-

Spices are the most valued and commonly used ingredients in food preparation around the world due to their unique flavors, colors, and fragrances. Among different spices Curcuma longa L., (turmeric) is used in Asian and Middle East countries as a spice, food preservative, and coloring agent in its dried and powdered form[1]. Turmeric is a tropical crop that grows up to 1 m under moist and hot climatic conditions, it requires well-drained, loose, and loamy soil without water-logging conditions[2]. Various cultivars are prevalent in the country, typically identified by the names of the localities where they are grown. Notable cultivars include Duggirala, Tekurpeta, Sugandham, Amalapuram, Erode local, Alleppey, Moovattupuzha, and Lakadong[3]. In regions like Kerala and along the West Coast, where rainfall commences early, the cultivation season begins in April−May with the onset of pre-monsoon showers. Depending on the specific cultivar, the turmeric crop reaches maturity for harvesting within 7−9 months after planting, typically falling between January and March. Early varieties are ready in 7−8 months, medium varieties in 8−9 months, and harvest stage varieties take more than 9 months to mature[4]. India is the world's leading producer and exporter of turmeric, with its unique qualities, and therapeutic properties turmeric is considered a herbal medicine and acts as a preventative agent against cardiovascular diseases[5]. To preserve, store, process any produce with minimal losses and to avoid harvest losses, determination of physical and engineering properties are necessary. Most of the horticultural produce (tubers and rhizomes) and food products characterized based on axial dimensions (length, width, and thickness) and density which are important properties for the determination of their size, shape, weight, and volume. Further, these properties are utilized in various processing operations like sorting, grading, filling into bags, loading, unloading, transportation, harvesting, and storage[6]. Frictional properties like the coefficient of friction, angle of repose, and static friction play a major role in designing handling equipment. Thus, in the case of horticultural produce, there is a need to determine and consider these properties for sorting, grading, packaging, transportation, and storage. Yet there is limited published work on the physio-chemical and engineering properties of turmeric rhizomes. In this study, turmeric rhizomes (var. Punjab Haldi-1, Punjab Haldi-2) at two harvesting stages; early harvest stage harvested during the first week of December (9 months after sowing) and harvest stage i.e. harvested during mid-March (11−12 months after sowing) were evaluated for physio-chemical, engineering, and bioactive properties. The hypothesis behind the selection of two harvest stages was to know the characteristics of turmeric at both harvest stages so that producer can vacate their field early and obtain a longer window for processing or processing units running for a longer time. The December to March period is the curing period, during which skin hardens, yield losses are negligible and there is more accumulation of curcumin. The objective of this study was to determine the physio-chemical and engineering properties of turmeric varieties Punjab Haldi-1 and Punjab Haldi-2 harvested at the early harvest and harvest stage so that the knowledge gained will be used in the design and development of equipment for cleaning, grading, dehydration, storage, and handling.

-

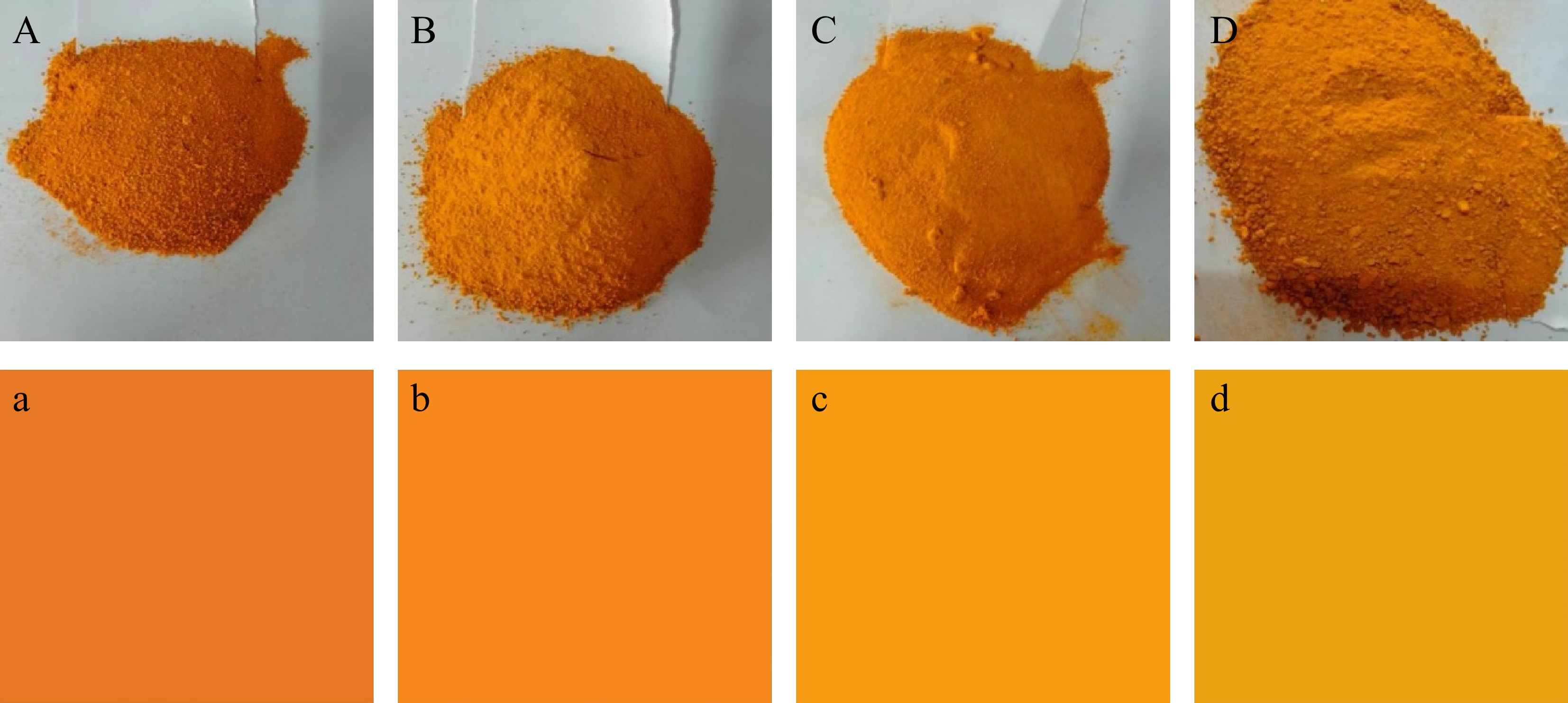

Turmeric rhizomes (var. Punjab Haldi-1, Punjab Haldi-2) at two harvesting stages i.e. early harvest stage−harvested during the first week of December (9 months after sowing) and harvest stage i.e. harvested during mid-March (11−12 months after sowing) were procured from University Seed Farm, Nabha and School of Organic Farming, Punjab Agricultural University, Ludhiana, India (Fig. 1). Punjab Haldi-1 is a medium height plant with green leaves and thick rhizomes with a brown skin color. Punjab Haldi-2 is a tall variety with broad leaves. Harvested rhizomes were cleaned and subjected to further studies.

Figure 1.

Turmeric varieties. (a) Early harvest Punjab Haldi-1; (b) Early harvest Punjab Haldi-2; (c) Harvest Punjab Haldi-1; (d) Harvest Punjab Haldi-2.

Axial dimensions of fresh turmeric rhizomes

-

Fresh rhizomes 10 kg of individual variety and harvest stage were chosen randomly, and graded into three batches (1: 100–130 mm, 2: 70–100 mm, 3: 40–70 mm) according to their size (length) in decreasing order. After grading, rhizomes were mixed well and selected randomly for measuring axial dimensions (length, breadth, and thickness) of each rhizome by using vernier calipers (Thermisto Th-m61, JIPVI tools, New Delhi, India) (least count 0.01 cm).

Gravimetric properties

Thousand seed mass (TSM)

-

The mass of 100 rhizomes were weighed on an electronic balance (SK-5000, Coleparmer, New Delhi, India) with a resolution of 0.01 g and the resultant weight was multiplied by 10 to get the 1,000 rhizome weight[6].

Bulk density

-

The bulk density (ρ) is defined as the ratio between the mass of turmeric rhizome in a container to its volume. Rhizomes were filled in a measuring cylinder of volume 1,000 cm3 and mass of rhizomes was determined.

${\rm{ Bulk\; density}} \;(\rho) =\rm \dfrac{Mass\;of\;known\;sample\;\left(g\right)}{Volume\;of\;cylinder\;\left(cm^3\right)} $ True density

-

True density was determined according to the method of Mohsenin[7] where fresh turmeric rhizomes were weighed in an electronic balance (SK-5000, Coleparmer, New Delhi, India) with accuracy ± 0.01 g. The weighed samples were immersed in a container filled with toluene without touching the side walls and bottom. From the mass of the displaced toluene, the true volume was determined as follows:

$ {\rm{True\; volume}} =\rm \dfrac{Mass\;of\;known\;sample\;\left(kg\right)}{Volume\;of\;sample\;\left(m^3\right)} $ True density can be calculated by using true volume and weight of rhizomes:

$ {\rm{True\; density }}\;(\rho t) =\rm \dfrac{Wa}{Vt} $ where, ρt = True density of turmeric rhizomes, kg/m3; W = Mass of turmeric rhizomes in air, kg; Vt = True volume of turmeric rhizomes, m3.

Porosity

-

Porosity is an important property used to determine percentage of voids in samples and also for creating heat and mass transfer process models[8]. It was calculated as the ratio of the difference in the true, bulk densities to true plant density and values were expressed as a percentage.

$ {\rm{Porosity}}\; (\varepsilon) = 1- \dfrac{{\rho }\mathrm{b}}{{\rho }\mathrm{t}} \times 100 $ where, ρb = Bulk density, (kg/m3); ρt = True density, (kg/m3).

Frictional properties

Angle of repose

-

The angle of repose indicates the cohesion amongst the individual units of the materials and angle made by turmeric rhizomes with the horizontal surface when heaped from a known height. Turmeric rhizomes were heaped in the form of cone over the horizontal surface slowly from a height of 50 cm, the slanted height of the heap was measured and the radius or diameter of the heap was calculated from the circumference of the heap[8].

${\rm {Angle\; of\; repose}}\; (\theta) =\rm tan -1 \left( \dfrac{2H}{D} \right) $ where, H = Height of the heap (mm); D = Diameter of the pile (m).

Geometric properties

Geometric mean diameter (GMD)

-

The geometric mean diameter for fresh turmeric rhizomes was determined by using the measured geometric dimensions of length (L), width (W), and thickness (T)[7]. GMD is the cube root of length, width, and thickness of a material or substance and denoted in mm.

$ \mathrm{GMD\;(mm)=(LWT)}^{ \mathrm{1/3}} $ Arithmetic mean diameter (AMD)

-

The arithmetic mean diameter is the average of three geometric dimensions and calculated by using the following formula given by Mohsenin[7].

$ {\rm{AMD\; (mm)}} =\rm \dfrac{L+W+T}{3} $ Square mean diameter (SMD)

-

The square mean diameter was calculated using the following formula given by Mohsenin[7].

$ {\rm{SMD\; (mm)}} = \sqrt{\rm LW+WT+LT} $ Equivalent diameter (ED)

-

The equivalent diameter was calculated using the following formula given by Mohsenin[7].

$ {\rm{ED\; (mm)}} =\rm \dfrac{GMD+AMD+SMD}{3} $ Sphericity

-

Sphericity (Φ) can be used to define the shape of a material, it is mostly used to calculate fluid flow, heat, and mass transfer calculations[8]. It can be determined by using the formula:

$ \Phi = \rm\dfrac{\left(LWT\right)^{1/3}}{L} $ Aspect ratio (AR)

-

Together with sphericity, aspect ratio is also an important parameter to determine the shape of produce. It can be determined by using the formula:

$ {\rm{Aspect\; ratio}}=\rm \dfrac{Width}{Length} \times 100 $ Surface area

-

The surface area was determined by tracing the periphery of the rhizome on a graph sheet for all four sides and counting the number of squares within the outline traced[9]. The sum of all the areas gives the surface area of the rhizome. Mass, volume, and surface area were determined for 25 randomly selected rhizomes[9].

Unit volume

-

The unit volume (V) was determined as per the following formula[10]:

$ {\rm{Unit\; volume\; (mm^{3})}} =\rm \dfrac{\pi B2L2}{6(2L-B)} $ Shape factor

-

Shape factor can be determined by using values of unit volume and surface area. It is determined according to the formula provided by Balasubramanian et al.[11].

$ \rm Shape\;factor=\dfrac{D}{C} $ where, C = V/ W; D = S/6W2.

Color

-

The color of agricultural produce is an important parameter which determines consumer acceptability, maturity indices and quality properties[3]. The color of fresh turmeric rhizomes was determined using the Hunter lab colorimeter (Hunter Lab Color Flex-150, USA). The color of 10 individual rhizomes were measured and their average values were calculated. From the above L*, a*, b* values, the chroma (C*) and hue angle (h*) were computed using the formulas below.

$ \mathrm{Chroma\;(C^*)=(a}^{ \mathrm{2}} \mathrm{+b}^{ \mathrm{2}} \mathrm{)}^{ \mathrm{1/2}} $ $ \mathrm{Hue\;angle(h^*)=arc\;tan(b^* / a^*)} $ Physio-chemical properties of turmeric rhizomes

-

In physio-chemical properties, different properties like moisture, ash, pH, titratable acidity, fat, crude fiber, reducing sugars, total sugars, TSS (total soluble solids), and vitamin C content were determined as per standard AOAC[12] methods. All determinations were analyzed in triplicate and the results were expressed as average values.

Preparation and evaluation of turmeric powder

-

The process of obtaining dry turmeric powder involves curing and drying of fresh turmeric. Rhizome fingers were separated from the mother rhizomes, cleaned thoroughly under running water. Curing was entailed by subjecting rhizomes to two processing methods (blanching and pressure cooking) to enhance quality with variation in time-temperature combinations. Blanching was performed at 70 °C, for 15 and 30 min, while in the pressure cooking process rhizomes were cooked individually under 15 psi pressure, at a temperature of 121 °C for 15 and 30 min, followed by cooling immediately in cold water for a few minutes. Rhizomes were shredded into small pieces and dried in a tray drier (Koyka SW-02, Faridabad, India) at 60 °C for 6–8 h. Dried slices were ground into fine powder (200 um sieve) by using a hammer grinding mill (Confider Pulverizer- 3Hp, Ahmedabad, India)

Physical properties of turmeric powder

-

Dispersibility, bulk density, water absorption capacity, swelling power and solubility were determined by the method of Tamuno[13] using the following formulas:

$\rm Dispersibility\; ({\text{%}}) = 100 - Dispersibility\; (Volume\; of\; settled\; segment) $ $\rm Solubility\;({\text{%}})=\dfrac{Weight\;of\;solute\;(g)}{Sample\;weight\;(g)}\times 100 $ $ \text{Bulk density}\;\text{(}\text{g/cm}^\text{3})=\dfrac{\text{Sample w}\text{eight}\text{after tapping}\;\text{(g)}-\text{sample weight before tapping}\;\text{(g)}}{\text{5 mL}\;\text{(Vol)}\;\text{of centrifuge tube}}\times{100} $ $ \text{Water absorption capacity}\;\left(\dfrac{\rm mL}{\mathrm{g}}\right)=\dfrac{\text{Initial volume water added}\text{}-\text{Volume of water decant}}{\text{Sample weight}}\times{100} $ $ \text{Swelling power}\;\text{(g/g)}=\text{}\dfrac{\left(\text{Weight of tube}+\text{Sediment}\right)-\text{Weight of empty tube}\;\text{(g)}}{\text{Sample weight}\;\text{(g)}} $ Curcumin content

-

The curcumin content was determined using the method of FSSAI[14]. The absorbance was measured using a spectrophotometer (Spectronic 20, USA) at 425 nm. Percentage (%) curcumin was determined as follows:

A standard curcumin 0.25 g/L gives absorbance at 425 nm = 0.42

$ {\text{%}}\;{\rm{ Curcumin}} =\rm \dfrac{OD\;value\; \times 125 \times 0.0025}{Abs\;of\;std \times Weight\;of\;sample \times Path\;length} $ Total phenols and antioxidant capacity

-

Total phenols and antioxidant capacity were determined according to the method of Chumroenphat et al.[15]. Total phenols were expressed in mg GAE per 100 g. Antioxidant capacity was determined according to the DPPH (2,2-diphenyl-1-picrylhydrazyl) method and results were expressed as % of inhibition.

Statistical analysis

-

Commercial statistical package SPSS-16 was used to compute mean, standard deviation, and ANOVA (analysis of variance). The data obtained was compared using Duncans multiple range test at 5% level of significance.

-

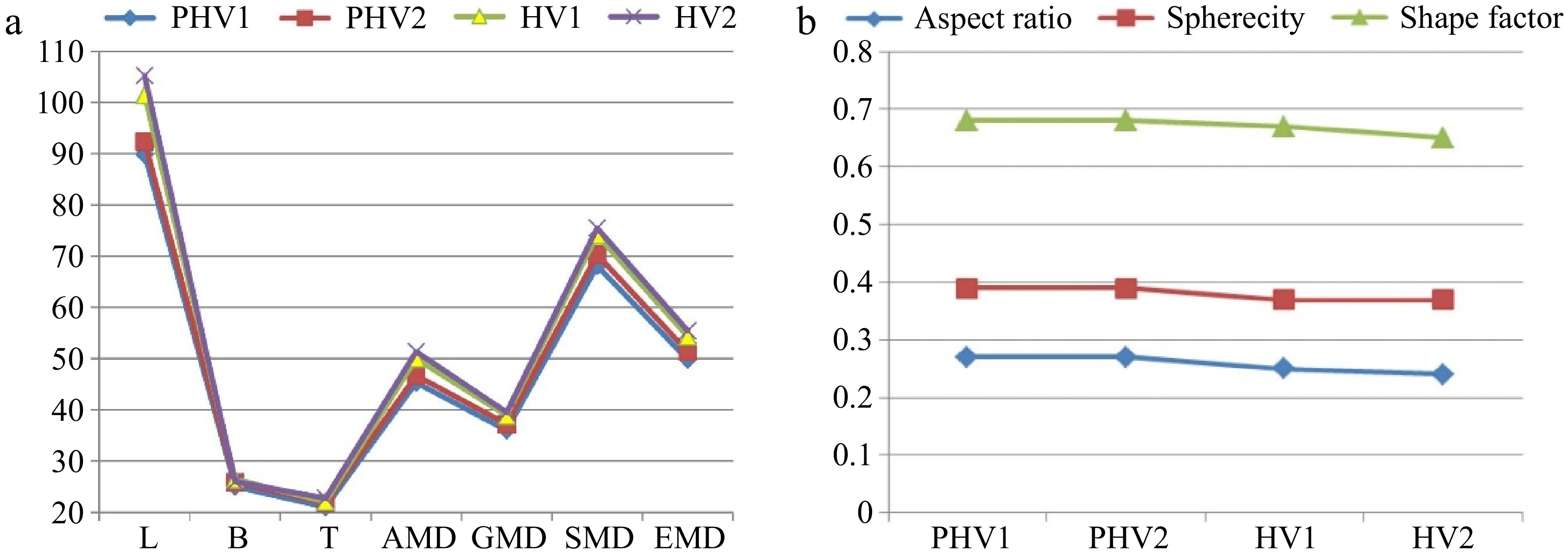

The effect of the harvest stage on axial dimensions, geometric and optical properties of turmeric rhizomes Punjab Haldi-1 and Punjab Haldi-2 were investigated and outlined in Table 1 and depicted in Fig. 1. From the above results obtained, Punjab Haldi-2 variety turmeric rhizomes of early harvest and harvest stage were superior in size, whose average values for length (three grades) ranged from 49.21 to 112.19 mm. There was no discernible trend in breadth and thickness with average values for breadth and thickness across all varieties ranging from 16.27 to 32.87 mm and 13.07 to 29.76 mm, respectively. Notably, rhizomes at the harvest stage exhibited significantly (p < 0.05) better physical properties compared to those harvested early. Similar findings were reported by Hailemichael & Zakir[4] in their literature, where turmeric rhizomes harvested earlier (7−8 months after sowing) demonstrated poor physical quality parameters. The results obtained in this study for engineering properties of turmeric rhizomes are in concordance with the findings of Hailemichael & Zakir[4]. De Ramos et al.[8] conducted a study on the physical properties of the Philippines' local turmeric variety and reported values for length ranging from 41.19 to 128.32 mm, width from 15.45 to 62.40 mm, and thickness from 13.09 to 30.15 mm. These values closely resemble the findings of the current study. The smallest values for all axial dimensions were observed in the early harvest of Punjab Haldi-1. The increase in rhizome size showed a corresponding upward trend in various geometric properties, including arithmetic mean diameter (AMD), geometric mean diameter (GMD), square mean diameter (SMD), and equivalent diameter (EQD), as illustrated in Fig. 2. Similar trends were reported by Farzana & Adeyemi[16] and Kumar & Kumar[6] in their studies on PTS-10 variety turmeric and Krishna and Salem variety turmeric, where AMD, GMD, SMD, and EQD values showed an increasing trend with increase in length, breadth, and thickness. The average mean values for AMD, GMD, SMD, and EQD in the current study ranged from 26.18 to 57.49 mm, 21.86 to 46.88 mm, 40.69 to 87.57 mm, and 29.58 to 63.91 mm, respectively. However, there was a decreasing trend observed in geometric properties such as sphericity, aspect ratio, and shape factor of the rhizomes, likely attributed to their irregular shape. Kumar & Kumar[6] found that an increase in the dimensions of turmeric rhizomes led to lower values of sphericity, aspect ratio, and shape factor, underscoring the impact of rhizome shape on these properties. The mean values for aspect ratio, sphericity, and shape factor ranged from 0.27 to 0.38, 0.41 to 0.50, and 0.70 to 1.14, respectively. A linear relationship was noted in the unit volume and surface area of rhizomes with grade size, depending linearly on the axial dimensions of the rhizomes. The average surface area values were 6,132.52 mm2 for Grade 1, 4,119.37 mm2 for Grade 2, and 1,752.09 mm2 for Grade 3. De Ramos et al.[8] also reported higher surface area values (1,303 to 6,374 mm2) for the Philippine variety of turmeric. The mass of 1,000 rhizomes exhibited a linear relationship and varied with an increase in moisture content, as evidenced in a study by Mishra & Kulkarni[17]. Furthermore, research conducted by Hailemichael & Zakir[4] indicated that rhizomes harvested at 9 to 11 months displayed superior size, a slender shape, and a deep orange-yellow color.

Table 1. Geometric properties of early harvest and harvest stage turmeric rhizomes.

Variety

ParameterEarly harvest Harvest Punjab Haldi-1 Punjab Haldi-2 Punjab Haldi-1 Punjab Haldi-2 Grade-1 Grade-2 Grade-3 Grade-1 Grade-2 Grade-3 Grade-1 Grade-2 Grade-3 Grade-1 Grade-2 Grade-3 Length (mm) 100.64 ± 3.24 76.13 ± 2.83 49.21 ± 3.91 106.51 ± 2.70 71.55 ± 1.81 52.14 ± 2.34 105.37 ± 2.49 72.64 ± 1.43 50.23 ± 6.20 112.19 ± 6.35 75.43 ± 5.05 56.15 ± 4.51 Breadth (mm) 31.09 ± 1.52 26.74 ± 1.63 16.27 ± 1.22 32.23 ± 1.31 26.59 ± 1.07 18.59 ± 1.48 32.87 ± 1.51 28.21 ± 1.30 18.27 ± 1.09 31.34 ± 4.98 27.93 ± 1.76 18.80 ± 0.68 Thickness (mm) 26.76 ± 1.97 23.31 ± 0.82 13.07 ± 1.09 27.78 ± 0.42 24.15 ± 0.43 13.58 ± 0.67 29.76 ± 1.34 23.14 ± 1.14 13.37 ± 1.22 28.94 ± 3.96 25.06 ± 0.55 14.27 ± 0.50 Arithmetic mean diameter (mm) 52.83 ± 1.47 42.06 ± 0.62 26.18 ± 1.52 54.17 ± 0.91 40.76 ± 0.75 28.10 ± 0.65 56.00 ± 0.84 41.33 ± 0.81 27.29 ± 2.11 57.49 ± 3.07 42.80 ± 1.74 29.74 ± 1.61 Geometric mean diameter (mm) 43.72 ± 1.79 36.20 ± 0.78 21.86 ± 0.83 45.09 ± 0.57 35.81 ± 0.49 23.63 ± 0.69 46.88 ± 0.71 36.19 ± 0.96 23.06 ± 1.04 46.68 ± 4.33 37.51 ± 1.06 24.69 ± 0.82 SMD (mm) 81.54 ± 2.87 66.57 ± 1.12 40.69 ± 1.79 83.94 ± 1.17 65.36 ± 1.01 43.92 ± 1.14 87.04 ± 1.22 66.20 ± 1.59 42.81 ± 2.20 87.57 ± 6.89 68.53 ± 2.13 46.09 ± 1.78 EMD (mm) 59.36 ± 2.00 48.27 ± 0.74 29.58 ± 1.37 61.07 ± 0.86 47.31 ± 0.74 31.88 ± 0.76 63.31 ± 0.88 47.90 ± 1.11 31.05 ± 1.72 63.91 ± 4.67 49.61 ± 1.60 33.51 ± 1.38 Aspect ratio 0.30 ± 0.01 0.35 ± 0.02 0.33 ± 0.01 0.31 ± 0.01 0.37 ± 0.009 0.35 ± 0.02 0.31 ± 0.01 0.38 ± 0.013 0.36 ± 0.02 0.27 ± 0.048 0.37 ± 0.02 0.33 ± 0.01 Surface area (mm2) 6,018.18 ± 488.92 4,119.371 ± 189.38 1,502.99 ± 134.73 6,392.94 ± 163.19 4,031.69 ± 121.25 1,752.09 ± 118.63 6,009.14 ± 218.49 4,117.74 ± 247.13 1,671.35 ± 173.35 6,132.52 ± 1234.06 3,802.81 ± 283.27 1,692.00 ± 146.99 Sphericity 0.43 ± 0.02 0.47 ± 0.01 0.44 ± 0.007 0.44 ± 0.009 0.50 ± 0.004 0.45 ± 0.01 0.44 ± 0.009 0.49 ± 0.008 0.45 ± 0.01 0.41 ± 0.04 0.49 ± 0.01 0.43 ± 0.01 Unit volume (mm3) 43,982.97 ± 5,304.70 24,833.49 ± 1,814.03 5,473.03 ± 865.65 48,064.72 ± 1,840.81 24,044.93 ± 1,191.45 6,888.56 ± 804.40 53,942.12 ± 2,666.86 24,815.37 ± 2,513.85 6,421.13 ± 1,144.76 30,781.31 ± 14,055.67 16,767.94 ± 3,003.25 4,618.93 ± 1,042.20 Shape factor 0.71 ± 0.01 0.73 ± 0.03 0.74 ± 0.04 0.71 ± 0.02 0.74 ± 0.01 0.78 ± 0.04 0.70 ± 0.02 0.78 ± 0.02 0.79 ± 0.03 1.04 ± 0.06 1.05 ± 0.03 1.14 ± 0.01 SMD-Square mean diameter, EQD-Equivalent mean diameter. Values are expressed as means of three replications ± standard deviation.

Figure 2.

(a) Axial dimensions. (b) Geometric properties of Punjab Haldi-1 and Punjab Haldi-2 turmeric. L: Length, B: Breadth, T: Thickness, AMD: Arithmetic mean diameter, GMD: Geometric mean diameter, SMD: Square mean diameter, EMD: Equivalent mean diameter, PHV1: Early harvest Punjab Haldi-1, PHV2: Early harvest Punjab Haldi-2, HV1: Harvest Punjab Haldi-1, HV2: Harvest Punjab Haldi-2.

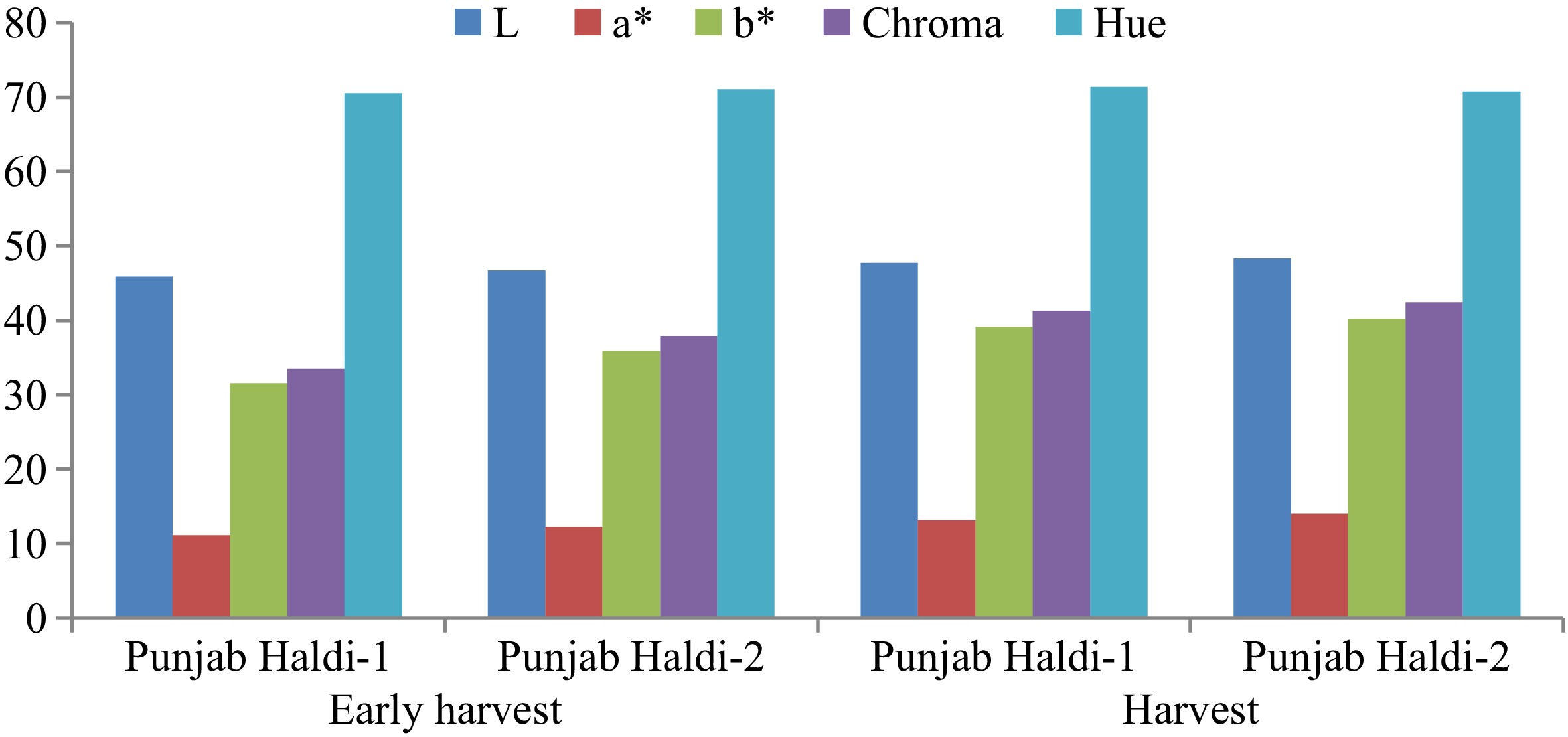

Effect of harvest stage on optical properties of turmeric rhizomes

-

The color of food is a pivotal factor influencing consumer choices Fig. 3 illustrates the optical properties of turmeric rhizomes. Stage of harvest show non-significant differences (p < 0.05) in color values, both harvest stage rhizomes displayed similar color values (L*, a*, b*) without much variation. The lightness value (L*), signifying the object's ability to reflect or transmit light[8] was noted to be higher in harvest-stage rhizomes, ranging between 47.72 and 48.35. Color values a* and b* for both harvest-stage rhizomes fell within the range of 11.12 to 14.03 and 31.56 to 40.23, respectively. Positive values for color value a* indicate a reddish hue which is consistent with the present findings, as turmeric typically exhibits a deep yellow-red color. The chroma value denotes the level of color saturation and is directly proportional to the color's intensity (L*), while the hue angle determines the true color of food samples[6]. The average values of chroma and hue angle were computed as 38.77 and 70.91°, respectively. By visual inspection, fresh turmeric rhizomes exhibited a brilliant golden color as their hue angle (70.91°) indicates an orange-yellow hue. Similar color values for turmeric powder and fresh rhizomes of Philippine turmeric variety were reported by De Ramos et al.[8].

Effect of harvest stage on physio-chemical attributes of turmeric rhizomes

-

The impact of the harvest stage on the physio-chemical, bioactive, gravimetric, and functional properties of turmeric rhizomes is summarised in Table 2. The harvest stage significantly (p < 0.05) influenced the physio-chemical attributes of the rhizomes. According to the results, rhizomes harvested at an earlier stage displayed a lower nutritional profile with a high moisture content of 80.81%. Similar elevated moisture values of 84.7% and 84.25% were reported by De Ramos et al.[8] & Mane et al.[2] for the Philippines' local variety and Salem variety turmeric rhizomes, respectively. The low nutritional profile observed in early harvest rhizomes may be attributed to various factors such as growth conditions, maturity, and environmental factors. Turmeric quality is influenced by many factors (field management, environment, post-harvest practices, and type of cultivar)[4]. No discernible trend or significant (p < 0.05) differences were observed among other parameters. However, the mean values for titratable acidity, TSS, fat, reducing sugars, total sugars, protein, crude fiber, and ash content of rhizomes at all stages ranged between 0.57 to 0.76, 5.0 °B to 5.5 °B, 1.03 to 1.42, 0.21% to 0.33%, 1.41% to 2.07%, 1.06% to 1.54%, 0.68 to 0.97, and 0.86% to 1.07%, respectively. These results align with the findings of Farzana & Adeyemi[16], who also reported non-significant (p < 0.05) differences in the chemical composition of different turmeric cultivars available in Maharashtra. Harvest stage rhizomes of both varieties demonstrate increased values in physio-chemical and bioactive composition, potentially indicating the optimal maturity of the rhizomes. Hailemichael & Zakir[4] also noted that rhizomes harvested within 7 to 8 months exhibited higher extraction, while those harvested at 9 to 11 months demonstrated greater physical quality parameters. Meanwhile, among both varieties, the Punjab Haldi-2 variety at the harvest stage was found to be superior in physio-chemical parameters. Among physio-chemical properties, Punjab Haldi-2 variety at harvest stage attained maximum values of fat content (1.42%), protein content (1.54%), and crude fiber (0.97 %), respectively. However, based on the results above, it can be inferred that early-harvested rhizomes yield high moisture content and total soluble solids (TSS) content (5.5 °B), thus these stage rhizomes were best suitable for extraction of juice and making of puree. The utilization of rhizomes for processing and product development has the potential to enhance the economic status of farmers, promote the consumption, development of value-added products from fresh rhizomes, and contribute to the improved health of consumers. All the physio-chemical parameter results are consistent with findings reported by Green & Mitchell[18], Mane et al.[2] & Lokhande et al.[19] across various turmeric cultivars.

Table 2. Physio-chemical, bioactive, gravimetric, and frictional properties of turmeric rhizomes.

Properties Variety parameter Early harvest Harvest Punjab Haldi-1 Punjab Haldi-2 Punjab Haldi-1 Punjab Haldi-2 Physio-chemical Moisture (%) 80.59c ± 0.18 80.81d ± 0.12 78.26b ± 0.10 78.15a ± 0.17 Titratable acidity (%) 0.70c ± 0.2 0.76d ± 0.3 0.57a ± 0.3 0.68b ± 0.1 pH 5.8d ± 0.2 5.5a ± 0.1 5.6b ± 0.2 5.7c ± 0.1 TSS (°B) 5.5d ± 0.01 5.3c ± 0.02 5.1b ± 0.01 5.0a ± 0.01 Fat (%) 1.08b ± 0.13 1.03a ± 0.10 1.26c ± 0.20 1.42d ± 0.08 Reducing sugars (%) 0.33d ± 0.01 0.31c ± 0.02 0.21a ± 0.01 0.26b ± 0.01 Total sugars (%) 2.07d ± 0.14 1.84c ± 0.06 1.41a ± 0.11 1.63b ± 0.03 Protein (%) 1.06a ± 0.01 1.17c ± 0.01 1.13b ± 0.02 1.54d ± 0.01 Crude fiber (%) 0.73b ± 0.03 0.68a ± 0.02 0.84c ± 0.12 0.97d ± 0.10 Ash (%) 0.98b ± 0.01 0.86a ± 0.02 1.07d ± 0.01 1.02c ± 0.02 Vitamin C (mg/100 g) 20.78b ± 0.12 18.49a ± 0.07 25.30c ± 0.11 22.50d ± 0.21 Bioactive Curcumin (%) 2.93a ± 0.1 3.25b ± 0.1 4.03c ± 0.1 4.52d ± 0.1 Total phenols (mg GAE/100 g) 47.34a ± 0.16 48.40b ± 0.12 51.50c ± 0.18 52.06d ± 0.11 Antioxidant activity (% inhibition) 41.02a ± 0.01 42.21b ± 0.02 45.64c ± 0.01 45.92d ± 0.01 Gravimetric Thousand seed mass (kg) 59.34a ± 1.72 61.40c ± 1.02 60.78b ± 1.18 62.90d ± 1.26 Bulk density (kg/m3) 498a ± 5.75 512b ± 4.89 526c ± 6.08 532d ± 5.10 True density (kg/m3) 994a ± 9.84 1013b ± 9.14 1036c ± 8.24 1048d ± 8.13 Porosity 49.89d ± 1.02 49.70c ± 0.87 49.21b ± 0.43 49.23a ± 0.72 Frictional Angle of repose (°) 26.71a ± 1.17 27.23b ± 1.12 27.65c ± 1.08 28.03d ± 1.29 Values are expressed as means of three replications ± standard deviation; values with different letters in superscript differ significantly (p ≤ 0.05). Effect of harvest stage on the bioactive profile of turmeric rhizomes

-

Turmeric is well known for its therapeutic properties due to the presence of the bioactive and natural phenol compound curcumin; which is light and heat sensitive and responsible for the yellow color of turmeric[20]. The results from Table 2 revealed that the harvest stage has a significant (p < 0.05) effect on the bioactive profile; early harvest rhizomes showed a low bioactive component profile. The Punjab Haldi-2 variety at the harvest stage, demonstrated elevated values in bioactive composition such as curcumin (4.52%), total phenols (52.06 mg GAE/100 g), and antioxidant activity (45.92% inhibition). The improvement in bioactive composition is primarily attributed to maturity factors of rhizomes. Green & Mitchell[18] reported similar outcomes, indicating that rhizomes harvested over 10−11 months exhibited elevated levels of moisture, oleoresin, and curcumin content, while antioxidant activity remained consistent. The current findings regarding the bioactive composition of turmeric rhizomes align with the results reported by Green & Mitchell[18] as well as Raza et al.[20].

Effect of harvest stage on gravimetric and functional properties of turmeric rhizomes

-

The summarized data in Table 2 represents gravimetric and functional properties of turmeric rhizomes. The findings revealed an increase in rhizome size and axial dimensions (length, breadth, and thickness) resulted in lower values of both bulk density and porosity, where true density values followed no change with axial dimensions because of variation in major and minor dimension values. Similar trends in bulk density, true density, and porosity were observed by Balasubramanian et al.[11] across various turmeric cultivars. The average values for bulk density ranged from 498 to 532 kg/m3, true density varied from 994 to 1,048 kg/m3, and porosity ranged from 49.21 to 49.89. Rhizomes harvested at the harvest stage demonstrated superior size and shape, resulting in elevated values of axial dimensions. Early-harvest rhizomes displayed maximum porosity, indicating more void spaces conducive to moisture absorption and weight gain during storage. In terms of frictional properties, the angle of repose was determined and whose mean values ranged from 26.71 to 27.23 in the harvest stage rhizomes, showcasing an upward trend than in the early harvest stage rhizomes. Farzana & Adeyemi[16] reported a similar increase in the angle of repose for PTS-10 variety turmeric rhizomes from Grade 1 to Grade 3.

Physical, functional, bioactive, and optical properties of turmeric powder

-

Among the studied varieties and harvest stages, Punjab Haldi-2 at the harvest stage possessed good characteristics in terms of proximate composition and bioactive properties. Consequently, this variety was selected for further processing into turmeric powder using two different time-temperature combination methods i.e. blanching (70 °C for 15 and 30 min) and pressure cooking (121 °C for 15 and 30 min at 15 psi). Among the physical properties of turmeric powder, the average mean values of bulk density, true density, and porosity for turmeric powder ranged from 0.73 to 0.81 g/cm3, 1.28 to 1.51 g/cm3, and 0.42 to 0.47, respectively. Functional properties like dispersibility, water absorption capacity, and solubility did not exhibit a consistent trend, while swelling power increased with variation in processing methods. The processing conditions (pressure cooking-30 min) significantly (p < 0.05) increased values of bulk density, water absorption capacity, and swelling power, while decreasing the dispersibility and solubility of turmeric powders. These changes were dependent on the particle size of the powder and its moisture content; in general powders tend to absorb more moisture during processing, resulting in higher bulk density values. Blanching conditions improved dispersibility and solubility of powders. Tamuno[13] also noted that processing methods (cooking/blanching, and drying) at high temperatures could reduce the solubility of powders. In earlier studies, it has been reported that the concentration of curcumin content in turmeric rhizomes is significantly affected during boiling, pressure cooking, and drying, resulting in losses of up to 27%−53%[20]. Turmeric powder obtained by blanching-15 min resulted in maximum values of curcumin content (4.52%), total phenols (52.06 mg GAE/100 g) and antioxidant activity (45.92% inhibition). In this study, rhizomes processed by pressure cooking for 30 min showed a greater loss of curcumin (Table 3).

Table 3. Physical, functional, bioactive and optical properties of turmeric powder.

Properties Parameter Punjab Haldi -2 (harvest) B-15 min B-30 min PC-15 min PC-30 min Physical Bulk density (g/cm3) 0.73a ± 0.01 0.76c ± 0.01 0.74b ± 0.02 0.81d ± 0.02 True density (g/cm3) 1.28a ± 0.01 1.34bc ± 0.01 1.36c ± 0.01 1.51d ± 0.01 Porosity 0.42ba ± 0.01 0.43b ± 0.01 0.46c ± 0.05 0.47d ± 0.02 Functional Dispersibility (%) 46d ± 0.01 44c ± 0.02 42b ± 0.01 40a ± 0.01 Water absorption capacity (mL/g) 4.14a ± 0.03 4.20b ± 0.09 4.27c ± 0.11 4.45d ± 0.07 Solubility (%) 3.53b ± 0.17 3.93d ± 0.14 3.90dc ± 0.17 2.90a ± 0.11 Swelling power (g/g) 5.93a ± 0.01 6.54b ± 0.01 7.38c ± 0.01 7.82d ± 0.03 Bioactive Curcumin content (%) 4.52d ± 0.1 4.38b ± 0.2 4.48c ± 0.2 4.26a ± 0.3 Total phenols (mg GAE/100 g) 52.06d ± 0.09 50.02b ± 0.11 51.64c ± 0.26 48.20a ± 0.14 Antioxidant activity (% of inhibition) 45.92d ± 0.01 44.20c ± 0.02 45.84b ± 0.02 43.89a ± 0.01 Optical L* 64.27d ± 0.52 63.71c ± 0.64 60.35b ± 1.07 59.41a ± 0.41 a* 18.45d ± 0.20 18.20c ± 0.45 17.75b ± 0.74 16.77a ± 0.51 b* 45.25d ± 0.72 43.03c ± 0.35 38.66b ± 0.51 36.38a ± 0.34 Chroma 49.52d ± 0.27 46.71c ± 0.23 42.53b ± 0.40 40.05a ± 0.59 Hue (°) 67.81d ± 0.36 67.07c ± 0.70 65.33b ± 0.63 65.25a ± 0.40 B: Blanching, PC: Pressure cooking; values are expressed as means of three replications ± standard deviation; values with different letters in superscript differ significantly (p ≤ 0.05). The turmeric powders exhibited water absorption capacity and swelling power ranging from 4.14 to 4.45 mL/g and 5.93 to 7.82 g/g, respectively, with the highest values observed in the pressure-cooked sample and the lowest in the blanched sample. The increased water absorption capacity and swelling power are likely due to the gelatinization of starch and protein denaturation during the cooking process, as noted by Tamuno[13]. Obatolu et al.[21] also observed that an extended cooking time led to protein denaturation in yam bean and turmeric powder, resulting in increased water absorption capacity.

Dispersibility ranged from 46% to 44% in the blanched sample and 40% to 42% in the pressure-cooked sample. Higher dispersibility values indicate superior reconstitution properties of turmeric powder, reflecting its ability to disperse and integrate with water molecules[13].

In terms of the optical properties of turmeric powder (Fig. 4), the average values of L*, a*, b* ranged from 59.41 to 64.27, 16.77 to 18.45, and 36.38 to 45.25, respectively. The average values of chroma and hue were computed as 40.05° to 49.52° and 65.25° to 67.81°, respectively. The color values of the powders were significantly (p < 0.05) influenced by the processing methods. Blanching resulted in improved color properties of powders in comparison to pressure cooking. This enhancement is attributed to the blanching process which has the ability to inhibit both enzymatic and non-enzymatic reactions. Similar findings were reported by Tamuno[13] & Ngoma et al.[22], who observed that the blanching process enhanced color values in turmeric and sweet potatoes.

-

The stage of harvest significantly (p < 0.05) affected the quality parameters of turmeric rhizomes. Increase in harvest period (9 to 12 months) improved the physical attributes and boosted the nutritional profile and bioactive composition of rhizomes. At the harvest stage, turmeric rhizomes were fully matured with good size, weight, color, and physio-chemical composition resulting in higher values of engineering properties (geometric and gravimetric). The harvest stage didn't show any significant effect on the optical properties of rhizomes. Rhizomes harvested at the early stage displayed a lower nutritional profile characterized by elevated moisture content. The heightened moisture values depict earlier spoilage, and mislead the appropriate rhizome weight, size, and physical characteristics of the rhizomes, thus these rhizomes are considered for immediate processing to production of juices, pastes, and puree. Among both varieties and harvest stages, Punjab Haldi-2 variety turmeric at the harvest stage exhibited superior engineering, physio-chemical, and bioactive properties. Evaluating these properties will be helpful in the rapid mechanisation process of processing conditions like cleaning, bulk loading, weighing, shifting, grading, transporting, packaging, and storage. Meanwhile turmeric powder obtained by blanching at 70 °C for 15 min resulted in better optical properties and a higher bioactive profile, while rhizomes processed by pressure cooking at 30 min drastically lowered and showed improved functional properties like water absorption capacity and swelling power. This comprehensive understanding will contribute to minimising harvest losses and aid in the design of specialized equipment, including feed hoppers, storage structures, material handling equipment, and packaging machinery. Overall, the Punjab Haldi-2 variety harvested at the harvest stage after 11–12 months showed better overall properties and thus can recommended for production and processing.

-

The authors confirm contribution to the paper as follows: methodology, validation, investigation, data curation, writing - original draft: Basha SJ; software, formal analysis, funding acquisition, supervision, review and editing: Kaur K; methodology, review & editing: Kaur P; software, investigation, formal analysis: Singh TP. All authors reviewed the results and approved the final version of the manuscript.

-

Data sharing not applicable to this article as no datasets were generated or analyzed during the current study.

Laboratory facilities provided by the Head, Department of Food Science and Technology, Punjab Agricultural University, Ludhiana, India to execute the present work are duly acknowledged.

-

The authors declare that they have no conflict of interest.

- Copyright: © 2024 by the author(s). Published by Maximum Academic Press, Fayetteville, GA. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Basha SJ, Kaur K, Kaur P, Singh TP. 2024. Effect of harvest stage on engineering, physio-chemical, bioactive and drying properties of turmeric. Technology in Horticulture 4: e022 doi: 10.48130/tihort-0024-0019

Effect of harvest stage on engineering, physio-chemical, bioactive and drying properties of turmeric

- Received: 23 May 2024

- Revised: 16 August 2024

- Accepted: 26 August 2024

- Published online: 12 September 2024

Abstract: Fresh turmeric rhizomes (var. Punjab Haldi-1 and Punjab Haldi-2) harvested at the early stage and harvest stage were evaluated for engineering, physio-chemical, and bioactive properties. Determination of engineering properties of agricultural produce (turmeric) plays a significant role in designing machines for processing, grading, separation, storage, and packaging systems. The stage of harvest significantly affected the engineering, bioactive, and physio-chemical properties of fresh turmeric rhizomes. Early harvest rhizomes of both varieties were irregular in growth, immature, and poor in nutritional value as compared to the harvest stage. Geometric properties increased with variation in the size and moisture content of rhizomes. Gravimetric and frictional properties of rhizomes at the harvest stage resulted in higher values which play key roles in bulk packaging, transport, and storage. The harvest stage didn't show any significant effect on optical properties. Rhizomes of Punjab Haldi-2 variety at the harvest stage resulted in superior properties, with high curcumin (4.52%), total phenols (52.06 mg GAE/100 g), and antioxidant activity (45.92% inhibition). Processing conditions (blanching and pressure cooking) altered the physical, functional and bioactive profile of turmeric powder. Turmeric powder processed by blanching at 70 °C for 15 min exhibited better optical properties and bioactive composition with minimal loss of curcumin and total phenols rather than pressure cooking. The functional and physical properties of turmeric powder improved on processing at higher temperatures for a longer time. Thus, the knowledge gained in this study will facilitate grading, transporting, packaging, and sorting, help in the reduction of harvest losses, and designing of equipment for turmeric processing.

-

Key words:

- Aspect ratio /

- Geometric property /

- Gravimetric property /

- Frictional property /

- Porosity