-

Agricultural waste generation and mismanagement have emerged as serious concerns in the continuous multiple cropping systems found across the globe, this escalating issue places significant strain on the environment and the economy of countries[1−3]. However, there is a glimmer of hope in the form of re-utilizing agricultural waste, offering a promising solution to multiple environmental challenges. This approach not only supports sustainable agriculture but also plays a crucial role in mitigating the impacts of climate change, making it a win-win situation benefiting the environment, farmers, and society as a whole. As the global population continues to grow, there is an ever-increasing demand for agricultural products, which subsequently leads to a rapid rise in waste production[4]. To tackle this escalating problem, the concept of re-utilizing agricultural waste to create beneficial new produce has gained significant traction and popularity in recent times. Coconut (Cocos nucifera L.) husk is one of the abundant agricultural wastes produced in almost all coconut states and industries as a by-product of crushing raw coconut nuts[5]. It is a carbonaceous mixture of cellulose (38%–39%), hemicellulose (17.33%), and lignin (46%–53%)[6].

The Sri Lankan coconut industry is blooming rapidly, with nearly around 400,000 hectares across the island giving 3,086 million nut yields in 2019, making it the world's fourth-largest producer[7]. This will give context to the scale of the annual coconut husk generation in Sri Lankan. Even though the majority of the coconut husks are burned or dumped in waste-lands, they can be used for bioenergy production such as second-generation ethanol[8], producing nano-crystalline cellulose for biodegradable films (by polymers)[6], extracting value-added organic acids such as formic acid and acidic acid[5], and isolating phenolic compounds (protein cross-linker agents) for strengthening protein gel[9]. In addition, coconut husks are utilized as mulching material in agricultural crops to conserve soil and moisture in the field. It can be either in the raw form of coconut husk or as a modified product such as coco-nets, and mats[10]. In addition to those uses, coconut husk has been identified as an excellent source of biochar production subjecting to thermochemical processes[11].

Biochar is an easy and cost-effective way of transferring nutrients in coconut husk into the cropping cycle. Simply, biochar can be defined as 'one of the products of pyrogenic carbonaceous materials through thermochemical conversion of biomass or biodegradable materials in a limited or absence of oxygen content'[12].

The re-utilization of agricultural waste through coconut-husk biochar production offers significant environmental and agricultural benefits. The porous structure and absorption properties of biochar might transform soil into an excellent habitat for soil macro and micro fauna populations as well as diversity, thereby increasing bio-enzymatic activities[13]. Field application may increase the overall plant root growth and its performance[14]. According to the literature, that could happen as stimulation for alkaline biochar applications, which have a higher specific surface area, water holding capacity, and release nutrients slowly[15,16]. Biochar increases plant performance by enhancing water use efficiency but relying on (1) soil factors like pH variation and soil texture, (2) biochar production parameters, and qualities, and (3) crop management practices especially irrigation[17]. Other than that, biochar can increase photosynthetic efficiency by modifying tissue chlorophyll concentration, stomatal conductance, transpiration rate, water use efficiency, and increasing shoot biomass[18]. He et al. reported that the response of C3 plants to biochar application was much higher than that of C4 plants[18]. It enhances some soil properties like porosity, aggregate stability, available water-holding capacity, and saturated hydraulic conductivity while negatively affecting soil bulk density[19,20]. Biochar increases the soil organic carbon content by increasing carbon sequestration and forming beneficial soil carbon sinks[21]. Thereby it ultimately helps to reduce atmospheric carbon dioxide content, alleviating greenhouse gases and mitigating global warming[22]. However, that effect is dependent on pyrolysis temperature, qualities of raw materials, soil pH, irrigation activities and fertilization practices, and surface area of biochar[23]. Pyrolysis temperature or the temperature at which biomass is pyrolyzed plays a crucial role in determining biochar quality than other factors. Excessive temperatures can lead to the loss of beneficial properties and the formation of undesired compounds. Optimal pyrolysis conditions need to be determined for each feedstock to achieve the desired biochar characteristics. This research was conducted to determine the effect of pyrolysis temperature on the chemical and physical composition of coconut-husked biochar in terms of agricultural benefits.

-

Coconut husks were collected from Rathmalagara sub-research station, Coconut Research Institute, Sri Lanka. Biomass was chopped and initially air-dried for 2 d before being oven-dried at a temperature of 60 °C for 24 h. Oven-dried biomass was tightly packed into metal containers and covered by a lid to facilitate the limited oxygen environment. Then samples were pyrolyzed in Muffle Furnace (Model P330, Nabertherm, Germany) at six different temperatures; 325, 350, 400, 500, 600, and 700 °C, maintaining 7 °C/min heating rate for 3 h until wood gas flow stopped. The labeled carbonaceous biochar was stored under room conditions until further studies.

Characterization of biochar

-

The structural and chemical properties of produced biochar were analyzed using Scanning Electron Microscope (SEM) with Energy Dispersive X-ray Spectroscopy (EDX) technique (Model Zeiss EVO LS15) at the laboratory, at the Faculty of Science, University of Peradeniya, Peradeniya, Sri Lanka. The samples were observed from the SEM at the same magnitude as the initial step and then the measurements were taken in percentage in weight basis. Three replicates were used for the evaluation.

Statistical analysis

-

All the statistical analysis was carried out using R statistical software (version 4.1.3). Finally, the mean values of the data were statistically compared using the One-way Analysis of variance (ANOVA) at 5% significance and Tukey's pairwise comparison test to determine whether there are any statistically significant differences between the means of biochar yield/nutrient content with six temperature levels.

-

A range of pyrolysis temperatures was chosen to encompass various thermochemical processes, including hydrothermal liquefaction (250−400 °C), pyrolysis (400−800 °C), and gasification (700−1,300 °C)[24]. This broad temperature selection aimed to determine the optimal temperature for producing coconut-husk biochar by gaining comprehensive insights into these processes. As mentioned by Xu et al., the pyrolysis temperature has a greater influence on the chemical and physical properties of coconut-husk biochar[25]. Therefore, SEM with EDX was employed for elemental analysis due to its effectiveness in comparison to other elemental digestion methods such as atomic absorption spectroscopy, inductively coupled plasma mass spectrometry, or wet chemical digestion considering several reasons; (1) allows for non-destructive analysis of samples; (2) high-resolution imaging capabilities; (3) detects a wide range of elements, from carbon to uranium, depending on the instrument's capabilities; (4) high sensitivity to detect elements present in very low concentrations; and (5) relatively fast compared to other elemental digestion methods. Supplemental Fig. S1 summarised the variation patterns of measured elements with the increasing pyrolysis temperature. A scree plot was developed to determine the number of principal components to retain in Principal Component Analysis (PCA) depending on the amount of variation they cover (Supplemental Fig. S2). Based on its results, PCA plots were designed with identified three major principal components to explain 78.6 % of the total variability (Supplemental Figs. S3 & S4). A small angle between two vectors implies a positive correlation between two variabilities while the formation of a large angle between two vectors suggests a negative correlation. A 90° angle indicates no correlation between the two characteristics.

Biochar yield

-

Figure 1a illustrates the variation in biochar yield across different pyrolysis temperatures. The highest biochar yield (42.79%) was recorded at 325 °C, whereas the minimum biochar yield (26.97%) was observed at 600 °C. According to these results, a significant decrement in biochar yield could be observed with the increment of pyrolysis temperature (at p < 0.05). That is mainly due to the increased primary and secondary decomposition of coconut husk structural components such as lignocelluloses and the greater release of volatile components with increasing temperatures[26]. As mentioned in previous literature, hemicellulose and cellulose complete their decomposition at 220–315 °C and 315–400 °C temperatures respectively[27]. Beyond 400 °C, crystalline celluloses begin to decompose, leaving lignin as the only remaining organic substance in the production process[28]. Notably, bio-oil is the predominant product after reaching 500 °C[24]. Similar results were recorded by Suman & Gautam[11].

Figure 1.

Variation of coconut-husk biochar properties with different pyrolysis temperatures.(a) Biochar yield. (b) Variation of biochar-C content. (c) Variation of biochar-O content. (d) Variation of biochar-N content. (e) Variation of biochar-P content. (f) Variation of biochar-K content. (g) Variation of biochar-Na content. (h) Variation of biochar-Ca content. (i) Variation of biochar-Mg content. (j) Variation of biochar-S content. (k) Variation of biochar-Cl content. (l) Variation of biochar-Si content. Means with different letters represent significant differences at p < 0.05 level.

Carbon (C) content

-

As shown in Fig. 1b, the C content showed an increment from 52.03% to 78.71% as a response to increasing pyrolysis temperature from 325 °C to 600 °C. However, that increment was not statistically different (at p < 0.05) among treatments. Elevated pyrolysis temperatures typically result in biochar with heightened carbon content, lower volatile matter, increased stability, and augmented resistance to decomposition[29]. Furthermore, the observed phenomenon suggests that the polymerization of organic substances may account for the elevated C yield at higher temperatures[28]. These findings are in line with the observations made by Brassard and colleagues, reinforcing the understanding of the relationship between pyrolysis temperature and carbon content[30]. Furthermore, a study investigated the use of SEM-EDX to effectively characterize biochar produced through different pyrolysis methods and temperatures showed that SEM-EDX can provide consistent measurements of carbon (C), oxygen (O), and C/O ratios in biochar which can be further explored as an operational tool for biochar characterization[31].

Oxygen (O) content

-

Figure 1c shows a decreasing trend with increasing production temperature could be observed in O content produced from coconut-husk biochar. The results indicated that the production temperature at 325 °C had the highest O yield which was recorded as 25.68%. Even though, there was no significant difference among the 325−400 °C range, after that a significant difference was identified. As shown by Sarkar & Wang, raising the pyrolysis temperature encourages the volatilization process leading low yield of O in the final product[32]. A similar result was obtained in rice-straw-based biochar production[33]. Since raising the pyrolysis temperature influences the dehydration, aromatization, decarboxylation, condensation, and polymerization processes, it will change the affinity level in chemical bonds between C, H, and O elements[33]. This will facilitate the volatilization of the above-mentioned nutrients leading to low H/C, and O/C ratios in biochar (Table 1). Biochar with lower values for these ratios indicates higher biochar C stability and maximum carbon sequestration ability[27,30]. According to that, it can be suggested that biochar produced at 600 and 700 °C are more suitable for carbon sequestration purposes and biochar produced at low temp would serve more soil nutrient retention by enhancing soil cation exchange capacity.

Table 1. Variation of O/C ratio at different pyrolysis temperatures.

Pyrolysis temperature (°C) O/C ratio of coconut-husk biochar 325 0.49 350 0.46 400 0.32 500 0.22 600 0.08 700 0.10 Nitrogen (N) content

-

N is the fourth most abundant element in plants after C, H, and O. It plays a significant role as a major structural component in various organic compounds found in plants, including proteins, nucleotides, porphyrins, and alkaloids. These compounds are essential for plant growth and function, contributing to processes such as enzyme activity, genetic information storage, photosynthesis, and various physiological functions in plants[34]. By adding N-rich biochar materials, chemical fertilizer requirements for agriculture can be minimized. Even though raising the pyrolysis temperature did not show a significant tendency of an increase in N yield in biochar production, it reported an unexpected increase at 700 °C (19.5%) (Fig. 1d). Generally N content in biochar shows a decreasing trend with the increasing pyrolysis temperature due to volatilization of N as Hydrogen cyanide and Ammonia in the un-condensable gas mixture and leaching of N as organic-N in the condensable liquid phase[35]. Dehydration and de-carbonization occurring in the production process can increase the N yield in biochar[25].

Phosphorus (P) content

-

P is a vital nutrient in agriculture, supporting plant growth, development, energy transfer, and various physiological processes such as photosynthesis, stress tolerance and resilience, and reproduction, ultimately contributing to improved crop productivity and quality[36]. According to Fig. 1e, increasing pyrolysis temperature from 350 to 700 °C has led to the reduction of P content by 0.06% to 0.02% respectively. However, a significant difference between the six different treatments was not observed. According to previous findings, inherent P concentration in biochar and P sorption capacity of biochar have a positive relationship leading to more P available for plants[37]. By applying those findings to this experiment, it can be concluded that biochar pyrolyzed at 350–400 °C could be used to increase the P availability as well as P sorption capacity.

Potassium (K) content

-

K also serves a crucial function in imparting resilience to plants when they encounter a range of biotic and abiotic stresses, which encompass diseases, pests, drought, salinity, cold temperatures, frost, and waterlogging[34]. Other than that, regulation of water balance, enzyme activation, and metabolism also can be maintained well by monitoring K requirement. With the increment of pyrolysis temperature, a significant decreasing trend in the K content of biochar from coconut husk was observed (Fig. 1f). The highest K yield (6.83%) was recorded at the temperature of 350 °C. According to previous studies, it had confirmed that biochar prepared at a lower pyrolysis temperature (around 400 °C) is the best based on the K specification[38]. At around lower production temperatures (around 400 °C), Potassium chloride (KCl), complex-K, and graphite layer-K (K in HOPG intercalation compounds) were formed, and at around increased temperatures (around 800 °C), Potassium sulfate was formed with the above-mentioned K forms. With the increasing pyrolysis temperature, complex-K and graphite layer-K starts to decompose and KCl will be volatilized leading to lower K concentration at the end of the process[38].

Sodium (Na) content

-

While Na is an essential nutrient for many living organisms, it is generally not considered a vital nutrient for most plants. In fact, excessive Na can be detrimental to plant growth and health. As shown in Fig. 1g, biochar produced from coconut husk showed a tendency to increase the yield of Na content with rising pyrolysis temperature due to minimum volatilization losses[39]. The maximum Na yield (0.54%) was observed around the temperature at 600 °C. Na compounds in the coconut-husk feedstock might have relatively high boiling points. At higher pyrolysis temperatures, these compounds may not undergo significant volatilization losses and, instead, remain within the biochar matrix. However, further research may need to confirm this. Similar results were obtained by Rafiq et al. concluding that crop-based biomass produces higher Na yield at higher pyrolysis temperatures[40].

Calcium (Ca) content

-

Ca serves an electrochemical function by acting as a counter ion for the anions found in both inorganic and organic acids[34]. With the increment of pyrolysis temperature from 325−700 °C, Ca content varied from 0.22%−0.07% range in a descending manner (Fig. 1h). That will indicate the less availability of Ca2+ ions as a plant nutrient. However, there was no significant difference among the six pyrolysis temperatures. Ca compounds present in the feedstock undergo thermal decomposition at elevated temperatures. This decomposition can result in the release of gaseous compounds or the formation of stable compounds that do not contribute to the Ca content in the biochar at elevated temperatures. Similar behavior was observed in different types of biochar produced by vine pruning, poultry litter, orange pomace, and seaweed[41].

Magnesium (Mg) content

-

Mg is an essential nutrient in agriculture, playing a vital role in chlorophyll synthesis, photosynthesis, enzyme activation, nutrient uptake, stress tolerance, and overall crop productivity[36]. Proper magnesium management is crucial for promoting healthy plant growth and maximizing agricultural yields. Figure 1i reveals that the maximum Mg content of 0.19% was obtained at a production temperature of 350 °C, whereas the minimum Mg content (0.02%) was recorded at a temperature of 325 °C. With the increment of pyrolysis temperature, a descending trend in the Mg element of biochar from coconut husk was observed indicating the less availability of Mg2+ ions for plant absorption. Tag et al. observed a similar variation of Mg yield with biochar pyrolysis temperature[42].

Sulfur (S) content

-

S is an essential macro-nutrient in plant growth, playing a vital role in protein synthesis, chlorophyll formation, nutrient uptake, and disease resistance[34]. The S element exhibited a slow descending trend with the increment in production temperatures (Fig. 1j). Even though it varied from 0.16%−0.01% in response to temperature change from 325–700 °C, there was no significant difference (at p < 0.05) among treatments. These variations might happen due to increased volatilization of water-extractable sulfate and organosulfur present in biochar[42]. Similar findings were reported by Zhao et al. for corn-straw biochar by observing a reduction in total S content and water-soluble sulfate with increasing HCl and NaH2PO4-extractable sulfate with increasing pyrolysis temperature[41]. Furthermore, biochar rich with various elements such as Na, Ca, K, Mg, P, and S showed a greater potential for immobilizing heavy metals in soil[43].

Chlorine (Cl) content

-

The presence of sufficient Cl content in plants will help the maintenance of turgor and osmoregulation functions[34]. Figure 1k, reveals that the highest Cl content of 4.35% was obtained at a temperature of 600 °C, whereas the lowest Cl content of 0.14% was recorded at 500 °C. A significant increase of this element could be recorded at 600 °C temperature range when compared to other treatments. Raising pyrolysis temperature causes an increase the heavy metal chlorination, especially with Zn, Cu, Ni, and Mn leading to low heavy metal concentration and Cl yield at the end product[44].

Silicon (Si) content

-

Si shows beneficial effects on plant growth and development, yield maximizing, and disease resistance[45]. As described in Fig. 1l, there is a significant difference between the treatments when considering the Si content with the changes in the production temperature. It showed an increasing trend with respect to the increasing pyrolysis temperature recording maximum Si content at the temperature of around 700 °C. Similar observations were recorded by Qian & Chen concluding higher quartz (SiO2) appeared at around 400 °C while higher kalsilite (KAlSiO4) and diopside (CaMgSi2O6) formed around 700 °C[46]. According to previous findings, Si-rich biochar is more active in balancing soil Si content, increasing the Si availability for plant functioning, remediation of some inorganic pollutants such as Al, As, Cd, and Cr, and increasing biotic stress (pest and diseases) tolerance. Nonetheless, Si is an essential plant nutrient for several major crops grown worldwide such as maize, wheat, and rice[47].

Correlation analysis among measured chemical properties of coconut-husk biochar

-

Correlation analysis of measured characteristics for coconut-husk biochar is shown in Fig. 2. As shown in the graphical illustration, hidden positive and negative correlations among variables can be identified in different absolute values of corresponding correlation coefficients. Pyrolysis temperature shows the strongest positive relationship with Na. Other than that, it shows fewer corresponding correlations with Si > C > N > Cl content. O is the element that shows the strongest negative relationship with pyrolysis temperature while reducing the strength of the negative relationship with S, Mg, P, Ca, and K content respectively. Biochar yield of produced coconut-husk biochar shows negative correlations with Na content, Si content, Cl content, N content, C content, K content, and Mg content while O content, S content, Ca content, and P content show positive correlations.

Figure 2.

Graphical display of the correlation matrix, using the 'corrplot' package of R-software. Red color indicates the negative correlations between shown variables; blue color indicates the positive correlations; white color indicates no correlation. The areas of the squares show the absolute value of corresponding correlation coefficients. Parameters covered by blue lines show similar correlation variation patterns.

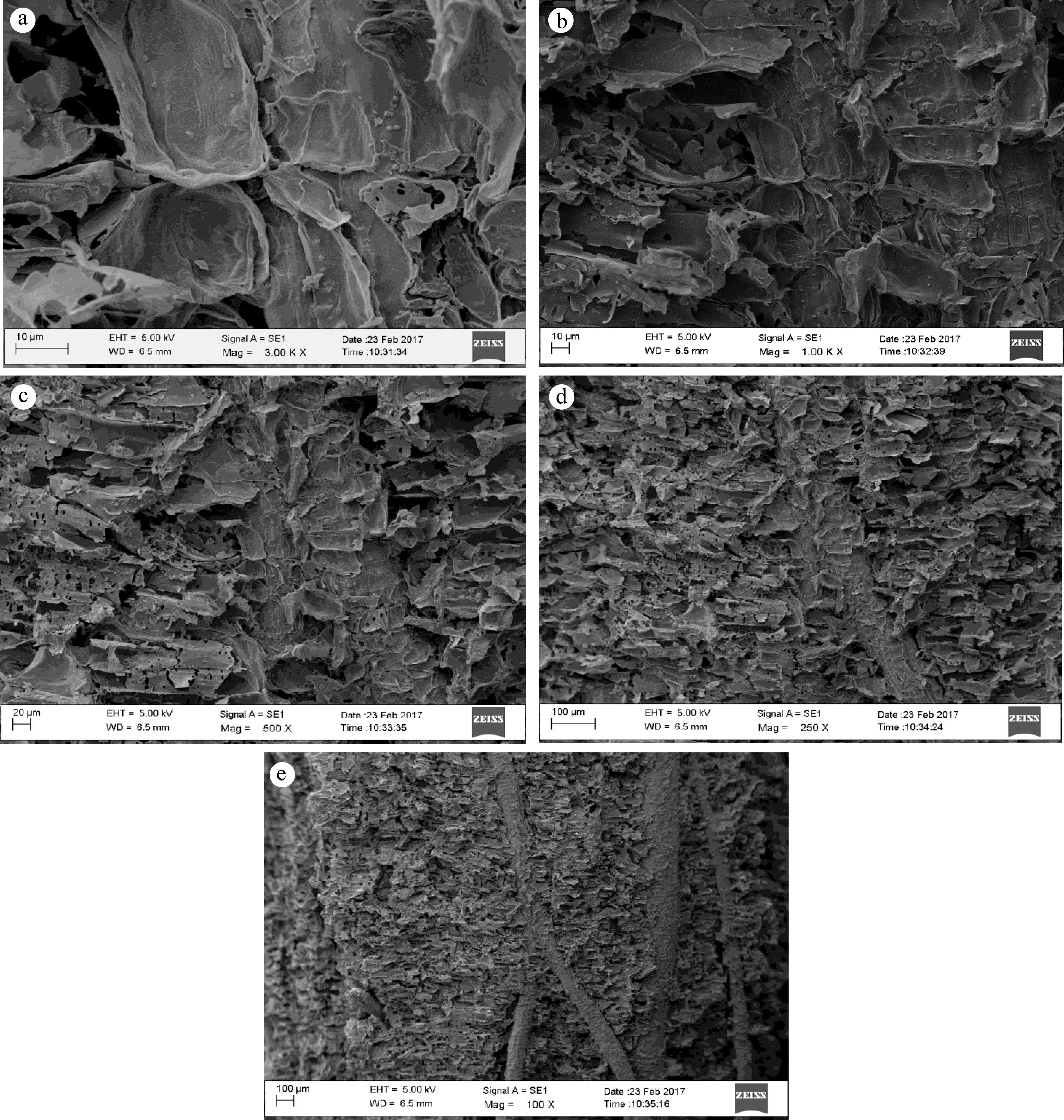

Other than the chemical properties of biochar, structural characteristics were significantly influenced by the production temperature[40]. Xu et al. confirmed the significance (p < 0.001) of pyrolysis temperature on the importance of biochar's sorption capacity[25]. Using SEM technique, surface morphology and changes in structural properties could be clearly investigated.

As shown in Fig. 3a−e, biochar derived from coconut husk has an uneven, heterogeneous porous-rich surface giving increased surface area and facilitating higher absorption capacity[48]. Volatilization of structural components will lead to the shrinkage of coconut fiber resulting in this uneven surface morphology. Pores are irregular and longitudinal in shape[49]. According to Dhar et al. surface porosity of biochar made from coconut husk will increase with the increasing pyrolysis temperature leading to lesser strength[29]. Those pores show 1–3 µm in length at lower pyrolysis temperatures (350–450 °C) and 3–10 µm in length at higher pyrolysis temperatures (500–600 °C) under x 2,000 magnification. The surface morphologies of coconut-husk biochar at 400 °C were examined with SEM techniques (Fig. 3).

-

The present study investigated the influence of pyrolysis temperature on coconut-husk biochar production with the purpose of optimizing biochar yield and its characteristics. The results demonstrated the profound influence of pyrolysis temperature on biochar characteristics and its usefulness as an agricultural input. The yield of biochar derived from coconut husk varied significantly with the changes in pyrolysis temperature. The maximum yield, which was recorded as 42.79%, was produced at 325 °C highlighting the suitability of low pyrolysis temperature for producing coconut-husk biochar. Raising pyrolysis temperature activates or deactivates the decomposition, volatilization, polymerization, chlorination, dehydration, and de-carbonization processes that can influence the biochar characteristics. As a result, O, Na, K, Mg, and Si yield in the biochar showed significant differences between the treatments. Notable changes were observed in structural properties as well. Biochar production by coconut husk resulted in a nutrient-rich source that could be used as a greater soil amendment. It could increase the soil nutrient content and water-holding capacity while reducing agricultural waste generation. Future studies are essential to observe the effect of pyrolysis time period, nutrient transferring capacity, and heavy metal composition of coconut-husk biochar.

-

Study conception and design: Dissanayaka DMNS, Atapattu AJ; data collection: Udumann SS; analysis and interpretation of results: Dissanayaka DMNS, Nuwarapaksha TD; draft manuscript preparation: Dissanayaka DMNS, Udumann SS, and Atapattu AJ. All authors reviewed the results and approved the final version of the manuscript.

-

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

-

We would like to express our appreciation to the technical staff of the Agronomy Division of the Coconut Research Institute.

-

The authors declare that they have no conflict of interest.

- Supplemental Fig. S1 Variation patterns of measured elements with the increasing pyrolysis temperature.

- Supplemental Fig. S2 Scree plot analysis showing percentage of explained variations in response to number of principle components for coconut husk biochar production.

- Supplemental Fig. S3 PCA for the parameters influencing coconut husk biochar production; relationship between principle components -I and II.

- Supplemental Fig. S4 PCA for the parameters influencing coconut husk biochar production; relationship between principle components -I and III.

- Copyright: © 2023 by the author(s). Published by Maximum Academic Press, Fayetteville, GA. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Dissanayaka DMNS, Udumann SS, Nuwarapaksha TD, Atapattu AJ. 2023. Effects of pyrolysis temperature on chemical composition of coconut-husk biochar for agricultural applications: a characterization study. Technology in Agronomy 3:13 doi: 10.48130/TIA-2023-0013

Effects of pyrolysis temperature on chemical composition of coconut-husk biochar for agricultural applications: a characterization study

- Received: 13 September 2023

- Accepted: 17 October 2023

- Published online: 16 November 2023

Abstract: Coconut husk, a plentiful agricultural waste, rich in cellulose and lignin, is abundant in tropical and subtropical regions worldwide. The emergence of new green energy technologies harnessing coconut husk has intensified interest in biochar production due to its affordability and low energy requirements. The effectiveness of biochar varies based on the raw materials and production process. Hence, this study aimed to evaluate the chemical and structural properties of coconut-husk biochar produced at different pyrolysis temperatures, focusing on its agricultural benefits. In this research, biochar derived from coconut husk was generated at varying pyrolysis temperatures 325, 350, 400, 500, 600, and 700 °C under limited oxygen supply and a heating rate of 7 °C/min for 3 h. The chemical and structural properties of the produced biochar were meticulously examined using Scanning Electron Microscope (SEM) with Energy Dispersive X-ray Spectroscopy (EDX) techniques. The findings underscored the significant impact of pyrolysis temperature on the chemical properties and structure of coconut-husk biochar, especially at lower heating rates. Remarkably, the highest yield, recorded at 42.79% (at p < 0.05), was achieved at 325 °C, emphasizing the suitability of lower pyrolysis temperatures for biochar production using coconut husk. Furthermore, alterations in pyrolysis temperature resulted in notable differences in elemental concentrations and significant changes in the biochar structure. These modifications enhance plant and leaf water use efficiencies, boost plant photosynthesis efficiency, modify soil properties, reduce greenhouse gas emissions, and contribute to mitigating global warming.

-

Key words:

- Agricultural waste /

- Coconut husk /

- Global warming /

- Photosynthesis /

- Pyrolysis