-

Mung bean (Vigna radiata (L.)) is a summer pulse crop with a short growth cycle (70−90 d), which has been widely grown in Asia and other parts of the world[1]. It demonstrates high potential as a sustainable and invaluable dietary protein source due to its low cost, easy digestibility, and low carbon footprint compared to animal protein sources[2]. El-Adawy et al.[3] reported that mung bean contains 23.8%−27% protein, 1.2% fat, 3.3% ash, 62.6% carbohydrates, and 16.3% fiber. Xie et al.[4] suggested that mung bean protein contains a high content of essential amino acids, which meets the requirement of human body. Moreover, the extracts of mung bean were reported to possess various biological activities such as antioxidant activities, angiotensin-I converting enzyme inhibitory, antidiabetic, and anti-tumor[4].

The seed coat serves as a protective barrier and information delivery medium between the cotyledon and the external environment of legume[5]. A hardening phenomenon (hard-to-cook, HTC) occurs in seed coat during storage at high temperature (> 25 °C) and high humidity (> 65% RH) conditions. The development of HTC defect causes a decreased water absorption capacity, a loss of cooking ability, and a lower digestibility and protein quality[6]. Ziegler et al.[7] reported that the cooking time of mung bean was gradually increased with storage at 15−35 °C for 1−6 months. Reyes-Moreno et al.[8] suggested that the hardening of chickpea grains caused a decrease in the in vitro protein digestibility. Hence, beans with HTC defect are of lower nutritive values and require long cooking time, which decrease its acceptability to consumers and limit its industrial utilization.

Recently, the market for ready-to-eat foods has grown rapidly owing to their advantageous minimal input of time and effort[9]. Many researchers have made attempts to develop quick-cooking drying beans. USDA Western Regional Research Center also developed several procedures for converting dry beans to quick-cooking bean products[6]. Typically, quick-cooking dehydrated beans are produced by soaking and hydrothermal treatment, followed by drying and are rehydrated before consumption[10]. For example, Schoeninger et al.[11] developed a quick-cooking common bean (cooking time reduced by 53%) by soaking (4−16 h) and blanching (70−90 °C, 30−180 s) in salt solutions (NaCl/NaHCO3, 0−4.5 g/100 mL), followed by drying at 50 °C. Aravindakshan et al.[12] prepared quick-cooking red kidney beans and the preparation process involved soaking dry beans in water at a mass ratio of 1:4 for 12 h, cooking at 95 °C for 60 min, drying, and dehydration. Their results suggested that different drying techniques would cause distinctly different microstructure, thus leading to different rehydration behaviors and functional properties of quick-cooking beans.

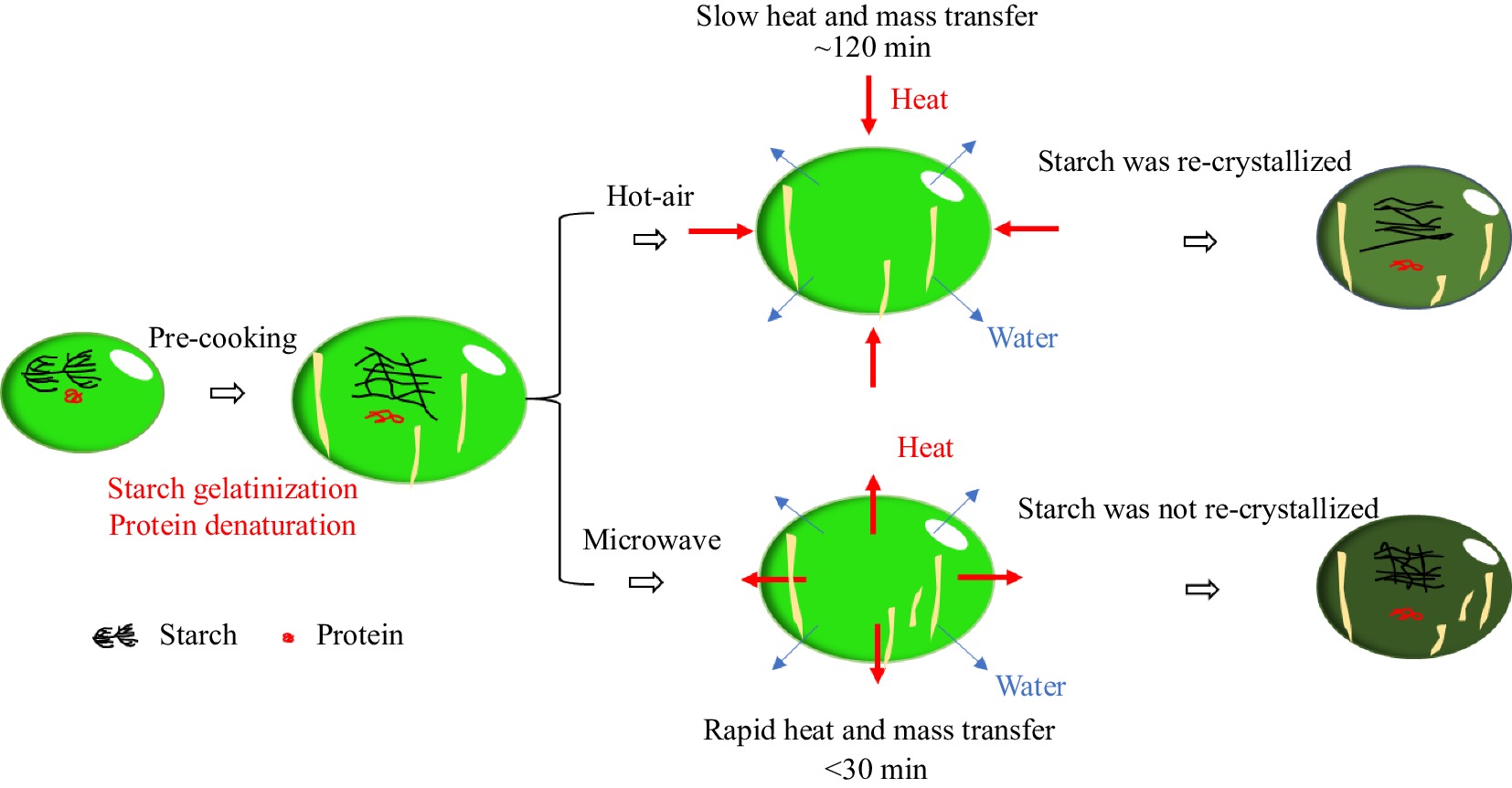

Drying is the last but not least process in preparing quick-cooking drying beans. It helps to diffuse the moisture inside to the outside, resulting in a volume decrease, weight loss and shelf-life extension of food products[13]. Air drying requires simple equipment and is easily operatable, thus being popular in industrial production. Unfortunately, this process requires high energy consumption and long drying time, and the quality of a hot air-dried product is largely reduced from that of the original foodstuff[14]. Compared with hot air drying, microwave treatment can achieve rapid and uniform heating of materials and offers advantages of shorter processing time and less energy input[15], thus being widely applied in drying foods including vegetables, fruits, and meats. More importantly, the thick seed coat of beans would retard the heat transfer from the outside to the inside during hot air drying, while microwave produces heat inside the food by utilizing electromagnetic waves, thus eliminating the obstruction of the seed coat to heat transfer. For example, Li et al.[13] reported that the incorporation of microwave radiation (microwave hot air rolling drying) decreased the drying time of pre-gelatinized kidney bean by 2.5 times at the same hot air temperature when compared with hot air drying.

In our previous study, ultrasound and NaHCO3 treatments were applied to improve the soaking and cooking quality of mung bean. The obtained mung bean showed a high gelatinization rate and a good sensory quality. However, the fresh pre-cooked bean is easy to spoil due to the high moisture content. Therefore, the pre-cooked bean was dried by hot air at temperatures of 50, 70, and 90 °C, or dried by microwave at powers of 60, 300, and 600 W. To our best knowledge, report on effects of hot air and microwave drying on pre-cooked mung bean quality is limited and the quality formation mechanism of quick-cooking beans during drying remains unclear. In this study, the advantages and disadvantages of hot air and microwave drying were compared from drying kinetics curves, energy consumption, and the quality of dried mung bean (appearance, color, recooking hardness and in vitro digestibility). The mechanism of quality formation was explored by monitoring the changes in microstructure, chemical structure, crystal structure and pasting properties of mung bean powder. The obtained results could provide a guide for choosing suitable drying methods in the preparation of quick-cooking beans.

-

Mung bean (100-grain weight 7.90 ± 0.13 g; length 4.84 ± 0.01 mm; width 4.16 ± 0.24 mm; rate of hard seeds 0.04 ± 0.02), harvested in fall 2021, was kindly provided by Nanjing Grain Group Co., Ltd. (Nanjing, China). Potassium bromide was of spectral grade and was purchased from Sinopharm Chemical Reagent Co., Ltd. (Suzhou, China). Sulfate acid, boric acid, copper sulfate, potassium sulfate, sodium hydroxide, ethanol, glucose, and all other reagents were of analytical grade and were purchased from Shoude Reagent Co., Ltd. (Nanjing, China). DNS reagent (analytical grade), pepsin (250 U/mg), trypsin (18,000 U/mg), and α-amylase (50 U/mg) produced from Aspergillus niger were purchased from Yuanye Biological Co., Ltd. (Shanghai, China).

Hot air and microwave drying

-

Mung bean was soaked in 1.9% (w/v) NaHCO3 solution (1:10 w/w) at 30 °C for 91 min with 800 W ultrasound treatment, steamed for 17 min (these conditions were optimized by our preliminary test), and the obtained product called pre-cooked mung bean. After cooling to room temperature, the pre-cooked mung bean (5.0 g) was placed on the center of a hot air drying oven or microwave oven, and then was dried by hot air at 50, 70, and 90 °C for 180 min or microwave at 60, 300, and 600 W for 30 min. In hot air and microwave drying processes, the weight of the sample was measured every 10 and 1 min, respectively. Once the moisture content of the beans reduced to 12% (wet basis), the drying was completed. The dried mung bean, which was named as quick-cooking drying mung bean in the following study, was used for further tests.

Drying kinetics determination

-

The changes in the moisture content of pre-cooked mung bean during hot air and microwave drying were determined by the oven drying method[15]. Mung bean (M1) obtained above was dried at 105 °C to a constant weight (M2), and then the moisture content in dry basis (MC) was calculated according to the following formula:

$ MC = \frac{{{M_1} - {M_2}}}{{{M_2}}} \times 100{\text%} $ (1) Energy consumption determination

-

The energy consumption during the beginning (time 0) and ending (time to obtain a moisture content of 12%) of hot air and microwave drying was determined by using a PS06S energy meter (Hualianshi Technique Co. Ltd., Shenzhen, China).

Color determination

-

The color of dried mung bean obtained above was determined by using a Minolta Chroma Meter CR-400 colorimeter (Minolta Camera Co., Ltd, Osaka, Japan)[16]. Mung bean powder was sealed in transparent self-sealing bag, and then the a* (redness), b* (yellowness), and L* (lightness) values were recorded. Before determination, the colorimeter was calibrated.

Recooking textural analysis

-

After boiling for 18 min, no white core was observed in the rice center. Therefore, the dried mung bean obtained above was boiled for 18 min, and then the hardness of re-cooked mung bean was measured by using a TMS-Pro texture analyzer (Food Technology Co., Ltd., Sterling, USA). A 2 mm-diameter stainless-steel needle probe (probe P-2N) was applied. The post-test and test speed were 1.00 mm/s. The puncture distance was 3 mm.

In vitro digestibility

-

The in vitro digestibility was measured according to the modified method reported by Englyst et al.[17]. The dried mung bean obtained from previous was ground, passed through a 100-mesh sieve, and then the obtained powder (500 mg, W) was mixed with 5 mL pepsin solution and incubated at 37 °C with continuously stirring at 120 r/min for 30 min. Next, 5 mL mol/L NaOH solution, 15 mL 0.1 mol/L phosphate buffer, 5 mL α-amylase solution, 0.1 mL glucoamylase solution, and 1 mL 1 mg/mL trypsin solution were added in sequence, and then kept at 37 °C with continuously stirring at 120 r/min. After heating for 20, 40, 60, 80, 100, 120, and 180 min, 1 mL of the suspension was taken, 3 mL of ethanol was added, and then the mixture was centrifuged at 8000 r/min for 10 min. One milliliter of the obtained supernatant was mixed with 2 mL DNS reagent, boiled for 8 min, rapidly cooled to room temperature, diluted to a certain extent, and then determined using a UV spectrophotometer at 540 nm. The reducing sugar content (RSC) was determined by using the calibration curve with glucose as standard. The hydrolysis rate (HR, %) was calculated using the following formula:

$ HR{{ (\text%)}} = \frac{{RSC \times 0.9}}{{{W_{}}}} \times 100{\text%} $ (2) Scanning electron microscopy (SEM)

-

The dried mung bean obtained above was ground, passed through a 100-mesh sieve, and then about 1 mg of the power was loosely placed on a stage using double-sided conductive tape, sprayed gold under vacuum, and then observed by using EVO MA10/LS10 ZX-01 scanning electron microscope (Zeiss Co., Ltd., Oberkochen, Germany) at an accelerating voltage of 10 kV and a magnification of 500×[18].

Fourier-transform infrared spectroscopy (FT-IR)

-

The difference in the chemical structure of pre-cooked mung bean dried by hot air and microwave was compared by using the Thermo Nicolet Nexus FTIR (Thermo Scientific Co., Ltd., Massachusetts, USA)[18]. The dried mung bean was ground, passed through a 100-mesh sieve, and then was mixed with potassium bromide at a mass ratio of 1:100, well ground, pressed into a tablet with a thickness of 0.5 mm, and finally scanned from 4,000 to 400 cm−1 with 64 scans and a resolution of 4 cm−1.

X-ray diffraction (XRD)

-

The crystal structure of pre-cooked mung bean dried by hot air and microwave was measured by using a D8-Advance X-ray diffractometer (Bruker AXS Co., Ltd., Karlsruhe, Germany) with an X-ray source of nickel-filtered Cu-Ka (wavelength 1.5405 Å) radiator at 40 kV and 40 mA[19]. The dried mung bean was ground, passed through a 100-mesh sieve, and then about 1 g of the powder was placed on a glass stage with a flat surface and scanned from 5 to 40° with a step of 0.1° and a rate of 2 °/min. Jade 6.5 was used to calculate the relative crystallinity (Rc, %):

$ {R_c}({\text%} ) = \frac{{{A_{\text{c}}}}}{{{A_a} + {A_c}}} \times 100{\text%} $ (3) Where Aa and Ac represent the area of amorphous and crystal regions within starch granules, respectively.

Rapid viscosity analysis (RVA)

-

The pasting properties of dried mung bean were measured by using RVA-4500 rapid viscosity analyzer (Newport Scientific Pty. Ltd., Australia)[18]. The dried mung bean obtained above was ground, passed through a 100-mesh sieve, and then 3.0 g of the obtained powder was mixed with 25 mL distilled water. Next, the mixture was heated according to the following procedure: incubated at 50 °C for 60 s, heated to 95 °C within 260 s, maintained at 95 °C for 110 s, cooled to 50 °C within 260 s, and finally maintained at 50 °C for 90 s. The suspension was stirred at 960 rpm at the initial 10 s to confirm the fully mixing and then stirred at 160 rpm throughout the measurement.

Statistics analysis

-

All tests were performed in triplicates. Data were presented as mean ± standard deviation. All data were compared using Fisher's least significant difference (LSD) test at a significance level of 0.05 (SPSS 20, IBM SPSS Statistics 20, Somers, USA).

-

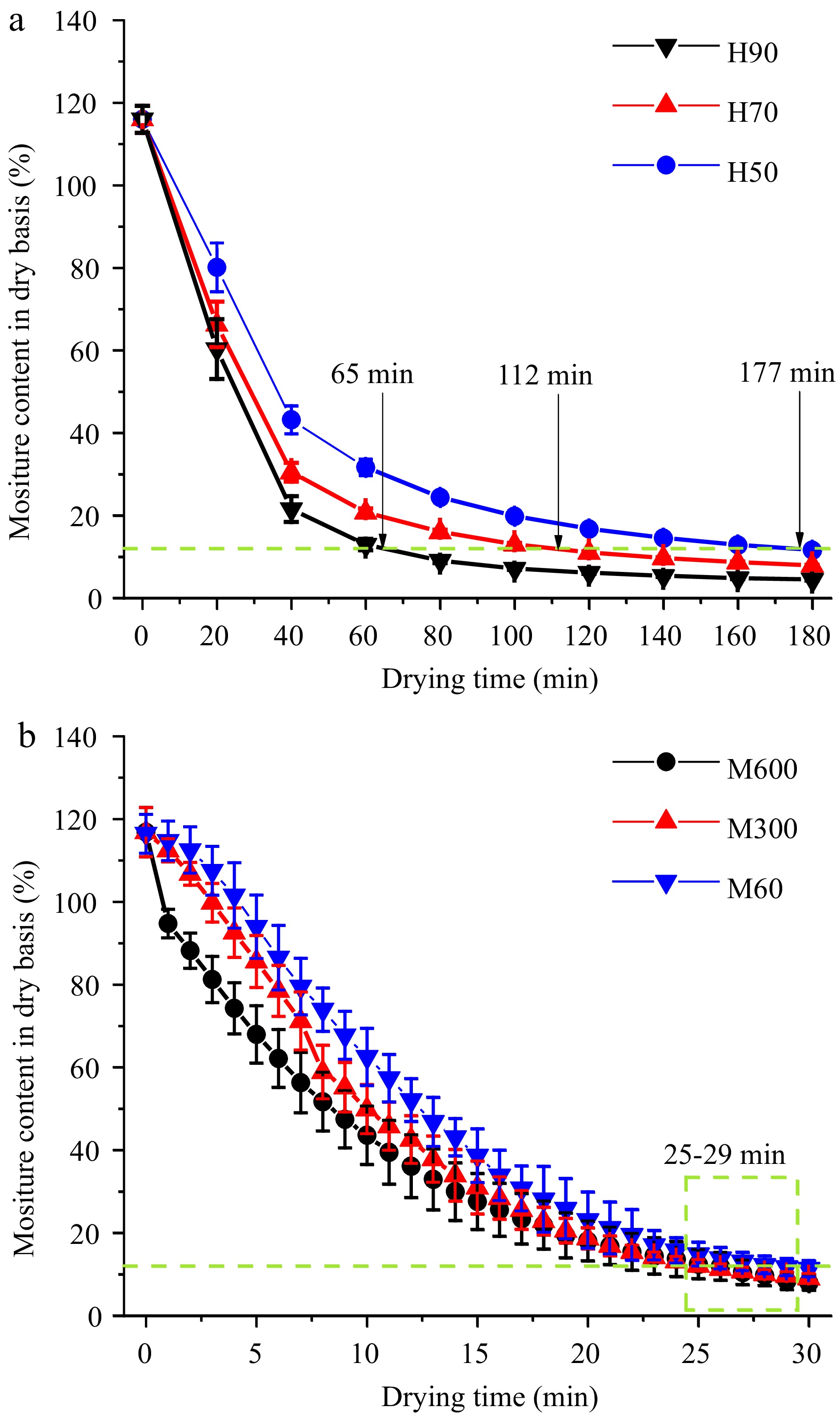

The drying kinetics of pre-cooked mung bean during hot air and microwave drying are shown in Fig. 1. All drying curves followed a first-order reaction kinetics model: a rapid decrease at an initial stage and a slow change in moisture at the following stage[20]. Hot air drying is the most popular dehydration technique in the food industry[21]. In this case, the drying kinetics is greatly affected by air temperature. Figure 1a suggested that the drying rate was increased while the equilibrium moisture content of dried mung bean was decreased by increasing the hot air temperature from 50 to 90 °C. At temperatures of 50, 70, and 90 °C, the time for mung bean obtaining a moisture content of 12% was 65, 112, and 177 min, respectively. A similar result was observed by Krokida et al.[20], who reported that the drying process of various vegetables was accelerated due to the increased air temperature from 65 to 85 °C. Compared with hot air drying, microwave treatment is an alternative method due to its low power input and higher thermal conductivity to the inner sides of the materials[22]. Figure 1b showed that microwave dramatically decreased the drying time to 25−29 min. As the microwave power increased, the drying rate increased while the equilibrium moisture content decreased. Palamanit et al.[23] investigated the drying characteristics of instant parboiled rice during hot air and microwave-assisted hot air drying, and found that microwave-assisted drying reduced the drying times by 50%.

Figure 1.

Drying kinetics of pre-cooked mung bean during (a) hot air and (b) microwave drying. Note: H50, H70, and H90 represent hot air drying at 50, 70, and 90 °C, respectively; M60, M300, and M600 represent microwave treatment at 60, 300, and 600 W, respectively.

Energy consumption of hot air and microwave drying

-

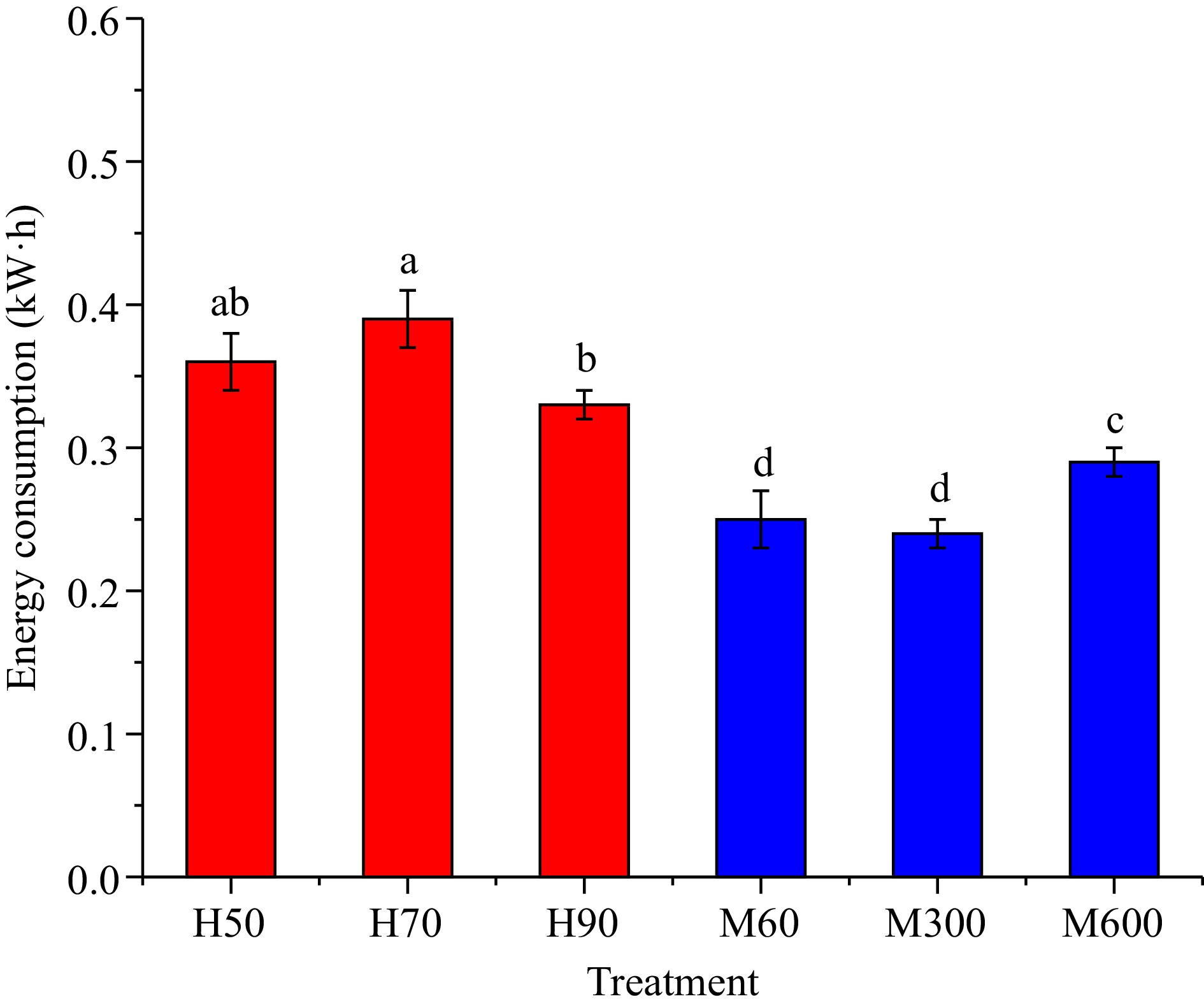

Energy consumption is one of the key factors determining the applications of drying techniques. As shown in Fig. 2, the consumed energy was slightly increased from 0.36 to 0.39 kW·h when the air temperature increased from 50 to 70 °C. However, as the air temperature further increased to 90 °C, the time to reach dry end point was much shorter, and thus a lower energy input was observed (0.33 kW·h). Microwave dramatically shortened drying time. Hence, the energy consumption for microwave treatment (0.24−0.29 kW·h) was significantly lower than that of air hot drying. Notably, when the microwave power increased from 300 to 600 W, the drying time showed no significant change. As a result, the energy consumption was slightly increased. Motevali et al.[24] evaluated the energy consumption in different drying methods including hot air convection, microwave drying, vacuum drying and infrared drying, and their results suggested that microwave caused the minimum energy consumption in pomegranate drying. Behera & Sutar[25] found that the drying rate of milled rice was increased with an increasing microwave power density and the specific energy consumption in microwave drying were lower than hot air drying. In general, microwave drying could dramatically shorten drying time and reduce energy consumption, thus being considered as an efficient method in preparing quick-cooking drying beans.

Figure 2.

Energy consumption during hot air and microwave drying of pre-cooked mung bean. Note: Same as Fig. 1.

Appearance and color of quick-cooking drying mung bean

-

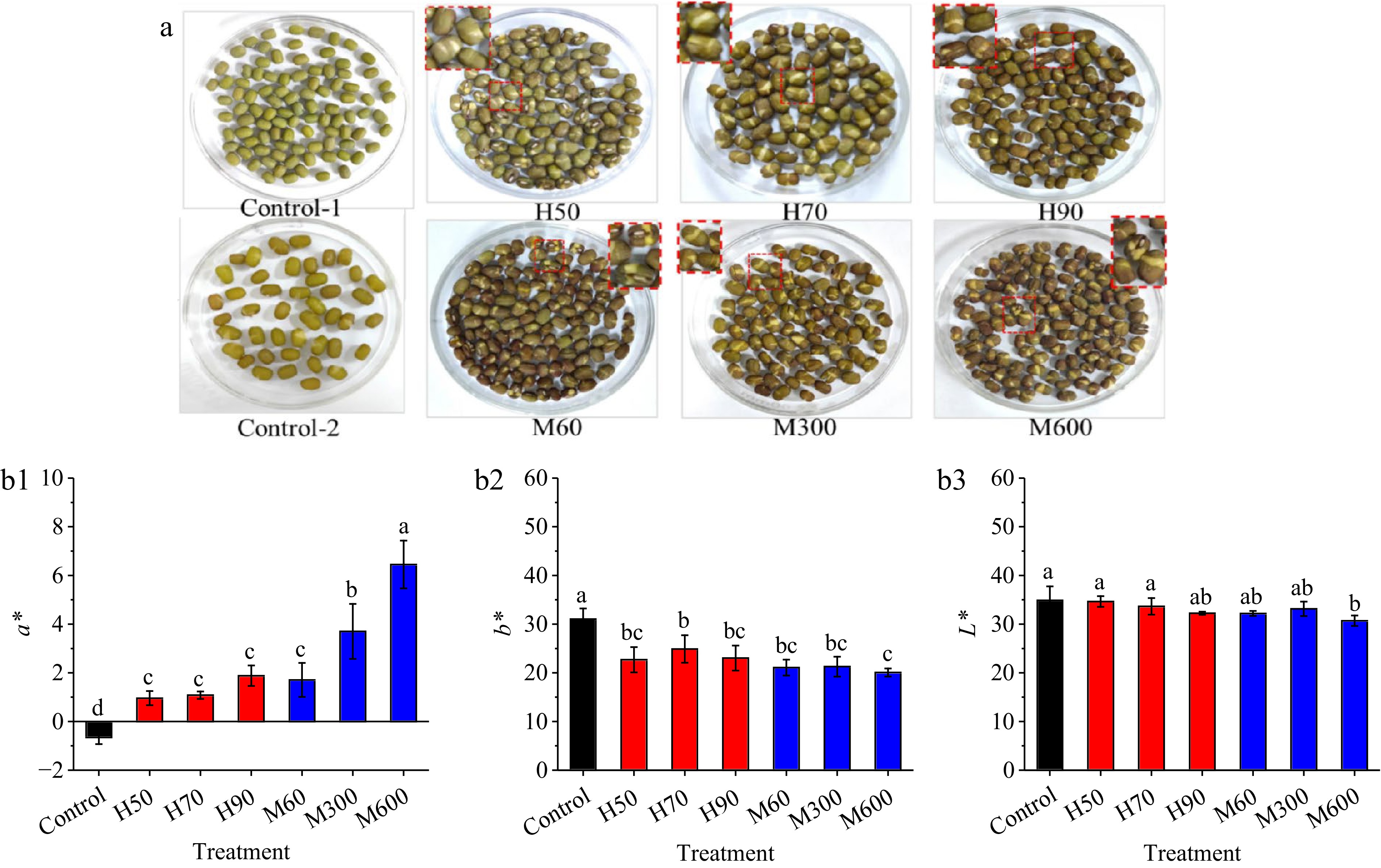

Appearance of food directly affects its acceptability to consumers. The visual images of native and pre-cooked mung beans after drying by hot air and microwave are presented in Fig. 3a. Native mung bean exhibited a green color, an ellipsoid shape, and a smooth surface[6]. During pre-cooking, mung bean starch absorbed water, swelled, gelatinized, and thus caused an increase in the volume of mung bean. Nonstarch polymers in seed coat such as fibers, proteins, and pectin also absorbed water, resulted in the softness and dehiscence in mung bean seed coat. As shown in Fig. 3a, pre-cooked mung bean had a larger volume and a dehiscent seed coat. After drying, although the volume became small and the seed coat became hard due to the removal of water, it was still larger and harder than native mung bean and microwave caused a smaller volume than hot air drying.

Figure 3.

Effects of hot air and microwave drying on (a) appearance and (b) color of pre-cooked mung bean. Note: Control-1/Control represents native mung bean; Control-2 represents pre-cooked mung bean; H50, H70, H90, M60, M300, and M600 were same as Fig. 1.

Grain color is correlated with compounds like polyphenols and carotenoids[1]. During heating, the oxidation of these compounds could be enhanced, and other browning reactions such as Millard reaction might occur[26, 27]. As a result, the mung bean became brown. Figure 3b suggested that the a* value steadily increased while L* value slightly decreased with increasing hot air temperature and microwave power. Compared with control, both hot air and microwave drying caused a significant decrease in b* value. Microwave treatment had a more extensive effect on the color of mung bean. For example, after drying by hot air at 90 °C and microwave at 600 W, the a* and L* values increased from −0.66 to 1.88 and 6.45, and decreased from 34.89 to 32.24 and 30.7, respectively. Based on the above, microwave drying could maintain the original shape and volume of mung beans, but the color became dark. Zhao et al.[28] suggested that the tempered samples exhibited a limited color change during microwave vacuum drying. Therefore, during industrial production, a pretreatment such as tempering could be conducted to improve the product quality during microwave drying.

Recooking properties of quick-cooking drying mung bean

-

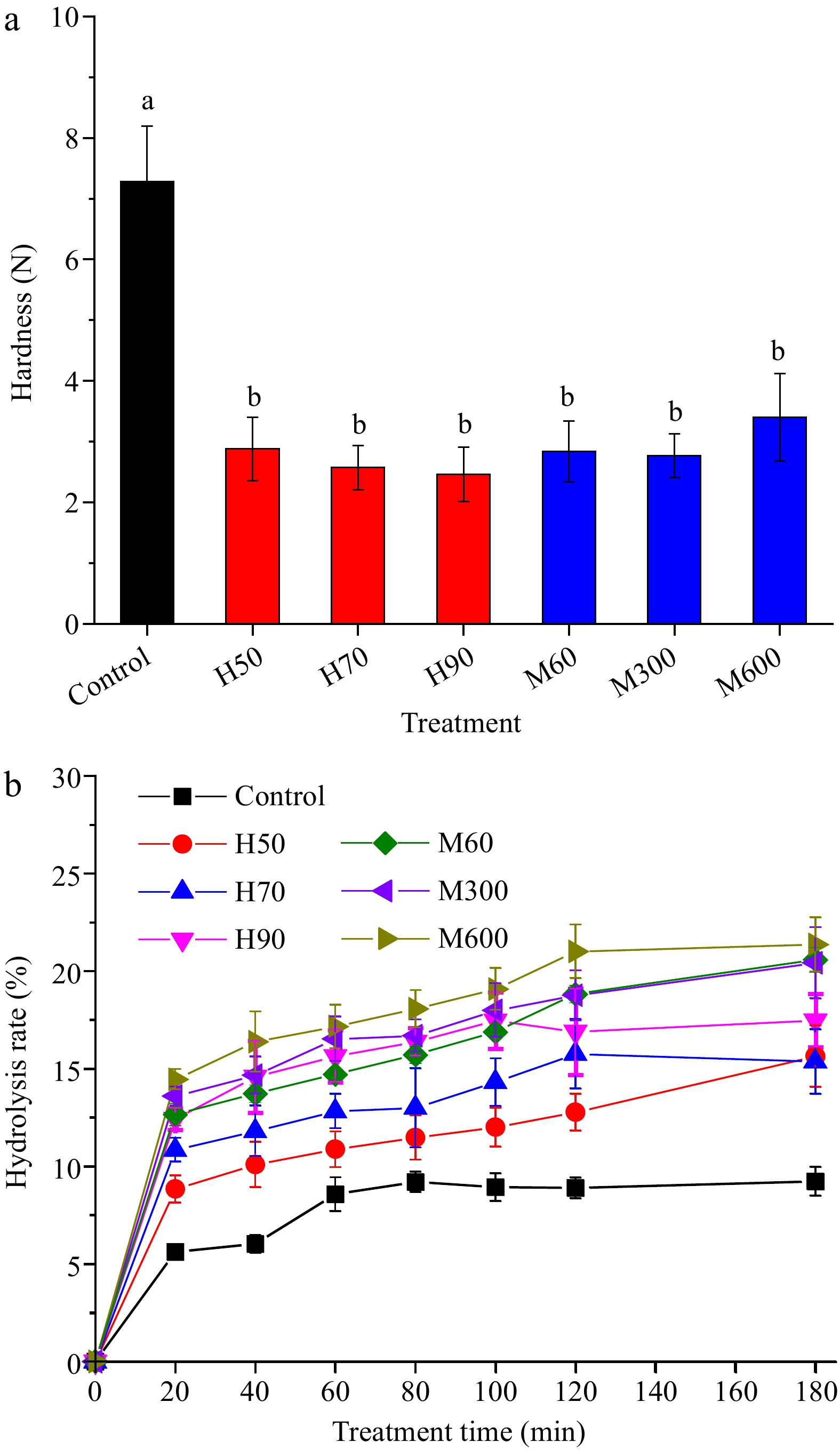

Cooking time is an important index that determines the acceptability of beans with HTC defect to consumers[9]. After steaming for 18 min, no white core was observed in the center of white rice. At this time, there was also no white core presenting in the center of pre-cooked mung bean, whereas it appeared for native mung bean. This result suggested that pre-cooked dried mung bean could be recognized as a kind of easy-to-cook food, which would be more popular among consumers. Li et al.[13] reported that pre-cooking and drying significantly improved the cooking efficiency of kidney beans, showing a decrease of hardness, gumminess and chewiness. In this study, the hardness of native and quick-cooking dried mung bean after steaming for 18 min are shown in Fig. 4a . Native mung bean exhibited the highest hardness, showing a value of 7.28 N. For the quick-cooking dried mung bean, the hardness was dramatically decreased to 2.46−3.40 N. As the hot air temperature increased, more gelatinization of mung bean starch occurred, thus causing a further decrease of hardness. Notably, the hardness was slightly increased when the power of microwave drying increased from 300 to 600 W, which might be caused by the reduced moisture content. Figure 1b suggested that the equilibrium moisture in microwave dried mung bean was lowered with the increasing microwave power. Overall, all dried pre-cooked mung bean could be regarded as quick-cooking food, regardless of the drying methods.

In vitro digestibility of quick-cooking drying mung bean

-

In vitro digestibility is an important indicator for evaluating the nutritional quality of mung bean. In the digestion system, α-amylase randomly hydrolyzed the α-1,4 glycosidic bonds in starch chains, while amyloglucosidase degraded the terminal or next-to-terminal glycosidic bonds from the non-reducing ends of starch chain. The digestion rate was correlated to the diffusion of enzyme to starch chains, the formation of glucan chain-enzyme complex, and the hydrolysis of glycosidic linkages[29]. Thermal treatment destroyed the granular structure, reduced the amounts of ordered structures such as crystallites, thus reducing the bulk compactness of glucan chain assembly, enhancing the diffusion of enzymes into the matrixes of starch substrates, and finally facilitating the formation of starch-enzyme complex and the followed hydrolysis[30]. In the present study, the effect of hot air and microwave drying on the in vitro digestibility of native and pre-cooked mung bean was presented in Fig. 4b. All quick-cooking dried mung beans showed a significant higher hydrolysis than native mung bean (~7.5%, 60−180 min). When the hot air temperature and microwave power increased, the hydrolysis rate gradually increased. For example, at a hydrolysis time of 60 min, the hydrolysis rate gradually increased from ~10% to ~15%, with hot air temperature increasing from 50 to 90 °C. Microwave treatment further increased the hydrolysis rate, showing a value of ~17.5% at a hydrolysis of 60 min after 600 W microwave drying. Compared with microwave drying, hot air drying required a long time (~120 min), which might enable pre-cooked starch chains more effectively reassembled into molecular orders, and hence decreased its digestibility, which was proved by XRD results. In summary, microwave allowed for the rapid removal of water from mung bean, and thus might contribute to restricting starch retrogradation and improving the in vitro digestibility of quick-cooking drying mung bean.

Figure 4.

(a) Hardness and (b) in vitro digestibility of native and pre-cooked mung bean dried by hot air and microwave. Note: Same as Fig. 3.

Quality formation mechanism of quick-cooking mung bean prepared by microwave and hot air drying

-

As stated above, microwave could shorten the drying period, reduce energy consumption, and improve the in vitro digestibility of mung bean when compared with hot air drying. To classify the underlying mechanism, the microstructure, chemical structure, crystal structure, pasting properties of mung bean powder, as well as the heat transmission patterns of microwave and hot air drying were discussed.

Morphology of quick-cooking drying mung bean

-

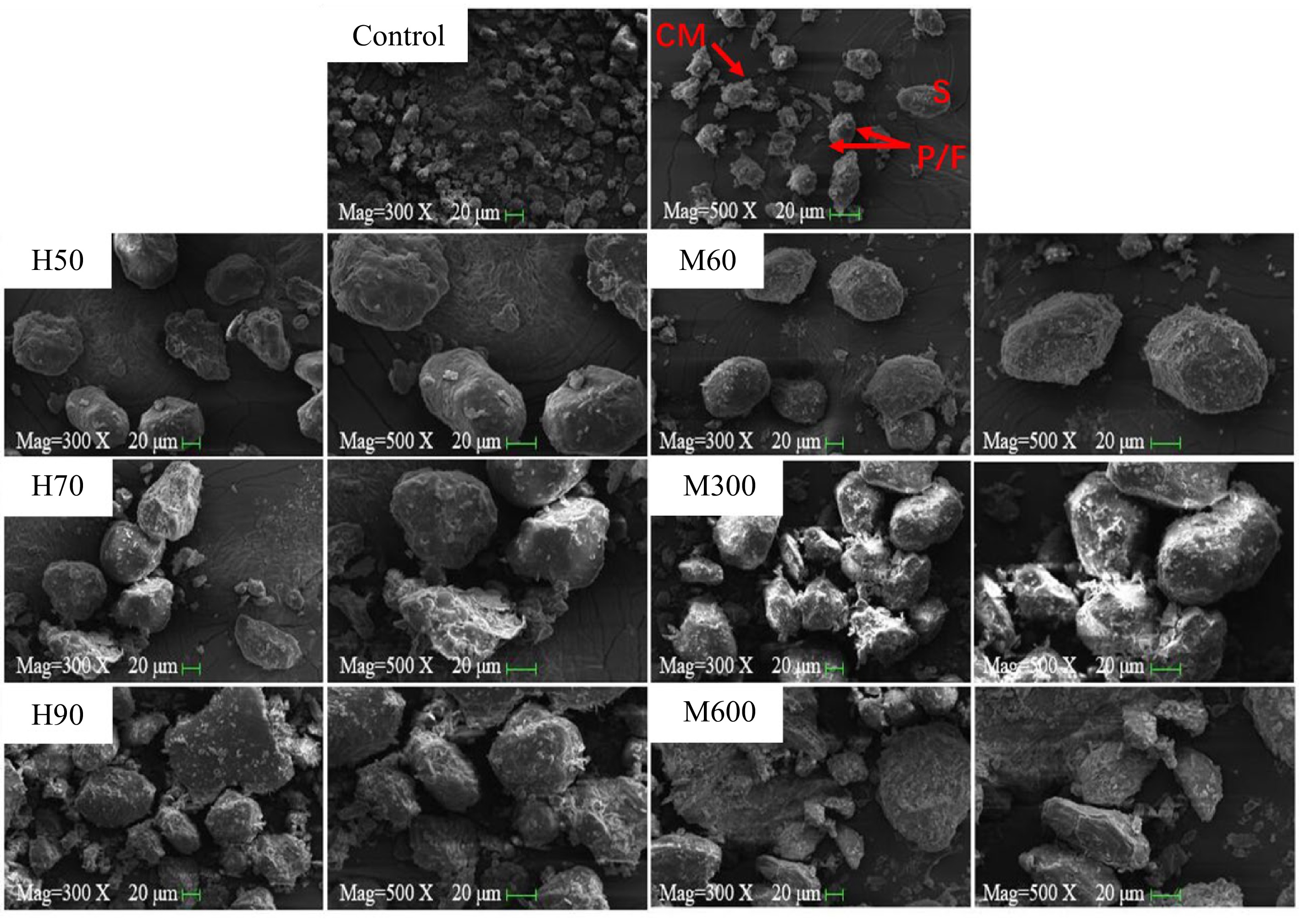

The SEM images of native and pre-cooked mung beans after drying by hot air and microwave are presented in Fig. 5. For native mung bean, the elongated and round particles were recognized as starch granules, indicated as S; the smaller and asymmetrical particles were most probably protein and fiber particles, shown as P or F; larger clusters were visible as the combination of starch and protein and/or fiber particles, presented as CM. Schlangen et al.[31] reported a similar result for mung bean, yellow pea, and cowpea flours. Yao et al.[19] reported that isolated mung bean starch demonstrates as being round, elliptical, and oval, with the granule surfaces being smooth and flat, though some ridges appeared. Zhu et al.[32] suggested a strong adhesion of protein/fiber particles to the surface of starch granules, thus causing a rough surface of starch in mung bean flours. During pre-cooking, the starch granules in mung bean experienced a gelatinization process, where the starch absorbed water, swelled, broken down, and then reaggregated into larger species; protein was denatured, and interacted with starch molecules. Figure 5 showed that large particles with a rough surface appeared for pre-cooked mung bean after hot air and microwave drying. Li et al.[33] reported that starch granules absorbed water, swelled, and finally disrupted and aggregated together after gelatinization. Considine et al.[34] suggested that protein could interact with starch during cooking, thus dramatically affecting the rheological, pasting, and textural properties of foods. The swollen starch granules and denatured protein were contributed to the shortened cooking time, decreased hardness, and increased in vitro digestibility. During drying, moisture in pre-cooked mung bean was removed, and theoretically, the drying method and temperature would affect the rehydration rate and thus alter the morphology of mung bean starch and protein. However, no significant difference in SEM images between microwave and hot air-dried samples were observed, suggesting that the destroyed microstructure was not the only reason for quality formation of quick-cooking drying mung bean.

Figure 5.

SEM images of pre-cooked mung bean after hot air and microwave drying. Note: Same as Fig. 3.

Chemical structure of quick-cooking drying mung bean

-

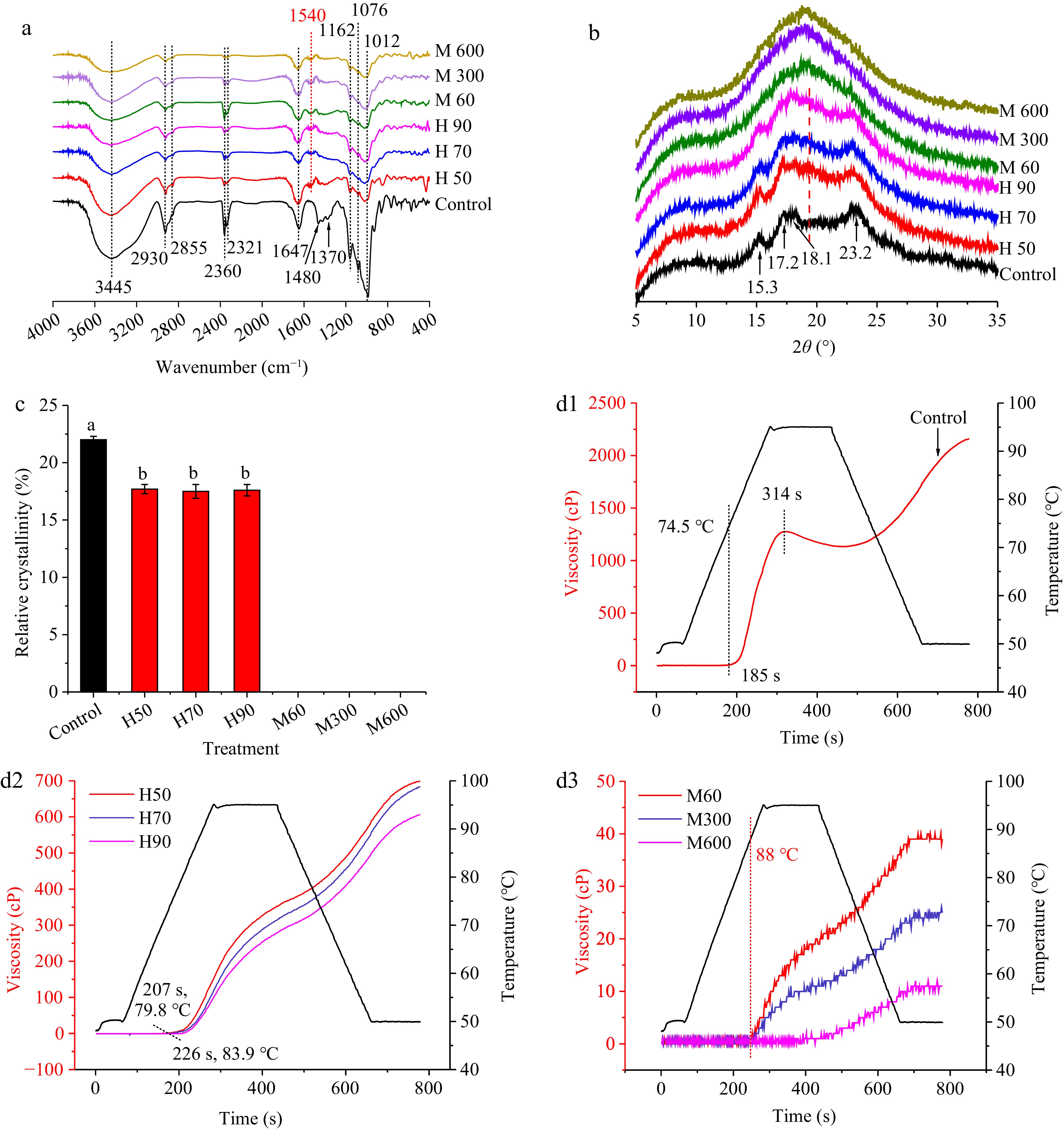

The FTIR spectra of native and pre-cooked mung beans after dried by hot air and microwave are presented in Fig. 6a. The wide band at 3,445 cm−1 was mainly assigned to O-H bond stretching; the peak at 2,930 cm−1 was attributed to C-H bond stretching vibrations; several discernible absorbencies at 1,012, 1,068, and 1,160 cm−1 were related to C-O bond stretching vibrations[35]. After pre-cooking and drying, the peak at 3,445 cm−1 was weakened, suggesting a disruption of hydrogen bonding and interactions between glucan chains originally existing in untreated starch. In addition, protein exhibited typical bands between 1,700 and 1,500 cm−1, which were assigned to amide I (1,580–1,720 cm−1) and amide II (1,480–1,580 cm−1)[36]. Figure 6a suggested that a new peak at 1,540 cm−1 appeared while several peaks between 1,370 and 1480 cm−1 disappeared after pre-cooking and drying, indicating the strengthen of N-H bending (amide II) and weakness of C-N-C stretching in mung bean protein. Meanwhile, the characteristic peak occurred at 1,647 cm−1, which was related to -C=O- and -C=N- stretching (amide I), was gradually weakened with hot air temperature and microwave power. After pre-cooking and drying, protein was denatured, and starch and protein and other nonstarch molecules might react with each other, thus causing a modification in the secondary structure of mung bean protein. Divekar et al.[37] pointed out that the modification of mung bean protein during microwave treatment involved a build-up of stable aggregates. The obtained results were consistent with SEM images (Fig. 5), which also confirmed the denaturation of protein during pre-cooking and drying.

Figure 6.

(a) FT-IR spectra, (b) XRD patterns, (c) relative crystallinity, and (d) RVA curves of native and pre-cooked mung bean dried by hot air and microwave. Note: Same as Fig. 3.

Crystal structure of quick-cooking drying mung bean

-

Non-starch polymers in mung bean showed no subversive effects on the crystal structure of mung bean starch[35]. Figure 6b illustrated the semicrystalline structure of native and pre-cooked mung bean after dried by hot air and microwave. Native mung bean starch exhibited a typical C-type crystalline pattern, showing strong reflections at 15.3°, 17.2°, 18.1°, and 23.2°. Notably, no reflection at 5.6° was observed, which suggested that mung bean starches displayed almost identical CA-type crystalline patterns. Similar phenomenon was observed by Yao et al.[19]. Undergoing pre-cooking, mung bean starch molecule chains disassembled from the hierarchical structure, resulting in a loss of C-type crystalline; then, the gelatinized starch chains tend to reassemble in the course of storage to form a new hierarchical structure[38]. According to the drying kinetics curve (Fig. 1a), hot air drying of pre-cooked mung bean required a long time (> 100 min), which allowed enough time to induce reassemble of disordered starch chains. Figure 6b & c indicated that mung bean starch displayed a dominant CA-type crystalline with peaks at 15.3°, 17.2°, 18.1°, and 23.2° and a weak V-type structure as indicated by a peak at about 20° after hot air drying, with the relatively crystallinity decreasing from 22.0% to 17.5%−17.9%. However, the moisture content in pre-cooked mung bean rapidly decreased to < 12% (w/w) within 30 min during microwave drying (Fig. 1b), thus restricting the reassembly of disordered starch chains. As shown in Fig. 6b, microwave-dried mung bean displayed predominantly an amorphous state without detectable long-range scale crystallites by the XRD technique. The disappearance of crystalline would increase the accessibility of starch chains to enzymes and chemical reagents, thus largely increasing their digestibility. Behera & Sutar[25] reported that the crystallinity of milled rice was decreased with an increasing power density of microwave during drying. Combined with SEM and FT-IR results, the difference of microwave and hot air drying on the microstructure and chemical structure of pre-cooked mung bean seemed to be unobvious; however, starch retrogradation occurred during hot air drying, thus decreasing the in vitro digestibility.

Pasting properties of quick-cooking drying mung bean

-

The RVA curves and related pasting parameters of native and pre-cooked mung bean after drying by hot air and microwave were presented in Fig. 6c and Table 1, respectively. The pasting viscosity (PV), tough viscosity (TV), final viscosity (FV), breakdown (BD), and setback (SB) of native mung bean was 560, 496, 1,011, 64.3, and 515 cP, respectively. After heat treatment, mung bean starch was gelatinized, and its granular and semicrystalline structure (Fig. 5 & 6b) were completely destroyed. As a result, the pasting viscosities of mung bean dramatically decreased. After drying by hot air at temperatures of 60-90 °C, the PV, TV, FV, BD, and SB decreased to 267−348, 216−295, 599−705, 51−55, and 383−420 cP, respectively. Microwave drying restricted the retrogradation of mung bean starch (Fig. 6b), thus leading to more decreases in pasting viscosities. After drying by microwave at 600 W, the pasting viscosity was nearly 0. The pasting temperature of mung bean was largely increased by heat treatment. On the one hand, most ready-to-gelatinization starches were gelatinized during pre-cooking and drying; and hence, the remaining starches in pre-cooked mung bean exhibited a much higher pasting temperature (Fig. 6c). On the other hand, lipids and proteins might inhibit the swelling of starch granules, and during pre-cooking and drying, the interactions between lipids and/or proteins and starch might be strengthened[39]. The pasting viscosities was in agreement with the results of SEM, XRD, and in vitro digestibility, which further confirmed that the advantages of microwave drying in improving the nutritional values of mung bean.

Table 1. RVA parameters of pre-cooked mung bean treated by hot air and microwave.

Treatment Peak viscosity

(cP)Trough viscosity (cP) Breakdown

(cP)Final viscosity (cP) Setback

(cP)Control 560 ± 24a 496 ± 24a 64 ± 2a 1,011 ± 35a 515 ± 18a H50 348 ± 6b 295 ± 5b 53 ± 1bc 705 ± 6b 410 ± 1b H70 319 ± 20c 263 ± 18c 55 ± 3b 683 ± 7b 420 ± 24b H90 267 ± 3d 216 ± 2d 51 ± 1c 599 ± 7c 382 ± 6c M60 19 ± 1e 14 ± 0.6e 4 ± 1d 39 ± 1d 25 ± 1d M300 9 ± 3e 6 ± 3e 3 ± 1d 22 ± 3de 16 ± 1d M600 2 ± 0e 0 ± 0e 2 ± 0d 10 ± 1e 10 ± 1d Different letters within same column represents significant difference (p < 0.05). Control represents native mung bean; H50, H70, and H90 represent hot air drying at 50, 70, and 90 ºC, respectively; M60, M300, and M600 represent microwave treatment at 60, 300, and 600 W, respectively. Drying process of pre-cooked mung bean during hot air and microwave drying

-

As shown in Fig. 7, starch was gelatinized, protein was denatured, the volume of mung bean was increased, and some cracks were formed on the surface after soaking and pre-cooking; and then, the pre-cooked mung bean was dried to diffuse the moisture inside the food to the outside, resulting in a volume decrease, weight loss and shelf-life extension of food products. The basic objective in drying food products is the removal of water in the solids up to a certain level, at which microbial spoilage and deterioration chemical reactions are greatly minimized. Air drying is easily operatable and cheap, thus being popular in industrial production. However, this drying method occurs by convection followed by conduction where heat must diffuse in from the surface of the material. The process is uneven and slow due to the thick seed coat of mung bean. Figure 1a & 2 suggested that this process requires high energy consumption and long drying time (~120 min). Meanwhile, XRD patterns showed that the slow dehydration during hot air drying allowed the rearrangement of disordered starch chains into ordered crystalline, which might decrease its hydrolysis rate (Fig. 6b). Microwave treatment offers advantages of shorter processing time and less energy input because it can achieve rapid and uniform heating from the inside of the mung bean. Figure 1b & 2 suggested that the drying time and energy consumption of microwave treatment dramatically decreased by 90−95 min and 0.04−0.15 kW·h, respectively. More importantly, the rapid dehydration process restricted the retrogradation of gelatinized starches in mung bean, which was beneficial to human digestion (Fig. 4b & 6b). Therefore, microwave could be an alternative technique for the drying of pre-cooked beans. The obtained dried bean exhibited a larger volume, a brown color, a shortened cooking time, a reduced hardness, and an increased in vitro digestibility.

-

This study suggested that microwave might be an alternative to traditional hot air drying in preparing quick-cooking bean. Compared with hot air, microwave treatment dramatically shortened the drying time from ~120 to 25−30 min and reduced the energy consumption by 0.04−0.15 kW·h. After drying, starch was gelatinized, protein was denatured, the volume of mung bean became large, a cracked surface appeared, the color turned brown, the in vitro digestibility was increased, and the cooking time was shortened. Notably, hot air drying allowed enough time for gelatinized starch chains to reassemble into an ordered structure, resulting in a formation of weak V-type crystalline, whereas microwave rapidly remove the moisture, which restricted the retrogradation of gelatinized starch and thus further increased the digestibility of mung bean. The obtained results confirmed that microwave treatment could shorten drying time and reduce energy consumption of quick-cooking mung beans, and the underlying mechanism of quality formation was explored, which could give a theoretical guide for the applications of microwave in the preparation of quick-cooking foods. However, during industrial application, manufacturers still need to optimize drying parameters because of the different quality requirement of products and different type of microwave dryer.

This work was financially supported by the National Nature Science Foundation of China (No. 32102131; 32102138), Jiangsu Agricultural Science and Technology Innovation Fund (No. CX(21)3185), and the China Postdoctoral Science Foundation (No. 2020M681631).

-

The authors declare that they have no conflict of interest.

-

These authors contributed equally: Yaning Shi, Ge Cao

- Copyright: © 2023 by the author(s). Published by Maximum Academic Press on behalf of Nanjing Agricultural University. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Shi Y, Cao G, Liu Y, Tao Y, Han Y, et al. 2023. Effect of microwave and hot air drying on the quality of quick-cooking mung bean. Food Materials Research 3:8 doi: 10.48130/FMR-2023-0008

Effect of microwave and hot air drying on the quality of quick-cooking mung bean

- Received: 20 February 2023

- Accepted: 21 April 2023

- Published online: 29 May 2023

Abstract: Recently, consumers prefer ready-to-eat foods due to their advantageous minimal input of time and effort. Soaking-cooking-drying is a typical procedure for preparing quick-cooking beans, where drying is the last but not least step. Therefore, this study aimed to compare the effect of microwave and hot air drying on the quality of quick-cooking mung bean. Mung bean was soaked, pre-cooked and then dried by microwave (60, 300, and 600 W) and hot air (50, 70, and 90 ºC). All dried beans exhibited a larger volume, a cracked surface, a browning color, a shortened cooking time, and an increased in vitro digestibility. However, microwave treatment decreased the drying time from ~120 to 25−30 min, and reduced the energy consumption by 0.04−0.15 kW·h. The quick dehydration process during microwave drying restricted the reassemble of gelatinized starch and the formation of weak V-type crystalline, thus further improving the digestibility of mung bean. Overall, this study suggested that microwave could be an alternative drying technique for preparing quick-cooking beans with high digestibility.

-

Key words:

- rehydration /

- ready-to-eat food /

- starch /

- digestibility