-

Conventional heating methods are most commonly used for processing and preservation of food by inactivation of enzymes and microbes and destroying foodborne pathogens to ensure that the meat is fit for consumption[1]. Exposure to the high temperatures in these traditional technologies, such as sterilization, drying, pasteurization and evaporation to process the raw material, often degrade the quality of the product and can cause unwanted changes in the sensory characteristics i.e. color, smell, texture and flavor and nutritional value of the product[2]. Meat is a vital part of the human diet and is a major source of high quality protein, vitamin B, fatty acids and trace elements[3]. Broiler meat is widely available, considered healthy[4] and possesses high protein content with low energy values, which places it as a healthy food when compared to other types of meat due to its higher proportion of polyunsaturated fatty acids (PUFA) and reduced-fat content[5]. These are the factors that make broiler meat popular worldwide[6]. Recently, consumers demand meat products that are safe to eat and possess high nutrition value with health benefits[7]. This has led the industry to adapt to alternate processing methods which can replace traditional thermal processing methods[8]. Non-thermal technologies are considered as an alternate method, which possess great potential in the processing of meat as their ability to inactivate enzymes, spores and microbes at ambient or lower temperature and preserve the nutritional and sensory quality of meat which is desired by both industry and the consumer[9, 10]. These technologies, such as high pressure, electrical pulses, microfiltration and ultrasound, are specially designed for economy, simplicity, and energy efficiency[11].

Ultrasound is novel and environmentally friendly technology that is used in food processing and analysis[7]. Recent studies have shown that ultrasound decreases the processing time and ensures food safety without damaging its nutritional quality[12]. For meat processing, ultrasound frequency of 16−100 kHz with an intensity range of 10−1,000 Wcm−2 is commonly used as these frequencies change the physical and chemical characteristics of meat products. When ultrasound is applied in a liquid medium, small cavitation bubbles are produced, which oscillate with pressure fluctuation and collapse. This phenomenon is caused by shock waves, micro jets and acoustic currents and may cause changes in meat characteristics, microstructure and its chemical reaction during processing[13]. Ultrasound can improve metabolism and enzyme activity within meat and promote oxidation, protein hydrolysis, esterification and maillard reaction that results in improved meat color, texture, flavor, tenderness and taste[14], which are the most significant quality characteristics for consumer satisfaction[15, 16].

Ultrasound-treated beef (20 kHz, 150−300 W) showed improved tenderness and water holding capacity during the curing process[17]. Ultrasound-assisted (20 kHz, 300 W) marination of chicken breast with sodium bicarbonate for 50 min significantly improved tenderness, curing effect and water holding capacity[18]. Ultrasound-assisted (300 W, 15 min) sodium chloride treatment improved the tenderness and WHC of chicken breast and extended its shelf life[19]. Zou et al.[20] demonstrated that ultrasound-assisted (20 kHz and 350 W) low-concentration sodium bicarbonate (0.3 M) treatment improved the tenderness of chicken breast meat. However, there is little data available on the effect of ultrasound-assisted cooking on broiler meat nutritional and eating quality.

Therefore, the objective of the current study is to investigate the effect of ultrasound assisted cooking on broiler meat quality, tenderness, pH, color, oxidation and sensory characteristics. The results will contribute to establishing ultrasonic technology at the industrial level for processing.

-

Thirty chicken breasts were acquired from a local poultry farm within a 2-h post mortem window. The breast fillets were kept in an ice box and transferred to the laboratory, (University of Veterinary and Animal Sciences, Lahore, Pakistan). Sixty fillets were prepared to weigh between 155−185 g ± 5 g, vacuumed pack (Multivac® baseline P100) in a polythene bag (150 mm × 200 mm, PA/PE 90) and stored at 0−4 °C for later use and the experimental treatment and quality determination were completed within 48 h. Twelve fillets were randomly selected for each experimental group and replicated three times.

Ultrasound assisted cooking

-

The breast fillets were cooked in an ultrasonic bath at different core temperatures (50, 60, 70 and 80 °C) for 20 min. The core temperature of breast fillets was monitored using a food thermometer (TP101, Cixi Sino, China). For ultrasound treatment, ultrasonic bath (Model B-22-4, Branson Ultrasonic Corp., Danbury, CT, USA) of the fixed frequency of 40 kHz and 120 W intensity was used[21]. The detailed experimental grouping and processing temperatures are shown in Table 1.

Table 1. Experimental design and treatment conditions.

Cooking method Core temperature Replicate Water bath (T0) 72 °C (control group) Thermo-

sonication(T1) 50 °C

(T2) 60 °C

(T3) 70 °C

(T4) 80 °C5 × 4 × 3 = 60 Birds

5– treatments

4– birds per treatment

3– treatment repetitionColor analysis

-

The Instrumental color values were measured using a Minolta Chroma meter (Konica Minolta® CR-410, Tokyo, Japan), provided with C illuminant, 2o standard observer, and 50 mm aperture, calibrated with a white tile each time before taking measurements of meat samples[22]. Color values were taken before and after the cooking of samples. Following the CIELAB color system, color values were measured, i.e., lightness (L*), redness (a*), yellowness (b*). Three values from each sample were taken by placing the chroma meter at three different locations, the mean value was calculated.

pH analysis

-

The pH values of samples, before and after treatment, were measured with a portable pH meter (WTW, 3210SET 2, Germany). Before each measurement, the pH meter was calibrated with a standard buffer. Each sample was measured three times from three different points. The average value of each sample was calculated.

Cooking loss measurement

-

Cooking loss was measured according to the method previously described by Zhang et al.[23] with minor modifications. The sample was weighed before treatment M1 and then vacuumed packed (via Multivac® Baseline P100) in a polythene bag (150 mm × 200 mm, PA/PE 90) and cooked according to each treatment. The sample was then cooled to room temperature and excessive moisture was absorbed from its surface with filter paper drained of excessive fluid. The sample was then immediately weighed as M2. Cooking loss was calculated as:

$\rm Cooking\; loss\; ({\text{%}}) =\frac{M1 - M2}{M1} \times 100 $ TBARS

-

Thiobarbituric acid-reactive substances (TBARS) assay was performed by the method described by John et al.[24] with minor modifications. Triplicate meat samples (2 g) were mixed with 2.5 mL stock solution containing a stock solution of 0.357% TBA, 15% TCA and 0.25 HCL. The mixture was heated for 10 min in a boiling water bath (100 °C) to develop a pink color, cooled and then centrifuged for 15 min at 2,000 revolutions per minute at 4 °C using Centurion Scientific K2015R. To determine the absorbance, 1 mL of the supernatant solution was separated and run against a blank at 531 nm in a spectrophotometer. The quantity of TBARS was expressed as milligrams of malondialdehyde (MDA)/kilogram of meat.

To calculate malonaldehyde (MDA) concentration, a coefficient of extinction (1.56 × 105 M–1 cm–1) for pink chromogen was used. The value of MDA concentration was converted to TBA number (mg MDA/kg meat sample) by the following method:

(1) TBA number (mg/kg) = Sample A532 × (1 M chromogen / 1.56 × 105) × [(1 mol/L)/M] × (0.003 L/0.5 g meat) × (72.07 g MDA/ mol MDA) × (1000 mg/g) × (1000 g/kg), or

(2) TBA Number (ppm) = Sample A532 × 2.77.

Shear force

-

Tenderness was determined by shear force value, measured by the Texture analyzer (TA XT plus®, UK). Cooked samples were placed to chill overnight at 0−4 °C in an overwrapped polystyrene tray and cut down parallel to the muscle fiber orientation with the help of scalpel-handle blades into 1 cm2 pieces and shear force value was measured using the 'V- Slot' blade in Newton per centimeter (Ncm−2)[25]. The shear force was measured at least three times and the average value was calculated.

Sensory analysis

-

For sensory evaluation, six semi-trained panelists were served cooked samples of 1.5 cm × 1.5 cm cubes. Three breast fillets per treatment were served to panelists randomly, they rinsed their mouths between samples to avoid carry-over taste. Samples were judged for odor, flavor, tenderness, juiciness and overall acceptability on a 9-hedonic scale (1 for extremely dislike, 9 for extremely like).

Statistical analysis

-

SAS 9.1 software was used to carry out an analysis of variance (ANOVA) and Duncan's multiple range test was employed to determine the difference. All results were expressed as mean ± standard deviation, and P < 0.05 was considered to have a significant difference.

-

Color is considered a key factor in meat quality because it is the first quality characteristic assessed by consumers. It is affected by meat protein structure, myoglobin chemical state, and lipid oxidation[26]. In the present study, color values of breast fillets are shown in Table 2; values were significantly different (P < 0.05). Compared to the control group, the brightness (L*) of ultrasound cooked meat increased (P < 0.005) (Table 2). The values of a* and b* were decreased. A study conducted on beef showed the same results with decreased a* and increased L* values[27]. The reason could be that ultrasound treatment increases the total color change, limits oxymyoglobin formation and decreases metmyoglobin production[28]. Previous studies suggested that ultrasound has little effect on meat color because the heat generated is insufficient to denature protein and pigment[29]. Similar results have been observed when only ultrasound (40 kHz, 11 Wcm−2 for 60 min) was applied before cooking at different storage days[30]. The redness (a*) and yellowness (b*) color values of ultrasound treated meat decreased gradually (T1 was significant) and (T1, T2, T3 were significant), respectively. This indicates that the lightness (L*) of ultrasound assisted cooked meat increases, and the redness (a*) and yellow-orange (b*) color decreases. On the contrary, some studies showed that the ultrasound treatment had a positive effect on pork meat color[31], which may be related to animal species, type of meat, muscle fiber type and ultrasound characteristics.

Table 2. Effect of ultrasound-assisted cooking on broiler meat color and pH.

Treatment L* a* b* pH T0 68.08 ± 0.70d 6.67 ± 0.26b 20.48 ± 1.00a 6.33 ± 0.10 T1 73.18 ± 1.24c 10.39 ± 0.61a 19.30 ± 0.40a 6.33 ± 0.10 T2 79.33 ± 0.44a 5.65 ± 0.16c 19.50 ± 0.50a 6.32 ± 0.08 T3 76.29 ± 0.85b 5.45 ± 0.22c 18.85 ± 0.45a 6.36 ± 0.10 T4 74.12 ± 0.89bc 5.19 ± 0.21c 16.82 ± 0.46b 6.17 ± 0.06 P-value < 0.0001 < 0.0001 0.0025 0.5753 Different superscripts (a, b and c) in the same column represent significant differences (P < 0.05) of mean values of this study.

T0: Control, T1: 50 °C + 20 min US, T2: 60 °C + 20 min US, T3: 70 °C + 20 min US, T4: 80 °C + 20 min US.pH is also one of the most important characteristics that has a strong impact on meat quality[32], because it directly affects the protein properties and its stability. A drop in pH causes shrinkage of polypeptides chains, which decrease the water holding capacity (WHC) of meat and meat products[33]. The values in Table 2 shows a non-significant difference (P > 0.05) in pH among ultrasound assisted cooked samples and water bath cooked samples. The same results were found when M. semimembranosus was treated with ultrasound (2.6 MHz, 10 Wcm−2) at different postmortem hours[34]. No change was also recorded by Jayasooriya et al.[35], when Longissimus lumborum et thoracis and semitendinosus muscles were treated with high-intensity ultrasound (24 kHz, 12 Wcm−2). Other studies have shown that ultrasonic treatment increases meat pH, but the difference is very small, which may be caused by factors such as meat type, stiffness time, and ultrasonic characteristics[36].

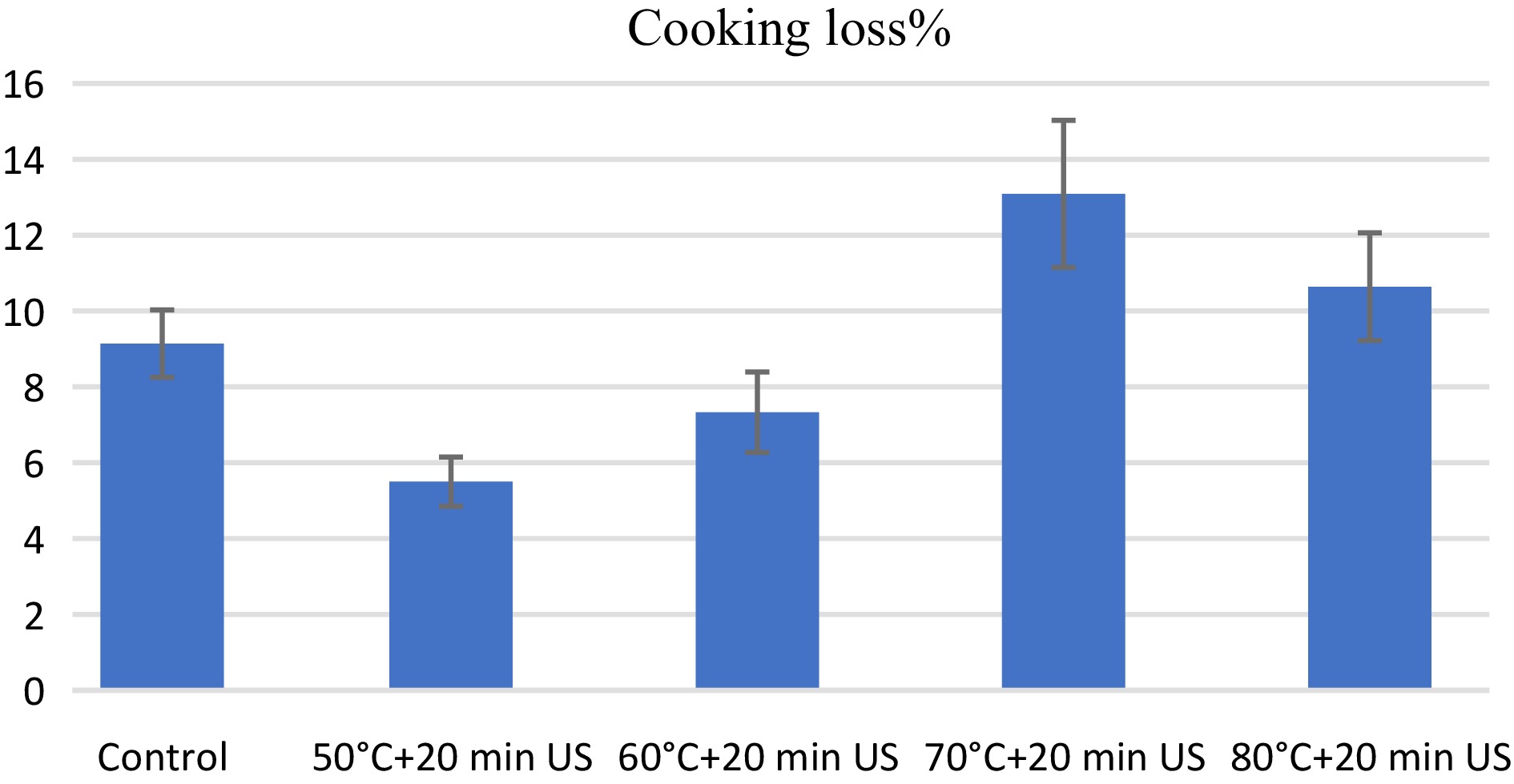

Effect of ultrasound-assisted cooking on cooking loss and tenderness of broiler meat

-

Cooking loss is also one of the important intuitive indicators to measure muscle WHC and contributes to overall meat quality. Compared to the control group, cooking loss of ultrasound assisted cooked meat was significantly decreased (P < 0.05) (Fig. 1). It could be because ultrasound treatment induces oxidation of myosin, causing polymerization, which could also contribute to an increase in water holding capacity and decrease in cooking loss %[17]. When compared to the control treatment, T1 and T2 values are significantly lower, which shows that these samples have higher cooking yields. The highest cooking loss was recorded at 70 °C in the ultrasonic bath. The reason might be that ultrasound radiation destroys the structure of myofibrils and increases the gap between myofibrils. When ultrasound radiation time is combined with temperature it destroys the fibers, and the water between the muscles can flow freely. The cooking loss percentage of T4 treatment is slightly high than the control treatment. Therefore, ultrasound bath can reduce the cooking loss in chicken breast meat. In the present study, cooking loss % is decreased as the temperature is increased in ultrasonic bath as compared to the control treatment. It is concluded that the use of ultrasound improves the cooking yield of the meat samples.

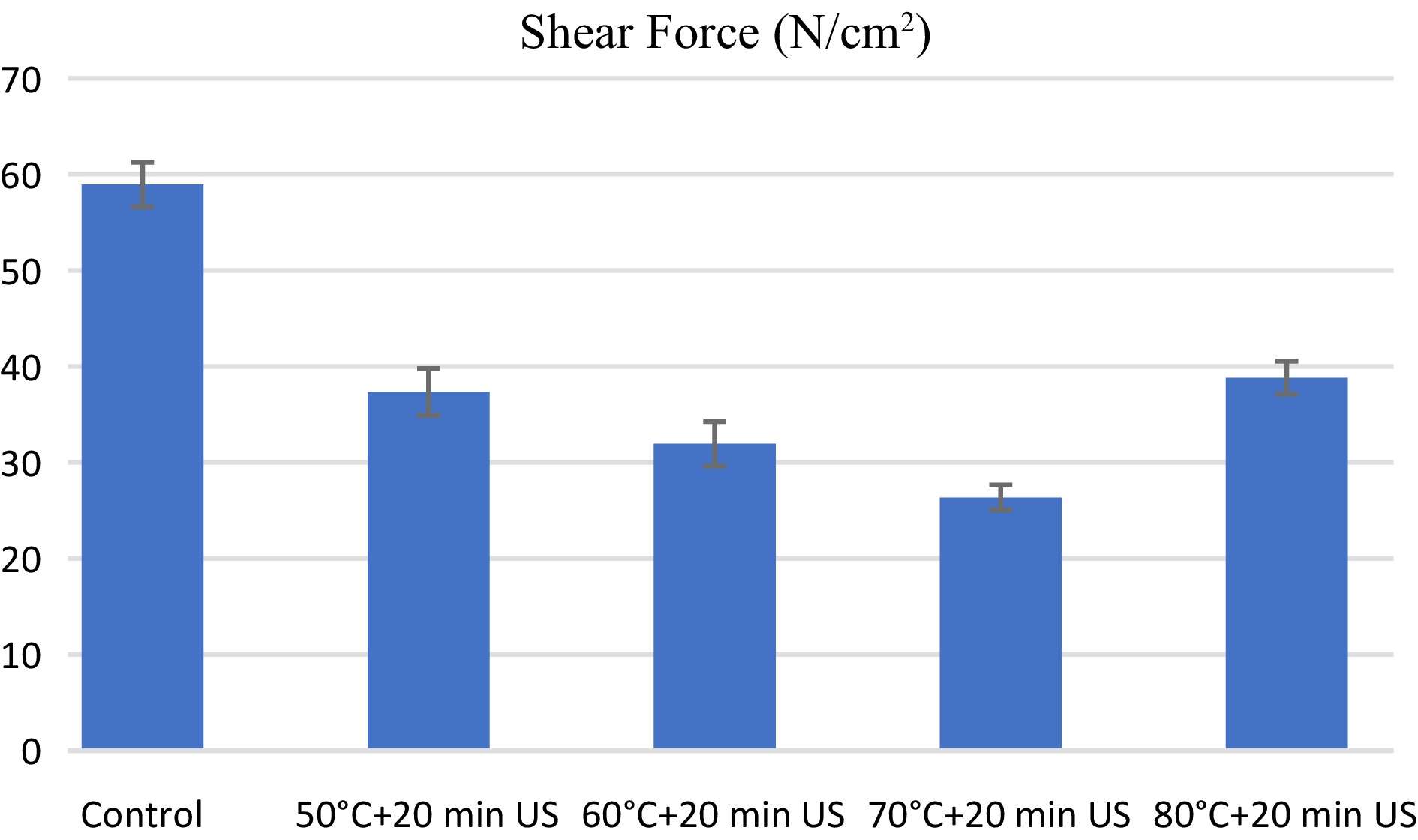

The most common method to measure shear force is the Warner-Bratzler test. Using more force to cut the meat means a firmer and resistant meat texture. So the higher the value of shear force means less brittle meat[37]. Tenderness in meat is determined by its texture. Tenderness is one of the most important attributes of meat quality and it is affected by the composition, structural organization and integrity of the skeletal muscle. Present study results show that ultrasound-assisted cooking improves meat tenderness compared to water bath cooking. Shear force values of ultrasound-assisted cooked at different temperatures and water bath cooked meat is shown in Fig. 2. As can be seen, the shear force values of ultrasound assisted cooked meat is significantly lower (P < 0.05) than water-bath cooked meat. Recent studies also show that using ultrasound treatment before cooking improves the tenderness of meat[38]. The least shear force was applied in T3 treatment, which implied that it had the most tenderization effect. Previously, bovine muscles treated with ultrasound and then stored show an increase in tenderness and decrease in pH with no changes in cooking loss[39].

Effect of ultrasound-assisted cooking on broiler meat oxidation and sensory profile

-

Cooked meat is more prone to oxidation as compared to raw meat as high temperatures used for cooking cause the release of oxygen and iron, therefore increasing free radical production[40]. The values in Table 3 show the TBARS content of ultrasound-assisted cooked broiler meat at different temperatures. The results indicated a slight increase in rate and extent of lipid oxidation in samples subjected to ultrasound treatment compared to those of the control group. The TBARS values also significantly increased with the increase in temperature levels. T0, T2 and T3 values are the same and significantly differ from the T1 and T4 treatment (P < 0.05). It seems likely that the ultrasound-assisted cooking induce lipid oxidation from cavitation which then generated free OH radicals by sonolysis[41]. A previous study found that the use of power ultrasound accelerated the biochemical reaction rate as evidenced by increasing TBARS content[42] so, the rate of oxidation and degradation increased at higher temperatures, which indicate that, the cavitation cause the increase in temperature 'hot spots' more readily which might also contribute in increasing TBARS values[43]. In contrast, Cichoski et al.[44] reported a decrease in the oxidation of ultrasound treated sausages. Overall T1 showed the best result among other treatment groups.

Table 3. Effect of ultrasound-assisted cooking on broiler meat oxidation and sensory characteristics.

Treatment TBARS Odor Flavor Tenderness Juiciness Overall acceptability T0 2.76 ± 0.12b 5.28 ± 0.39bc 5.72 ± 0.44b 6.67 ± 0.41a 6.17 ± 0.39ab 5.94 ± 0.42b T1 1.42 ± 0.28c 3.83 ± 0.24d 3.89 ± 0.49c 4.17 ± 0.56b 5.33 ± 0.47b 4.39 ± 0.54c T2 2.92 ± 0.66b 4.59 ± 0.50cd 3.52 ± 0.22c 4.70 ± 0.45b 4.94 ± 0.43b 3.94 ± 0.35c T3 2.94 ± 0.18b 5.89 ± 0.33b 6.05 ± 0.35b 6.50 ± 0.31a 6.67 ± 0.47a 6.06 ± 0.39b T4 4.30 ± 0.41a 7.83 ± 0.18a 7.28 ± 0.22a 7.22 ± 0.34a 6.83 ± 0.31a 7.50 ± 0.18a P-value < 0.0001 0.0000 0.0000 0.0000 0.0075 0.0000 Different superscripts (a, b and c) in the same column represent significant differences (P < 0.05) of mean values of this study.

T0: Control, T1: 50 °C + 20 min US, T2: 60 °C + 20 min US, T3: 70 °C + 20 min US, T4: 80 °C + 20 min US.In the present study, fillets cooked at 70 and 80 °C in an ultrasonic bath have more flavor, juiciness, tenderness and acceptability when compared with other treatments (P < 0.05). The values for sensory evaluation are shown in Table 3. There was the least significant difference between treatments when compared to the control treatment. The T2 and T3 samples show relatively low scoring for odor, flavor, tenderness, juiciness and overall acceptability compared to control samples. For tenderness and juiciness, control, T3 and T4 treated samples show highest scores. As for overall acceptability samples cooked at 80 °C core temperature with ultrasound were most likable with the highest score. The same results are shown when spiced beef was cooked with ultrasound at a higher intensity (800 W)[45].

-

It is concluded that the use of ultrasonic bath for cooking at 70 °C improves the tenderness of cooked meat. It reduces the cooking time and temperature and also improves the nutritional quality of cooked meat. According to the present study results, ultrasonic technology can be used in the meat industry to produce meat products that possess high nutritional and organoleptic quality in less time and lower temperatures. Cooking at low temperature with ultrasound causes an increase in tenderness and a decrease in lipid oxidation. Hence, the use of ultrasound for processing is economical and environmentally friendly.

This research was financially supported by the Department of Meat Science and Technology, University of Veterinary & Animal Sciences, Pakistan. Authors are thankful to the department.

-

The authors declare that they have no conflict of interest.

- Copyright: © 2023 by the author(s). Published by Maximum Academic Press on behalf of Nanjing Agricultural University. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Ashar N, Ali S, Asghar B, Hussnain F, Nasir J, et al. 2022. Application of ultrasound-assisted cooking temperature for improving physicochemical and sensory properties of broiler meat. Food Materials Research 2:16 doi: 10.48130/FMR-2022-0016

Application of ultrasound-assisted cooking temperature for improving physicochemical and sensory properties of broiler meat

- Received: 16 August 2022

- Accepted: 16 October 2022

- Published online: 08 November 2022

Abstract: The current study investigates the effect of ultrasound-assisted cooking on broiler meat quality. The objective of this study was to explore the combined effect of ultrasound treatment (US) (40 kHz, 120 Wcm−2) at different cooking temperatures (50, 60, 70, 80 °C) on physicochemical and sensory attributes of broiler meat. Therefore, pH, cooking loss %, Thio-barbituric acid reactive substances (TBARS), shear force, color, and sensory properties were investigated and compared with the control group. The result showed that the ultrasound treatment had no significant effect on pH values compared to the control group. The cooking loss % decreased with the application of US treatment at higher temperatures, which implied a higher cooking yield. Furthermore, sonicated meat showed lower shear force values even at 80 °C cooking temperature, which indicates increased tenderness. In addition, lower TBARS values were recorded at 50 °C temperature in combination with ultrasound, but the other treatments were similar to the control group. The application of ultrasound increased the lightness of meat with a significant decrease in lightness and yellowness. Meat cooked at 80 °C with US showed a significantly higher sensory score (odor, flavor, tenderness, juiciness, overall acceptability) than other treatment groups. The treatment of ultrasound combined with temperature was considered a promising and efficient technique for processing as it increased the perception of tenderness with less cooking losses and higher sensory attributes.

-

Key words:

- Ultrasonic cooking /

- Temperature /

- Broiler /

- Cooking loss /

- Tenderness