-

With the rapid development of the world economy, air pollution and fossil fuel consumption is gradually becoming more serious, finding new clean energy sources is becoming ever more urgent. Hydrogen has recently drawn intensive attention due to its recyclable and non-polluting characteristics[1−4]. It is widely utilized in many fields, such as glass production, metal welding and the food industry[5, 6]. However, because of the high diffusivity, wide range of explosion limits (4.0%−75.6%), low ignition energy and hydrogen embrittlement properties[7]. From 2000 to 2020, there were more than 90 incidents in the hydrogen energy industry chain at home and abroad, such as the explosion of hydrogen storage tanks in South Korea in 2019 and hydrogen explosion in a Taiwan power plant in 2022. These accidents are mainly due to the following reasons: (1) Design defects; (2) seal failures; (3) equipment failure; (4) operation errors or improper maintenance; (5) traffic accidents. So it is necessary to solve the safety issues that the use of hydrogen brings to the industrial and domestic fields.

China attached great importance to hydrogen energy and issued relevant regulations. In 2006, the State Council of China promoted the following: Outline of the national medium and long term science and technology development program (2006−2020). In 2014, China further issued Strategic Action for Energy Development (2014−2020), which proposed to take hydrogen as a new energy technology and innovation strategy. In June 2020, China drafted the Technical code for hydrogen fueling stations (Draft for comments on partial amendments)、Technical standard of fueling station, which further confirmed its energy status. However, safety is still a major constraint on hydrogen market promotion.

The real-time detection of hydrogen is significant in industry. The electrochemical sensors that are widely used at present may generate electric sparks during usage[8]. Optical fiber hydrogen sensors can overcome the shortcomings of traditional sensors, and has the characteristics of anti-electromagnetic interference, light weight and small volume[9]. Therefore, it has been widely considered by domestic and foreign scholars.

The development of hydrogen safety is reviewed in this paper. The properties of hydrogen, the use and promotion of hydrogen and related monitoring standards are mainly elucidated.

-

At present, high-pressure gas tanks are still the most widespread method of hydrogen storage[10, 11]. The release of pressurized hydrogen into the air may lead to spontaneous combustion. This process is extraordinarily complex, involving turbulence, boundary mixing, shock wave action and microscopic dynamics. At present, the diffusion ignition theory has been investigated and recognized by many scholars[12, 13]. In diffusion ignition theory, the produced incident shock wave ahead of the released high-pressure hydrogen is responsible for the spontaneous ignition. Part of the hydrogen is mixed with air by diffusion and convection to form a combustible gas mixture. The shock wave heats the mixture, which will lead to the temperature of the mixture rising and eventually resulting in spontaneous combustion.

Diffusion characteristics

-

Table 1 shows the leakage rates of hydrogen and propane relative to natural gas[14, 15]. The leakage rate of hydrogen is much higher than the other two gases in the diffusion and turbulent states, while the difference is not prominent in the laminar condition. Hydrogen may leak in three states: subsonic jet, critical jet and supersonic jet. In a confined space, the leaked hydrogen will accumulate at the top vessel, resulting in a significant hazardous increase.

Table 1. Leakage rates of hydrogen and propane relative to natural gas.

Gas state Natural gas Hydrogen Propane Diffusion state 1.0 3.8 0.63 Laminar condition 1.0 1.26 1.38 Turbulent condition 1.0 2.83 0.6 Hydrogen embrittlement characteristics

-

Hydrogen molecules can diffuse into steel and other metals, which reduces the strength of materials. Moreover, it is convenient to enter the pipe gap to form local stress concentration and air leakage[16, 17]. Therefore, hydrogen embrittlement (HE) often occurs in hydrogen transmission pipelines and hydrogen storage tanks. On the basis of full research, domestic and foreign scholars proposed the following measures to prevent HE:

(1) Controlling the mass fraction of S and P in the cylinder material

(2) Enhancing the tensile strength and hardness of the cylinder

(3) Reducing the stress concentration of the cylinder

(4) Inspecting the cylinder parameters at definite time points.

-

In recent years, hydrogen fuel cell vehicles have accessed development opportunities due to its no-pollution, high energy density, shorter hydrogenation time and good endurance characteristics. With the continuous expansion of the hydrogen fuel cell vehicle market, the safety problem of hydrogen fuel cell vehicles and hydrogen refueling stations cannot be ignored.

Safety of hydrogen fuel cell vehicles

-

In the case of safe application of hydrogen storage and transportation, fuel cell technology is a promising way to utilize hydrogen energy. It can efficiently convert chemical energy into electrical with only water as a by-product. Therefore, it may have wide applications in the future[18, 19]. However, security became the main factor restricting its development. In fuel cell vehicles, hydrogen storage systems, supply systems and stack systems are the main hydrogen present areas[20, 21]. The safe design of these areas is essential for their use.

Vehicle-mounted high-pressure hydrogen cylinders and transmission pipes are more prone to corrosion due to HE characteristics. Therefore, the selection of appropriate materials is particularly important for fuel cell vehicles. At present, fully wrapped aluminum lined carbon fiber cylinders are widely used because of their high hydrogen storage density and light weight. The low-strength seamless steel pipe is also an ideal material for the hydrogen transmission pipeline. These strongly support the popularity of fuel cell vehicles.

A safety monitoring device can ensure the timely detection and treatment of vehicle fuel system faults[22−24]. For example, the pressure monitoring and protection device can automatically depressurize and cut off the hydrogen source when the pressure is too high. The principle of the temperature and flow protection device is similar to the pressure protection device. Collision sensors are necessary for the vehicle. In case of an accidental collision, it can control the vehicle to interrupt the hydrogen supply to avoid hydrogen leakage. Hydrogen detectors are set in places where hydrogen is prone to leak, such as pipeline interfaces and valves. It can immediately give an alarm and ensure the vehicle takes emergency measures.

The vibration and impact generated by the vehicle during operation will inevitably be transmitted to the fuel cell stack, so it must work normally under these conditions[25, 26]. The fuel cells stack also needs to work normally in a high temperature environment. In addition to setting the hydrogen detector, hydrogen leakage can also be predicted in advance by monitoring the voltage change caused by the membrane rupture. Therefore, the safety design of the fuel cell stack should ensure it can resist vibration, high-pressure, high-temperature and has the function of ventilation and monitoring working voltage.

Safety of hydrogen refueling station

-

Flammable and explosive gases gather around the hydrogen refueling station (HRS). In HRS, hydrogen is usually stored and filled under high pressure, which has a high risk[27]. This section introduces the safety countermeasures of HRS from layout, equipment safety and management.

In HRS, the hydrogen production process may have an impact on the surrounding environment, and a reasonable layout is a prerequisite for its construction and development. To solve the power demand of fuel cell vehicles and promote the development of fuel cell vehicles, more HRS will be built on main roads. At the same time, it is very important to build HRS around urban areas and form a perfect hydrogen fuel supply network centered on large cities[28−31].

During the operation of HRS, hydrogen leakage caused by various hydrogen-related equipment failures and the electrical equipment irregular operation have become the major potential risks[32]. The security recommendations for equipment are as follows: (1) Strictly control the selection of equipment and material to meet the relevant standards; (2) Install hydrogen concentration and flame detectors where hydrogen easily accumulates; (3) Safety valves should be set on hydrogen storage equipment to cut off the hydrogen source in time in case of an accident; (4) Explosion proof equipment should be selected in the operation station to deal with accidents and eliminate fire sources.

The recommendations on security management are as follows: (1) Suggest a perfect organizational structure. Each department should deploy adequate management and technical personnel. Technicians have to obtain professional and technical qualifications before taking work, and strictly implement the relevant requirements and operating rules; (2) Establish a perfect institutional system. Specialists are responsible for the establishment of equipment operation rules, inspection and maintenance procedures, emergency treatment plans and inspection standards. Leaders at all levels are responsible for daily inspection, risk identification, hidden trouble investigation and management[33−35].

-

Hydrogen energy standardization research is important for the development and promotion of the hydrogen energy industry. In the international society, Technical Committee for Standardization of Hydrogen Energy Technology (ISO/TC197) is committed to the formulation of hydrogen energy-related standards. In 2008, China established the committee for Hydrogen Energy (SAC/TC309) and Fuel Cell and Flow Battery (SAC/TC342) to undertake the standardization work of hydrogen energy.

Globally, hydrogen energy standards mainly focus on hydrogen energy applications and lack of hydrogen safety standards[35]. The first hydrogen safety standard, ISO/TR15916, was issued by ISO in 2004. GB/T29729-2013 is the first safety standard for hydrogen systems in China, which is applicable to the preparation, storage and transportation of hydrogen. Compared with the ISO/TR15916, GB/T29729-2013 has a wider range of use. Table 2 lists relevant hydrogen safety standards in China and abroad. It can be seen that compared with similar foreign hydrogen safety standards, the number and coverage of domestic standards are higher.

Table 2. Overview of hydrogen safety standards at home and abroad.

Order Organization Standard number Standard names 1 Standardization Administration of the People's Republic of China (SAC) GB/T 23751.1-2009 Micro fuel cell power systems—Part 1: Safety 2 GB/T 24549-2009 Fuel cell electric vehicles-Safety requirements 3 GB/T 27748.1-2017 Stationary fuel cell power systems—Part 1:safety 4 GB/T 29729-2013 Essential requirements for the safety of hydrogen systems 5 GB/T 30084-2013 Portable fuel cell power system-Safety 6 GB/T 31036-2014 Proton exchange membrane fuel cell backup power system-Safety 7 GB/T 31037.1-2014 Fuel cell power system used for industrial lift truck applications—Part 1: Safety 8 GB/T 31139-2014 Safety technical regulations for mobile hydrogen refueling facility 9 GB/T 34539-2017 Safety requirements on hydrogen-oxygen generator 10 GB/T 34544-2017 Safety test methods for onboard low pressure hydrogen storage devices for small fuel cell vehicles 11 GB/T 34583-2017 Safety technical requirements for hydrogen storage devices used in hydrogen fuelling station 12 GB/T 34584-2017 Safety technical regulations for hydrogen refueling station 13 GB/T 36288-2018 Fuel cell electric vehicles-Safety requirement of fuel cell stack 14 International Organization for Standardization (ISO) ISO/TR 15916:2015 Basic considerations for the safety of hydrogen systems 15 ISO 16110-1:2007 Hydrogen generators using fuel processing technologies Part1: Safety 16 ISO/TS 19883:2017 Safety of pressure swing adsorption systems for hydrogen separation and purification 17 ISO 21266-1:2018 Road vehicles — Compressed gaseous hydrogen (CGH2) and hydrogen/natural gas blends fuel systems—Part 1: Safety requirements 18 ISO 23273:2013 Fuel cell road vehicles — Safety specifications — Protection against hydrogen hazards for vehicles fuelled with compressed hydrogen 19 American National Standards Institute (ANSI) ANSI/AIAAG-095A-2017 Hydrogen and Hydrogen Systems Worldwide, vehicle-mounted hydrogen cylinder standards mainly include European Union standards, American standards and Japanese standards. In China, researchers in Zhejiang University took the lead in establishing a hydrogen safety research laboratory. They had conducted systematic studies on hydrogen leakage explosion, fire resistance of vehicle-mounted hydrogen cylinders, and hydrogen risk assessment. In 2017, China issued the recommended national standard GB/T 35544-2017. It had solved the problem that there was no national standard for vehicle-mounted hydrogen storage cylinders. The differences between ISO/CD 19881:2015[36] and ANSI HGV2-2014 is shown in Table 3.

Table 3. Main differences between domestic and foreign standard clauses.

Standard Scope of

applicationsGas cylinder test items Normative requirements

of the industrial chainOther quality assurance terms GB/T 35544-2017 Aluminum liner carbon fiber fully wound gas cylinder Winding layer mechanical property test, winding layer appearance inspection, hydraulic pressure test, air tightness test, hydraulic burst test, normal temperature pressure cycle test, fire test, extreme temperature pressure cycle test, accelerated stress rupture test, crack tolerance test, environmental test, drop test, hydrogen gas cycle test, gunshot test, durability test, performance test The packaging, transportation and storage of cylinders after the completion of the manufacture are specified, without involving the storage and transportation of relevant raw materials Only manufacturing units are required to provide mass inspection quality certificates ANSI HGV2-2014

and ISO/CD 19881:2015Four types of gas cylinders Environmental cycling test, extreme temperature cycling test, hydraulic burst test, defect tolerance test, drop test, fire test, accelerated stress fracture test, high strain rate impact test, penetration test, torque test, hydrogen cycle test, leakage test before fracture No related terms The manufacturing units needs to establish and operate a quality management system in accordance with the provisions of ISO9001. It can be seen from the comparison that three issues exist in national standards. Firstly, the current national standards are only applicable to fully-wrapped carbon fiber cylinders with an aluminum liner, but not applicable to Class I, Class II and Class IV cylinders. Secondly, national standards cannot meet the requirements of all hydrogen-related industrial chains. Thirdly, they also lack self-evaluation of production consistency and quality assurance provisions.

In summary, scholars have made great progress and achievements in hydrogen safety standardization. However, some standards directly refer to or copy foreign standards, resulting in inconsistencies with the actual situation. Therefore, domestic research is required to address the occurrence, development process and the potential mechanism of hydrogen accidents to continuously promote the scientific and localization of hydrogen energy safety standardization.

-

Hydrogen detection is significant to the safety of both industrial manufacturing and everyday life. The hydrogen sensor shall have the characteristics of large detection range, high selectivity, high sensitivity and strong anti-interference ability[37]. At present, hydrogen sensors mostly work based on electrochemical principles, and sparks may be generated during usage[38]. Therefore, optical fiber sensors have attracted wide attention due to their small size, light weight, anti-interference performance and intrinsic safety[39, 40].

Optical fiber hydrogen sensing technology was first studied by NASA in 1984[41], and they have made great progress. Domestic research on this technology is mainly concentrated in the laboratories of Harbin University of Technology, Huazhong University of Science and Technology and Wuhan University of Technology among others.

Hydrogen sensitive membrane is mainly made of palladium (Pd) metal or its alloy material, which can expand after absorbing hydrogen[42]. The expanded hydrogen sensitive film monitors the hydrogen concentration by changing the characteristics of light intensity and wavelength. The existing optical fiber hydrogen sensors are mainly divided into interferometer sensor, micro-mirror sensor, evanescent sensor, fiber grating sensor and surface plasmon resonance sensor (SPR). This section describes the principles, characteristics, and research progress of several existing optical fiber hydrogen sensors.

Interferometer hydrogen sensor

-

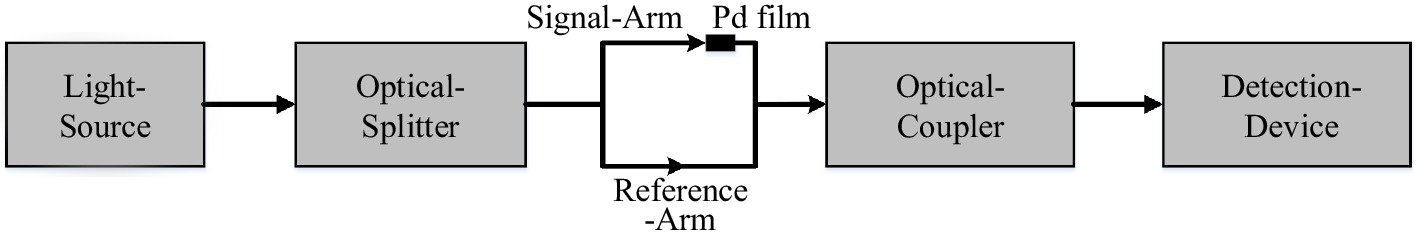

The Mach-Zehnder interferometer (MZI), Fabry-Perot interferometer (FPI), and Sagnac interferometer (SI) are used for hydrogen interferometers. Here we mainly introduce the MZI interferometer sensor as an example. The working principle of MZI is shown in Fig. 1. Pd film is coated on the surface of the optical fiber by electroplating. Pd film will expand after absorbing hydrogen, which causes deformation of the fiber. Then, with the change of signal light path, interference occurs between the signal light and reference light, resulting in the shift of wavelength in the spectrum[43].

In 1988, Butler & Ginley[44] made the first interferometer sensor by electroplating 10 nm Ti film and depositing 10 um Pd film on an optical fiber. Subsequently, the length of single-mode fiber was increased to 20 cm and the film thickness was reduced to 1 um. The response time was shortened to 30 s. In 1994, Zeakes et al.[45] built the first FPI hydrogen sensor consisting of single-mode fiber and multimode fiber with 50 um interval. However, due to the limitation of Pd, the sensing film easily became detached. In 2007, Maciak & Opilski[46] developed an interferometer hydrogen sensor including a TiO2 film and NiOx film. It had good stability and high sensitivity. Later, relevant researchers made great progress in interferometric hydrogen sensors[47−50]. The performance of hydrogen sensors are shown in Table 4.

Table 4. Performance comparison of interferometer hydrogen sensors.

Author Published Sensor head Performance Reference Butler & Ginley 1988 10 nm Ti + 10 um Pd Detecting concentration (DC) > 0.6%, response time (RT): 3 min [44] Zeakes et al. 1994 50 um Fabry-Perot cavity RT: 5 s, Sensitivity: 35 ppm/%, poor repeatability [45] Maciak & Opilski 2007 TiO2 film + NiOx film DC < 4%, RT < 1 min, Recovery time (RCT) < 1 min, excellent stability [46] Wang et al. 2012 Pd-coated open air-cavity Sensitivity: 155 pm/%, Weak anti-interference ability [47] Kim et al. 2012 Ni (adhesion layer) +

Pd(sensing layer)DC: 4%, RT: 50 s, Sensitivity: 0.7 nm to 4% H2 [48] Gu et al. 2015 Pd-Au alloy nanowire DC: 0−20%, RT: 200 s, Sensitivity: 0.175 nm/%, RCT: 400 s [43] Xu et al. 2017 Hollow core fiber + Single mode fiber (SMF) + Fiber Bragg grating DC: 0.2%, RT < 30 s, Sensitivity: 0.85 nm/%, greet repeatability [49] Liu et al. 2019 Nanopatterned Pd film DC: 1%−3%, RT: ~25 s, Sensitivity: ~1.3 nm/% [50] In general, interferometer hydrogen sensors have a simple and flexible structure. Its manufacturing process does not require a polished fiber, which reduces the manufacturing difficulty and improves the mechanical strength. Moreover, interferometer sensors have high sensitivity, good repeatability, high measurement accuracy and good ability of multi-point distributed detection. However, the demodulation of the interference spectrum requires expensive instruments, and its detection performance is easily affected by environmental factors.

Micro-mirror hydrogen sensor

-

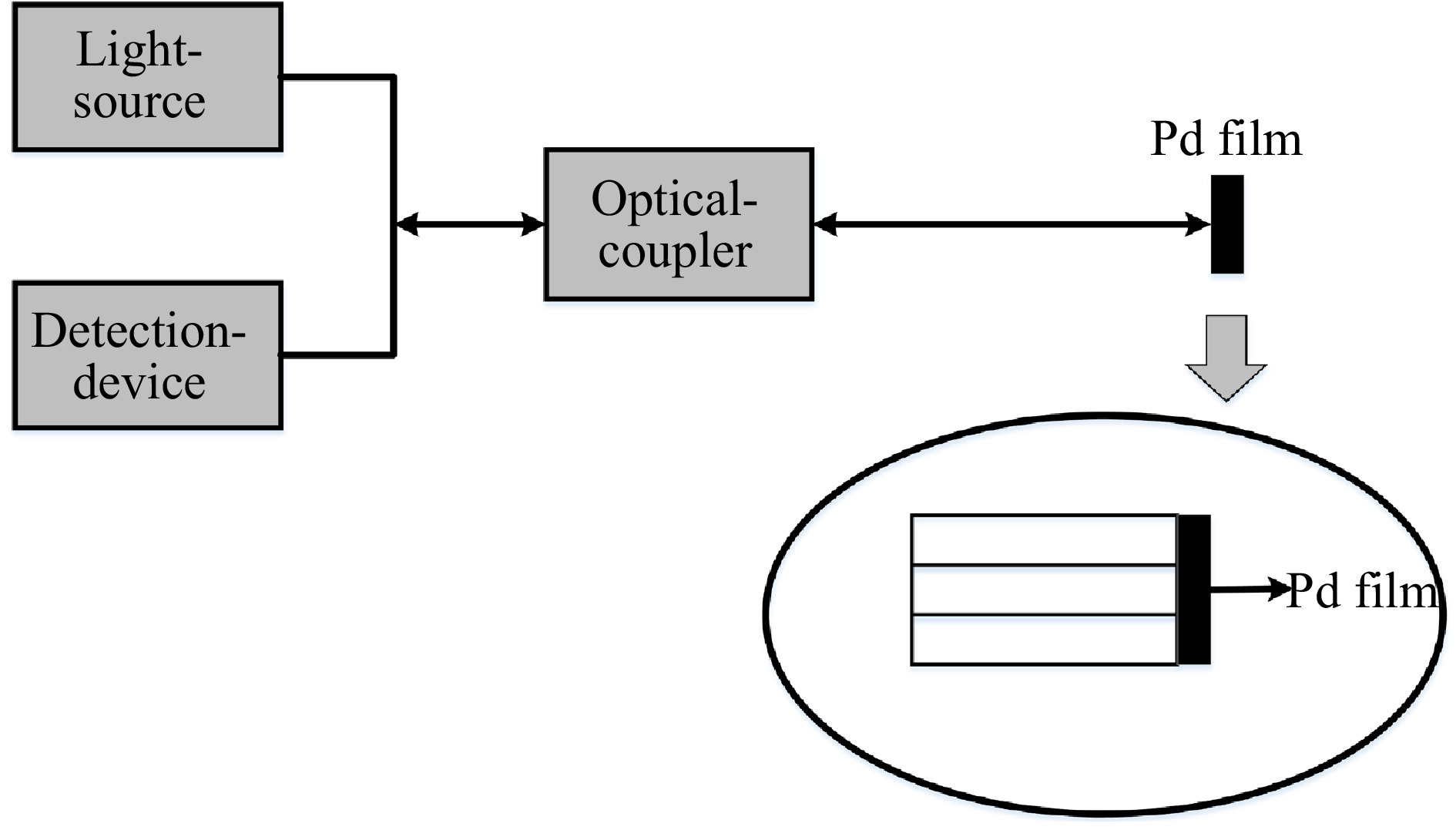

A micro-mirror sensor is mainly composed of a light source, coupler, optical fiber, sensitive film and detection device, as shown in Fig. 2. The sensitive film is deposited on the end of the fiber and the light intensity changes with film reflectivity when in a environment containing hydrogen. Therefore, there is a correlation between light intensity and hydrogen concentration.

In 1991, Butler[51] first made a micro-mirror sensor by depositing Pd film on the end of a multimode fiber. Subsequently, in 1988, Jung et al.[52] made a Pd alloy film as a sensing film to improve the performance of the sensor. Bévenot et al.[53] investigated the response performance of micro-mirror sensors in ultra-low temperature environments from −196°C to 23°C. The results show that it can work normally in harsh environments. In 2013, Westerwaal et al.[54] demonstrated a multilayer sensitive film consisting of Pd81Au19 and Ti layer, which had great selectivity and repeatability. Table 5 shows the performance of the above-mentioned micro-mirror sensors.

Table 5. Performance comparison of micro-mirror hydrogen sensors.

Author Published Sensor head Performance Reference Butler 1991 10 nm Pd film Detecting concentration (DC): 0.2%−2%, sensitivity: ~0.035/% [51] Jung et al. 1998 Pd alloy film DC: ~4%, RT: ~20 s, great repeatability [52] Bévenot et al. 2000 13 nm Pd metal layer DC: 1%−17%, RT < 5 s, poor stability [53] Westerwaal et al. 2013 Pd81Au19 + Ti DC: 0.5%−4%, RT < 15 s, good hydrogen selectivity and repeatability [54] The structure and fabrication process of micro-mirror sensors are simple and only requires the deposit of sensing film at the end of the optical fiber. However, its disadvantages are also obvious. Firstly, the multi-point distributed monitoring ability of the micro-mirror sensor is limited. Then, the hydrogen sensitive film is easily displaced, resulting in poor repeatability. Finally, restricted by the detection principle, its accuracy will be affected by the light source power fluctuation and fiber loss.

Hydrogen sensors of evanescent field and surface plasmon resonance (SPR)

-

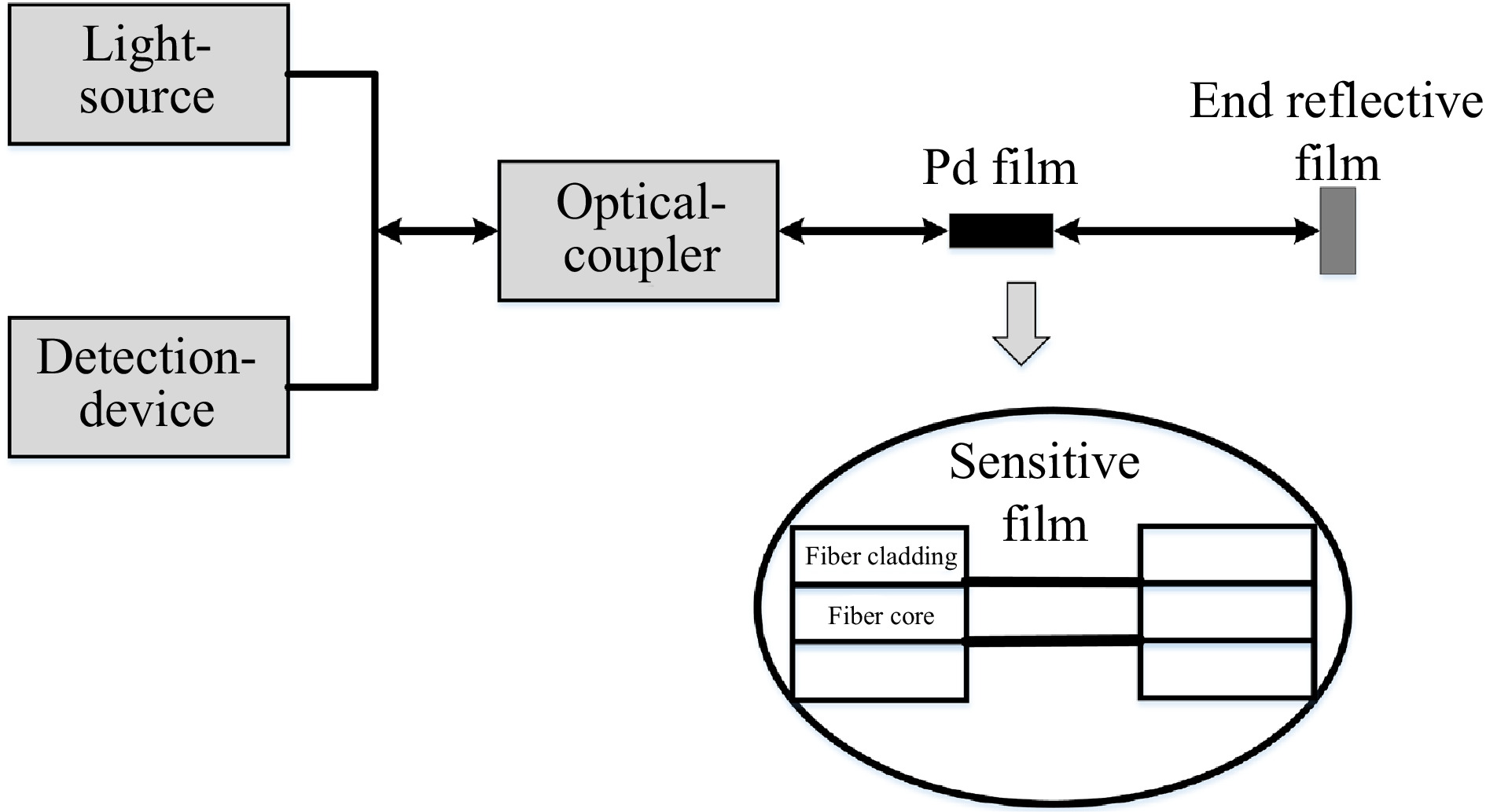

Evanescent field hydrogen sensors mainly depend on the evanescent field between the naked optical fiber and sensitive film, as shown in Fig. 3. In an environment containing hydrogen, the sensitive film claddings can change the evanescent field, resulting in a change of transmitted light in the fiber[50]. Therefore, hydrogen concentration can be detected by monitoring the intensity of transmitted light.

The structure of surface plasmon resonance sensor (SPR) is similar to evanescent field sensor. Their difference is that SPR sensors need to be coated with metal film in the detection area. When the incident angle satisfies specific conditions, strong coupling will occur between incident and surface plasma waves. This causes the energy of the incident light to be absorbed, thereby reducing the intensity of the reflected light[55].

In 1999, an evanescent field hydrogen sensor was fabricated by Tabib-Azar et al.[56], which was coated with a palladium film on the optical fiber core by etching technology. In 2000, Sekimoto et al.[57] polished the side of the optical fiber and deposited the Pd/WO3 composite film to form the evanescent field structure. WO3 was used as the substrate layer to improve the binding force between the hydrogen sensitive film and the optical fiber. In 2003, Villatoro et al.[58] fabricated a sensor based on Pd-coated tapered single-mode fiber (SMF). The sensing sensitivity can be adjusted by changing the diameter and length of the tapered area. Subsequently, they optimized the sensor by coating a Pd film on the tapered waist of a multimode fiber[59]. The diameter of the tapered region, the wavelength of the incident light and action region can influence the performance of the sensor. In 2010, Monzon-Hernandez et al.[60] prepared Au-Pd nanoparticle thin films at the tapered waist of the fiber by sputtering and heat treatment. Li et al.[61] improved stability and sensitivity of the sensor by adding Pd nanoparticles to PMMA matrix. The performances of the above sensors are shown in Table 6.

Table 6. Performance comparison of evanescent field hydrogen sensors.

Author Published Sensor head Performance Reference Tabib-Azar et al. 1999 Pd film with 10 nm thickness and 1.5 cm length Detecting concentration (DC): 0.2%−6%, response time (RT): 20−30 s, great repeatability [56] Sekimoto et al. 2000 Pd/WO3 composite film DC: ~0.2%, RT: 20 s, great repeatability [57] Villatoro et al. 2003 SMF + Pd film DC: ~0−10.5%, RT < 100 s, Recovery time (RCT): 75 s [58] Villatoro et al. 2005 Multimode tapered fiber + Pd film When the thickness of Pd film is 4 nm, the response time of the sensor with a concentration of 3.5% is 10 s [59] Monzon-Hernandez et al, 2010 Au-Pd nanoparticle film The response time of the sensor to 4% hydrogen is 5s, poor sensitivity [60] Li et al. 2018 Pd +Poly(methyl methacrylate) DC: 0.2%−1%, RT: 5 s, sensitivity: 5.58 nm/% [61] The first SPR hydrogen sensor was designed by Chadwick & Gal[62] in 1993. They used Pd/Ni alloy film which successfully improved the sensor performance. In 2011, Perrotton et al.[63] reported the SPR hydrogen sensor based on spectral modulation principles. They deposited a multilayer film composed of Ag, SiO2 and Pd on the outside of the naked multimode fiber (MMF) and found that the highest sensitivity was achieved at a Pd film thickness of 3.75 nm. In 2013, Wang et al.[64] proposed a new sensing film with 35 nm Ag/100 nm SiO2/180 nm WO3/3 nm Pd. Hosoki et al.[65] added Ti2O5 to Au and Pd to form a novel multilayer hydrogen-sensitive film. In 2019, Beni et al.[66] found that Y/Pd nano-disks had a higher sensitivity. Table 7 sums up the performance of the SPR hydrogen sensors.

Table 7. Performance comparison of SPR hydrogen sensors.

Author Published Sensor head Performance Reference Chadwick & Gal 1993 Pd/Ni alloy film DC: 0.1%−10%, response time (RT): ~30 s [62] Perrotton et al. 2011 35 nm Ag/100 nm SiO2/3.75 nm Pd DC: ~4%, RT < 15 s [63] Wang et al. 2013 35 nm Ag/100 nm SiO2/180 nm WO3/3 nm Pt DC: < 2%, sensitivity: 17.4 nm at 2% [64] Hosoki et al. 2014 25 nm Au/60 nm Ti2O5/10 nm Pd DC: 4%, RT: 8 s, sensitivity: 7 nm/% [65] Beni et al. 2019 WO3/Pd + Y/Pd nano-disk DC: 0−100%, RT: 10 s, sensitivity: 60 nm at 4%,

RCT: 5 min[66] Evanescent field sensors are mainly characterized by high sensitivity, rapid response to low concentration and wide temperature range. Moreover, they can adjust the thickness and length of Pd film to achieve independent optimization of sensitivity and response time. However, evanescent field sensors need complex manufacturing processes and are high cost. Besides, most evanescent field sensors use the intensity demodulation method, resulting in light source power ambient temperature change which may affect its measurement accuracy.

Similarly, SPR hydrogen sensors have the advantages of high sensitivity, high measurement accuracy and fast response rate. But they have disadvantages such as complex structure, weak mechanical strength, high manufacturing difficulty and high cost. It is well known that hydrogen sensitive film is the core of the sensor. Therefore, in order to further improve the performance of SPR hydrogen sensors, higher-grade membrane structures can be constructed by nanotechnology.

Fiber grating hydrogen sensor

-

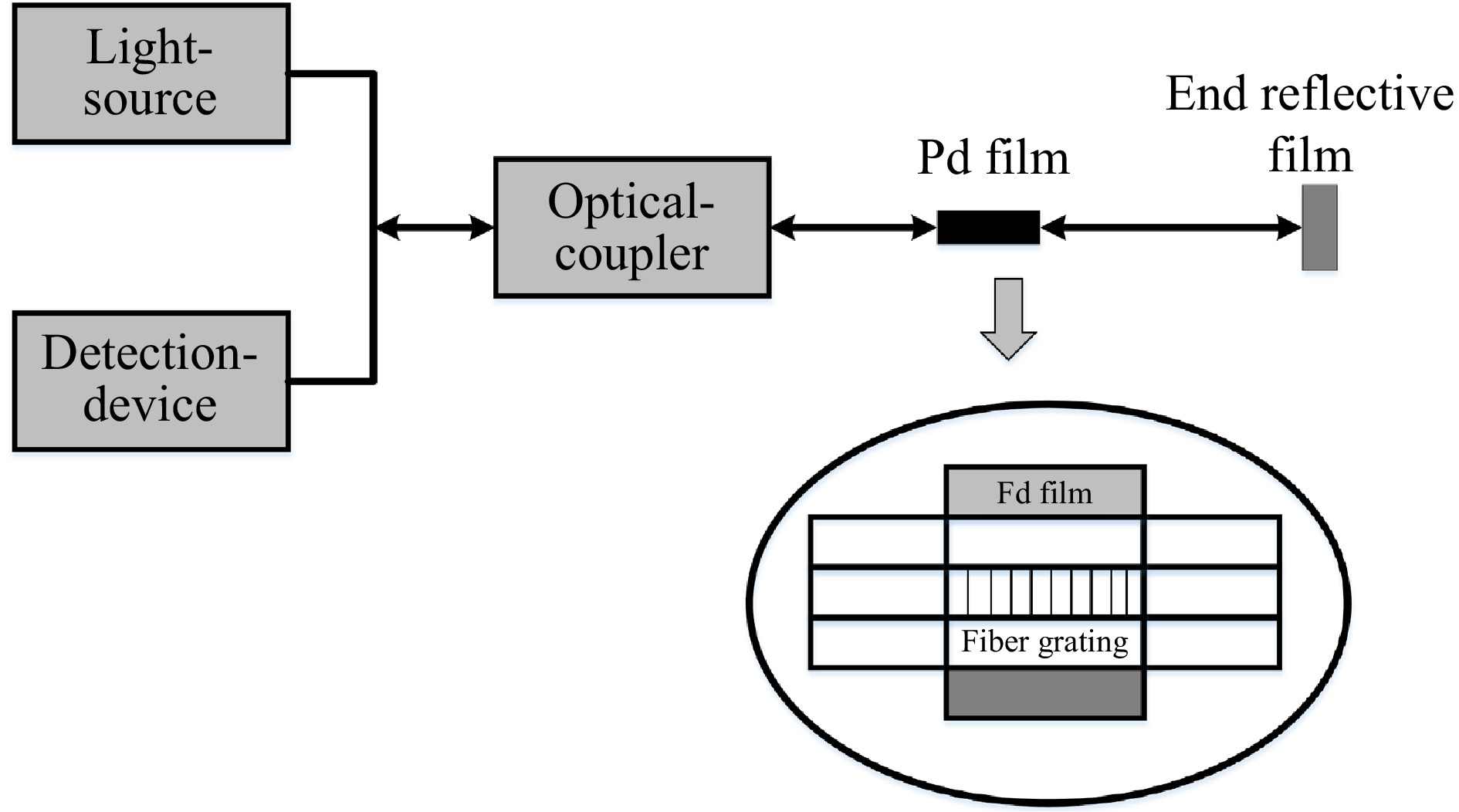

Fiber grating is an optical structure with periodic refractive index change, which can reflect light of a specific wavelength. The period and effective refractive index of the fiber grating can determine the reflected light wavelength. When the sensitive material is exposed to hydrogen, it can expand or release heat to change the period or effective refractive index of fiber grating. The wavelength of reflected light varies accordingly[67]. The magnitude of wavelength shift is related to hydrogen concentration in the environment. Based on this principle, online real-time monitoring of hydrogen concentration can be realized. The schematic diagram of fiber grating sensors is shown in Fig. 4.

In 1999, Sutapun et al.[68] firstly electroplated 560 nm Pd film on the 2–3 cm fiber grating to make a fiber grating hydrogen sensor. The sensor showed excellent linearity at hydrogen concentration of 0.8%–1.3%. In 2005, Aleixandrea et al.[69] made the sensor through sputtering 5 nanometer Pd film on one side of the fiber grating. Then, Troulillet et al.[70] developed fiber bragg grating (FBG) and long period fiber grating (LPG) hydrogen sensors coating a 50 nm Pd film on the side of the fiber cladding. Based on the evanescent field interaction, Schroeder et al.[71] introduced a Pd-coated FBG hydrogen sensor. The experiment showed that for 50 nm Pd film, the sensor could detect below 4% hydrogen and had a sensitivity of 33 pm/% hydrogen. However, the Pd film may be delaminated when the concentration is above 5%. In 2016, Yan et al.[72] demonstrated a sensor that superimposed 100 nmAu/50 nm WO3/30 nm Pd on the end surface of the fiber. Table 8 shows the performance comparison of fiber grating hydrogen sensors.

Table 8. Performance comparison of fiber grating hydrogen sensors.

Author Published Sensor head Performance Reference Sutapun et al. 1999 Fiber Grating + 560 nm Pd Detecting concentration (DC): 0.8%−1.3%, response time (RT): 10 min [68] Aleixandrea et al. 2005 Fiber grating + 5 nm Pd film DC: ~0.8%−1.3%, sensitivity: 8.4 pm/% [69] Trouillet et al. 2005 5 nm Pd film DC: < 4%, sensitivity: 14 pm at 4% [70] Schroeder et al. 2009 Pd film + fiber grating DC: 0−2%, sensitivity: 33 pm/% [71] Yan et al. 2016 100 nmAu/50 nm WO3/ 30 nm Pd DC: 0.086 cc, RT: 4 s, sensitivity: 70 nm/cc [72] The rapid development of fiber grating makes the application prospect of fiber grating hydrogen sensors broader. On the one hand, FBG hydrogen sensors can essentially eliminate the interference of optical power fluctuation due to their wavelength modulation principle. On the other hand, the reference grating can perform temperature compensation to improve the reliability of the sensor. However, the detection of wavelength shift requires expensive devices and complex technologies. Moreover, the thicker hydrogen sensitive film leads to longer response time. In the future, with the development of science and technology, the cost of demodulation technology is gradually reduced and some new technologies (such as nanoparticle films) can be applied to solve the problem of response time.

Summary of issues

-

Each sensor has unique characteristics. Evanescent field sensors can achieve independent optimization of the sensitivity and response time by adjusting Pd film length. The contradiction between sensitivity and response time of other sensors is preliminarily solved. The interferometric sensor has higher sensitivity and response time than other sensors. Micro-mirror sensors are low cost due to their simple structure and manufacturing process. Based on the distributed multi-point detection feature of SPR sensors, distributed hydrogen monitoring systems can be built. The sensing mechanism of FBG sensors is based on the wavelength modulation principle, so it has stronger stability and interference resistance than other sensors. However, each sensor has issues that limit its widespread usage.

At present, optical fiber hydrogen sensors generally have the following problems:

(1) Due to the limitations of hydrogen sensitive materials, the hydrogen sensitive film is easy to crack and bubble, which affects the sensitivity and detection accuracy.

(2) The limitations of optical fiber signal demodulation technology and film preparation technology result in high cost.

(3) Some operations such as tapering and etching during sensor fabrication may reduce the mechanical strength of the sensor.

(4) The response time and sensitivity are difficult to achieve independent optimization.

-

Safety is an important restrictive factor for the development of the hydrogen energy industry. Hydrogen leakage is the core risk factor, which runs through hydrogen production, storage, transportation and usage. Here, we put forward relevant safety countermeasures for hydrogen fuel cell vehicles and hydrogenation stations. Combined with the relevant hydrogen energy safety standards, essential safety research on hydrogen leakage, cylinder quality and other issues are still needed in order to promote hydrogen energy industry safety standards.

Optical fiber hydrogen sensors have excellent applicability for hydrogen leakage monitoring due to its characteristic of short response time and high selectivity. More importantly, it can meet the requirements of intrinsically safe principles. We briefly reviewed the research progress of optical fiber hydrogen sensing technology and introduced the existing achievements. In general, compared with other types of sensors, optical fiber hydrogen sensors have great application potential.

Financial support for this work by the National Key Research and Development Program of China (Grant No. 2021YFB4000902) and the Key Research and Development Project of Hubei Province (Grant No. 2021BCA216) are both highly appreciated.

-

The authors declare that they have no conflict of interest.

- Copyright: © 2022 by the author(s). Published by Maximum Academic Press on behalf of Nanjing Tech University. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Chen X, Zhang C, Li Y. 2022. Research and development of hydrogen energy safety. Emergency Management Science and Technology 2:3 doi: 10.48130/EMST-2022-0003

Research and development of hydrogen energy safety

- Received: 16 January 2022

- Accepted: 08 April 2022

- Published online: 29 April 2022

Abstract: Hydrogen has been recently utilized in many fields due to its recyclability and non-pollution characteristics. Hydrogen fuel cell vehicles and hydrogen refueling stations have become the main carrier of hydrogen energy application. However, due to the inflammable and explosive characteristics, the safety problems of hydrogen became indispensable. This paper introduces the safety problems and countermeasures of hydrogen fuel cell vehicles and hydrogen refueling stations. The research progress and achievements of hydrogen energy standards are then comprehensively discussed. Finally, the development status, existing problems and future development direction of five kinds of optical fiber sensors are pointed out.