose crystallization manners[66]. The carbon dioxide gas can significantly improve milk's dimension, firmness, and number of fat crystals. A study found that butter from carbonated dairy cream exhibits improved physical attributes[67]. In addition, the micro-nano bubbles were applied on the ultrasound-assisted freezing process of maltodextrin solution. The results revealed that the nucleation and crystal growth periods increased with the introduction of NBs.

Nano bubble assisted foams/structure

-

NBs can be more useful in the food liquid foam industry due to their high specific area and high stagnation in the liquid phase. Nanoscale bubbles were produced in the 100–200 nm range along the spray drying technique inside the coffee. This technology preserved the coffee foam and maintained the foam structure[18]. The generation of quasi 2-dimensional micro and nano-foams is entrusted on an inundated solid surface. More than 80% inundated solid surface can be occupied by quasi 2-dimensional foam. Another research reported that hydrophobin protein can be purified using NBs technology without chromatographic methods. A similar technique may be used to purify different proteins[68]. The interplay of food proteins and nanobubbles at the air-water interface that shaped the ultimate structures of proteins is well-known (i.e., NBs). It was revealed that air NBs acted as soft templates to trigger 7S globulins self-assembly into core-shell nanospheres adjacent to the protein isoelectric point (~pH 5). Air NBs induced reversible self-assembly of 7S globulins isolated from pea (Pisum Sativum L.)[69]. Amalgamation of gas into food material can offer a lot of privileges like improving the texture and mouthfeel of the food and improving its sensorial attributes, examples included various carbonated beverages, cotton candies and whipping creams. It is possible to alter the sensory qualities of different foods, like flavour, colour, and taste with the help of nanobubble aided technology[70]. NBs have sophisticated surface area and lower pH values so when the tiny bubbles existing in food come into interaction with the tongue they provide a silky sensation[71].

Films/gels

-

NBsa green and energy-saving technology, appeared to be a latent method for the dispersion of hydrophobic particles. Air NBs water treatment, was employed to improve the functional performances of packaging films. NBs have the potential to significantly alter the film's mechanical strength, water vapour permeability, and surface tension. The study aimed to inhibit the accumulation of Zein and thymol nano particles in the gelatine films. Incorporation of antibacterial zein/thymol nanoparticles dispersed using NBs technology improves the functional performance of gelatin films[72]. Food films can produce NBs utilising a variety of techniques, including ultrasound, electrolysis, and high-pressure homogenization. By increasing the amount of film interfaces when these bubbles are introduced, they can improve the mechanical strength of the film. In addition, the high surface area-to-volume ratio of the bubbles can aid in lowering the film's water vapour permeability, improving its effectiveness as a moisture barrier. Another important attribute of NBs is their ability to alter the surface tension of the film[73]. Nanobubbles can modify the wettability of the film and its capacity to cling to various surfaces by changing the surface tension. This feature can be especially helpful in creating food packaging materials, where the film must stick to the food's surface to avoid moisture loss or contamination[74]. NBs employment in the formation of films has many benefits because of enhanced mechanical attributes of films including enhanced shelf life and improved quality. To completely comprehend the impact of nanobubbles on food films and to maximise their incorporation into food packaging materials, further research is required.

Antimicrobial

-

The extraordinary properties of NBs, which have a high gas transfer capacity and the potential to generate ROS, may be partially responsible for their antibacterial power to reduce the danger from organic contaminants and foodborne pathogens. The high abundance of hydroxyl radicals can destroy the microbial cell. Incorporation of antibacterial zein/thymol nanoparticles dispersed using nanobubble technology improves the functional performance of gelatine films[72]. The antibacterial activity of the gelatine nano composite films against Escherichia coli and Staphylococcus aureus within 24 h were analysed. Another study reported that organic material could be removed from silicon crackers with ozone bubbles 1.3 times more quickly than with the same amount of ozone in bubble-free water[36]. Another study reported that ultrafine ozone bubbles stayed steady in the water for 3 h, supplying the gas continually[27]. Due to ozone gas's powerful sanitizing capabilities, it has long been known that applying it is a promising strategy for oxidizing and disinfecting a variety of harmful bacteria or contaminants in either water or wastewater[75]. Ozone can also be used to sterilize spore-forming bacteria, like Bacillus subtilis, resistant to chemicals[76]. It was reported that during aeration, when applying bubbles, NBs can last for weeks and even up to months, while MNBs only last for several minutes; consequently, the presence of NBs can improve the dissolved ozone gas[33]. Table 1, showed the application of nanobubbles in food products.

Table 1. Nanobubble applications in food products.

Sample NBs method

(alone or coupled)Process mechanism Process parameters Process efficiency References Camellia oleifera shells Coupled with ultra-sonication Nano jet formation Rhamnolipid concentration (5 CMC), time (16 min) Efficient green method for extraction [16] Carya cathayensis Sarg (Walnut shells) Coupled with ionic

liquid solutionIonic liquid Nano jets formation Ionic liquid concentration (1 M), time (9 min), temperature (30 °C) Showed better extraction of phenolic compounds than ethanolic [12] Mustard Alone Air and O2 NBs generated through nano bubble aerator Cavitation time (30 min), pump speed (3,600 rpm) Weight increased by 35% [13] Tomato Coupled with micro

bubble technologyAir NBs injection method Air NBs concentration

(15 and 25 mg/L)Improved tomato yield and enhanced vitamin C and lycopene content [77] Cucumber Coupled with micro

bubble technologyAir NBs injection Air NBs concentration

(15 and 25 mg/L)Improved cucumber yield [77] Maize Coupled with micro

bubble oxygenation

technologyGas liquid mixing O2 NBs concentration

(10, 20, and 30 mg/L)Yield increased up to 11.7% [78] Sugarcane Coupled with micro

bubble water technologyPasteurization MNBs water (1:0 and 1:4) Increased soil fertility and yield increased up to 17.6% [79] Barley Coupled with low-concentration H2O2 NBs Water stimulated the expression of genes involved in cell division and cell wall thinning NBs generation time

(60 min)Germination rate increased up to 25% [80] Camellia oleifera shells Coupled with ultra-sonication Green extraction methods crucial for efficient and safe extraction Tween 80 and rhamnolipid NBs concentration (5 CMC), time 16 min) Increased total phenolic and flavonoid content [58] Carrots and fava beans Alone Compression and decompression method NBs generator pressure (414 KPa), time (90 min), flow (0.4 L/m) Increased seed germination rate [9] Chinese cabbage Couple with micro

bubble technologyOstwald ripening Electrolyzed solution

(50 mg/L) and NBs

solution (50 ppm), pH 4.0Enhanced microbial cleaning [81] Instant coffee Coupled with spray

freeze dryingStable NBs foams Pressure (588.39 KPa),

flow rate (6 mL/min)Outstanding foam stability and unbroken foam surface [18] Apple Juice concentrate Alone CO2 NBs influence

on juice on viscosityNBs pressure (300 Kpa), time (5, 13, 26 min), temperature (23 °C) Significant reduction in viscosity [82] Ice cream Coupled with micro

bubble technologyEffect of CO2 NBs on physicochemical properties NBs concentration (2,000 ppm), temperature

(5 °C), time (1 min)Enhanced the sensory and physicochemical prope [83] Milk Coupled with spray

dryingNano bubbles helped

to produce milk via

non-aggregationAir NBs flow rate

(0.3 L/min)Enhanced process efficiency and reduced viscosity [84] Apple Coupled with micro

bubble technologyOzone MNBs for removing pesticide residue MNBs pressure (0.5 MPa) Improved residual removal efficiency [85] Eggs (without

shells and boiled)Coupled with micro

bubble technologyFood seasoning N/A Improved liquid seasoning permeation [86] Protein (hydrophobin) Alone Supporting in protein purification Purity improved by 2.8 times [68] -

A study reported that smaller bubbles are preferred in beverages since they are thought to improve the beverage's mouthfeel and texture. According to the findings, 87% of tasters could identify the more carbonated sample, and 73% said that the sample with little bubbles was carbonated more than the other[87]. It has been reported that adding bubbles helps enhance the textural properties of gel-like foods. The addition of carbon dioxide-based bubbles can also cause an alteration of textural attributes. Using a gas-filled gelatin gel, researchers found that the air, nitrogen, and helium bubbles grew larger as the protein concentration rose[88]. NBs provide foam like texture to the liquid-based food products. NBs can produce a creamy, smooth feel in liquid meals like beverages, soups, and sauces that is very appealing to customers. NBs enormous surface area, which aids in stabilizing foams and emulsions, is the cause of this phenomenon[89]. NBs can be utilized in solid foods to enhance texture by boosting their volume, softness, and moisture retention. This is so that the food matrix's tiny holes made by the NBs may capture moisture and give the texture a softer, moister feel. This effect can be seen in products such as bread, cakes, and biscuits, where the addition of NBs can result in a softer, more tender crumb. In food products like mousse, ice cream, and whipped cream, aerated structures can be produced using NBs. This is due to the NBs ability to be disseminated throughout the product and produce a light, airy texture due to their small size. When a light, smooth texture is sought for a product, this effect is highly desirable[90].

Viscosity

-

NBs technology was also applied in high viscosity beverages/liquids. Addition of NBs to liquid foods increases its viscosity. Although its mechanism is not known well, it is thought that it may be due to the nature and way NBs interact with liquid-based food products. One possible theory is that the NBs are tiny particles with reduces the friction between the particle of liquid food products and so, as a result, increases their viscosity. Due to this property NBs have many potential benefits including improving texture, mouth feel of the food products[91]. The study was performed on lactose solution and it was reported that micro and nano bubbles addition provides more nucleating sites, which aids in forming lactose crystals[66]. Another research was performed on apple juice concentrate to reduce the viscosity of juice. It was noticed that NBs treatment on apple juice concentrate significantly reduce the viscosity of samples[82]. The reducing effect of NB treatment on viscosities has also been shown to diminish with time as NBs size increased and dissolved gas content decreased. The application of NBs can be a practical method to decrease viscosity and improve the processing efficacy of food fluids[82].

Seasoning

-

NBs have many applications in the food industry because of their unique chemical and physical attributes, one of them being the impact of NBs on seasonings. The MNBs in the liquid seasoning make it easier to get the perfect colour and flavour of the cooked eggs in about 5 h. The standard permeation method of soaking boiling soybeans in a seasoning solution took 12 d or longer to complete. However, fully saturated soybeans' soaking time was drastically reduced by almost 2 d when MNBs were exposed to the liquid seasoning[92]. The improved penetration of the seasoning particles into the food matrix may be one effect of NBs on spices in foods. The distribution and potency of the seasonings may be improved because of the NBs ability to ingest more of the food and transport spice particles with them[71]. To properly comprehend the effect of NBs on food flavouring, more study is necessary. The pros and downsides of using NBs in food processing should be carefully considered, and any new technologies should be reliable, efficient, and long-lasting.

-

This review presented the fundamental traits, generation processes, evaluation methods, and potential implementations of NBs in different research areas, especially its application in the food sector. It is clear that NBs have unique qualities, like extraordinary stability, enormous size-to-volume proportions, tremendous gas dissolution degree, and creation of free radicals can offer several ways to change the aqueous medium's physical properties and environmental conditions. To fully understand the factors having significant effects, further investigating the use of NBs in food applications is crucial. Although there are many promising uses for NBs technology in the food industry, there are still only a few active projects. Undoubtedly, there are many new advancements and inventions in NB generation methods. However, there are still many difficulties in enhancing the permanence and durability problems of these NBs for applications in the food sector. It is equitable in the future to consider the massive applications of NBs generation technology in the food sector just because of their quality attributes and ease of generation of NBs. The use of NBs to improve the effectiveness of gas-liquid phase processes holds promise for various applications. NBs generation technologies have many food applications as they can create fine and undeviating gas diffusion characteristics; because of these characteristics, they can regulate the uniformity and textural properties of different creamy and gel-based foods. NBs technologies can also be regarded as new, improved, and environmentally safe technologies because they potentially remove organic compounds and infectious and fouling agents. The most common or quite important limitation in most food processing processes is the viscosity of the food product. NBs technologies offer a simple and affordable way to regulate viscosity-related problems, especially liquid-based foods. Researchers have infrequently discussed the effects of NBs on grade, separation efficiency, and selectivity of separation, even though a reasonable level of recovery enhancement has been commonly reported in the literature. In this regard, further research is advised. Additionally, due to their high mass transfer capacity and surface absorption, NBs manipulation may be useful for extracting numerous substances beyond employing certain emulsifiers and different solvents. Future objectives include the synergy of chemical, physical, and hydrodynamic properties for NBs creation in an energy-efficient, technically sound, and user-friendly way, with controllable sizes of created bubbles. In these ways, using NBs in food technology is significant and has a bright future. Still, additional research is required to fully comprehend NBs fundamental properties and how they interact with convoluted food systems, to produce NBs reliably, to expand their use in food technology, and to use the technique for large-scale operations.

This work was financially supported by the National Key Research and Development Program of China, China (2022YFD2100100), National Natural Science Foundation of China, China (32272776; 32001748), Natural Science Foundation of Ningbo, China (202003N4311), Zhejiang Public Welfare Technology Application Research Project, China (LGN21C200018), Key Research and Development Program of Zhejiang Province (2022C02033, 2021C02014), China and 72nd Postdoctoral Foundation (2022M713423). Young Elite Scientists Sponsorship Program by CAST (2022QNRC001)

-

The authors declare that they have no conflict of interest.

- Copyright: © 2023 by the author(s). Published by Maximum Academic Press on behalf of China Agricultural University, Zhejiang University and Shenyang Agricultural University. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Javed M, Matloob A, Ettoumi F, Sheikh AR, Zhang R, et al. 2023. Novel nanobubble technology in food science: Application and mechanism. Food Innovation and Advances 2(2):135−144 doi: 10.48130/FIA-2023-0014

Novel nanobubble technology in food science: Application and mechanism

- Received: 20 April 2023

- Accepted: 10 May 2023

- Published online: 20 June 2023

Abstract: Nanobubble technology is one of the latest green technologies in food industry applications. Nanobubbles (NBs) are gas-filled nanoscopic bubbles with a diameter of < 500 nm. The mass production of bulk nano-bubbles raises growing interest due to their high stability, internal pressure, and an enormous surface-to-volume ratio. Also, they can increase surface area, alter the physicochemical characteristics of the medium, and facilitate mass transfer. Along with their size and stability, air, nitrogen, and carbon dioxide, NBs are widely recognized for their significance in food processing. The potential existence and ability of NBs to remain stable in liquids under ambient conditions have been a contentious issue for a long time due to the conventional thermodynamic theory. In this review, fundamental properties, and several generation methods of NBs have been described along with their mechanism. Moreover, NBs generation methods can produce fine and undeviating gas diffusion characteristics, which can be used to control the uniformity and textural qualities of various creamy and gel-based foods. Thus, we also described the possible applications of NBs along with their mechanism of action in extraction, freezing, foams, and film formation. The ability of NBs to impart health benefits makes them new, improved, and environmentally safe green techniques.

-

Key words:

- Nanobubbles /

- Generation methods /

- Fundamental properties /

- Food application /

- Mechanism of action