-

Abalone, known as a highly valuable single-shell shellfish, is a traditional and precious seafood in China and other countries and regions in Asia[1]. In 2020, the global production is 22,000 tons[2]. It’s meat is tender and delicious, earning it the title of 'the crown of seafood'. Abalone, as a high protein and low-fat healthy seafood, has high nutritional and therapeutic values[3, 4]. Abalone products include various forms, such as fresh and dried products, frozen, canned, seasoning, and nutritional and health products[5]. Among these forms, dried Abalone is the main form of production and consumption. The reason is that during the drying process of fresh Abalone, its physical and chemical properties and organizational structure are changed, resulting in a softening effect inside, making its taste more delicious[6, 7]. Usually, dried Abalone requires a long period of swelling before formal cooking, and different methods of swelling can directly affect the taste, nutritional composition, and quality. The degree of freshness of dried Abalone after rehydration is an important indicator to measure its quality. After reabsorbing water, dried Abalone should be similar in weight, texture, flavor, size, shape, color, nutritional composition, tissue structure, etc. to the state before freshness or dehydration and drying[8, 9]. The process of dry Abalone swelling is very complex. There are two main methods for swelling of dried Abalone: water and alkaline swelling. Water swelling of dried Abalone refers to the use of purified water to treat dried Abalone, and through the natural infiltration and diffusion of water molecules, it enters the intercellular and intracellular spaces of dried Abalone tissue, thereby restoring the dried Abalone to its fresh state[3]. Alkaline welling of dried Abalone is a method of soaking dried Abalone in an alkaline solution to soften it. There are three main types of alkalis used to swell dried Abalone, namely sodium carbonate, sodium hydroxide, and sodium bicarbonate, and they are often used in the swelling of dried products such as Abalone[10], sea cucumber[11], tendon[12], hairy belly[13], and fish skin[14]. However, such swelling methods further bury hidden dangers in food safety. At the same time, it also causes a significant loss of nutrients inside Abalone[15]. Although China's Abalone production ranks among the top in the world, Abalone processing is mostly concentrated in European and American markets[16, 17]. With the continuous improvement of people's material living standards and health awareness, the quality of the food consumed is increasingly receiving attention. Thus, it is particularly important to detect and control the quality of dried Abalone during processing.

At present, there is no detailed report on the swelling standards for dried Abalone in the world, so conducting research on the changes in Abalone quality using different swelling methods is more conducive to better eating effects of Abalone. Therefore, this study takes dried Abalone as the research object, and measures its changes in pH, centrifugal loss, shear force, texture, color, cooking loss, sensory, and swelling rate under different swelling (water and alkali) methods. At the same time, low-field nuclear magnetic resonance technology is used to analyze the water distribution status, and to study the changes in their texture during the swelling process, providing theoretical support and scientific basis for the swelling of such aquatic products.

-

Dried Abalone rugosa, commercially available (60 pieces/500 g); Sodium carbonate (Food grade) was purchased from Tongbai Boyuan New Chemical Co., Ltd. (China).

Swelling of dried Abalone

-

Water swelling: soak dried Abalone in water for 4 h at 25 °C, then boil in water for 5 min, and then let it cool for 12 h at 4 °C before weighing. Then calculate the growth rate of Abalone, conduct sensory evaluation, and measure various indicators.

Alkali swelling: A concentration of 5% sodium carbonate solution was selected. Abalone was soaked in 5% sodium carbonate solution for 2 d at 4 °C, then boiled in water for 40 min; finally, swelling in cold water (4 °C) for 8 h.

pH measurement

-

The surface moisture of the sample was dried and a portable pH meter (205, Testo, Germany) was used to measure the pH of Abalone foot muscles. Before conducting the experiment, the pH standard buffer solution was used for calibration. The pH meter was then directly inserted into Abalone samples treated with different expansion methods at a depth of approximately 10 mm.

Swelling rate

-

According to the method of Li et al.[18], the swelling rate of dried Abalone was calculated under different swelling methods. Before swelling, the quality of dried Abalone was measured and recorded as W0. After swelling, the surface was dried with absorbent paper and the weight of the swollen Abalone was weighed again, recording it as W. This was repeated five times for each sample. The calculation of the Abalone swelling rate was as follows:

Swelling rate (%) = (W − W0)/W0 × 100%

In the formula: W - mass of Abalone after swelling, g; W0 - Mass of Abalone before rising, g.

Centrifugal loss

-

Centrifuge loss referred to the method of Bertram et al.[19] with slight modification. A certain amount of swelling Abalone that has been processed by water and alkali were taken, and cut it into pieces. A degreased cotton was placed at the bottom of the centrifuge tube, and the chopped Abalone was wrapped in a double layer filter paper, and placed in the centrifuge tube. The centrifuge speed to was set to 4000 g, and centrifuged at 4 °C for 15 min, the weight of the Abalone was weighed before and after centrifugation, and denoted as W1 and W2. The centrifugal loss is calculated as follows:

Centrifugal loss (%) = (W1 − W2)/W2 × 100%

In the formula: W1 - weight of the sample before centrifugation, g; W2 - Weight of the sample after centrifugation, g.

Cooking loss

-

The cooking loss referred to the method of Kang et al.[20] with slight modification. The swelling Abalone surface was dried with a tissue and the quality of the Abalone was weighed before cooking, denoted as W1. The Abalone was placed in a sealed bag and immersed in water at 100 °C for 15 min. Throughout the heating process, the Abalone did not come into direct contact with the hot water. After heating, the sample was removed, the surface moisture was wiped off, and the mass of the steamed Abalone was weighed, denoted as W2. The cooking loss was calculated as follows:

Cooking loss (%) = (W1 − W2)/W3 × 100%

In the formula: W1 - mass of the sample before cooking, g; W2 - Mass of the sample after cooking, g.

Texture properties

-

The swollen Abalone stored overnight at 4 °C was removed and left at room temperature for 2 h. Subsequently, the Abalones under different treatment conditions were cut into cylinders with a diameter of 10 mm and a height of 10 mm. The texture properties were measured using a texture analyser (TA-XT.plus, Stable Micro Systems Ltd., Surrey, UK). The measurement parameters were set as follows: compression ratio of 30%, triggering force of 5 g, speed before and after testing were 3.00 mm/s, and speed during testing was 1.00 mm/s. The obtained texture parameters were hardness, springiness, cohesiveness, and chewiness.

Shear force

-

The middle part of the Abalone foot muscle was taken, and the Abalone sample was a cylindrical shape with a diameter of approximately 12 mm and a height of 10 mm. The shear force was measured using a digital muscle tenderness meter (C-LM3B, China). The testing rate of the test probe (HDP/PS) was set to 1.00 mm/s, and the data acquisition rate was set to 400 p/s[21].

Color

-

A CR-400 portable colorimeter (Minolta Camera Co., Japan) was callibrated in advance and used to analyze the color differences of dried Abalone with different swelling methods. Six randomly selected Abalone samples with water and alkali swelling were taken, three measurements of L*, a*, and b* values were taken on each swelling Abalone[22].

Low-field nuclear magnetic resonance (low-field NMR)

-

Low-field NMR measurements were performed according to Kang et al.[23]. The puffed Abalone were kept at 32 °C for 2 h, excess water was removed from the surface of the swelling Abalone, and cut into 2 g cubes for later use. The swelling Abalone was placed into an NMR tube with a diameter of 25 mm and a PQ001 low-field NMR analyser (Niumag Corporation, Shanghai, China) was used to measure the relaxation time (T2) and moisture distribution.

Data and analysis

-

The whole process of pork batter production was repeated three times on different days (three independent batches). The data were analyzed using the statistical software package SPSS V.27.0 (SPSS Inc., Chicago, USA) through the one-way ANOVA program, the difference between means was considered significant at p < 0.05. Significant differences between samples were identified by an independent-sample t-test.

-

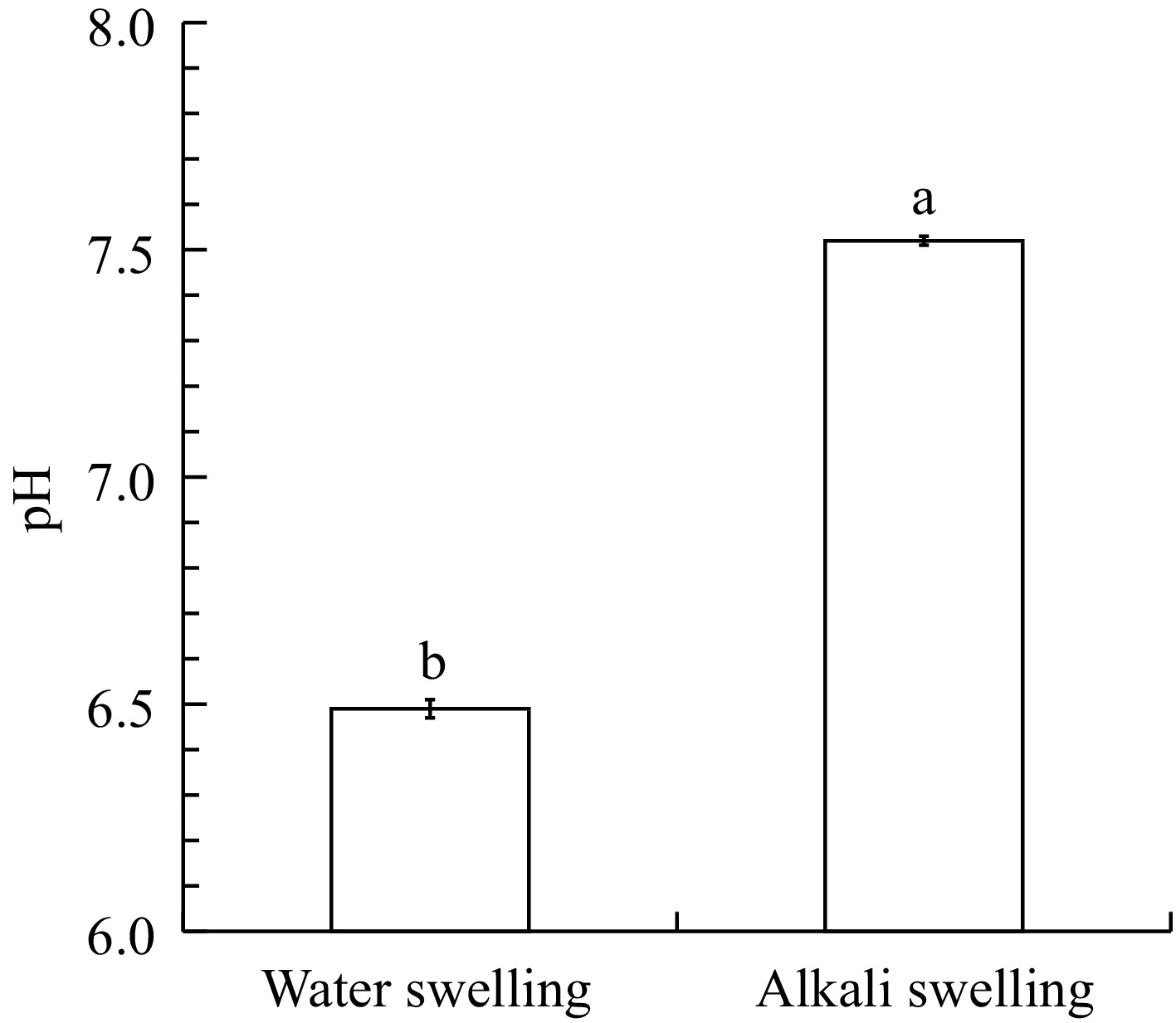

The effect of water and alkali swelling on the pH of dried Abalone muscle is shown in Fig. 1. Compared to the water swelling Abalone muscle (6.49 ± 0.02), the swelling rate of the sample treated with sodium carbonate solution (7.52 ± 0.01) significantly increased (p < 0.05). It is well known that sodium carbonate decomposes into OH−, HCO32−, HCO3−, Na+, etc., in the aqueous solution, which shifts the pH of the solution[24, 25]. Some studies found that the increase in pH of Abalone is related to protein denaturation[26], indicating that the Abalone has higher protein stability. In addition, the increase in pH maybe due to the protein unfolding in the Abalone foot muscle under alkaline conditions, exposing alkaline groups and thus burying acidic groups[27].

Figure 1.

Effect of water and alkali swelling on the pH of dried Abalone muscle. Each value represents the mean ± SD, n = 3. Different superscripts in the same column indicate significant differences (p < 0.05).

Swelling rate

-

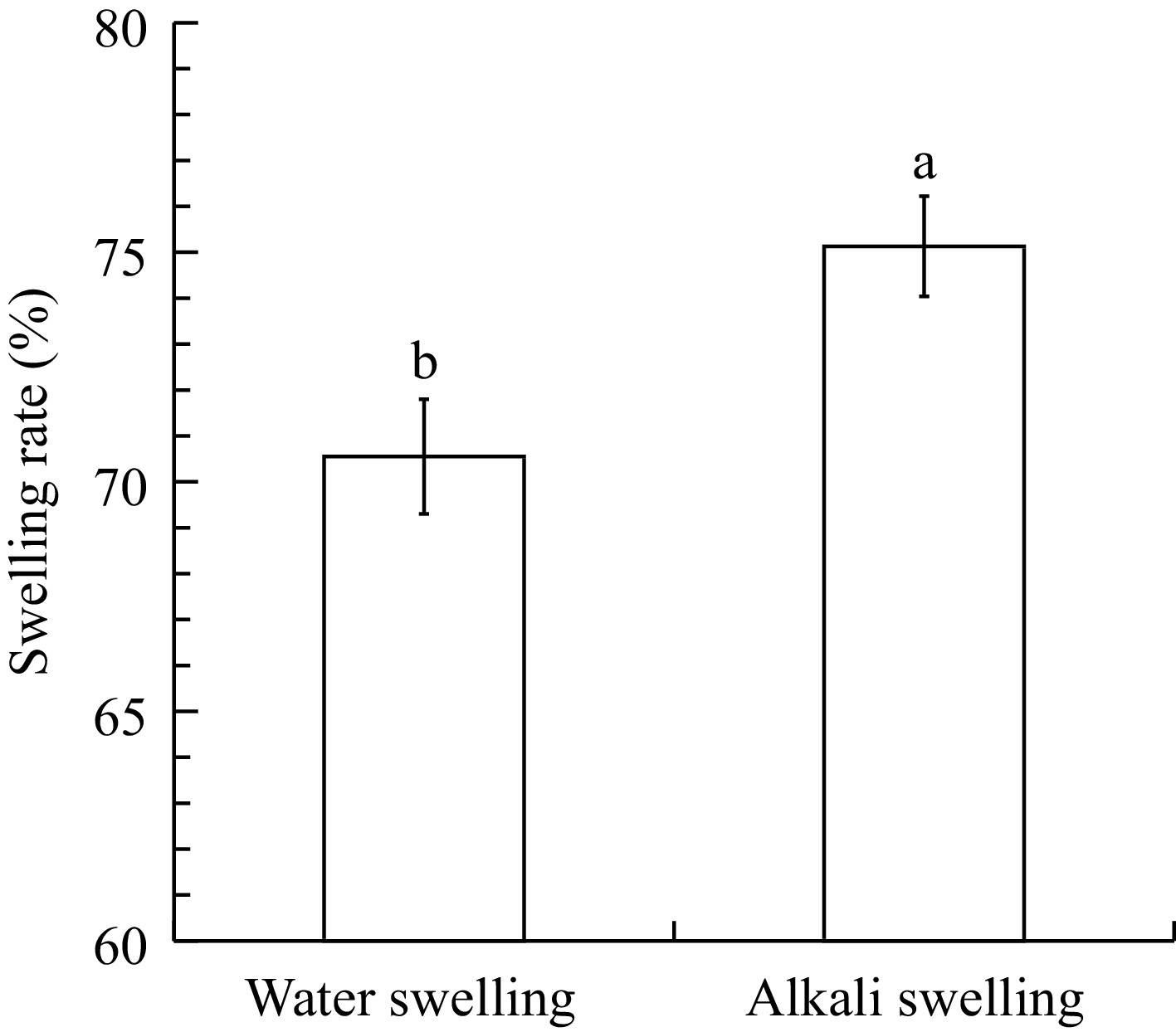

The effect of water and alkali swelling on the swelling rate of dried Abalone muscle is shown in Fig. 2. Compared to the water swelling Abalone muscle (70.55% ± 1.25%), the swelling rate of the sample treated by alkali swelling significantly increased (p < 0.05). Olaechea et al.[28] reported that Abalone muscle are rich in protein, and composed of 30%−50% myofibrillar proteins, 10%−20% water-soluble proteins and 10%−30% connective tissue protein. Myofibrillar protein is a salt soluble protein with good water retention properties[29]. Thus, the reason is that adding sodium carbonate increases the osmotic pressure of the aqueous solution and accelerates the permeation of water. In addition, increasing the pH (Fig. 1) and ionic strength of the solution enhances the hydration of myofibrillar protein and connective tissue protein in dried abalone during the swelling processing[30].

Figure 2.

Effect of water and alkali swelling on the swelling rate of dried Abalone muscle. Each value represents the mean ± SD, n = 3. Different superscripts in the same column indicate significant differences (p < 0.05).

Centrifugal loss

-

Centrifugal loss is one of the important indicators for measuring the water holding capacity of Abalone, and it is directly proportional to the quality. The effect of water and alkali swelling on the centrifugal loss of dried Abalone muscle is shown in Table 1. Compared to the water swelling Abalone muscle, the centrifugal loss of the sample treated by alkali swelling significantly increased (p < 0.05). That meant that due to the effect of centrifugal force, more water were lost from the sample treated by alkali swelling during the centrifugation process. This may be due to the addition of sodium carbonate causing the denaturation of Abalone protein, which in turn affects the tissue structure of Abalone, leading to structural looseness and exacerbating water loss under external forces[31]. Generally speaking, muscle fibers store a lot of water, there being a clear gap between the muscle bundle and the sarcolemma, where the water discharged by cells can be stored, but the water stored in the gaps is not tightly bound to the muscles, which can be easily expelled under centrifugal action, leading to an increase in centrifugal loss[32, 33].

Table 1. Effect of water and alkali swelling on the centrifugal loss and cooking loss of dried Abalone muscle.

Swelling method Centrifugal loss (%) Cooking loss (%) Water swelling 5.15 ± 0.38b 12.26 ± 0.42b Alkali swelling 7.29 ± 0.03a 15.30 ± 0.88a Each value represents the mean ± SD, n = 3. Different superscripts in the same column indicate significant differences (p < 0.05). Cooking loss

-

The effect of water and alkali swelling on the cooking loss of dried Abalone muscle is shown in Table 1. Compared to the water swelling Abalone muscle, the cooking loss of the sample treated by alkali swelling significantly increased (p < 0.05), this was consistent with the result of centrifugal loss (Table 1). A previous study reported that the magnitude of water holding capacity is closely related to the interaction between water and macromolecules, as it is influenced by factors such as pH, protein denaturation, the size of the inner and outer space of myofibrils, and the length of sarcomere[34]. Due to adding sodium carbonate caused more excessive protein denaturation, leading to the water holding capacity being decreased[35]. In addition, because the Abalone treated by alkali swelling has a higher swelling rate than the sample treated by water swelling (Fig. 2), it had higher moisture content, then was prone to water loss during heating.

Texture properties

-

Texture properties of swelling Abalone are an important factor to consumers, the taste of swelling Abalone is soft and sticky. The effect of water and alkali swelling on the texture properties of dried Abalone muscle is shown in Table 2. Compared to the water swelling Abalone muscle, the hardness, cohesiveness and chewiness of the sample treated by alkali swelling significantly increased (p < 0.05), and the springiness significantly decreased (p < 0.05). This is possible that adding sodium carbonate increased the pH of swelling Abalone, and caused more myofibrillar proteins and connective tissue protein denaturation and loss during swelling, leading to hardness, cohesiveness and chewiness being increase[35]. The other, due to the water content increased (Fig. 2), caused the springiness to decrease. Previous studies found that the decrease in muscle elasticity is caused by a decrease in myofibrillar protein content, which also leads to a decrease in the water holding capacity of the muscle[36, 37].

Table 2. Effect of water and alkali swelling on the texture properties and shear force of dried Abalone muscle.

Swelling method Hardness (N) Springiness Cohesiveness Chewiness (N.mm) Shear force (N) Water swelling 69.23 ± 0.22b 0.926 ± 0.005a 0.830 ± 0.018b 51.83 ± 0.44d 32.40 ± 0.34a Alkali swelling 78.82 ± 0.35a 0.902 ± 0.008b 0.886 ± 0.022a 64.81 ± 0.25a 35.31 ± 0.21b Each value represents the mean ± SD, n = 3. Different superscripts in the same column indicate significant differences (p < 0.05). Shear force

-

Tenderness is a key indicator reflecting the quality of swelling Abalone, and shear force is one of the important indicators to measure the tenderness of swelling Abalone. The smaller the shear force, the greater the tenderness of muscle[38]. The effect of water and alkali swelling on the shear force of dried Abalone muscle is shown in Table 2. Compared to the water swelling Abalone muscle, the shear force of the sample treated by alkali swelling significantly increased (p < 0.05), this was consistent with the result of hardness and chewiness (Table 2), which is caused by the excessive protein denaturation during alkali swelling. The results indicate that the use of water swelling can significantly improve the tenderness of Abalone, thereby obtaining ideal shear forces and springiness.

Color

-

The first impression of Abalone products by consumers usually comes from their color, which determines their purchasing desire and is also the most commonly used standard for judging the acceptability of Abalone products[39]. The effect of water and alkali swelling on the shear force of dried Abalone muscle is shown in Table 3. Compared to the water swelling Abalone muscle, the L*, a* and b* values of the sample treated by alkali swelling significantly increased (p < 0.05). Qiao et al.[40] found a significant correlation between meat pH and meat color, with lower pH leading to a lower L* value. In addition, the alkaline swelling Abalone has a high moisture content, which may enhance surface reflectivity, then causes an increase in brightness value[41]. Meanwhile, the excessive protein denaturation caused by sodium carbonate, leads to the a* and b* values being increased.

Table 3. Effect of water and alkali swelling on the color of dried Abalone muscle.

Color Water swelling Alkali swelling L* 60.67 ± 0.36b 69.47 ± 0.43a a* 1.25 ± 0.34b 3.17 ± 0.18a b* 19.41 ± 0.34b 21.37 ± 0.23a Each value represents the mean ± SD, n = 3. Different superscripts in the same column indicate significant differences (p < 0.05). Low-field nuclear magnetic resonance

-

The water content of aquatic products accounts for over 70%, and the physical and chemical properties of products, such as appearance, water holding capacity, tenderness, and juiciness, are influenced by water binding and distribution fluidity[42]. Due to the wide range of changes in transverse relaxation time and the high sensitivity of water distribution, some studies reported that most of the inherent water characteristics in muscle are mainly concentrated on the transverse relaxation time (T2)[43−45]. T2 reflects the binding force between water and muscle tissue, which is closely related to the water holding capacity of muscle tissue. The shorter the relaxation time T2, the closer the water binds to the substrate and the lower the degree of freedom. Conversely, the longer the relaxation time T2, the more free the water[46]. From Table 4, three different initial relaxation times can be found between the Abalone treated by water and alkali swelling. The first initial relaxation time ranges from 0−10 ms (T2b), which corresponds to the water in swelling Abalone muscle that binds to proteins and other macromolecules, that is, bound water; the second initial relaxation time ranges from 10−100 ms (T21), which corresponds to immobile water located at the periphery of myofibrils, the third initial relaxation time ranges from 100−1,000 ms (T22), which has the longest relaxation time, corresponding to the surface free water with the weakest binding to the tissue structure[45, 47]. Compared with the alkaline swelling Abalone, the initial relaxation time of T2a, T21, and T22 from the water swelling Abalone significantly decreased (p < 0.05), which indicated that the structure of water swelling Abalone restricted the movement of water, reduced the fluidity of water, and shortened the relaxation time, so it had higher water holding capacity[46].

Table 4. Effect of water and alkali swelling on the initial relaxation time (ms) and peak ratio (%) of dried Abalone muscle.

Swelling method Initial relaxation time (ms) Peak ratio (%) T2b T21 T22 P2b P21 P22 Water swelling 1.65 ± 0.17a 57.23 ± 3.63b 627.00 ± 54.09b 0.93 ± 0.09a 80.03 ± 1.07a 19.22 ± 0.78b Alkali swelling 1.73 ± 0.13a 97.92 ± 5.27a 907.86 ± 51.20a 0.95 ± 0.08a 75.65 ± 1.33b 24.21 ± 0.90a Each value represents the mean ± SD, n = 3. Different superscripts in the same column indicate significant differences (p < 0.05). The changes in peak ratios of P21 and P22 from water swelling Abalone is significantly different from those from alkaline swelling Abalone (Table 4). The peak ratio of P21 from water swelling Abalone significantly increased (p < 0.05) compared with that of alkaline swelling Abalone, and the peak ratio of P22 significantly decreased (p < 0.05), which indicated that the content of immobile water in the water swelling Abalone was higher, and the content of free water was lower[48], thus, the water swelling Abalone was conducive to forming a good structure, increasing the capillary force and reducing the loss of water[49].

-

Compared with alkaline swelling Abalone, water swelling Abalone had lower pH, L* value, centrifugation loss, and cooking loss, and significantly increased elasticity and tenderness. The results of low-field nuclear magnetic resonance showed that the initial relaxation times in water swelling Abalone were relatively short, indicating that the water did not flow easily nor was tightly bound, while the peak ratio of P21 in water swelling Abalone increased and the peak ratio of P22 decreased. This indicated that the content of immobile water in water swelling Abalone was relatively high, and the content of free water was low. Overall, the use of water to swell dried Abalone could improve its’ water holding capacity and texture properties.

-

The authors confirm contribution to the paper as follows: study conception and design: Liu Y, Kang Z, Ge Q; data collection: Liu Y, Hou Q, Liu R; analysis and interpretation of results: Kang Z, Liu R, Meng X; draft manuscript preparation: Kang Z, Ge Q, Meng X. All authors reviewed the results and approved the final version of the manuscript.

-

All data gererated or analyzed during this study are included in this published article.

This study was supported by National Natural Science Foundation of China (NSFC, Grant No. 32272365).

-

The authors declare that they have no conflict of interest.

- Copyright: © 2024 by the author(s). Published by Maximum Academic Press on behalf of Nanjing Agricultural University. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Liu Y, Kang ZL, Ge Q, Hou Q, Liu R, et al. 2024. Effect of water and sodium carbonate swelling on the texture properties and water distribution of dried Abalone rugosa muscle. Food Materials Research 4: e004 doi: 10.48130/fmr-0023-0039

Effect of water and sodium carbonate swelling on the texture properties and water distribution of dried Abalone rugosa muscle

- Received: 07 October 2023

- Revised: 08 November 2023

- Accepted: 17 November 2023

- Published online: 15 January 2024

Abstract: The study investigated the optimal swelling method for dried Abalone rugosa by assessing the impact of water and alkali swelling methods on various parameters including swelling rate, centrifugal loss, cooking loss, pH, texture characteristics, color, and water distribution of abalone. The findings revealed that water swelled abalone exhibited higher water holding capacity and lower pH compared to alkali swelled abalone. Moreover, the texture characteristics of abalone were significantly altered by the swelling process; specifically, water swelled abalone showed remarkable improvements in tenderness and elasticity as opposed to alkali swelled counterparts which displayed significantly lower (p < 0.05) hardness, cohesiveness, and chewiness values. Additionally, water swelling resulted in reduced water fluidity and shortened initial relaxation times of abalone samples, leading to a higher content of immobile water while decreasing the content of free water. Based on these outcomes, it can be concluded that employing the water swelling method enhances both quality and moisture retention capacity of swollen Abalone when compared to using alkaline swelling.

-

Key words:

- Swelling rate /

- Centrifugal loss /

- Tenderness /

- Cooking loss /

- Immobile water