-

A near miss is an unexpected, dangerous, or problematic situation that suddenly occurs during daily work or activities in (inorganic) chemistry laboratories in universities. Various factors, including carelessness and ignorance, cause these problems. Accidents and other problems can occur if workers ignore procedures or do not receive proper training and instructions during work. Faulty equipment can also cause near misses, and unexpected problems can occur because of poor maintenance or aging equipment. In addition, deficiencies in work processes and procedures can cause near misses. Lack of appropriate confirmation procedures or excessive worker workloads can increase the risk of accidents and problems[1,2].

Several measures are necessary to prevent near misses. First, it is important to provide sufficient training and education to employees. Employees trained in proper work procedures and safety regulations can reduce near misses[3]. Additionally, they must enhance their work environments and minimize risks by conducting routine safety inspections and proactively identifying and fixing equipment and system issues. Moreover, increasing employee safety awareness and ensuring the entire team is alert to danger is important. Near misses can cause unexpected problems; however, taking appropriate countermeasures and precautions can minimize accidents and trouble.

The causes of near misses are (1) lack of preparation, (2) physical and mental fatigue, (3) lack of organization of the experimental environment, and (4) inadequate management during normal times[4].

(1) Regarding the lack of preparation, it is necessary to check the MSDS in advance to determine what kind of reaction will occur when using the reagent. Additionally, when experimenting, if the order of connecting and operating the equipment is incorrect, something dangerous may occur. One must also know what to do when dangerous situations arise. For example, the temperature of the hot water bath and the position of the flask in the hot water should be kept constant to avoid bumping into the evaporator. In addition, moisture may enter the vacuum line and expand rapidly, causing the glass tube to burst. This can be avoided by researching and following the correct procedures in advance. Regarding waste liquids, when acid and cyanide waste liquids are mixed, highly toxic cyanide gas is generated. This can be prevented by checking the properties of the waste liquid and knowing the method of disposing and storing it correctly.

(2) With regard to physical and mental fatigue, it is necessary to rest sufficiently before conducting experiments under good conditions. Even if you do not have time, it is best to take a break before doing so. When you are physically and mentally fatigued, your attentiveness decreases, and you overlook things or make simple mistakes that you ordinarily do not notice.

(3) Regarding the lack of organization in the experimental environment, equipment, and reagents used in experiments may be placed too close together or in an undetermined location, resulting in damage due to incorrect operation or falling equipment. For example, when moving or dropping reagents with a Pasteur pipette, the pipette may hit something and the tip may break and fly off. In addition, there are other cases where a burette or the like is intended to be fixed with a clamp. However, the scissors are weak and fall, causing damage to the tip. This can be prevented by organizing the surrounding environment during the operation, deciding where to place the equipment according to the procedure, and moving it away from the operational range when finished.

(4) Regarding deficiencies in management during normal times, issues such as how glassware is placed and the condition of the stored reagents need to be constantly monitored. For example, a metal reagent shelf rusted because the plastic bottles containing the reagents used for disinfection were damaged, and the reagents leaked. This can be prevented by carefully checking the bottle regularly and immediately replacing it if damaged. If you place glassware roughly when you put it away, it may collide with other glassware and break, or it may collapse and break when you take it out the next time.

Laboratory safety requires management of five elements: machinery, materials, laws, and environment. However, in the one-year experience at a university chemistry laboratory (there were some elements that were mostly safe), the focus in this article was on chemical substance management, equipment management, and personnel management.

-

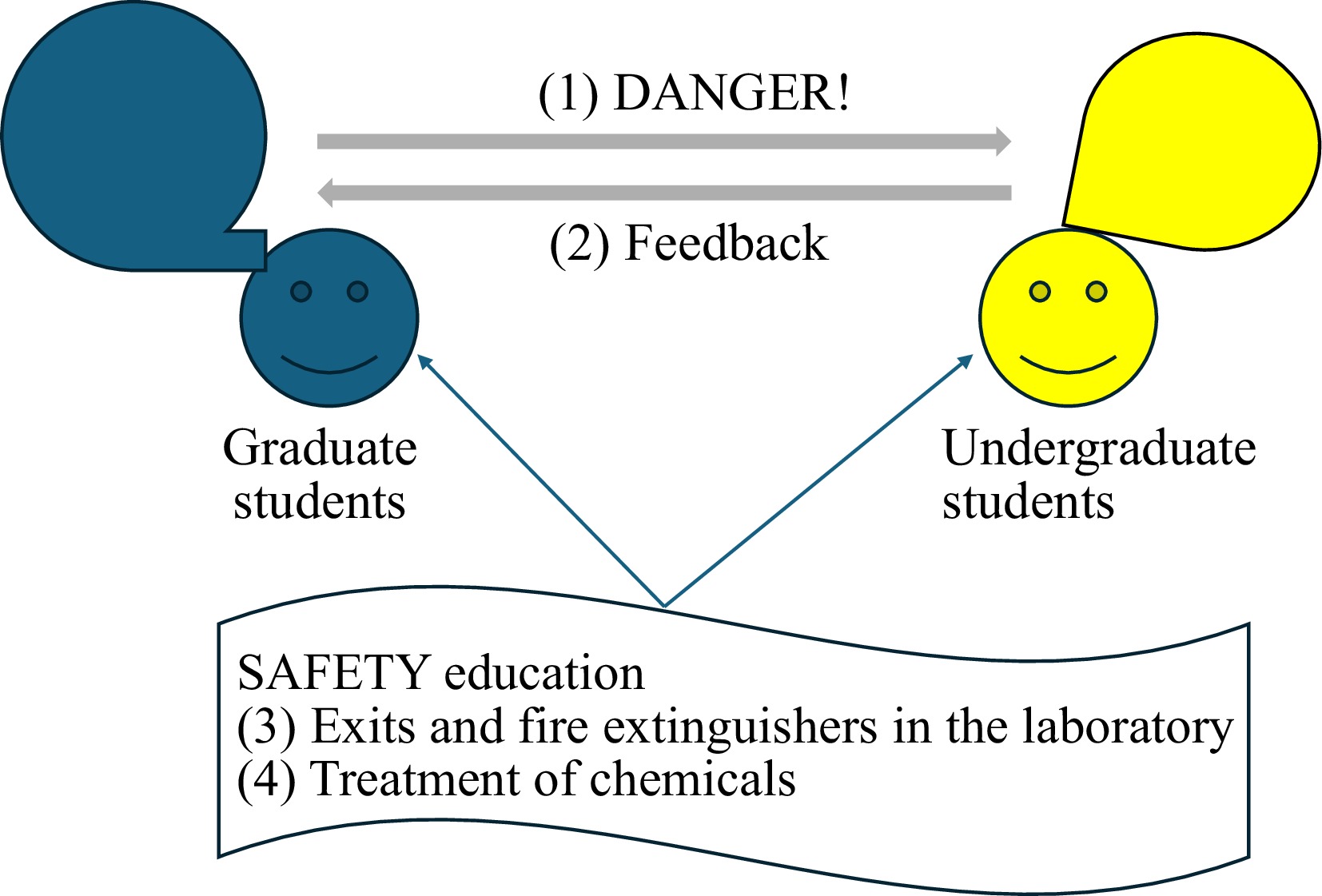

A near miss is realizing a danger or problem before it leads to a severe accident[5,6]. This is an important concept for ensuring safe work environments. Near misses can occur during laboratory experiments in an inorganic chemistry at a university. Specific examples and countermeasures in our laboratory for 2023 (comments from master graduate students [GS] with laboratory experience and undergraduate students [US] with no experience) are provided below (Fig. 1).

Laboratory safety education in the author's laboratory (as part of April 13, 2024) 'Information sharing and countermeasure reports (1) and (2) on last year's near-miss incidents' were imposed.

(1) During the academic year 2023, we heard about cases where an accident was likely to occur during an experiment (six graduate students in the academic year 2024).

(2) All the members of this laboratory shared information on effective measures and lessons learned (10 undergraduate students in 2024), and once again shared the information with everyone to alert them.

(3) In addition, information on exits in the laboratory, fire extinguishers, disaster prevention equipment around the laboratory, and safety was also made known.

(4) In addition, all members confirmed the storage status of chemicals and reagents in the laboratory.

Here, the authors will discuss a case study of a university inorganic chemistry laboratory to which the author belongs and directs. Since the laboratory majors in inorganic and coordination chemistry, they will conduct organic synthesis of ligands, inorganic synthesis of metal complexes, crystallization using organic solvents, spectroscopic and electrochemical measurements of solutions, X-ray crystal structure analysis, theoretical calculations, etc. It differs from the organic synthesis laboratory in that, there is less use of organic solvents, heated stirring reactions, and analyzes specific organic substances, and differs from the physical analytical chemistry laboratory in that the use of measuring equipment is limited and involves synthesis experiments.

-

The (nine) main contents of the interview survey on dangerous experiences described in the method section and suggestions for countermeasures will be described below as 'results'.

The gas generated when a highly volatile acid was added to a stirring solution was sucked out

-

[GS] There was a [US]’s comment on experimenting within the draft. There have been such cases in the past, not in fume hoods but in laboratory shelf spaces. The characteristics of highly volatile acids must be understood before they can be handled.

[US] Work in a well-ventilated area.

[US] Operate within a draft.

[US] If highly volatile hazardous substances are added, conducting the experiment in a fume hood is preferable. In addition, be careful not to inhale highly concentrated gas by covering it with a watch glass, and if you do not have one, use a beaker, gloved hands, or fingers to keep the gas away from your face.

[US] On days (or weeks) when you will be handling dangerous chemicals or fire, take measures such as emailing everyone on the day or at the beginning of the week. It is possible to immediately understand which reagents are being used and the risks in an emergency.

When I was transferring a highly dangerous solution into a graduated cylinder using a Pasteur pipette, the tip of the Pasteur broke, and I almost got splashed with the liquid. In addition, the tip of the Pasteur pipette is placed upwards, so it is dangerous if it accidentally hits and falls

-

[GS] There was a comment about wearing white coats, safety glasses, and gloves. They must be worn when working with potentially hazardous solutions because exposure to solutions on clothing poses additional risks.

[GS] Some commented that the Pasteur pipette should be placed with the tip facing down or that you can put the Pasteur pipette in a container taller than the tip of the Pasteur pipette to prevent it from dropping or getting stuck. Also, wash the used pipette immediately. It is important not to leave the path unattended after use.

[US] If the risk is high, operate in a fume hood and wear safety glasses and gloves.

[US] Never work near your face, always wear a lab coat, and take precautions, such as washing it off immediately.

[US] When transferring a liquid, the distance that the Pasteur pipette must move is shortened by bringing the container containing the solution closer to the opening of the graduated cylinder. Alternatively, to prepare a volume of less than one drop by bringing the tip of the Pasteur pipette close to the inner wall of the graduated cylinder, and place your hand against the mouth of the graduated cylinder. This prevents the Pasteur pipette from accidentally moving or breaking.

[US] Maintain the pipette tip facing downward as far as possible. Wash the used Pasteur pipettes as soon as possible, return them to the original box, and dispose of the unusable ones.

[US] If it is in use, place it on a stand, immediately wash it, and store it in a place where it will not be touched accidentally, such as on a shelf.

[US] Place the Pasteur pipette so that the tip faces downward.

[US] Place the tip of a Pasteur pipette in a beaker.

[US] Placing the Pasteur pipette in a container taller than the tip of the Pasteur pipette prevents it from getting caught. It can also be made more stable by placing the container carrying the Pasteur pipette close to the wall and gluing the bottom of the container to the desk.

[US] When working, place the equipment as far inwards as possible from the shoulder to prevent objects from falling on the tabletop.

When I swept the chromatography adsorbent, it flew up and almost hit my eye

-

[GS] There were comments about the use of safety glasses or a vacuum cleaner when the product contains harmful substances. Chromatography adsorbents may have a negative effect on the human body; therefore, protective goggles and masks must be worn.

[US] First, be sure that safety glasses are worn and that the adsorbent is removed before cleaning.

[US] Wear safety glasses and masks after exposure to dust.

[US] It is important that you and those around you wear safety glasses.

[US] Wear safety glasses to protect your eyes.

[US] Wearing masks and goggle-type safety glasses (with rubber frames) is recommended when handling large quantities of hazardous powdered substances. Furthermore, using a vacuum cleaner rather than a broom is desirable to clean the chromatography adsorbents.

How to handle glassware: The glassware broke when it was stored, and pieces of the glassware were left in the tray

-

[GS] Perform inspection. Comments included wearing protective gloves. If broken glassware is left unattended, remove it, put on protective gloves, and dispose of it in a trash bin designated for the equipment.

[US] When storing, leave plenty of room in the storage space and dispose of any broken glassware immediately.

[US] Be sure to clean any broken glass, as it is dangerous and can cause cuts to your hands. In addition, wear gloves when handling them to avoid cutting your hands.

[US] Do not leave broken glass unattended; clean all broken glass.

[US] Be sure to perform inspections. Rubber gloves are always worn when handling glassware.

[US] To prevent glassware from being damaged during storage, it is a good idea to line the storage case with a bubble wrap or paper towel. In addition, when removing glassware, they should be aware of the possibility of breakage. It is advisable to wear gloves when handling the glassware.

When I was washing a large amount of glassware at once, I dropped it, and it broke

-

[GS] The glassware should be washed carefully, and the number of pieces should be reduced. I think you should wash glassware in several batches.

[US] Glassware should be washed in batches to make it easier to carry. In addition, hold each item in your hand and wash carefully.

[US] If you try to carry a large amount or put it together, it may cause an accident, so divide it into parts you can safely carry.

[US] Handle each piece of glassware carefully. Protect your feet with shoes.

[US] First, when you realize there is a large amount, you should judge the danger and reduce the amount of glassware.

The stirrer was poorly used

-

[GS] A stirring bar may have been dropped on the floor or thrown away by mistake. If a stirring bar is included in the equipment, a magnet should be attached to the bottom of the beaker or flask for cleaning or disposing of the solution.

[US] When putting a stirrer into a beaker, put it in before adding the liquid so that the liquid does not splash. Also, tilt the beaker to avoid impacting the glass and place it as quietly as possible.

[US] Glassware may get damaged while handling the stirrer, so handle it carefully.

[US] When using a stirrer, do not drop it directly into the flask, but instead place it along the wall of the flask.

[US] After using the stirrer, it is necessary to soak it in a liquid to prevent the substance from sticking. In addition, to prevent the stirrer from dropping or accidentally being thrown away, make sure to stick it to a designated place or dip it in a liquid.

[US] If you have any concerns about the experimental procedure before proceeding, check it immediately so that serious accidents can be prevented.

I left the lights on while going home

-

[GS] There was a comment on turning off lights. If several individuals are present in the laboratory, they should be confirmed. You must turn the lights off if you are alone in the laboratory.

[US] Electricity in a room is safer and better than keeping it dark during experiments; however, lights that are not in use should be turned off for the sake of the environment. In addition, in the case of electricity in laboratory equipment, there is a risk that heat may build up or that you may touch it without knowing that it is on; therefore, you should turn it off frequently when it is not in use.

[US] Turn off lights when you finish using them.

[US] Glow-starter-type fluorescent lamps consume more power and the life of the glow lamp increases as they are turned on; therefore, turning them off frequently during the day is considered unnecessary. Those who remain until the end of the night or on holiday must thoroughly check the checklist before returning home.

I tripped over the oil bath cord and almost dropped the equipment

-

[GS] There was a comment about extending the power cord of the oil bath with a tassel wire and fixing it to the floor with duct tape. I think you should use a power cord as close as possible to the oil bath.

[US] Watch the steps. If possible, plug the oil bath cord into an outlet on a desk in the laboratory so that movement is not obstructed.

[US] Dust may cause fire or unintentional electrical leakage, so turn off the power and unplug the cord if it is unnecessary.

[US] Cords must be strategically placed so that they are not placed in aisles or caught.

[US] The power cord of the oil bath should be extended with a cable and secured to the floor with duct tape to prevent it from being caught.

[US] When installing power cords and extension cords on the floor, it is necessary to minimize the risk of the experimenter's legs becoming tangled using plastic wrap or curing tape from the floor to the legs of the laboratory table.

[US] Do not place reagents or equipment used in the experiment at the back of the workspace. This prevents you from knocking over objects in the front when trying to reach objects at the back or from encountering hot objects when heating.

The passageways in the laboratory are narrow, so if you do not speak to someone, you may end up bumping into someone

-

[GS] There were comments about taking a detour to an empty aisle or putting the necessary items in a tray and bringing them to the lab table before the experiment. When the corridors of a laboratory are crowded, it is necessary to gather everything required before starting an experiment.

[US] Speak to others and think about shelf placement to make the aisles as wide as possible.

[US] If possible, remove obstructions to passageways and change the layout to allow quick and safe movements during emergencies.

[US] Another person may be using dangerous chemicals, so call out to them before passing behind.

[US] When passing each other in aisles, say hello to each other and be careful not to bump into or overflow with potentially dangerous objects. In addition, the amount of movement could be reduced by placing the necessary items in a tray and bringing them to the laboratory bench before the experiment. Furthermore, experimenters should operate the installed equipment at desks near the equipment.

[US] When passing behind a worker, say, 'I'll pass behind you'. Accidental contact can be avoided even if the aisle is not narrow.

-

The results collected dangerous experiences and countermeasures. Four of the measures considered important by the students were supplemented with a supplementary report that investigated them in more detail. For this reason, the content of the supplementary report on important items is included in the discussion. Although the items are limited and the degree to which the results are considered is a little weak, at least we can infer the depth of graduate students' understanding and knowledge of safety issues.

Toxic gas: consciousness if it is a gas cylinder[7]

-

Chemicals are often used in experiments, but their appearance or smell cannot be identified in many, and there is a risk of using a chemical different from the one planned. This could cause a reaction different to what is expected, resulting in a near-miss situation where toxic gas is generated, and you will have to evacuate in haste. One possible solution to this problem is to label all chemicals accurately so that they can be identified. This includes any glassware, such as beakers or flasks, that you are using. In addition, removing all the labels after the experiment is completed means there is no possibility of confusion the next time the experiment is performed.

However, when handling gas cylinders in a laboratory, incorrect handling of the type of gas can damage the surrounding area, causing injury or fire. Therefore, it is necessary to follow safe usage methods for gas cylinders.

High-pressure gas cylinders contain toxic, flammable, inert, and combustion-supporting gases. In Japan, oxygen is black, hydrogen is red, nitrogen is grey, carbon dioxide is green, and ammonia is white, methane in ash-colored cylinders, chlorine in yellow, acetylene in brown, argon in ash, and propane in ash-colored cylinders.

A pressure regulator is attached to the gas cylinder to use the gas. However, choosing a pressure regulator depending on the gas type is necessary. Please note that high-concentration oxygen gas can easily generate heat and catch fire owing to oil; therefore, it should be used without oil. With carbon dioxide and methane gases, depressurization causes an extreme temperature drop, which may cause impurities to precipitate and prevent normal pressure adjustment. Hydrogen gas is prone to high temperatures and vibrations in pressure regulators. Ammonia and chlorine gas easily dissolve in water and react with water in the air, corroding equipment and preventing normal pressure adjustment.

Gas cylinders contain information about the container and the filled gas. When some of them contained the word 'oxygen' in the manufacturer's name, there were cases in which people mistakenly thought the gas in the cylinder was oxygen. Accidents caused by incorrect gas cylinders include the leakage of toxic gases and fires caused by incorrect selection of pressure regulators. Gas cylinder errors can be prevented by checking the color of the cylinder, having two or more people check the gas cylinder, and providing safety education. We believe that these methods can reduce human errors. Safety education requires correct knowledge about selecting and using pressure regulators; therefore, it is necessary to acquire this knowledge through regular studies. It is also important to learn how to reduce damage in the laboratory in the event of an accident involving a gas cylinder.

Chromatography adsorbents[8]

-

Chromatography is often used in experiments to separate substances. However, because various substances are used as adsorbents, there are some questions regarding the effects of the adsorbents on the human body.

There are two types of adsorption in chromatography: physical adsorption (mainly through intermolecular forces) and chemical adsorption (mainly through hydrogen, coordination, and covalent bonds). This study focused on activated carbon and silica gel adsorbents from the former and calcium oxide from the latter.

Activated carbon poses no risk of exposure and is a relatively easy-to-use adsorbent. However, because it generates toxic carbon monoxide and carbon dioxide during thermal decomposition, it cannot be used at high temperatures, in direct sunlight, or with strong oxidizing agents. Therefore, it is necessary to be careful about these issues.

Similar to activated carbon, silica gel is often used as a physical adsorbent; however, it may be carcinogenic and harmful to aquatic environments. In addition, blue indicates the conditions to be avoided, including high temperature, direct sunlight, and humidity. The dangerous and harmful decomposition products include silicon-derived compounds, metal oxides, and halides.

As mentioned above, calcium oxide is used as a chemical adsorbent and as a heating agent for lunch boxes. However, it can cause skin irritation, serious eye damage, and organ damage (respiratory system) through prolonged or repeated exposure. It is basic in nature and reacts with water. Avoidable conditions include high temperatures, direct sunlight, moisture, and water. Incompatible materials include acidic substances, water, hazardous decomposition products, and metal oxides.

When examining these three oxidizing agents, it was found that, according to their chemical properties, adsorbents that employ chemical adsorption have contraindications and decomposition products in contrast to adsorbents that utilize physical adsorption. Charcoal is also a common ingredient in activated charcoal, which is made from charcoal used in barbecues.

Many of these precautions can be predicted based on chemical knowledge and are useful when implementing preventive measures; however, this information may not be utilized and may hinder fire-extinguishing operations. Therefore, it is important to understand these chemical findings and proceed with the experiments calmly.

Organizing glassware[9]

-

The closest near-miss experience I had ever experienced was when I was diluting or synthesizing various solutions in several chemical-filled flasks on my desk, and my sleeve happened to hit the flasks accidentally. Once the flask was moved, it almost dropped off.

In the experiment, approximately 10 solutions were prepared, the absorbance of each solution was measured, and the relationship between the differences in concentration and absorbance was considered.

Therefore, many flasks were inevitably scattered on the desk during the experiment. However, during the experiment, all the flasks were within easy reach; therefore, the flasks were thought to hit the sleeve. In addition, another participant alerted me that the flask was about to fall over, and by asking someone to hold the flask, the flask did not fall over, and the medicine inside spilled out.

As a countermeasure, we believe that it is important to place items that can break if they fall at the center of the desk where they cannot be touched, regardless of whether they contain chemicals. In addition, when conducting experiments, it should be ensured that the experiments are performed with collaborators rather than alone so that it can be mutually confirmed whether there are any risks. In addition, before experimenting, confirm with your collaborators the risks that may arise during the experiment and conduct the experiment safely by paying attention to those points.

Of course, improvements should be made to the layout of laboratories where many people are crowded and near dangerous materials, as well as the walking lines during work. In contrast, conducting experiments alone in a laboratory (such as at night) is prohibited, even if there are few people present.

Static electricity (which can lead to fire)[10]

-

Near misses may also have been caused by static electricity. When handling liquids in the laboratory, static electricity may be generated, and the liquid may splatter. In particular, when using highly volatile chemicals, such as organic solvents, there is a risk of fire or explosion caused by static electricity. Possible countermeasures to this problem include using appropriate protective equipment, such as rubber gloves, to reduce the generation of static electricity and maintaining appropriate humidity in the laboratory to prevent the air from drying out. In addition, electrostatic shoes can help to discharge static electricity.

-

In conclusion, predicting near misses that may occur during experiments and taking appropriate countermeasures against them are essential for the safety and efficient progress of the experiments. A sophisticated understanding of the risks in the experimental environment and adequate precautions based on this understanding is the basis for ensuring the safety and sustainability of experimental work. Furthermore, appropriate safety training and regular reviews of safety measures are essential to maintain the safety of the experimental work. By maintaining a safe experimental environment and prioritizing the health and safety of the experimenters, we can maximize the results of our experiments and contribute to research progress. Therefore, we believe that predicting near misses during experiments and taking appropriate countermeasures are essential to ensure safety, which is the foundation of our research[11].

In addition, various near misses in experiments include risks related to the safety of the experimental equipment, risks due to human factors, and even risks related to handling waste. Regarding the safety of experimental equipment, improper handling may cause equipment failure or accidents. Human factors in this work are also important and can lead to errors and accidents owing to carelessness and fatigue. Furthermore, following the appropriate disposal methods and treatment procedures when handling waste is important. To minimize these risks, it is essential to improve the training and awareness of experimenters and the entire research team, as described below.

· Maintenance of workspace: Reduce the risk of falling equipment or falling by always keeping the workspace and aisles clean.

Be aware of where the equipment and chemicals are placed, and be sure to avoid confusion when others use them.

· Personal precautions: When conducting experiments, wear a lab coat and gloves to prevent chemicals from coming into contact with your skin, and wear goggles and glasses to protect your eyes.

In addition, periodic equipment inspection and replacement should be established to ensure safety.

Do not force yourself to conduct experiments if you do not feel well; the same applies if you do not feel mentally well.

· Emergency contact: When an incident occurs that cannot be solved by oneself, and there is no one in the laboratory, or it is impossible to solve it by the laboratory personnel.

In this way, the two leading causes of near misses are 'inattention' and 'lack of awareness'. The former can be avoided if one approaches it calmly, while the latter can be avoided by preparing and researching before working on an experiment. Although it may seem simple, you should always check what you're handling beforehand, return any equipment or chemicals you use to their rightful location, and alert those nearby if you're using dangerous chemicals. By considering this basic safety measure while conducting your research activities, you can prevent accidents from occurring, and if they do occur, you can respond quickly.

However, if only a few people were aware of this, the laboratory would not function. In laboratories, it is common for different experiments to be conducted simultaneously; in some cases, conducting them in a small space may be necessary. Under such circumstances, a person's carelessness or lack of awareness may affect the entire laboratory. In addition, people often have a high level of awareness when they first join the laboratory or after they have had the opportunity to think about near misses. However, as time passes, their level of awareness decreases. There must be a common understanding within the laboratory that dangers can be avoided by conducting research activities appropriately and that any perceived danger must be dealt with immediately.

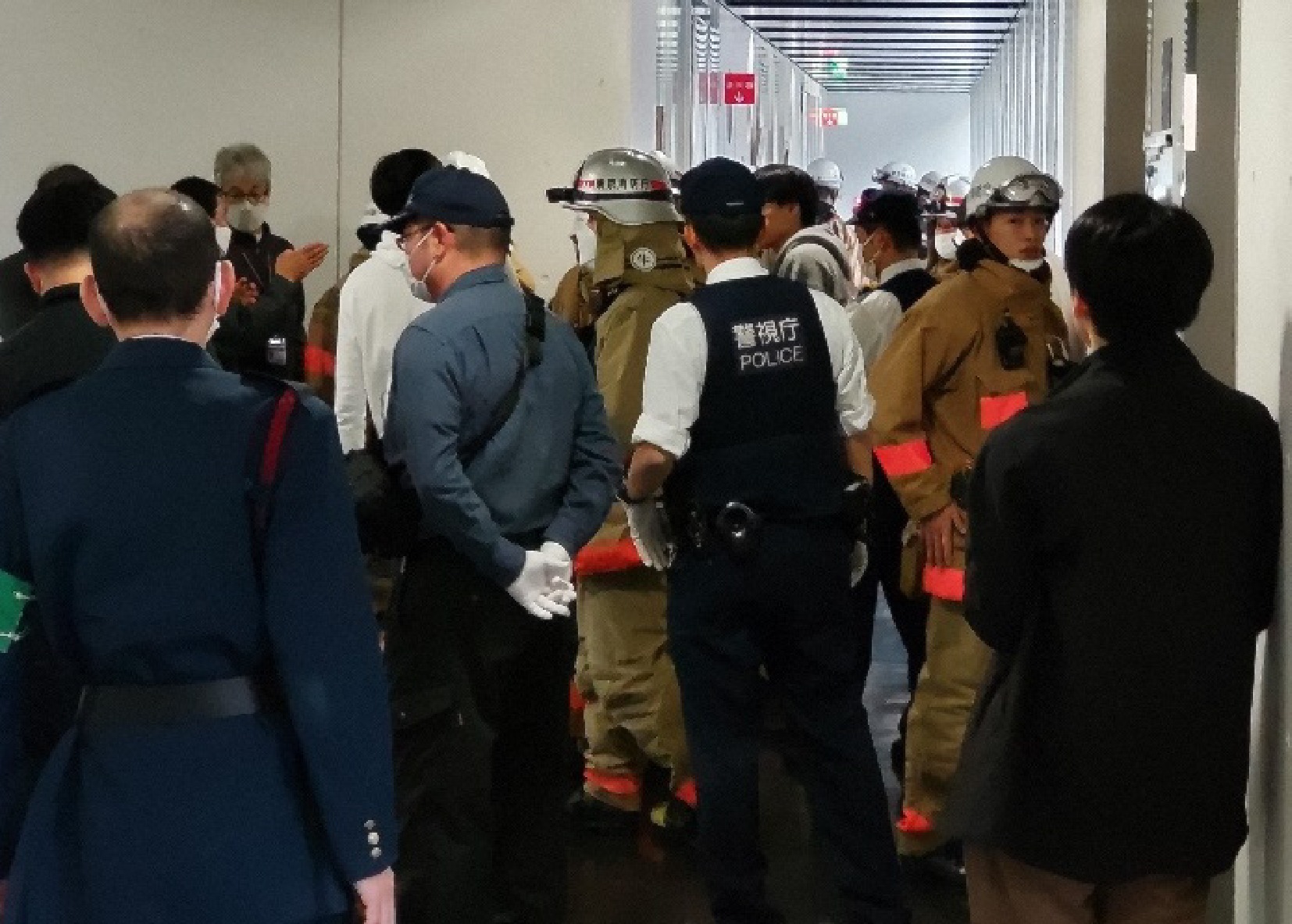

Although it is not possible to compare the emergency response abilities of undergraduate and graduate students, it seems to be a fact that there is a difference in the knowledge of undergraduate students with no laboratory experience and graduate students with several years of experience. This is because (to prevent accidents involving inexperienced undergraduate students) universities have established rules that allow different actions depending on the number of years of experience. The authors believe that this finding will serve as a guideline for safety education. In the unfortunate event that a small fire occurred in a certain laboratory (Fig. 2), graduate students were able to quickly extinguish the fire and notify the fire department. However, university regulations prohibit undergraduate students from conducting experiments during times when there are fewer people.

Figure 2.

Verification work by fire department, police, and related parties after a small-scale fire in a laboratory (January 2024).

Presently, the author is focusing on the university’s inorganic chemistry laboratory near misses. There must be a big difference in the proficiency level of experimenters, work content, and scale between universities and companies. However, as research activities frequently require the use of equipment and devices outside of the lab, it is important to be mindful of potential risks in any situation. If you avoid a near miss, you might be able to learn from it for yourself, but if not, you need to approach your research activities knowing that it could result in major accidents and damage.

-

The authors confirm contribution to the paper as follows: study conception and design, draft manuscript preparation: Akitsu T; Akitsu T and Nakane D reviewed the results and approved the final version of the manuscript.

-

All data generated or analyzed during this study are included in this published article.

-

The authors would like to thank all 2024 students of the Akitsu Laboratory, Department of Chemistry, Faculty of Science, Tokyo University of Science, Tokyo, Japan.

-

The authors declare that they have no conflict of interest.

- Copyright: © 2024 by the author(s). Published by Maximum Academic Press on behalf of Nanjing Tech University. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Akitsu T, Nakane D. 2024. Cases of near misses in chemical laboratories of universities and their countermeasures. Emergency Management Science and Technology 4: e019 doi: 10.48130/emst-0024-0019

Cases of near misses in chemical laboratories of universities and their countermeasures

- Received: 28 June 2024

- Revised: 27 August 2024

- Accepted: 13 September 2024

- Published online: 10 October 2024

Abstract: In this study, interviews with undergraduate and graduate students about incidents that did not result in an accident but felt dangerous (so-called near miss incidents) that occurred in the chemical laboratory at the university (to which the author belongs) in 2023 were conducted. An explanation of near-miss cases and the causes attributed to the experimenter is provided. Specifically, potential dangers related to (1) contact with hazardous chemicals, (2) handling of glassware, and (3) working spaces and electricity frequently occur. Comparing undergraduate and graduate students, it was found that the former tended to think about concrete and individual countermeasures, while the latter tended to discuss causes and countermeasures from a broader perspective; therefore, they were differentiated based on the description column. Comments from the graduate students were categorized into corresponding case categories and recorded in a discussion column. Furthermore, a summary section is included on who should be careful, their outlook, and their mindset.

-

Key words:

- Chemical laboratory /

- Near miss /

- Toxic chemicals /

- Glassware /

- Electric accident /

- Laboratory arrangement