-

Corporate safety culture can be defined as the safety opinion of value, safety consciousness, moral principles, and norms of conduct shared by leaders and employees of an enterprise[1]. Safety culture will promote employees to consciously standardize safety behavior, find out the shortcomings in the development of the actual safety production process, and improve the safety of operation. In addition, safety opinion of value and safety concepts, formed during the safety culture construction can produce a spiritual power of safety production of enterprise development, improving the spiritual style of employees affect the way of work, consciousness and behavior habits of employees, stimulate the enthusiasm and initiative of employees, and promote the safe and stable development of enterprises[2,3]. Therefore, enterprise safety culture construction is an important way to shape the safety opinion of value, awareness, ability, and behavior of the enterprise and improve further the production of intrinsic safety[4−6].

The safety culture construction in Chinese enterprises started from the 1980s, and initially mainly focused on coal mining enterprises, followed by electricity, construction and other types of enterprises[7]. According to the experience of DuPont, Shell, and other famous companies in safety culture construction, the development stages of all corporate safety culture are from passive strict supervision to independent management, and finally team management[8]. It is found that the safety culture development of most Chinese enterprises has gone through a stage of passive implementation of standards and regulations, passive indoctrination of safety concepts, and has developed towards autonomous and team-based management. In this situation, studying the system and connotation of safety culture will greatly improve the safety culture construction and enhance the employees' safety literacy[9]. However, building a corporate safety culture is a systematic and complex task. It is also difficult to directly apply the experience of famous big companies for medium and small enterprises, which usually have a weak corporate culture and limited economic strength[10]. Here, medium enterprises are enterprises with more than 300 employees but less than 1,000 employees, with an operating income of more than 20 million RMB but less than 400 million RMB, and small enterprises are enterprises with 20 to 300 employees and an operating income of 3 million to 20 million RMB according to MIIT Joint Enterprise (2011) No. 300. In 2008, 'the Guidelines for the Construction of Enterprise Safety Culture' (AQ/T9004-2008) was promulgated by the Chinese government, which identified the core content of enterprise safety culture construction. However, due to its guiding nature, this document provided limited details for specific operational steps.

At present, most of the Chinese companies have already established complete security management systems, conducted safety standardization work, and built dual prevention mechanisms, i.e., security risk control and hidden danger investigation. Integrating safety culture construction into existing enterprise safety work will contribute to the smooth implementation of this work. This study is based on a thorough understanding of the current situation of safety production of medium and small enterprises in a national industrial park of southern Jiangsu. First, the elements system of safety culture construction was reconstructed by incorporating the AQ/T 9004-2008 core content to the current situation of management and safety culture in these enterprises. And then specific content and implementation recommendations for the elements of safety culture construction were subsequently proposed communication with experts such as the company's safety director and safety officer. Next, the weight and ranking of each factor were determined using AHP and the SPSSAU online analytical software, which could provide a reference for the efficient development of the construction of corporate safety culture[11,12]. Last, a set of evaluation methods for corporate safety culture, combining direct evaluation with a fuzzy comprehensive evaluation method was proposed, which could provide support for continuous improvement of corporate safety culture construction.

-

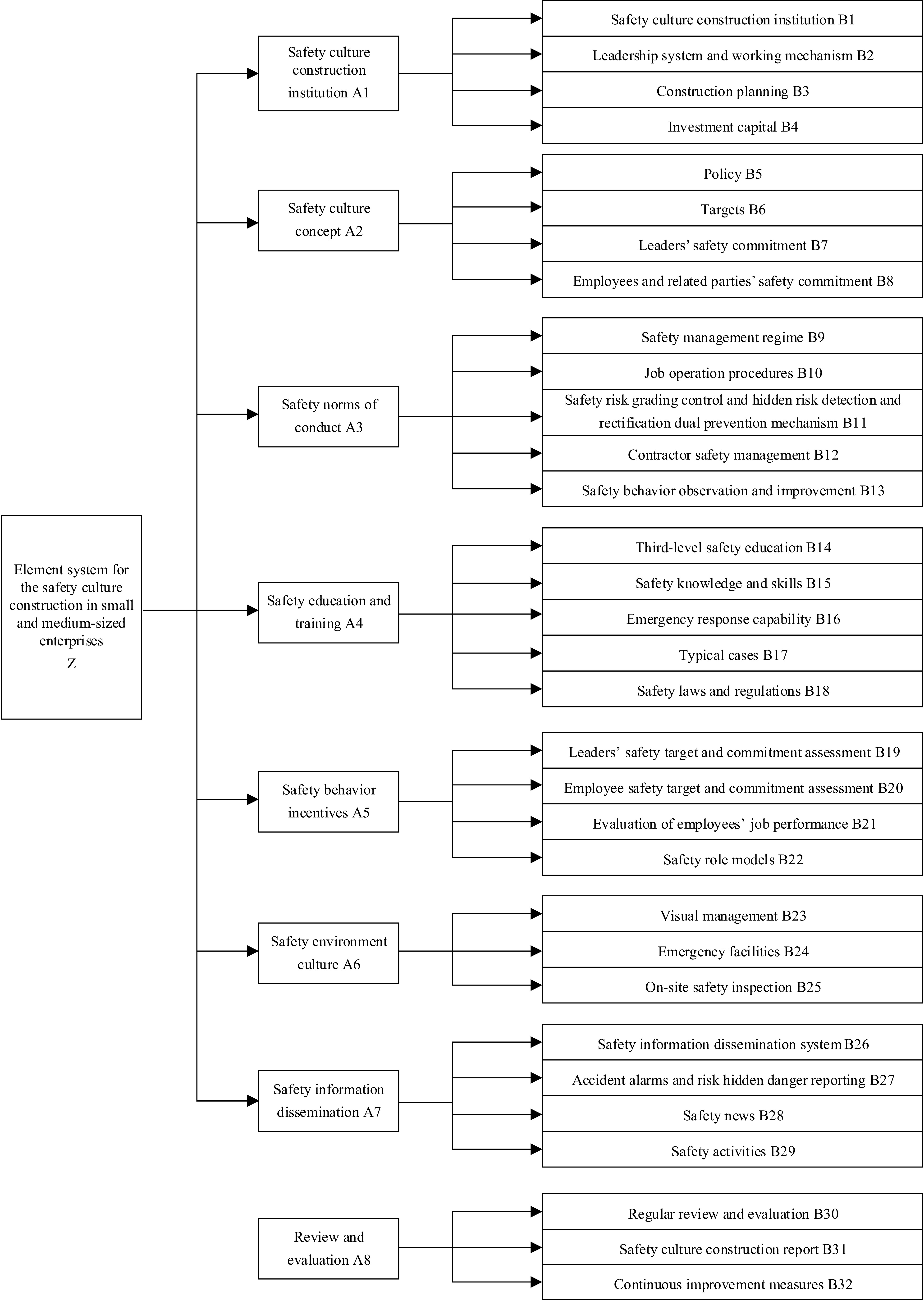

Combing the enterprise safety management system, including safety standardization (GB/T 33000-2016), dual prevention mechanism, an implementation plan for safety culture construction in a new materials industry park in 2023 with the main content of AQ/T9004-2008, an elements system draft of safety culture was developed and formed questionnaire 1 (see Supporting Information). This system has been designed to be consistent with the existing safety management system and work content as much as possible, such as adding some content instead of changing the original content, fully utilizing existing job content to obtain information, and so on. Then, using the expert survey method, opinions on how to modify and improve the element system were obtained through communication and exchange with the main responsible persons, safety management personnel, supervisors of the enterprise, and safety industry experts. Finally, a safety culture construction element system containing eight primary elements and 32 secondary elements were developed for medium and small enterprises (Table 1).

Table 1. Element system for safety culture construction in medium and small enterprises.

Serial no. Primary element Serial no. Secondary element 1 Safety culture construction institution 1.1 Safety culture construction institution 1.2 Leadership system and working mechanism 1.3 Construction planning 1.4 Investment capital 2 Safety culture concept 2.1 Policy 2.2 Targets 2.3 Leaders' safety commitment 2.4 Employees and related parties' safety commitment 3 Safety norms of conduct 3.1 Safety management regime 3.2 Job operation procedures 3.3 Safety risk grading control and hidden risk detection and rectification dual prevention mechanism 3.4 Contractor safety management 3.5 Safety behavior observation and improvement 4 Safety education and training 4.1 Third-level safety education 4.2 Safety knowledge and skills 4.3 Emergency response capability 4.4 Typical cases 4.5 Safety laws and regulations 5 Safety behavior incentives 5.1 Leaders' safety target and commitment assessment 5.2 Employee safety target and commitment assessment 5.3 Evaluation of employees' job performance 5.4 Safety role models 6 Safety environment culture 6.1 Visual management 6.2 Emergency facilities 6.3 On-site safety inspection 7 Safety information dissemination 7.1 Safety information dissemination system 7.2 Accident alarms and risk hidden danger reporting 7.3 Safety news 7.4 Safety activities 8 Review and evaluation 8.1 Regular review and evaluation 8.2 Safety culture construction report 8.3 Continuous improvement measures Specific content and implementation suggestions

Safety culture construction institution

-

Generally, the enterprise has already established a safety management organization. In order to not to increase the workload of enterprise staff, the element of 'safety culture construction institution' can be achieved by adding personnel and responsibilities for safety culture construction on the basis of the safety management organization. The elements of 'leadership system and working mechanism' need to clarify the organizational structure of safety culture construction and the responsibilities of leaders at all levels. This element should clarify how to organize, deploy, promote, and supervise the construction of safety culture, and ensure the funding investment for the construction of safety and security culture in the form of systems. The 'construction planning' element is needed to clarify the tasks, methods, measures, division of work, schedule, and evaluation method for the construction of safety culture. The element of 'investment capital' needs to specify the amount and details of the investment. The investment in safety culture should be included in the total budget for enterprise safety investment.

Safety culture concept

-

The safety policy, is the guideline for the construction of enterprise safety culture, which reflects the overall safety point of value of the enterprise. Its formulation can refer to national safety production policies or safety guidelines for large enterprises. 'Targets' is the expected situation of the construction of enterprise safety culture, which usually includes different levels of goals, such as overall company targets, departmental targets, and individual targets. The 'Leaders' safety commitment' element sets it imperative for the leader to fulfill their responsibilities in the work safety accountability system, i.e., pay attention to, personally carry out and practice the safety commitment, setting an example for the staff. The element of 'Employees and related parties' safety commitment' requires all employees and stakeholders to make safety commitments and consciously fulfill them.

Safety norms of conduct

-

The 'Safety management regime' element require enterprises to add regimes related to safety culture construction in the existing safety management regimes, such as safety investment, observation, and improvement of safety behavior, safety activities, safety role models, and assessment of safety culture construction. It is recommended that leaders at all levels, including upper, middle, and lower levels, as well as grassroots employees, jointly participate in the establishment of safety management regimes. The 'Job operation procedures' are the operation rules and procedures for the various jobs of the enterprise, which contain the safety requirements for the job, aiming at standardizing the operation conduct of the employees and preventing and safeguarding against insecurity. Currently, medium and small enterprises generally have relatively complete job operation procedures. Now, almost all the enterprises have been carrying out 'Safety risk grading control and hidden risk detection and rectification dual prevention mechanism'. It is strongly advised that all employees actively participate in identifying, assessing, managing hidden risks associated with their jobs, equipment, and operations. The element of 'contractor safety management' aims to standardize the safety behavior of contractors and enhance safety awareness, which has already been implemented by most enterprises. 'Safety behavior observation and improvement' require administrators using various methods, such as the STOP Card to standardize safety behavior and Behavior Based Safety (BBS) to encourage employees to carry out safety discussions, and then obverse their remarks and safety behavior, improving employee safety conduct[13,14]. It is a brand-new element for most enterprises, and it is very useful for the construction of safety culture.

Safety education and training

-

The 'Third-level safety education' element requires the company to provide safety production education, training, and assessment to new employees at the company level, workshop or department level, and position level. Only after passing the assessment, employees can take up their posts. This element has already been set up in most enterprises. The 'Safety knowledge and skills' element refers to the training on the job safety operating procedures, the ability to identify work risks and hidden dangers, safety policy, safety objectives, and so on. The 'Emergency response capability' element means cultivating all employees' evacuation and accident response capabilities. The main purpose of 'Typical cases' is to learn about accident cases and near misses that occurred within the enterprise or in similar work in other enterprises. The element of 'Safety laws and regulations' is to educate leaders and employees about their obligations and rights in terms of safety. Most of the above elements are already part of the work of most companies, but the content needs to be further improved.

Safety behavior incentives

-

The element of 'Leaders' safety targets and commitment assessment requires the enterprise safety culture construction organization to regularly evaluate the achievement of enterprise leaders' goals and safety commitments, remind and supervise them to complete safety targets and commitments. 'Employee safety targets and commitment assessment' requires the enterprise safety culture construction organization to regularly evaluate the completion status of employees, reminding them to achieve safety targets and obligations, and fulfill employee responsibilities. 'Evaluation of employees' job performance' requires that enterprises evaluate employees' safety targets and commitments while also assessing their job performance. The above evaluation results are also valuable information as a basis for effectively customizing safety education and training plans. It is worth mentioning that provision rewards should be emphasized and penalties should be avoided. The 'Safety role models' element is a relative new element for many enterprises. It requires enterprises to reward individuals or groups who have achieved good safety targets and commitments, and set them as role models to motivate more employees to learn and improve.

Safety environment culture

-

The 'Visual management' element requires enterprises to post safety signs, major safety risk areas or safety risk warning signs, major safety risk notification signs, signs displaying the wearing of personal protective equipment, and safety production announcement signs. This element has generally been carried out in most enterprises. The 'Emergency facilities' element requires enterprises to configure suitable emergency equipment and devices in appropriate locations and maintain them to ensure their effectiveness. The 'On-site safety inspection' element requires enterprises to conduct safety inspections for all positions, departments, and specialties with the participation of staff. It is especially necessary to strengthen the self-inspection of employee job safety.

Safety information dissemination

-

The elements of 'Safety information dissemination system' require enterprises to establish security information release platforms such as telephone, SMS, email, information platforms, and conference rooms to provide hardware support for security information release. The element of 'Accident alarms and risk hidden danger reporting' requires enterprises to establish the procedure of security risks accident reporting and emergency response to report related information. It is not necessary to limit escalation to level by level in reporting an incident. The 'Safety news' element requires enterprises to promote internal safety models, safety accidents, safety incidents related to enterprise production, the latest security technologies, policies, standards, and major safety production accidents in the form of news. The 'Safety activities' element requires companies to regularly organize activities for groups, departmental, or full-staff safety communication activities, to disseminate safety information and exchange security experience.

Review and evaluation

-

The 'Regular review and evaluation' element requires enterprises to regularly review and evaluate the construction of a safety culture. It can be considered to combine the direct evaluation of secondary factors with the fuzzy comprehensive evaluation of the overall safety culture construction effect, and the evaluation frequency can be once a year. The element of the 'Safety culture construction report' requires enterprises to compile the evaluation process and results into a safety culture construction report, providing information support for subsequent improvement of safety culture construction. The 'Continuous improvement measures' element requires enterprises to propose improvement measures for the limitations in the current process of safety culture construction, for continuous improvement.

-

According to the system and connotation of safety culture construction outlined in the above section, enterprises should be able to build their safety culture based on their actual situation. However, the construction of safety culture is a systematic project which is very complex. So, it needs to grasp the main contradictions and critical issues during the process of practice. This requires the analysis of the importance of 32 elements, i.e., calculating the weight of every element. How to address this issue? In 1970, American mathematician Saaty put forward a hierarchical weighted decision analysis method, the analytic hierarchical process, this method can effectively deal with this kind of problem[15,16]. To calculate the weight of elements, it is necessary to analyze, compare, judge, and evaluate each element, establish a judgment matrix, and then calculate the weight. In this process, subjective elements account for a large proportion, and the effectiveness of the judgment matrix needs to be determined.

Hierarchical structure model of safety culture construction elements in medium and small enterprises

-

The AHP method was used to calculate the weight of safety culture elements. Taking safety culture construction of enterprises as the target layer, eight primary elements as the indicator layer, and 32 secondary elements as the solution layer, the safety culture hierarchical structure model was established and is shown in Fig. 1. This model had a relatively independent hierarchical structure.

Building judgment matrix

-

The judgment matrix is a matrix formed by the judgment values of element importance, which is the basic information of element weighted analysis. In this case, the judgment matrix included two kinds of matrix. The first matrix formed by the importance of each primary element with respect to the target of safety culture construction of enterprises. The other matrixes were composed by the judgment value of the importance of each secondary element with respect to each primary element. The specific method is to compare, evaluate, and assign values to the importance of any two elements relative to the previous level element. Usually, a 1−9 scale method is used to score the weights[17], and aij is used to construct a judgment matrix, aij represents the comparison results of each element in the ith row relative to the elements in the jth column. The detail meaning of the 1−9 scale is illustrated in the Supporting Information. Five enterprise experts were invited to evaluate and assign values to the elements, average values were adopted finally (as detailed in questionnaire 2 in the Supporting Information). According to questionnaire 2, an eighth order matrix, two fifth order matrices, four fourth-order matrices and two third-order matrices, a total of 9 matrices were obtained, which were as follows:

(1) Safety culture construction in enterprises judgment matrix

$ \mathrm{A}=\left[\begin{array}{cccccccc}1& \dfrac{1}{5}& \dfrac{1}{7}& \dfrac{1}{5}& \dfrac{1}{3}& 1& \dfrac{1}{3}& 1\\ 5& 1& \dfrac{1}{5}& 1& 3& 5& 3& 5\\ 7& 5& 1& 5& 5& 7& 5& 7\\ 5& 1& \dfrac{1}{5}& 1& 3& 5& 3& 5\\ 3& \dfrac{1}{3}& \dfrac{1}{5}& \dfrac{1}{3}& 1& 3& 1& 3\\ 1& \dfrac{1}{5}& \dfrac{1}{7}& \dfrac{1}{5}& \dfrac{1}{3}& 1& \dfrac{1}{3}& 1\\ 3& \dfrac{1}{3}& \dfrac{1}{5}& \dfrac{1}{3}& 1& 3& 1& 3\\ 1& \dfrac{1}{5}& \dfrac{1}{7}& \dfrac{1}{5}& \dfrac{1}{3}& 1& \dfrac{1}{3}& 1\end{array}\right] $ (2) Judgment matrix of safety culture construction institutions

$ {B}_{1}=\left[\begin{array}{cccc}1& \dfrac{1}{5}& \dfrac{1}{3}& 1\\ 5& 1& 3& 5\\ 3& \dfrac{1}{3}& 1& 3\\ 1& \dfrac{1}{5}& \dfrac{1}{3}& 1\end{array}\right] $ (3) Judgment matrix of safety culture concept

$ {B}_{2}=\left[\begin{array}{cccc}1& \dfrac{1}{3}& \dfrac{1}{5}& 1\\ 3& 1& \dfrac{1}{3}& 3\\ 5& 3& 1& 5\\ 1& \dfrac{1}{3}& \dfrac{1}{5}& 1\end{array}\right] $ (4) Judgment matrix of safety norms of conduct

$ {B}_{3}=\left[\begin{array}{ccccc}1& 1& \dfrac{1}{5}& 3& \dfrac{1}{3}\\ 1& 1& \dfrac{1}{5}& 3& \dfrac{1}{3}\\ 5& 5& 1& 7& 3\\ \dfrac{1}{3}& \dfrac{1}{3}& \dfrac{1}{7}& 1& \dfrac{1}{5}\\ 3& 3& \dfrac{1}{3}& 5& 1\end{array}\right] $ (5) Judgment matrix of safety education and training

$ {B}_{4}=\left[\begin{array}{ccccc}1& \dfrac{1}{5}& 1& 3& 3\\ 5& 1& 3& 5& 5\\ 1& \dfrac{1}{3}& 1& 3& 3\\ \dfrac{1}{3}& \dfrac{1}{5}& \dfrac{1}{3}& 1& 1\\ \dfrac{1}{3}& \dfrac{1}{5}& \dfrac{1}{3}& 1& 1\end{array}\right] $ (6) Judgment matrix of safety behavior incentives

$ {B}_{5}=\left[\begin{array}{cccc}1& 3& 1& 1\\ \dfrac{1}{3}& 1& \dfrac{1}{3}& \dfrac{1}{3}\\ 1& 3& 1& 1\\ 1& 3& 1& 1\end{array}\right] $ (7) Judgment matrix of safety environment culture

$ {B}_{6}=\left[\begin{array}{ccc}1& 3& \dfrac{1}{3}\\ \dfrac{1}{3}& 1& \dfrac{1}{5}\\ 3& 5& 1\end{array}\right] $ (8) Judgment matrix of safety information dissemination

$ {B}_{7}=\left[\begin{array}{cccc}1& \dfrac{1}{5}& 1& \dfrac{1}{3}\\ 5& 1& 5& 3\\ 1& 5& 1& \dfrac{1}{3}\\ 3& \dfrac{1}{3}& 3& 1\end{array}\right] $ (9) Judgment matrix of review and evaluation

$ {B}_{8}=\left[\begin{array}{ccc}1& 3& 1\\ \dfrac{1}{3}& 1& \dfrac{1}{3}\\ 1& 3& 1\end{array}\right] $ Weight calculation of every element

-

The calculation method was determined with reference to a previous study[18] using SPSSAU online analysis software[19], the results are shown in Table 2.

Table 2. List of weighting results.

Goal level Indicator layer (primary element) Weight of

element A to ZSolution layer (secondary element) Weight of element

B to AWeight of

element B to ZTotal sorting Safety culture construction of medium and small enterprises Z A1 0.03444 B1 0.09670 0.00333 31 B2 0.55495 0.01911 16 B3 0.25165 0.00867 25 B4 0.09670 0.00333 31 A2 0.16715 B5 0.09670 0.01616 18 B6 0.25165 0.04206 6 B7 0.55495 0.09276 3 B8 0.09670 0.01616 18 A3 0.39755 B9 0.10531 0.04187 7 B10 0.10531 0.04187 7 B11 0.49712 0.19763 1 B12 0.04688 0.01864 17 B13 0.24539 0.09755 2 A4 0.16715 B14 0.17438 0.02915 10 B15 0.49361 0.08251 4 B16 0.18817 0.03145 9 B17 0.07192 0.01202 22 B18 0.07192 0.01202 22 A5 0.08242 B19 0.30000 0.02473 11 B20 0.10000 0.00824 26 B21 0.30000 0.02473 11 B22 0.30000 0.02473 11 A6 0.03444 B23 0.26050 0.00897 24 B24 0.10616 0.00366 30 B25 0.63335 0.02181 14 A7 0.08242 B26 0.09670 0.00797 27 B27 0.55495 0.04574 5 B28 0.09670 0.00797 27 B29 0.25165 0.02074 15 A8 0.03444 B30 0.42857 0.01476 20 B31 0.14286 0.00492 29 B32 0.42857 0.01476 20 The consistency check data of the weights of every element are shown in Table 3. Because the consistency of all elements had been verified, the above data of weights and importance sorting were valid.

Table 3. Consistency checking table for each judgment matrix.

The construction of a judgment matrix $ {\lambda }_{max} $ n CI RI CR Consistency Safety culture construction in medium and small enterprises 8.357 8 0.051 1.410 0.036 Verified Safety culture construction institutions 4.044 4 0.015 0.890 0.016 Verified Safety culture concept 4.044 4 0.015 0.890 0.016 Verified Safety norms of conduct 5.127 5 0.032 1.120 0.028 Verified Safety education and training 5.137 5 0.034 1.120 0.031 Verified Safety behavior incentives 4.000 4 0.000 0.890 0.000 Verified Safety environment culture 3.039 3 0.019 0.520 0.037 Verified Safety information dissemination 4.044 4 0.015 0.89 0.016 Verified Review and evaluation 3.000 3 0.000 0.520 0.000 Verified It can be seen from Table 2, for the goal of 'safety culture construction in construction enterprises' the weights of safety culture construction institution A1was 0.03444, safety culture concept A2 was 0.16715, safety norms of conduct A3 was 0.39755, safety education and training A4 was 0.16715, safety behavior incentives A5 was 0.08242, safety environment culture A6 was 0.03444, safety information dissemination A7 was 0.08242, review and evaluation A8 was 0.03444. The weights were ranked as: A3 > A2 = A4 > A5 = A7 > A1 = A6 = A8. According to the sorting results, it can be concluded that special attention should be paid to the construction of safety norms of conduct for enterprise employees in the process of corporate culture construction, followed by the conduct of safety education and training, as well as the cultivation of safety culture concept.

For the construction of 'safety culture construction institution A1' in the indicator layer, the weights of safety culture construction institution B1, Leadership system and working mechanism B2, Construction planning B3, Investment capital B4 were 0.09670, 0.55495, 0.25165, 0.09670, respectively. The weights were ranked as B2 > B3 > B1 = B4. Which meant that the construction of 'Leadership system and working mechanism' was the most important. Similarly, it was calculated that for the construction of 'Safety culture concept A2' in indicator layer, the importance of the secondary elements was: leaders' safety commitment B7 > targets B6 > policy B5 = employees and related parties' safety commitment B8. For the construction of 'Safety norms of conduct A3' in indicator layer, the importance of the secondary elements was: safety risk grading control and hidden risk detection and rectification dual prevention mechanism B11 > safety behavior observation and improvement B13 > safety management regime B9 = Job operation procedures B10 > contractor safety management B12.

For the construction of 'Safety education and training A4' in indicator layer, the importance of the secondary elements was: safety knowledge and skills B15 > emergency response capability B16 > third-level safety education B14 > typical cases B17 = safety laws and regulations B18. For the construction of 'Safety behavior incentives A5' in indicator layer, the importance of the secondary elements was: leaders' safety target and commitment assessment B19 = evaluation of employees' job performance B21 = safety role models B22 > employee safety target and commitment assessment B20, respectively. For the construction of 'Safety environment culture A6' in indicator layer, the importance of the secondary elements was: on-site safety inspection B25 > visual management B23 > emergency facilities B24, respectively. For the construction of 'Safety information dissemination A7' in indicator layer, the importance of the secondary elements was: accident alarms and risk hidden danger reporting B27 > safety activities B29 > safety information dissemination system B26 = safety news B28. For the construction of 'Review and evaluation A8' in indicator layer, the importance of the secondary elements was: regular review and evaluation B30 = continuous improvement measures B32 > safety culture construction report B31.

The weight and ranking of each secondary element relative to the overall goal of enterprise safety culture construction are shown in the sixth and seventh columns of Table 1. The ranking of its importance reflected the key to improving the essence of safety, which was consistent with the content of enterprise safety work. For example, the element of safety risk grading control and hidden risk detection and rectification dual prevention mechanism (0.19763) was the first important. In fact, it has always been a key focus of enterprise security work in recent years, and it is also an important lever for the government in enterprise supervision. It is proven that establishing such a mechanism can greatly improve employees' safety awareness and abilities, and reduce the occurrence of accidents and near misses. In terms of weight value safety behavior observation and improvement (0.09755) was the second most important, it was also a key focus of safety culture construction which was proved by many well-known companies. Employing appropriate methods to observe and improve the safety behavior of employees could increase their awareness and behaviors related to safety and the safety of their operations.

As analyzed above, the weighted analysis of the elements of the safety culture construction system for medium and small enterprises could provide practical references for the effective development of enterprise safety culture and necessary data for evaluating the effectiveness of enterprise safety culture construction. However, the above analysis results may not be applicable to all types of enterprises. At this point, it is necessary to hire experts to compare and score the first and second level elements separately based on the situation of the enterprise, forming a new judgment matrix; then calculating the weights and sorting of the elements at all levels using SPSSAU online analysis software. It should be noted to perform consistency checks on each matrix. All consistency checks must pass before the calculation results are valid. Otherwise, it is necessary to re-construct a judgment matrix and perform calculations.

-

The secondary elements were the concrete content of safety culture construction, which could be directly and quantitatively evaluated based on the actual situation. Taking 'the leader's safety commitment' as example, if the enterprise leader has made a safety commitment and understood the content and significance of his safety commitment, the effect of the construction of this secondary element was good or accomplishment. For the element of 'emergency facilities', if the enterprise's emergency facilities were complete and intact, the construction effect of this secondary element was good or accomplishment. If the emergency facilities are not fully equipped or individual facilities cannot operate normally, the evaluation of the construction effect of this element can be assigned based on the ratio of intact equipment. It was note that the score assignment way must was consistent for the evaluation of different elements.

Fuzzy comprehensive evaluation of safety culture construction result of medium and small enterprises

-

As we know that each major element contained several minor elements, and the construction effect of each minor element was not consistent. For example, the primary element of 'safety culture concept' included four secondary elements, each of the elements had a different construction effect and importance, so it was difficult to evaluate the construction effect of safety culture concept. The evaluation of primary elements was a fuzzy phenomenon, so did the evaluation of the overall effect of the construction of enterprise safety culture. Fortunately, the fuzzy comprehensive evaluation method can address this kind of issues[20]. The specific evaluation steps are as follows:

(1) Establishing a multi-level fuzzy comprehensive evaluation model, which divides the element domain U into several subsets, i.e., U = {U1, U2, ..., Up}.

According to Table 1 and Fig. 1, the safety culture construction system of medium and small enterprises consisted of nine fuzzy sets, i.e., one first-level set consisting of eight factors and another eight second level subsets composed of different factors. The element domain of one first-level set was: U = {u1, u2, u3, u4, u5, u6, u7, u8}. u1 was Safety culture construction institution, u2 was safety culture concept, u3 was safety norms of conduct, u4 was safety education and training, u5 was safety behavior incentives, u6 was safety environment culture, u7 was safety information dissemination, u8 was review and evaluation. The element domain of u1 subset was: u1 = {u11, u12, u13, u14}, and u11 was establishment of safety culture construction institution, u12 was establishment of Leadership system and working mechanism, u13 was construction planning, u14 was capital investment in safety culture. Similarly, the elements in the other subsets of u2, u3, u4, u5, u6, u7, u8 were their own secondary elements respectively, as shown in Table 1 and Fig. 1.

(2) Determining the domain of comment level V, V = {v1, v2, …, vn}

For example, the domain of comment level could be determined as V = {excellent, good, medium, pass, poor}, and the value could be given as: excellent was 95, good was 85, medium was 75, pass was 60, poor was 45.

(3) Setting the weight for each element or subset

The weight for each element or subset was determined as described prior, the weight of u1, u2, u3, u4, u5, u6, u7, u8 in were 0.03444, 0.16715, 0.39755, 0.16715, 0.08242, 0.03444, 0.08242, and 0.03444, they formed a domain of a. The weight of element in subset of u1 = {u11, u12, u13, u14} was b1 = {0.09670, 0.55495, 0.25165, 0.09670}. Similarly, the other weight of other subsets could be obtained from the fifth column of Table 2.

(4) Establishing a fuzzy relationship matrix for each subset by evaluating all factors in each subset

Each element in the subset was evaluated based on the V = {Excellent, Good, Medium, Pass, Poor} rating scale using the scoring method by evaluators. For example, for the evaluation of the u6 subset, if 10 people were invited to conduct a review, six of them evaluated the enterprise visual management u61 as excellent, two of them rated good, two of them rated medium, no one rated only pass or poor, then the comment affiliation of u61 was obtained and shown in the second row of Table 4. Similarly, the evaluation of u62 and u63 and the results were obtained and shown in the third and fourth rows of Table 4.

Table 4. Table for u6 subset rubric level assignment.

Element Excellent Good Moderate Pass Poor u61 0.5 0.4 0.1 0 0 u62 0.3 0.4 0.2 0.1 0 u63 0.4 0.5 0.1 0 0 According to the above table, the fuzzy relationship matrix of the u6 subset was as follows:

$ {\rm u}_{6} =\left(\begin{array}{ccccc}0.5& 0.4& 0.1& 0& 0\\ 0.3& 0.4& 0.2& 0.1& 0\\ 0.4& 0.5& 0.1& 0& 0\end{array}\right) $ (5) Comprehensive evaluation of each subset using synthetic operators

Taking subset u6 as example, according to prior, the element weights of u6 = {u61, u62, u63} was b6 = {0.26050, 0.10616, 0.63335}. The synthesis operator, b6·u6 =

$ ({c}_{ij}{)}_{3\times 5}={\mathop{\stackrel{s}\vee}\limits _{k=1}}({a}_{ik}\wedge {b}_{kj}) $ $\begin{aligned} {\rm b}_{6}\cdot {\rm u}_{6}=\;&\{0.26050,\;0.10616,\;0.63335\}\cdot \left(\begin{array}{ccc}0.6& 0.2& 0.200\\ 0.5& 0.3& 0.10.10\\ 0.2& 0.4& 0.20.10.1\end{array}\right)\\ =\;&\{0.26050,\;0.4,\;0.2,\;0.1,\;0.1\}\\ =\;& \{0.246,\;0.377,\;0.189,\;0.09,\;0.09, 0 \}\\&\rm(after\; normalization\; process)\end{aligned} $ It can be seen from the above results that the construction effect of 'safety environment culture' had a degree of affiliation of {0.362, 0.452, 0.096, 0.090, 0} for the {Excellent, Good, Medium, Pass, Poor}. The degree which u6 belonged to 'Good' was the highest, so it could be inferred that 'safety environment culture' construction effect was good. In addition, the evaluation score of the construction effect of the enterprise's 'safety environment culture' was 85.4 points according to the assigned value. The calculation process was as follows: 0.362 × 95 + 0.452 × 85 + 0.096 × 75 + 0.090 × 60 = 85.4.

(6) After each subset is calculated in this way, the synthesis of high-level operators is carried out until the highest level[22].

$\begin{aligned} U=\;& \mathrm{a}\cdot\mathrm{b} =\{0.03444,\;0.16715,\;0.39755,\;0.16715,\;0.08242,\\&0.03444,\;0.08242,\;0.03444\}\cdot \left(\begin{array}{c}b1\\ b2\\ b3\\ b4\\ b5\\ b6\\ b7\\ b8\end{array}\right) \\=\;& \{\mathrm{x}1,\;\mathrm{x}2,\;\mathrm{x}3,\;\mathrm{x}4,\;\mathrm{x}5\} \end{aligned}$ So, the fuzzy relation set of U was obtained, which was U = {x1, x2, x3, x4, x5}. This meant that the overall evaluation of the result of enterprise safety culture construction was of a membership degree of {x1, x2, x3, x4, x5} for the comment domain of V = {Excellent, Good, Medium, Passed, Poor}. The overall evaluation of the result of safety culture construction was the highest membership degree or calculated score according to the assigned value. Through this method, it is possible for enterprise employees or external experts to evaluate the secondary elements of enterprise safety culture construction, and then to conduct fuzzy synthesis of the main elements or overall construction effect of enterprise safety culture, thereby providing reference for continuous improvement.

-

This paper was studied by incorporating the core content of AQ/T9004-2008 into the actual safety situation of medium and small enterprises in an industrial park in southern Jiangsu, and drawing on the experiences of famous companies in building a safety culture. A complete element system for safety culture construction in medium and small enterprises was proposed by literature research, theoretical study, and questionnaire investigation. This system included eight primary elements and 32 secondary elements. The primary elements were safety culture construction institution, safety norms of conduct, safety culture concept, safety education and training, safety environment culture, safety behavior incentives, review and evaluation, and safety information dissemination. After a thorough analysis of the various elements of safety culture, detailed work content and implementation suggestions were proposed, providing reference for the construction of medium and small enterprise safety culture. The weights and rankings of various levels of elements in the system were calculated utilizing SPSSAU online analysis software based on an expert survey method and AHP method. This could help enterprises understand the key and primary tasks of carrying out safety culture construction, thereby effectively promoting safety culture construction. A set of evaluation methods for assessing the effect of enterprise safety culture construction were developed, i.e., evaluating directly the secondary elements according to their complete content; evaluating quantitatively the effect of the main elements and overall result of safety culture construction using the fuzzy comprehensive evaluation method. During the evaluation process, deficiencies in the construction of safety culture could be identified and suggestions could be provided for continuous improvement. The evaluation method and results could also serve as a reference for government regulatory agencies, insurance companies, or third-party organizations to assess enterprise security.

This research was sponsored by the construction special project (JG-03-04) of the school of emergency management, Jiangsu university and the Jiangsu provincial social science foundation, research on the collaborative mechanism of safety production governance for small and medium sized enterprises in Jiangsu province (20GLB009).

-

The expert survey method is a commonly used research method. All the experts were entirely voluntary. The survey in this manuscript didn't involve any personal privacy. The experts' answers were entirely based on their own views without any restrictions or inducements. The feedback from the experts can reflect the actual safety culture situation of an enterprise and this was what was being investigated. For such non-interventional studies, ethical approval is not required.

-

The authors confirm contribution to the paper as follows: study conception and design, manuscript review: Li L; diagram and draft manuscript preparation: Yan P; formal analysis, investigation and data curation: Wang X; guidance of the survey: Liu S; liaison with the company and relevant experts: Zhang Y; validation and project administration: Cheng Y. All authors reviewed the results and approved the final version of the manuscript.

-

The dataset used and analyzed in this study can be obtained from the article and its supplementary information files, or from the corresponding authors upon reasonable request.

-

The authors declare that they have no conflict of interest.

- Supporting Information Investigation letter of experts on elements of safety culture construction system in small and medium-sized enterprises 1 and 2.

- Copyright: © 2024 by the author(s). Published by Maximum Academic Press on behalf of Nanjing Tech University. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Li L, Yan P, Wang X, Liu S, Zhang Y, et al. 2024. Research on the safety culture in medium and small enterprises. Emergency Management Science and Technology 4: e021 doi: 10.48130/emst-0024-0022

Research on the safety culture in medium and small enterprises

- Received: 05 July 2024

- Revised: 29 September 2024

- Accepted: 08 October 2024

- Published online: 30 October 2024

Abstract: Economic development is often accompanied by a variety of production safety accidents. Currently, human factors have become the main constraint on safety for enterprises, especially small and medium-sized. Establishing corporate safety culture is an important approach to addressing that issue and improving the intrinsic safety level of enterprises. In this paper, an element system for safety culture construction, containing eight primary elements and 32 secondary elements, for medium and small enterprises was put forward according to the actual situation of safety production in enterprises in industrial parks using an expert survey method. This system integrated the construction of safety culture into the existing management system and specific safety work so that it had good implementability. Then, using SPSSAU online analysis software, expert surveys, and analytic hierarchy process (AHP), as well as the expert survey method, weights and rankings of every element of this safety culture element construction system were determined, which could provide a reference for the efficient of the safety culture construction. It is very important to evaluate the enterprise safety culture construction. Here, a set of quantitative evaluation methods was proposed, which combined a direct quantitative evaluation for secondary elements and a fuzzy comprehensive evaluation method for the primary elements and the whole safety culture construction. This method can be used to evaluate the effectiveness of enterprise safety culture construction, identify weaknesses and continuously improve, and could also serve as a reference for government regulatory agencies, insurance companies, or third-party organizations to assess enterprise security.