-

The agricultural industry utilizes 1 million metric tons of plastic films (used for greenhouse, mulching and silage) annually on a global scale[1]. Plastic mulch is predominately made of non-biodegradable polyethylene (PE) with low-density polyethylene (LDPE) and ethylene vinyl alcohol (EVOH) comprising approximately 40% of the total plastic films used in agriculture[1−4]. Plastic mulch was first used in agriculture in the 1950s, and today is widely used in modern farming systems worldwide for its ability to suppress weeds, retain soil moisture, modify soil temperature, shorten time to harvest, and overall increase crop yield and quality[5,6]. Shogren & Hochmuth[7] estimated that United States vegetable farmers used approximately 0.13 million metric tons of PE mulch annually. About one decade later, Fessesden[8] reported that 0.45 million metric tons of plastics were utilized annually for crop production in the United States in 2021, the value of the global agricultural film market was US

${\$} $ ${\$} $ Mulch films are generally classified according to their primary constituents, thickness, density and color, and are characterized by their tensile strength, flexibility, biodegradability, and recyclability[2,10]. Commonly used mulch films range in thickness from 0.015 to 0.05 mm and are deployed in the field for 4–9 months for annual crops to several years for perennial crops; perennial systems primarily use high-density woven plastic PE mulches and not films[11−13]. The growth in the use of plastic mulch poses serious environmental challenges as PE can take several hundred years to degrade depending on environmental factors (e.g., moisture, heat, light, microbial actions) and microplastics are released into the environment during the degradation process[14].

The recycling of PE mulch has been limited due to high levels of soil and plant debris contamination (30% to 80% by weight) that interferes with or influences end-product yields with most recycling processes[15−19]. These contaminants also increase transportation costs and tipping fees, which are based on weight, and should be removed before recycling, preferably at the growers' field site to reduce costs and conserve resources. Furthermore, removing soil contaminants at growers' fields decreases the amount of topsoil removed and may benefit long-term soil health. However, removing surface contaminants is difficult due to frequent embossing of the mulch surface, which improves its horticultural benefits but increases adherence of soil particles[18,20]. Agrochemical contamination is another issue limiting the recyclability of plastic mulches. A study by Guo et al.[21] reported that plastic mulch can potentially adsorb up to 20 times more pesticides than is absorbed by soil, signaling that plastic film fragments could play a role in the distribution, transport, and persistence of pesticides in the environment[22]. Soil-biodegradable plastic mulch is an option for some farming systems but is currently not allowed in United States organic agriculture[18,23]. Considering the projected increase in the use of plastic mulch and the concerns regarding plastic waste and pollution, it is worthwhile to find sustainable and cost-effective recycling options to safeguard the environment.

-

There is widespread usage of PE mulch across the United States today. Growers in Florida and California produce most of the nation's supply of specialty crops using PE mulch with California using approximately 13.6 to 18 thousand metric tons annually[24−26]. PE mulch is widely used for strawberry production, which encompasses approximately 16,000 and 4,000 ha in California and Florida, respectively[27,28]. Disposal methods for PE mulch in strawberry production in California, the Pacific Northwest (Washington and Oregon) and Mid-Atlantic (New York and Pennsylvania) varied by region, with landfilling as the most common disposal method in all three regions[29]. Recycling was more common in California than the other two regions due to the state's recycling programs and incentives[30]. Burning was more prevalent in the Mid-Atlantic region due to local ordinances allowing it[29,31]. In a study of fruit and vegetables growers in Tennessee, most of the respondents (75%) reported disposing of PE mulch in landfills, 15% buried it on-site, and 22% burned PE mulch on site, despite this being an illegal practice in the state[32]. Overall, 15% of the growers reported using more than one disposal method.

Landfill disposal of PE mulch is the most common option among growers, and there is a range in tipping fees by region based on landfill capacity. South Central states such as Arkansas, Louisiana, New Mexico, Oklahoma and Texas have more available landfill space and have an average tipping fee of US

${\$} $ ${\$} $ ${\$} $ Incineration has evolved as a potential option for waste disposal in the United States, especially in areas with stricter landfill regulations and limited landfill space. In the 1990s, the deregulation of interstate waste exportation enabled the establishment of large regional waste facilities, which were rebranded as 'Waste-to-Energy' (WTE) facilities. Marketed as advanced waste management systems that generate energy from burning trash, including plastic waste, waste incineration produced about 0.4% of the total electricity generation in the United States[37]. However, incinerators produce significant air pollutants, including nitrogen oxides, particulate matter, dioxins, furans, and carbon dioxide[37,38]. Incineration facilities can emit higher levels of greenhouse gases compared to coal plants and consume substantial amounts of energy when considering the entire life cycle of the materials burned[37,38].

Open burning of plastic on farms is prohibited in many states including Arizona, California, Colorado, Connecticut, Hawaii, Idaho, Kentucky, Massachusetts, New York, Ohio, Tennessee, Vermont, Washington, and Wisconsin[36,39] but it is permitted in the state of Florida. According to section 403.707—(2)(e) of Florida's Solid Waste Act, solid waste generated from regular farming activities including agricultural plastics can be disposed of through open burning under conditions that they do not: 1) create a public nuisance; 2) have a negative impact on the environment; and 3) comply with state and federal ambient air quality standards. It is unclear how burning plastic waste in the field meets these criteria, but the practice is currently common in Florida (Fig. 1). Burning plastic does have human-health and environmental ramifications due to impacted air and soil quality as it is considered toxic to humans and environmental health[40].

On-site stockpiling involves storing used mulch in designated areas on the farm until it can be properly managed or disposed (Fig. 2). This option provides a temporary solution but may pose challenges in terms of space utilization as well as potential risks to the environment if the stockpiles are not managed well. Stockpiled mulch may also accumulate more plant and soil debris, further constraining recycling efforts. Burial of plastic mulches on-site includes burying used mulch at the edges of fields, along drainage ditches and along on-farm roadways. This practice aims to minimize the visual impact of the mulch and reduce the need for off-site disposal. This practice likely has long-term consequences as the buried plastic mulch will degrade slowly over time, leading to environmental contamination including soil degradation[19,41].

Overall, these disposal practices for plastic mulch have varying implications in terms of human health and environmental impacts, compliance with regulations, and long-term consequences. Sustainable strategies and technologies are needed for plastic mulch disposal that are cost and resource effective. Recycling provides an opportunity for growers and the recycling industry as mulch waste is often concentrated in very large amounts within areas where it is used. There are several methods available for recycling PE that can be used for plastic mulch, including mechanical, advanced (chemical and thermal), and biological methods. These methods are described below and key similarities and differences are summarized in Table 1.

Table 1. Comparison of mechanical, thermal, and biological plastic recycling processes.

Mechanical Advanced (thermal and chemical) Biological Process description Physical shredding and melting of plastic to produce new products[52,83] Molecular breakdown of plastics into chemical components as feedstock for

new plastics or chemicals.

Thermal – pyrolysis or gasification.

Chemical – solvolysis[52,83−85]Using enzymes or microorganisms

to breakdown plastics into simpler substances[42,99]Types of plastics Limited to specific types of plastics, typically clean and separated such as PET, *HDPE and **LDPE[52] Can recycle a wider range of plastics, including mixed plastics (except PVC) depending upon the process[52] Currently limited to a few types of plastics (PET, polyurethane, and PE) to some extent[99] Allowable feedstock contaminate level ≤ 5%[19] 15% to 20%[106] Not available Efficiency Dependent on the quality and purity of the input waste plastic stream Dependent on the quality and purity

of the input waste plastic streamDependent on the quality and purity of the input waste plastic stream Product quality Lower quality products with lower mechanical properties with the exception of ***rPET[52] High-quality products with properties similar to new plastics in some cases[52] Potential to produce high-quality recycled materials, but further research is needed to optimize product properties[99] Economic viability Generally considered the most economical option due to established infrastructure and process[52] Capital intensive as it requires more investment and development of specialized equipment and facilities[52,105] Cost considerations include enzyme production, process optimization, and scaling up[42,99] Technological maturity Well-established and widely adopted[107] Under development, technological advancement needed to reduce

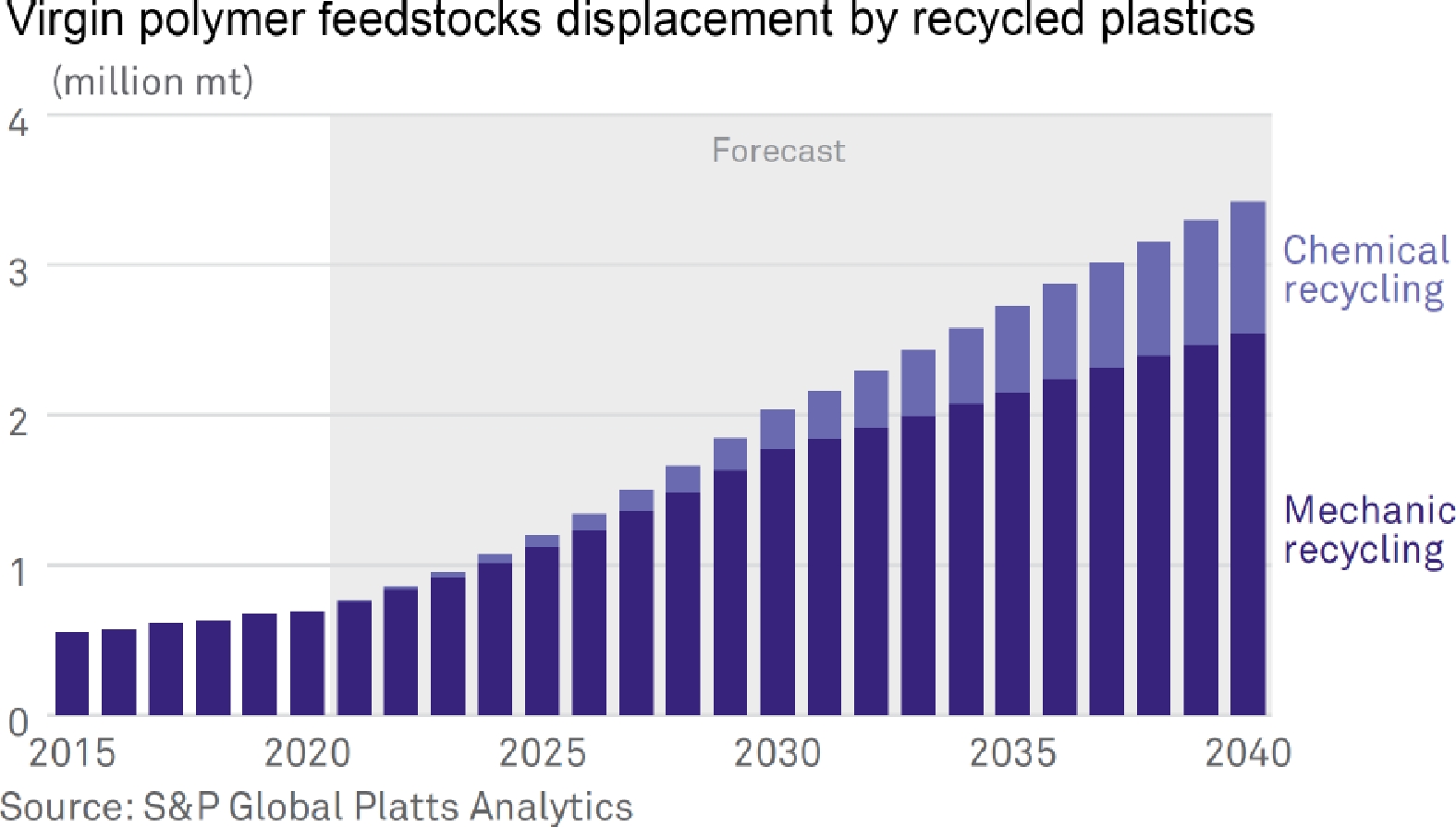

recycling cost[52,108]In early stages[42] Challenges Contamination, mixed plastic types, degradation of plastic properties[52] Contamination, economic viability considering low cost of virgin plastics, supply variability, sorting challenges especially films and other flexible plastics[52] Implementation costs, limited applicability (current enzymes limited to a few plastics)[42] * HDPE – high density polyethylene; ** LDPE – low density polyethylene; *** rPET – recycled PET. Mechanical recycling is the most widely used method of plastic recycling, and accounts for essentially all plastic recycling in the United States and worldwide (Fig. 3)[42,43]. Chemical and thermal recycling, while promising recycling methods, face several financial and technical challenges that limit their widespread implementation. Plastic mulch may be suitable for biological recycling, but this recycling technology is still in the early development stages and has major challenges. The primary issue limiting plastic mulch recycling is its contamination with soil and plant debris after use, which has been reported as 30%–80% by weight[15,16,18]. Cleaning used plastic mulch to enable it to be recycled is an essential first step that must occur for recycling to be a viable option. Another challenge for recycling plastics is that recycling processes tend to be more expensive compared to landfill disposal options and the cost of new plastics. In the near term, government programs and subsidies will likely be needed to launch and sustain plastic recycling industries. Despite these challenges, recycling holds promise for a more closed-loop system, as it can divert plastic waste from landfills and on-site disposal while reducing reliance on virgin materials.

Figure 3.

Amount (million metric tonnes per day) of recycled plastic entering the market through mechanical and chemical recycling technologies from 2015 through 2020 (actual) and 2021 through 2040 (projected)[43].

-

The classification of contaminants in recycled plastics, specifically polyolefins (family of thermoplastics that include PE and polypropylene), can vary quite dramatically based upon the end use and process to manufacture them. Contaminants can be other polymer types, such as polyethylene terephthalate (PET), polyvinyl chloride (PVC), polyurethane (PU), and polyacrylonitrile butadiene styrene (ABS). Contaminants can also be performance or processing additives, fillers or fibers that are added intentionally to the initial product, or chemicals, glass, food stuff, and soil that end up in the plastic recycling stream unintentionally. Since this paper is focused on agricultural mulches, we will consider soil and fertilizers as the primary contaminants found in agricultural-based applications.

-

The presence of soil and fertilizer contaminants in plastic waste streams can have an impact on recyclability of plastics, influencing both the attributes and behavior of the plastic during processing. Soil and organic matter can infiltrate plastic waste streams during disposal, and if incorporated into the recycled product, will influence the plastic mechanical and chemical characteristics[44]. Soil particles can function as fillers or reinforcements within the plastic matrix for some properties such as stiffness, however they can also negatively impact parameters such as tensile strength, impact resistance, and machinery wear. For example, fine powder soil in PE films can cause the plastic to be stiffer, which reduces strain yield (the maximum amount of strain a material can endure before permanent deformation). Kim et al.[45] found that soil residues present on used PE had an impact on the color of the recycled end-product, which may be considered a negative outcome.

Day et al.[46] found that in polymeric recycling processes, dirt contamination within automobile shredder residue (ASR) significantly impacted the degradation kinetics of various polymers. Similarly, polypropylene (PP) exhibited a substantial alteration in activation energy, leading to accelerated degradation rates in the presence of ASR dirt[47]. Additionally, other polymers such as PVC, ABS, and PU exhibited varying degrees of sensitivity to ASR dirt contamination. These findings provide valuable insights into the intricate interactions between contaminants and the thermal degradation of recycled polymers, highlighting the critical importance of understanding such dynamics within recycling processes.

In agriculture, fertilizers encompass a range of various chemical compounds containing nitrogen, phosphorus, potassium, and other elements that are applied directly to the soil, through drip irrigation systems (i.e., fertigation), or onto plant canopies (i.e., foliar feeding). Other mineral or organically derived fertilizers are applied containing a range of macro- and micro-nutrients (e.g., calcium, zinc, magnesium, etc.) as well as biological products designed to stimulate plant growth (e.g., humic/organic acids, kelp and seaweed extracts). These nutrients and other residues from the fertilizer can adhere to plastic and become contaminants, altering the composition of recycled plastics[48]. Plastic agricultural films have been found to contain minimal amounts of low molecular weight compounds, likely resulting from the photooxidation of PE molecules and the absorption of residues from fertilizers and pesticides[49]. Importantly, these compounds are present in such small quantities that they do not significantly impede the utilization of recycled materials across various applications[49]. However, these low amounts of contaminants in the recycled plastic stream will likely make the end-product unavailable for food contact applications.

The introduction of fertilizer residues may induce chemical instabilities in recycled plastics. For example, the presence of nitrates can initiate degradation reactions, reducing the chemical stability of the material and potentially affecting the long-term durability of recycled plastic products[50]. Additionally, the influence of soil and fertilizer contaminants extends to the rheological properties of recycled plastics. For example, these contaminants have the potential to modify material viscosity, influencing the flow characteristics during processing[50]. High levels of contaminants may also result in inconsistent flow, making it challenging to achieve uniform products and maintain a steady state flow of materials for processing[51].

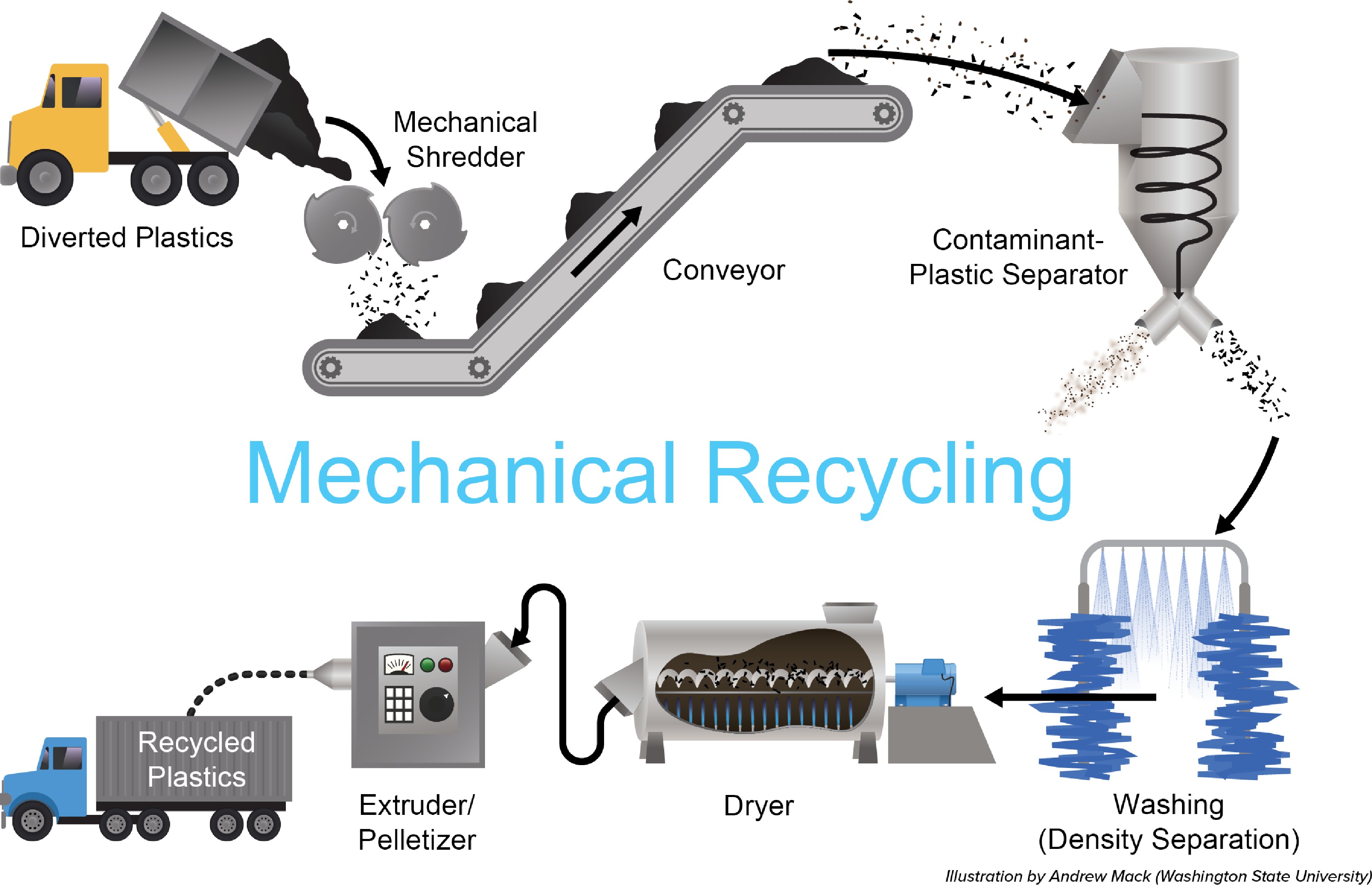

Mechanical recycling

-

Mechanical recycling involves collection, sorting, size reduction, washing and often heating the plastic to form pellets that can be used to make new plastic products (Fig. 4)[52,53]. Generally, all plastic recyclers require contaminant levels of the incoming plastic feedstocks to be about 5% or less[19], depending highly on the final product or application. Common contaminants for mechanical recycling include organic substances (e.g., food waste, plant material, soil or dirt and dissimilar plastic products)[54,55].

Incoming plastics are often sorted into a single polymer type, color, size, and application. Techniques for sorting plastic waste are determined by their physio-chemical properties such as shape, color, size and chemical compositions[56]. Size reduction (cutting or shredding) and cleaning may be done before or after sorting and is determined by the type of waste plastic stream and the structure of the facility[57]. The washing process for synthetic mulch involves several stages. Pre-washing is the initial stage: the mulch film is soaked in water to soften and loosen dirt and contaminants. Agitators or paddles are often used to agitate the material, further dislodging contaminants[58]. Powerful water jets are directed at the mulch film to remove persisting dirt and residues. Depending on the level of contamination, mild detergents or cleaning agents may be added to enhance cleaning. The mulch film is rinsed thoroughly to remove any remaining detergent or contaminants[59]. Excess water is removed from the mulch film through mechanical means or air drying. The washed mulch film is passed through screens or filters to separate out any remaining impurities, such as small particles or foreign materials[60]. The final steps are thermal extrusion and/or granulation, which can be performed in a variety of methods that are based on the requirements of the final product[56].

Mechanical recycling generally results in two distinct end products: pellets that will be used as a feedstock for a plastic part in a secondary operation, such as injection molding; and direct extrusion of the shredded plastic residue into products such as decking and wood plastic composites (WPC)[44]. Agricultural films such as greenhouse films and mulches that are made with recycled plastic can include up to 30% of recycled transparent plastic. For example, mechanically recycled agricultural film from low tunnels and greenhouse coverings may be used in the production of transparent films with comparable characteristics as conventional renewable materials[61,62]. Plastic crates and similar durable goods can include up to 95% of post-consumer plastic, which can include mulch films, drip tape and other agricultural plastics[63].

Recycling waste often involves shaping materials into large, structural components like beams, boards, or pipes. These applications are often used in critical sectors such as construction and infrastructure, where ensuring structural integrity and long-term durability is paramount for safety and performance[64]. Safety considerations further drive the need for stricter regulations on contaminate levels, especially when recycled plastics are used in applications with life-safety concerns, such as construction. Adhering to stringent safety standards is essential to prevent accidents or structural failures that could lead to injury or property damage.

WPCs can provide an effective mechanical recycling strategy for agricultural plastic waste streams. WPCs can be made from a variety of virgin and recycled thermoplastics. WPCs became financially viable primarily due to their ability to utilize a wide range of plastic flow characteristics and contaminate levels, making them ideal candidates to use recycled plastics[65,66]. WPCs have been used successfully to produce exterior products such as deck boards and poles for homes, docks, piers, and pedestrian bridge decks, as well as gates, horse stalls, traffic stops and outdoor furniture[44,67]. WPC planks and poles are usually easy to work with (saw, plane, mechanically fasten, paint), are resistant to insect pests, rot and decay, and are easy to clean and disinfect as compared with wood[68].

Mechanically recycled plastics can be used as an aggregate or filler in concrete[69]. For example, Hama & Hilal[70] successfully designed and characterized self-consolidated concrete with plastic waste to partially replace sand. Recycled plastic waste can also be used in concrete as fiber reinforcement for structural purposes. For example, compressional force, bending strength and shear strength were increased when ring-shaped PET was added to concrete[71]. Furthermore, studies have demonstrated that addition of plastic fibers significantly improved structural strength and load characteristics of concrete beams without affecting failure modes[69,71,72].

Recycled plastic wastes can also be added as asphalt modifiers (wet process) or aggregate replacement (dry process) to enhance the mechanical performance of asphalt pavements[73−78]. Among the various types of plastics (e.g., PET, PE, PP), PE is the most compatible with asphalt binders, as the melting point of PE is around 110–130 °C, which is lower than the typical production temperature (150–170 °C) of asphalt paving materials. Furthermore, the recycled PE could improve resistance to permanent deformation of asphalt paving mixtures[79,80]. However, these studies used relatively clean plastic wastes from other sources instead of agricultural plastic mulch that has significant amounts of surface contamination. Further research work is needed to assess the recycling of waste plastic mulch in asphalt pavements[81,82].

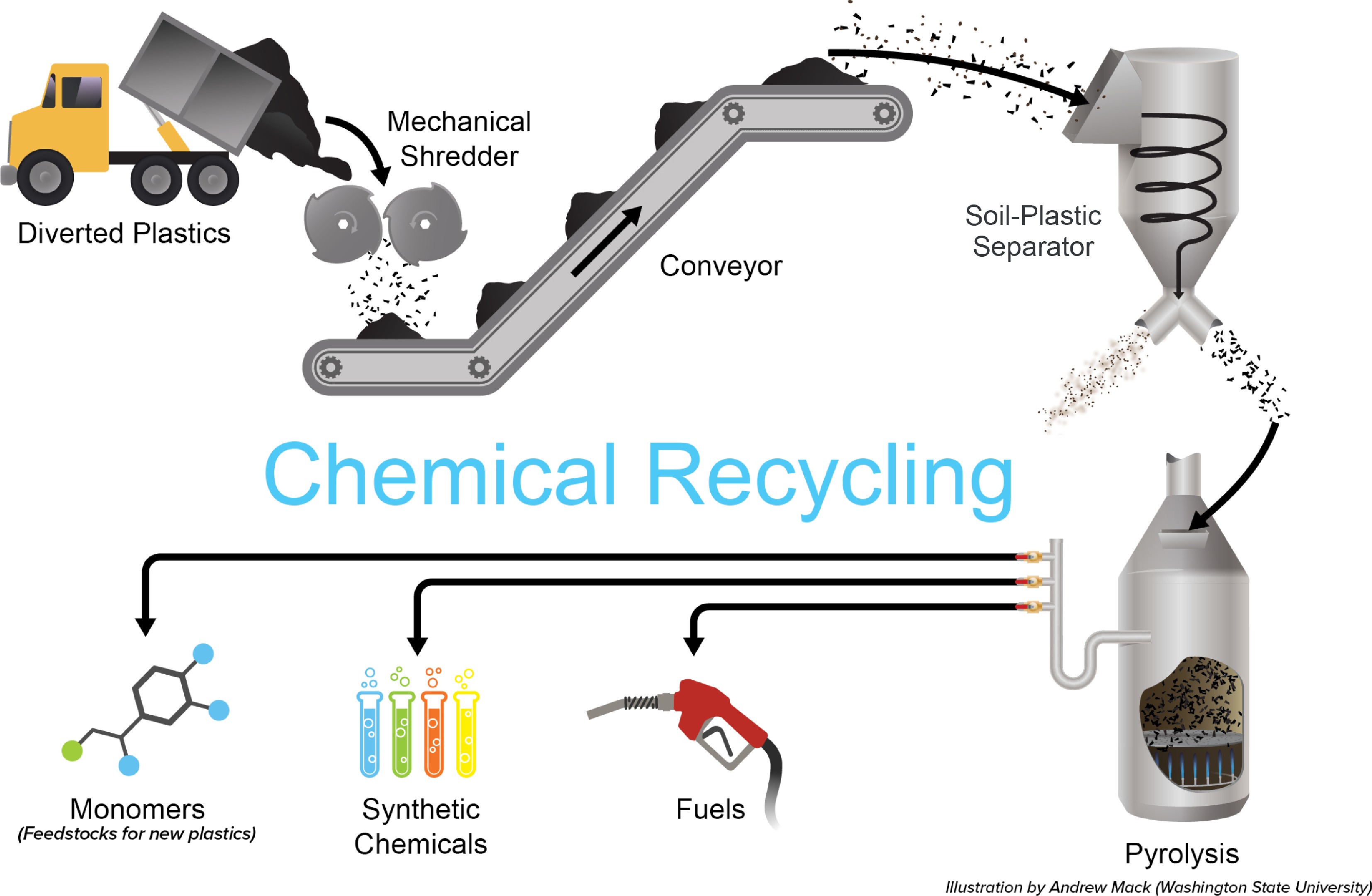

Advanced recycling

-

Advanced recycling is an umbrella term coined by the petrochemical industry to refer to chemical and thermal recycling whereby plastics are broken down into their constituent monomers that can be used to manufacture new plastic products, chemicals or fuel, in place of raw virgin materials (Fig. 5)[72,83−85]. Chemolysis utilizes solvolytic reactions, which are chemical reactions that occur when the plastics are dissolved in an organic solvent such as trichloroethylene, trifluoroacetic acid/dichloromethane and nitrobenzene. Currently, chemolysis is a preferred technique for recycling PET, and very little PE is being recycled with this method[86,87].

Thermal recycling has been proposed as the process most suitable for the advanced recycling of PE plastics[88]. Thermal recycling uses techniques such as pyrolysis and gasification. Plastic pyrolysis involves the heating of the plastics in the absence of oxygen, while gasification employs a limited supply of oxygen. Pyrolysis requires medium to high temperatures, in the range of 400−700 °C, and can be achieved either in the presence or absence of catalysts[89]. Pyrolytic conditions that include no oxygen and a temperature less than 600 °C can minimize the emissions of CO2 and other harmful pollutants such as poly-chlorinated dibenzofuran (PCDF) and polychlorinated dibenzo-para-dioxin (PCDD)[90]. Pyrolysis can simultaneously recycle waste, create energy, and produce petrochemical products that can be used to produce new plastic products[52,88,91]. Pyrolysis of plastics yields three categories of products: gases, liquids and solids. Gaseous products are mainly hydrogen, methane, carbon oxides and very short chain hydrocarbons[91]. Some of these gaseous products are monomers and are regarded as alternative chemical feedstocks due to their potential to be converted into polymers. There is high interest in exploring monomer production from pyrolysis of plastic waste due to the desire to close the loop on circular economics of plastics[92].

Utilizing pyrolysis to break down waste plastic material is advantageous for several reasons. Mixed, or commingled, resin types can be treated as a single feed stream with some exceptions, and external tramp materials or contaminants (e.g., soil residue) are typically segregated following the process. Preparation of the feedstock is typically a simple process, and some operations needed for mechanical recycling can be eliminated, such as washing and sortation. Disadvantages for advanced recycling technologies like pyrolysis are the energy-intensive nature of the process. Furthermore, commercial-scale operations require significant investments in equipment and infrastructure, with far higher operating costs as compared to mechanical recycling or disposal options such as landfilling.

Research has shown that LDPE, which is commonly used in the production of mulch films, has low ash content but high volatile matter[93]. Further, condensation of volatile materials produced from pyrolysis of LDPE can yield large quantities of liquid fuels and chemicals[89]. Susastriawan et al.[94] reported 60%−70% yield of high-quality liquid oil within 3 h of pyrolysis. The main components of these oils are fuel grade, with heating value of up to 41 MJ/kg[89]. Pyrolysis of LDPE with activated carbon catalyst has been reported to yield about 87% of liquid hydrocarbons in the gasoline, kerosene and diesel oil range[95]. Both catalytic and non-catalytic pyrolysis of LDPE for production of a wide range of liquid fuels have been studied extensively and methods are now very efficient[96]. The liquid fuels produced from pyrolysis have been blended at various ratios with regular transportation fuels and reported to enhance power outputs and emission characteristics of internal combustion engines[89]. Modern pyrolysis facilities have demonstrated that production of these liquid fuels from plastic waste on an industrial scale is feasible[92].

Gaseous products are mainly oxides of carbon, hydrogen and volatile gases, including methane. Methane along with other combustible gases from plastic pyrolysis have high heating values, making them suitable for use as fuel in thermal power generation, gas turbines or steam boilers. The non-condensable gas stream from LDPE pyrolysis has been reported to contain up to 72% ethylene gas, which can be re-polymerized, thus making this product stream an excellent chemical feedstock recovery route for the polymer industry[89]. Solid products from pyrolysis of LDPE film are in the form of char, which is either carbon from condensation of carbonized matter from plastics pyrolysis in the flue gas stream, or carbonaceous materials from lignocellulosic biomass contamination that is common for agricultural mulch films. Char has a significant calorific value, about 18.84 MJ/kg, making it a viable solid fuel. Char also has the potential use as a chemical adsorbent for removal of harmful substances such as arsenic in water[97].

The disadvantages of advanced recycling can be offset if demand for and value of the product is high enough to offset the increased capital and operating expenses. Currently, the projected demand for pyrolysis oil is expected to be extremely high through 2030, and that demand will continue to grow through 2060 (Einschuetz, opening keynote, AMI Chemical Recycling Conference, March 21, 2023). Federal governments across the globe are in the process of incentivizing multi-national oil, gas, and petrochemical companies to pursue this advanced recycling pathway, and the message from these governments to the pyrolysis companies is clear: do what it takes and do it quickly. Achieving high conversion rates and maintaining the quality of the recycled products can be challenging as the efficiency of these processes and the ability to scale them up to commercial levels still require further optimization[52,98]. Additionally, there is not currently an established pipeline of PE mulch waste moving into advanced recycling facilities; the quality of the material and the logistical challenges must still be addressed. Nevertheless, proper incentivization will motivate companies to revisit hard-to-recycle materials like PE mulch film with renewed effort, while casting a critical eye toward the most important business metrics: economic viability and sustainability.

Biological recycling

-

Biological recycling, or 'bio-recycling', involves the use of exogenously-applied microbes to break down plastics with enzymes into simpler compounds, which can be further processed into value-added chemicals. This is different than for soil-biodegradable plastic mulches, which must meet specific compostability or in-soil biodegradability standards and the end-of-life is biodegradation by native microorganisms present in compost or soil. However, the applicability of currently available enzymes for bio-recycling is limited, as they can only degrade a few specific types of plastic (e.g., PET and polyurethane). Furthermore, there are knowledge gaps that need to be addressed, particularly regarding the potential unintended consequences of bio-recycling. For instance, the risks associated with the release of engineered enzymes into the environment have not been thoroughly assessed. There is a high start-up cost associated with establishing bio-recycling facilities as much of the technology is not readily available[42,99].

-

One of the major issues in plastic recycling overall is the general lack of acceptance of mechanically recycled plastics for uses that include contact with food[100]. A recycled plastic product can only be used for food contact applications if a letter of no-objection (LNO) is obtained from the FDA. The main safety concern with using recycled plastic materials for food contact materials is the potential contamination of the plastic waste feedstock.

Adaptations are necessary to overcome the processing challenges related to films, which tend to curl, require rigorous washing, trap water and dirt, and cause clogs in filtering screens[44]. The thickness (15−150 microns) of agricultural plastic films is also a critical factor in the recycling process, and additional adaptations will be required to process thick film into pellets and flakes for recycling[101]. Thicker films inherently contain a larger volume of material, which significantly impacts their processing during the extrusion and size reduction phases (LabelAgriWaste project, 2006–2009). Thicker films have a greater amount of plastic material that requires higher-capacity equipment for efficient processing, and results in the production of larger pellets[102]. The thickness of the film also influences flow characteristics and uniformity during the extrusion process (LabelAgriWaste Project, 2006–2009). Adjustments in quality control measures may be necessary for thicker films to ensure that the final product meets specified requirements[44]. Enhanced regulations will help maintain a high level of quality control throughout the production process, minimizing the risk of defects or substandard products[101]. However, it should be recognized that thicker films have implications for growers in that they generally increase the recycling cost due to increased material.

The costs of production with virgin materials are lower than with post-consumer plastic when waste collection and processing are considered[103]. The low price of virgin plastic resin is a barrier for PE recycling, and the price of recycled materials is strongly influenced by crude oil prices, which fluctuate on the world market[44]. The costs of collecting and transporting plastic mulch waste to recycling facilities can be high, particularly in remote areas with limited access to recycling infrastructure. However, cost constraints may be overcome through progressive policy and incentives that reduce cost barriers, development of collection and aggregation programs, as well as shifts in producer-responsibility requirements. Mechanical plastic recycling processes create heat that must be managed, and as yet there is no effective and efficient method to sort plastic waste as polymers have different heat sensitivities[103,104].

-

Recycling of plastic mulch is a critical step in reducing plastic waste and its impact on the environment. Mechanical and advanced recycling are the two main options for recycling plastic mulch. Mechanical recycling is the most cost-effective and energy-efficient method of recycling, and recycling requires less energy compared to producing new plastic from raw materials. A primary challenge for mechanically recycling PE mulch is the potential quality reduction of the plastic recyclate due to contaminants. Contaminants such as soil, crop debris, and fertilizer and pesticide residues on used PE mulch can reduce the quality of pellets produced and prevent the recycled plastic from being used in applications that contact food. Advanced recycling technologies are still in the early stages of development. Current technologies are energy-intensive, and significant investments are required for equipment and infrastructure with far higher operating costs as compared to mechanical recycling[105]. An advantage of advanced recycling is it can be used on a wider range of plastics than mechanical recycling and produces high-quality plastic products with properties similar to those of new plastics. Advanced recycling also can be used for plastics with up to 15% or 20% w/w contaminants, thus may be more suitable for recycling plastic mulch. Biological recycling is an emerging technology and still in the early stages of development. Further research is needed to address its challenges, but it could be well suited for recycling plastic mulch. A primary need for all methods of plastic mulch recycling is cleaning to remove soil and plant debris, as levels of contamination are 30% to 80% when it is removed from the field. Robust life-cycle-assessments of these technologies can inform optimal recycling strategies.

While each recycling method has its advantages and limitations, innovative solutions and technology development are ongoing to overcome the challenges of plastic mulch recycling and increase efficiency and economic viability. Recycling of plastic mulch is essential to the circular economy and reduces the accumulation of plastic waste in landfills and the natural environment. Greenhouse gas emissions associated with manufacturing are reduced when recycled materials are used, and natural resources are conserved. If recycling infrastructure can be established in regions where there is intensive use of plastic mulch, then costs of the recycling system can be minimized. Government support in the form of subsidies and policies are needed to establish, promote, and sustain the recycling of plastic mulch.

-

The authors confirm contribution to the paper as follows: study conception and design: Miles C; draft manuscript preparation: Sarpong KA, Adesina FA; figures 4 & 5 preparation: Sarpong KA. All authors reviewed the results and approved the final version of the manuscript.

-

Data sharing not applicable to this article as no datasets were generated during the current study. The authors have reviewed the published literature and provided overall summaries and conclusions based on their expert knowledge and experience.

This work is supported by Specialty Crops Research Initiative Award 2022-51181-38325 from the USDA National Institute of Food and Agriculture and Hatch Projects 1008680 and 1017286. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the view of the United States Department of Agriculture. We would also like to acknowledge Andrew Mack for generating the graphics.

-

The authors declare that they have no conflict of interest.

- Copyright: © 2024 by the author(s). Published by Maximum Academic Press, Fayetteville, GA. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Sarpong KA, Adesina FA, DeVetter LW, Zhang K, DeWhitt K, et al. 2024. Recycling agricultural plastic mulch: limitations and opportunities in the United States. Circular Agricultural Systems 4: e005 doi: 10.48130/cas-0024-0003

Recycling agricultural plastic mulch: limitations and opportunities in the United States

- Received: 25 November 2023

- Accepted: 31 January 2024

- Published online: 07 March 2024

Abstract: Plastic mulches have become an essential component of modern agriculture since their introduction in the 1950s. However, disposal of plastic mulches poses serious environmental challenges as plastics that are not considered biodegradable or compostable can take several hundred years to degrade. Each year in the United States, only 9% of overall plastic waste is recycled while 79% is accumulated in landfills or the natural environment. Recycling of plastic mulch is especially constrained due to the contamination that results from their use in farming. Currently, recovered mulches are reported to have 30%–80% surface contamination, primarily from soil and plant debris. Plastic mulch waste is concentrated in areas where they are used and can provide logistical opportunities to the plastic recycling industries. Plastic recycling includes mechanical, advanced (chemical and thermal), and biological methods, that may all be used for polyethylene (PE). Most plastic is recycled using the mechanical method, while advanced and biological methods are promising but face significant financial and technical challenges. For all recycling methods, strategies are needed for managing surface contamination to realize the recycling potential of plastic mulch.