-

The decline of the environment and limited agricultural land have impacted the production of traditional natural fibers such as cotton and hemp, while the demand for high-quality fibers has risen due to improved living standards. Developing new fibers can help address these challenges by reducing the consumption of natural resources and environmental pollution, while ensuring that fiber needs are met. Therefore, it is crucial to develop new types of natural fibers that meet daily wearing and environmental protection requirements[1]. This approach can alleviate the production pressures on traditional fibers and provide more benefits to people's lives[2,3]. The CG plant is a resilient plant with the ability to grow in unfavorable environments, including deserts and saline-alkali soil[4]. Its seed crown fiber, CGF, has gained attention due to its exceptional hydrophilic, warmth retention, and bio-functional properties. CGF is lightweight[5], possesses remarkable antibacterial properties[6], and is biodegradable and regenerable[7]. Compared to other natural fibers, CGF has a smoother and softer surface due to fewer natural curls in the longitudinal direction and an 80%−90% hollow structure[8], resulting in excellent hydrophilic or oleophilic properties[9]. CGF has been applied in textiles[10], medicine[11,12], adsorption[13,14], and sensors[9,15] due to its advantages. Textile products made from CGF are warm, soft, antibacterial, and absorb moisture well, showing great potential in adsorption materials, biomedical textiles, and wearable electrical devices.

This review provides a comprehensive survey of CGF and their functionalized applications, including properties, processing methods, yarns, fabrics, and fiber-based composite functional materials. The biological, chemical, and physical characteristics of CGF are reviewed, including porosity, moisture regain rate, and antibacterial properties. Cost-effective and efficient fiber treatment technologies are presented, including fiber extraction and pre-treatment. Methods for spinning Calotropis gigantea yarn (CGY) and preparing CG fabrics are described, including blending with other fibers. Potential applications of CGF are detailed in three areas: as an adsorbent material, a source of compounds for disease treatment and prevention, and a substrate for intelligent sensing. Existing gaps and future remarks on CGFs and composites in real applications are critically evaluated.

-

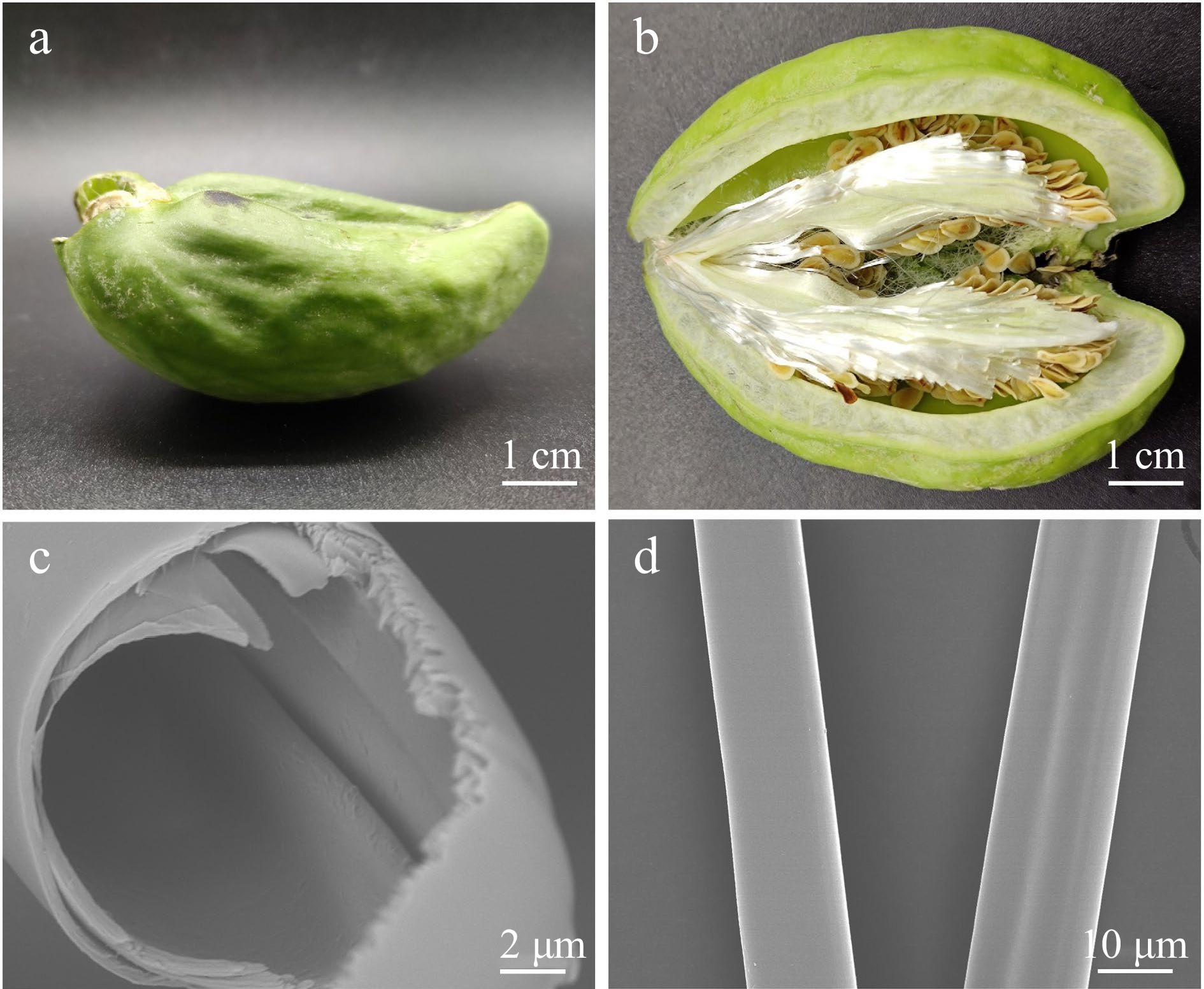

The CG fruit gets its name from its horn-like shape and is also called 'crystal cotton' because of its shiny fibers. CG plants grow on sunny hillsides and barren land below 1,700 meters, resisting drought and salinity while also growing quickly[1]. CG plants mainly come from Guangxi and Yunnan provinces in China, with some in Hainan and Sichuan provinces[16]. CGFs are obtained by processing the crown hair fibers in the CG fruit after removing its seeds. The CG fruit is about 10−15 cm long, green, and horn-shaped, as shown in (Fig. 1a). The CGFs are white to yellow, fluffy, and about 23−33 mm long[17], as shown in (Fig. 1b). Compared to other natural fibers like linen, cotton, and wool, CGF has fewer natural curls, resulting in a smoother and softer surface[9]. The cross-section of CGF is hollow (Fig. 1c), and its longitudinal direction is smooth (Fig. 1d).

Figure 1.

(a) CG fruit. (b) CG seeds and fibers. (c) SEM image of the cross-section of the CGF. (d) SEM image of the longitudinal direction of the CGF.

Characteristic of CGF

-

The CGFs are resistant to alkalis but not to acids and are not soluble in common solvents, such as 20% hydrochloric acid at room temperature[18]. Weak acids and alkalis have little effect at room temperature. The CGF has a complex chemical composition, with cellulose (mass fraction of about 66%), hemicellulose (mass fraction of about 21%), lignin (mass fraction of about 8%–9%), pectin (mass fraction of about 3%), wax (mass fraction of about 1.8%–3%), and ash (mass fraction of about 1.7%)[18]. Table 1 shows the main chemical composition of CGF and several other cellulose fibers, such as cotton, kapok, and flax, including cellulose, hemicellulose, lignin, pectin, wax, and ash. CGF has a chemical composition similar to that of cotton, kapok, and flax fibers. Compared to kapok fiber, the non-cellulose content of CGF is relatively low, which is beneficial for its spinning and other processing. The cellulose content in CGF (66%) is lower than that in cotton fiber (94%). Hemp fiber contains about 7%–9% of hemicellulose, while CGF has a higher content of hemicellulose (21%) than hemp fiber.

Table 1. Comparison of the main chemical components between the CGF and several cellulose fibers.

Formation CGF Kapok fiber Cotton fiber Linen fiber Cellulose (%) 66 35−50 94 73−77 Hemicellulose (%) 21 22−45 0 7−9 Lignin (%) 8−9 13 0 2−6 Pectin (%) 3 < 1 1.2 5.2 Wax (%) 1.8−3 0.8 0.8−1.3 1.4 Ash (%) 1.7 1.6 1.27 0.22 The smooth longitudinal surface of CGF has a silky luster under weak diffuse reflection. With a hollow structure that reaches 80%–90%, CGF has excellent moisture absorption properties, with a moisture absorption rate of approximately 10.8% and a moisture regain rate of 11.9%[18]. Compared to cotton fiber, CGF has higher fiber breaking strength, elongation at break, and moisture absorption capacity, and its hollow structure contributes to better moisture absorption and lower fiber fineness. CGF is also softer and has better affinity compared to hemp fiber. Its unique hollow structure gives it a lower linear density of only 0.93−0.97 dtex, making it lightweight. CGF exhibits outstanding mechanical properties, with a fiber breaking strength of approximately 4.73 cN/dtex, a breaking elongation of around 3.40%[18], and a fiber length of approximately 23−33 mm, surpassing those of cotton and hemp fibers. Table 2 provides a comprehensive summary of the characteristic indices of CGF, cotton fiber, and hemp fiber, providing a useful reference for CGF development[19−22]. The CGF has strong antibacterial properties against Staphylococcus aureus with a rate of over 99% and inhibitory effects on Escherichia coli[4]. However, the natural antibacterial properties and mechanical properties of the CGF may decline during textile processing, resulting from undergoing chemical and physical treatments such as bleaching, softening, wrinkle resistance, coating, high temperature, and pressure, limiting its potential applications. Therefore, it is important to enhance the antibacterial durability, stability, and safety of the CGF, while also ensuring environmentally-friendly treatment processes[4].

Table 2. Comparison of the physical properties of the CGF, kapok, and cotton fiber.

Formation CGF Kapok fiber Hemp fiber Cotton fiber Breaking strength (cN/dtex) 4.73 1.29 2.7−6.9 8.37 Elongation at break (%) 3.40 3.06 1.6 9.00 Length (mm) 23−33 8−32 8.3−14 34 Linear density (dtex) 0.93−0.97 0.9−1.2 1.8−3.7 1.43−2.22 Rate of moisture regain (%) 11.90 9.33 14.94 7.00 Rate of moisture absorption (%) 10.80 8.69 12 6.71 -

Conventional mechanical equipment is insufficient to extract CGF due to fragility and insufficient clamping force[4]. Hand extraction leads to poor fiber cleanliness, low yield, high cost, and low efficiency. To address this issue, an extraction machine is urgently needed. One approach is to use CGF separation equipment that breaks and dries CG fruits, followed by separation procedures, allowing for direct spinning[23]. Another method involves a continuous microwave extraction apparatus (Fig. 2a) that separates fibers (Fig. 2b), capsules, and seeds from CG fruits without damaging fibers. Both methods effectively solve problems and reduce the cost of extraction[24].

CGF toughening treatment processing

-

The smooth surface and low friction coefficient of fibers make it difficult to directly fabricate yarns and fabrics from CGF. Furthermore, the high non-cellulose content poses challenges for further processing. To overcome these challenges, using functional reagents to pretreat CGF is a feasible method. Previous studies have shown that treating cellulose fiber with sodium carbonate, ethanol, starch solution, sodium carboxymethyl starch solution, and polyvinyl alcohol solution can improve the surface roughness, continuity, and mechanical properties of the fiber[25]. Other pretreatment methods, such as ethanol, starch solution, sodium carboxymethyl starch solution, and polyvinyl alcohol solution, have also been found to significantly improve the surface smoothness, continuity, and mechanical properties of CGF[26]. However, the mechanical performance of CGF still needs to be improved for spinning, and functional additives such as plasticizing and toughening agents or nutrients consisting of water and glycerin can be used to enhance spinnability[27].

CGF spinning processing

-

Treatment with a 30% aqueous polyurethane solution has been shown to significantly improve the modulus of elasticity, breaking tenacity, and breaking elongation of CGF[28]. CGF has short fibers, low holding strength, and poor consistency, which makes it difficult to spin 100% CGF-containing CGY[29]. Researchers have optimized spinning procedures to increase spinnability and have successfully spun CGY. The use of siro-spinning and agglomerated siro-spinning has improved yarn strength and uniformity[30]. Polyvinyl alcohol treatment has also significantly improved fiber spinnability and strength[31].

CGF weaving processing

-

Blending CGF with other fibers is an effective method for CGY preparation[32]. Studies have shown that blending with cotton or cotton-polyester fibers improves yarn strength and meets weaving requirements, avoiding the weak strength of CGF for spinning[33]. CGFs have significant potential in producing both knitted and woven fabrics, thanks to their impressive antibacterial properties, biodegradability, highly hollow structure, and hydrophilic or oleophilic properties. For example, a fabric was made by blending 40% CGYs and 60% cotton yarns using the knitting technique, resulting in a lightweight, elastic, warm, and soft fabric[34]. Another study explored knitted fabrics with different CGF blending ratios, finding that mechanical qualities decreased while warmth and wearing comfort increased with higher CGF content[35]. Another approach involved weaving blend yarns of CGF (20% content) and cotton fibers (80% content), treated with polyvinyl alcohol and acrylic acid solutions prior to weaving[36]. This method produced a highly flexible and fluffy CG fabric with exceptional thermal insulation, antibacterial properties, adsorption rate, and deodorization, although its breaking strength is slightly lower than pure cotton fabrics.

-

CGF is a promising material for use as an adsorbent due to its 80%−90% hollow structure and waxy surface[37,38]. Recent studies have shown that functionalized adsorbents can be produced by in-situ growth of various polymers on CGF using a bio-template[39]. These adsorbents have high perfluorooctanoic acid removal capacity and good reusability. Additionally, eco-friendly oil-absorbing MoS2-CGF materials have been prepared with excellent oil absorption capacity and reusability[40]. Other studies have explored various treatments to improve the oil absorption of CGF, including using nanoparticles or treating with NaOH and NaClO2[41]. Table 3 provides a summary of the oil absorption capacity of CGF and other materials, which may serve as a reference for the development of reusable CG fiber-based adsorbent materials. However, an important issue that requires attention and resolution in the field of CGF materials is the improvement and enhancement of the recycling of CGF adsorbents.

Table 3. Oil absorption of different materials with different treatments.

Adsorbent material Processing Oil absorption

amount (g/g)Oil Ref. Kapok fiber Packed 36

43

45Diesel

Hydraulic oil

Motor oil[36] Calotropis

gigantea

fiberIn natura

NaClO2 + Carbonized60.59

84.71Kerosene [38] Cotton fiber Loose fiber

Fiber pad shape22.5

18.43Lubricating oil [41] Cellulose aerogel Methyltrimethoxysilane 40−95 Oil [41] The CGF-based antibacterial materials

-

Plants are a valuable resource for humans in treating illnesses and developing new pharmaceuticals. Certain compounds found in the CG plant, such as flavonoids[42,43], tannins[44], cardiac glycosides[45,46], and terpenoids, can be used to treat and prevent various ailments, including ulcers, cancer, and leprosy[47,48]. Recent studies have demonstrated the potential of CG latex encapsulated zeolitic imidazole frameworks and silver nanoparticles extracted from the CG leaf to be used as antibacterial and anticancer agents[49]. Additionally, frugoside extracted from the CG fruit/leaf has shown anti-inflammatory potential and potential in treating osteoarthritis[50]. Caloside G, a cardenolide glycoside obtained from CG roots, has also shown significant cytotoxicity against human pancreatic cervical carcinoma cell lines[51]. Another study investigated the self-assembly of silk fibroin, chitosan, and nano-silver microspheres to create antibacterial microspheres. The modified CG fabric with these antibacterial microspheres demonstrated good breathability and durable antibacterial properties, achieving a high antibacterial rate of 99.9% against Escherichia coli (E. coli) and Staphylococcus aureus (S. aureus)[4]. Nonetheless, some challenges also exist in the extraction and isolation of drugs from CG, which should be investigated in the future.

CGF-based smart materials

-

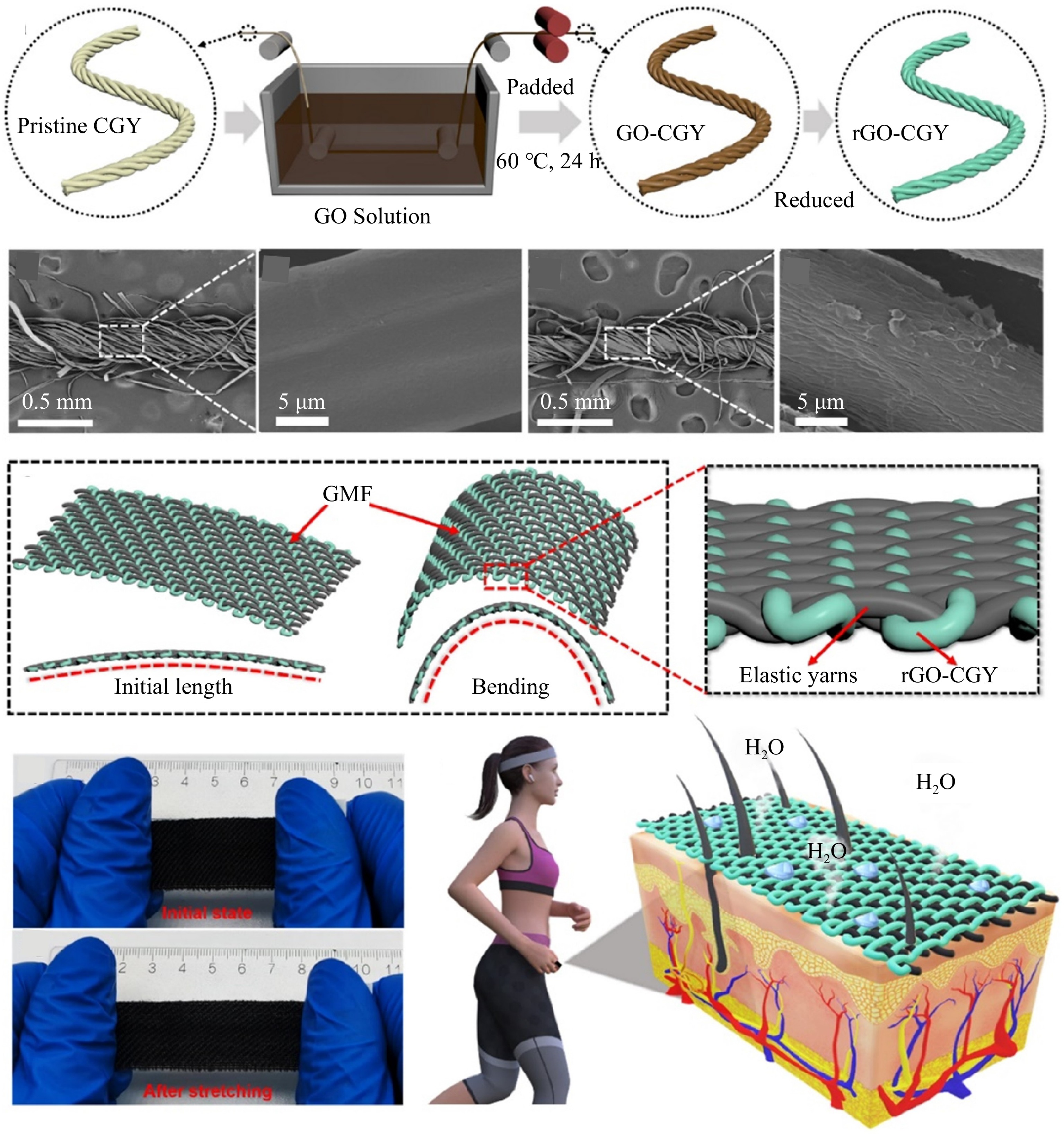

Compared with cotton fibers, CGF has a smoother and softer surface[52], a greater specific surface area, and a highly-hollow structure[53], presenting superior advantages in the field of functional and intelligent textiles[54]. For example, the pad dyeing technique has been used to produce conductive yarns by coating CGY with graphene oxide, resulting in high conductivity and outstanding electrical stability[55]. This graphene-coated CGY is highly stretchable and conductive, making it suitable for motion detection and health management. Additionally, a cost-effective method was developed to produce dye-sensitized solar cells using a non-precious counter electrode made from ball-milled tellurium-doped graphene and a natural sensitizer extracted from CG leaves, resulting in a significant enhancement in efficiency[56]. Another alternative strategy utilized CGF with hydrophobic surfaces to confine conductive polymer of polypyrrole to enhance supercapacitor performance[57]. Lastly, a fabric-like strain sensor was developed by fabricating graphene-modified CGY and Spandex yarn, paving the way for low-cost, highly breathable, high-performance, and reliable sensing strain sensors for monitoring body movements and vital signs[9] (Fig. 3). More importantly, further investigation is needed into other vital CGF-based materials' smart properties, including their applications in motion detection, healthcare, man-machine interaction, future entertainment, and multifunctional sensing.

Figure 3.

Illustration of the graphene-modified fabric fabrication process[9].

-

With the global increase in environmental awareness, the development of green and biodegradable materials has become a focal point. CGF and CGF-based materials have garnered significant interest due to its unique hollow structure and lightweight nature, particularly in materials and environmental science. Mechanical extraction techniques have been employed to obtain CGF, and toughening treatment processes have been applied to enhance fiber strength, enabling the realization of spinning and weaving processes for CGF. The application areas of CGF are expanding beyond traditional textiles to include adsorbents, antibacterial agents, smart materials, and more. Researchers have made noteworthy progress in CGF-related studies, driven by the growing emphasis on biomass-based fibers. However, it is crucial to acknowledge current limitations and address areas of concern. Representative applications have been provided to illustrate these limitations and research gaps.

Extensive research and efforts made in areas such as extraction, textile processing, environmental treatment, antibacterial applications, and smart materials within CGF. However, there are still numerous issues that need to be further explored and resolved in the future. Currently, the CGF textile market has not achieved a complete industrial chain, lacking intensive and large-scale production lines for CGF extraction, spinning, weaving, and garment manufacturing. Benefited from thin-walled lumen and hydrophobic-lipophilic surface, CGF material has shown great potential as one kind of oil-absorbing materials, demonstrating not only fast absorption kinetics, high absorption capacity, but also high absorption selectivity for the model oils. Nevertheless, the reusability of CGF as an adsorbent material still poses challenges. CGF has gained attention in the field of smart materials due to its unique thin-walled tubular structure. Functionalization techniques, such as facile coating, are crucial for unlocking its full potential as a smart material. However, most of these studies remain confined to the laboratory, and there is a need for further research addressing real-world challenges to facilitate practical applications. Looking ahead, CGF is expected to possess even greater development potential in areas such as thermal energy storage, ion batteries, catalysts, buoyancy, and insulation materials, beyond its current uses.

This work was financially supported by the National Key R&D Program of China (2021YFE0111100), the Science and Technology Partnership Program, the Ministry of Science and Technology of China (KY202201002) and the Jiangsu Provincial Department of Science and Technology (BZ2022017). We also thank the support of China National Textile and Apparel Council (J202002), Jiangsu Advanced Textile Engineering Technology Center (XJFZ/2021/7).

-

The authors declare that they have no conflict of interest. Jianchu Xu and Gang Li are the Editorial Board members of Circular Agricultural Systems who were blinded from reviewing or making decisions on the manuscript. The article was subject to the journal's standard procedures, with peer-review handled independently of these Editorial Board members and their research groups.

-

# These authors contributed equally: Weiqiang Li, Junze Zhang

- Copyright: © 2023 by the author(s). Published by Maximum Academic Press, Fayetteville, GA. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Li W, Zhang J, Luo T, Liu J, Zhao G, et al. 2023. Research progress in development and application of Calotropis gigantea fiber. Circular Agricultural Systems 3:9 doi: 10.48130/CAS-2023-0009

Research progress in development and application of Calotropis gigantea fiber

- Received: 25 April 2023

- Accepted: 31 July 2023

- Published online: 19 October 2023

Abstract: Calotropis gigantea fiber (CGF) is to a type of seed fiber collected from the fruits of the Calotropis gigantea (CG). From a sustainable biomass resource, CGF is a naturally abundant cellulose fiber with good economic value, excellent biocompatibility and biodegradability. CGF has a high hollow structure and is lightweight, which means CGF has received increasing attention in recent years as the starting material for fabrication of different types of functional materials. In this paper, we have reviewed the morphology and characteristics of CGF, including its biological properties, chemical composition, and physical properties. Additionally, we provide an overview of the recent advancements in the extraction process, toughening treatment process, spinning process, and weaving process of CGF, which have garnered significant attention from researchers in the field. The applications of CGF in the fields of environment processing, antibacterial, and smart materials are also summarized. Finally, the challenges and development prospects of CGF are introduced with the ultimate goal of implementing its potential in real-world applications.