-

The use of composite flour in wet noodles has been widely used to increase its functional value and several characteristics, including physical, chemical, and sensory properties. Siddeeg et al. [1] used wheat-sorghum-guar flour and wheat-millet-guar flour to increase the acceptability of wet noodles. Efendi et al.[2] stated that potato starch and tapioca starch in a ratio of 50:50 (% w/w) could increase the functional value of wet noodles. Dhull & Sandhu[3] stated that noodles made from wheat flour mixed with up to 7% fenugreek flour produce good texture and high consumer acceptability. Park et al.[4] utilized the mixed ratio of purple wheat bran to improve the quality of wet noodles and antioxidant activity.

A previous study used stinky lily flour or konjac flour (Amorphophallus muelleri) composited with wheat flour to increase the functional value of noodles by increasing biological activity (anti-obesity, anti-hyperglycemic, anti-hyper cholesterol, and antioxidant) and extending gastric emptying time[5,6]. Widyawati et al.[7] explained that using composite flour consisting of wheat flour, stink lily flour, and κ-carrageenan can improve the swelling index, total phenolic content (TPC), total flavonoid content (TFC), and 2,2-diphenyl-1-picrylhydrazyl free radical scavenging activity (DPPH), which influences the effectivity of bioactive compounds in the composite flour that serve as antioxidant sources of wet noodles. Therefore, other ingredients containing phenolic compounds can be added to increase composite flour's functional values as a source of antioxidants. Czajkowska–González et al.[8] mentioned that incorporating phenolic antioxidants from natural sources can improve the functional values of bread. Widyawati et al.[7] added pluchea extract to increase the TPC, TFC, and DPPH of wet noodles, however, this resulted in an unattractive wet noodle color. Therefore, it is necessary to incorporate other ingredients to enhance the wet noodles' color profile and their functional properties, one of which is the butterfly pea flower.

Butterfly pea (Clitoria ternatea) is a herb plant from the Fabaceae family with various flower colors, such as purple, blue, pink, and white[9]. This flower has phytochemical compounds that are antioxidant sources[10,11], including anthocyanins, tannins, phenolics, flavonoids, flobatannins, saponins, triterpenoids, anthraquinones, sterols, alkaloids, and flavonol glycosides[12,13]. Anthocyanins of the butterfly pea flower have been used as natural colorants in many food products[14,15], one of them is wet noodles[16,17]. The phytochemical compounds, especially phenolic compounds, can influence the interaction among gluten, amylose, and amylopectin, depending on partition coefficients, keto-groups, double bonds (in the side chains), and benzene rings[18]. This interaction involves their formed covalent and non-covalent bonds, which influenced pH and determined hydrophilic-hydrophobic properties and protein digestibility[19]. A previous study has proven that the use of phenolic compounds from plant extracts, such as pluchea leaf[7,20], gendarussa leaf (Justicia gendarussa Burm.F.)[21], carrot and beetroot[22], kelakai leaf[23] contributes to the quality, bioactive compounds, antioxidant activity, and sensory properties of wet noodles. Shiau et al.[17] utilized the natural color of butterfly pea flower extract to make wheat flour-based wet noodles, resulting in higher total anthocyanin, polyphenol, DPPH, and ferric reducing antioxidant power (FRAP) than the control samples. This extract also improved the color preference and reduced cooked noodles' cutting force, tensile strength, and extensibility. Until now, the application of water extract of butterfly pea flowers in wet noodles has been commercially produced, but the interactions among phytochemical compounds and ingredients of wet noodles base composite flour (stinky lily flour, wheat flour, and κ-carrageenan) have not been elucidated. Therefore, the current study aimed to determine the effect of composite flour and butterfly pea flower extract on wet noodles' quality, bioactive content, antioxidant activity, and sensory properties.

-

Butterfly pea flowers were obtained from Penjaringan Sari Garden, Wonorejo, Rungkut, Surabaya, Indonesia. The flowers were sorted, washed, dried under open sunlight, powdered using a blender (Philips HR2116, PT Philips, Netherlands) for 3 min, and sieved using a sieve shaker with 45 mesh size (analytic sieve shaker OASS203, Decent, Qingdao Decent Group, China). The water extract of butterfly pea flower was obtained using a hot water extraction at 95 °C for 3 min based on the modified method of Widyawati et al.[20] and Putri et al.[24] to obtain three concentrations of butterfly pea extract: 0 (T1), 15 (T15), and 30 (T30) (% w/v). The three-composite flour proportions were prepared by mixing wheat flour (Cakra Kembar, PT Bogasari Sukses Makmur, Indonesia), stink lily flour (PT Rezka Nayatama, Sekotong, Lombok Barat, Indonesia), and κ-carrageenan (Sigma-Aldrich, St. Louis, MO, USA) at ratios of 80:20:0 (K0), 80:19:1 (K1), 80:18:2 (K2), and 80:17:3 (K3) (% w/w).

Chemicals and reagents

-

Gallic acid, 2,2-diphenyl-1-picrylhydrazyl (DPPH), (+)-catechin, and sodium carbonate were purchased from Sigma-Aldrich (St. Louis, MO, USA). Methanol, aluminum chloride, Folin–Ciocalteu's phenol reagent, chloride acid, acetic acid, sodium acetic, sodium nitric, sodium hydroxide, sodium hydrogen phosphate, sodium dihydrogen phosphate, potassium ferricyanide, chloroacetic acid, and ferric chloride were purchased from Merck (Kenilworth, NJ, USA). Distilled water was purchased from a local market (PT Aqua Surabaya, Surabaya, Indonesia).

Wet noodle preparation

-

Wet noodles were prepared based on the modified formula of Panjaitan et al.[25], as shown in Table 1. In brief, the composite flour was sieved with 45 mesh size, weighed, and mixed with butterfly pea flower extract at various concentrations. Salt, water, and fresh whole egg were then added and kneaded to form a dough using a mixer (Oxone Master Series 600 Standing Mixer OX 851, China) until the dough obtained was smooth. The dough was sheeted to get noodles about 0.15 cm thick and cut using rollers equipped with cutting blades (Oxone OX355AT, China) to obtain noodles about 0.1 cm wide. Raw wet noodle strains were sprinkled with tapioca flour (Rose Brand, PT Budi Starch & Sweetener, Tbk) (4% w/w) before being heated in boiled water (100 °C) with a ratio of raw noodles : water at 1:4 w/v for 2 min. Cooked wet noodles were coated with palm oil (Sania, PT Wilmar Nabati, Indonesia) (5% w/w) before being subjected to quality and sensory properties measurements, whereas uncooked noodles without oil coating were used to analyze bioactive compounds and antioxidant activity.

Table 1. Formula of wet noodles.

Treatment Code Ingredients Salt

(g)Fresh

whole

egg (g)Water

(mL)Butterfly

pea extract

solution (mL)Composite

flour (g)1 K0T0 3 30 30 0 150 2 K0T15 3 30 0 30 150 3 K0T30 3 30 0 30 150 4 K1T0 3 30 30 0 150 5 K1T15 3 30 0 30 150 6 K1T30 3 30 0 30 150 7 K2T0 3 30 30 0 150 8 K2T15 3 30 0 30 150 9 K2T30 3 30 0 30 150 10 K3T0 3 30 30 0 150 11 K3T15 3 30 0 30 150 12 K3T30 3 30 0 30 150 K0 = wheat flour : stink lily flour : κ-carrageenan = 80:20:0 (%w/w). K1 = wheat flour : stink lily flour : κ-carrageenan = 80:19:1 (%w/w). K2 = wheat flour : stink lily flour : κ-carrageenan = 80:18:2 (%w/w). K3 = wheat flour : stink lily flour : κ-carrageenan = 80:17:3 (%w/w). T0 = concentration of the butterfly pea extract = 0%. T15 = concentration of the butterfly pea extract = 15%. T30 = concentration of the butterfly pea extract = 30%. Extraction of bioactive compounds of wet noodles

-

Wet noodles were extracted based on the method of Widyawati et al.[7]. Raw noodles were dried in a cabinet dryer (Gas drying oven machine OVG-6 SS, PT Agrowindo, Indonesia) at 60 °C for 2 h. The dried noodles were ground using a chopper (Dry Mill Chopper Philips set HR 2116, PT Philips, Netherlands). About 20 g of sample was mixed with 50 mL of solvent mixture (1:1 v/v of methanol/water), stirred at 90 rpm in a shaking water bath at 35 °C for 1 h, and centrifuged at 5,000 rpm for 5 min to obtain supernatant. The obtained residue was re-extracted in an extraction time for three intervals. The supernatant was collected and separated from the residue and then evaporated using a rotary evaporator (Buchi-rotary evaporator R-210, Germany) at 70 rpm, 70 °C, and 200 mbar to generate a concentrated wet noodle extract. The obtained extract was used for further analysis.

Moisture content analysis

-

The water content of cooked wet noodles was analyzed using the thermogravimetric method[26]. About 1 g of the sample was weighed in a weighing bottle and heated in a drying oven at 105−110 °C for 1 h. The processes were followed by weighing the sample and measuring moisture content after obtaining a constant sample weight. The moisture content was calculated based on the difference of initial and obtained constant sample weight divided by the initial sample weight, expressed as a percentage of wet base.

Water activity analysis

-

The water activity of cooked wet noodles was analyzed using an Aw-meter (Water Activity Hygropalm HP23 Aw a set 40 Rotronic, Swiss). Ten grams of the sample were weighed, put into an Aw meter chamber, and analyzed to obtain the sample's water activity[27].

Tensile strength analysis

-

Tensile strength is an essential parameter that measures the extensibility of cooked wet noodles[28]. About 20 cm of the sample was measured for its tensile strength using a texture analyzer equipped with a Texture Exponent Lite Program and a noodle tensile rig probe (TA-XT Plus, Stable Microsystem, UK). The noodle tensile rig was set to pre-set speed, test speed, and post-test speed at 1, 3, and 10 mm/s, respectively. Distance, time, and trigger force were set to 100 mm, 5 s, and 5 g, respectively.

Color analysis

-

Ten grams of cooked wet noodles were weighed in a chamber, and the color was analyzed using a color reader (Konica Minolta CR 20, Japan) based on the method of Harijati et al.[29]. The parameters measured were lightness (L*), redness (a*), yellowness (b*), hue (oh), and chroma (C). L* value ranged from 0-100 expresses brightness, and a* value shows red color with an interval between −80 and +100. b* value represents a yellow color with an interval of −70 to +70[30]. C indicates the color intensity and oh states the color of samples[31].

Swelling index analysis

-

The swelling index was determined using a modified method of Islamiya[32]. Approximately 5 g of the raw wet noodles were weighed in a chamber and cooked in 150 mL boiled water (100 °C) for 5 min. The swelling index was measured to observe the capability of raw wet noodles to absorb water that increased the weight of raw wet noodles[33]. The swelling index was measured from the difference in noodle weights before and after boiling.

Cooking loss analysis

-

The cooking loss of the raw wet noodles was analyzed using a modified method of Aditia et al.[34]. The cooking loss expresses the weight loss of wet noodles during cooking, indicated by the cooking water that turns cloudy and thick[35]. About 5 g of the raw wet noodles was weighed in a chamber and cooked in 150 mL boiled water (100 °C) for 5 min. Then, the sample was drained and dried in a drying oven at 105 °C until the weight of the sample was constant.

Total phenolic content analysis

-

The total phenolic content of the wet noodles was determined using Folin-Ciocalteu's phenol reagent based on the modified method by Ayele et al.[36]. About 50 μL of the extract was added with 1 mL of 10% Folin-Ciocalteu's phenol reagent in a 10 mL volumetric flask, homogenized, and incubated for 5 min. Then, 2 mL of 7.5% Na2CO3 was added, and the volume was adjusted to 10 mL with distilled water. The solution's absorbance was measured spectrophotometrically at λ760 nm (Spectrophotometer UV-Vis 1800, Shimadzu, Japan). The standard reference used was gallic acid (y = 0.0004x + 0.0287, R2 = 0.9877), and the result was expressed as mg GAE (Gallic Acid Equivalent) per kg of dried noodles. TPC of samples (mg GAE/kg dried noodles) was calculated using the equation:

$\begin{split}&\rm TPC\; (mg\; GAE/kg\; dried\; noodles)\\=\;& \rm\dfrac{As - 0.0287}{0.0004} \,\times\, \dfrac{2\; mL}{ x\; g}\,\times\\& \rm\dfrac{1\; L}{ 1000\; mL}\,\times\, \dfrac{1000\; g}{1\; kg}\end{split} $ where, As = absorbance of the samples, and x = weight of the dried noodles.

Total flavonoid content analysis

-

Total flavonoid content was analyzed using the modified method of Li et al.[37]. The procedure began with mixing 0.3 mL of 5% NaNO2 and 250 μL of noodle extract in a 10 mL volumetric flask and incubating the mixture for 5 min. Afterward, 0.3 mL of 10% AlCl3 was added to the volumetric flask. After 5 min, 2 mL of 1 M NaOH was added, and the volume was adjusted to 10 mL with distilled water. The sample was homogenized before analysis using a spectrophotometer (Spectrophotometer UV-Vis 1800, Shimadzu, Japan) at λ510 nm. The result was determined using a (+)-catechin standard reference (y = 0.0008x + 0.0014, R2 = 0.9999) and expressed as mg CE (Catechin Equivalent) per kg of dried noodles. TFC of samples (mg CE/kg dried noodles) was calculated using the equation:

$\begin{split}&\rm TFC\; (mg\; CE/kg\; dried\; noodles)\\=\;& \rm\dfrac{As - 0.0014}{0.0008} \,\times\, \dfrac{2\; mL}{ x\; g}\,\times\\& \rm\dfrac{1\; L}{ 1000\; mL}\,\times\, \dfrac{1000\; g}{1\; kg}\end{split} $ where, As = absorbance of the samples, and x = weight of the dried noodles.

Total anthocyanin content analysis

-

Total anthocyanin content was determined using the method of Giusti & Wrolstad[38]. About 250 μL of the sample was added with buffer solutions at pH 1 and pH 4.5 in different 10 mL test tubes. Then, each sample was mixed and incubated for 15 min and measured at λ543 and λ700 nm (Spectrophotometer UV-Vis 1800, Shimadzu, Japan). The absorbance (A) of samples was calculated with the formula: A = (Aλ543 − Aλ700)pH1.0 − (Aλ543 − Aλ700)pH4.5. The total anthocyanin monomer content (TA) (mg·mL−1) was calculated with the formula:

$ \dfrac{\mathrm{A}\mathrm{\ \times\ }\mathrm{M}\mathrm{W}\mathrm{\ \times\ }\mathrm{D}\mathrm{F}\mathrm{\ \times}1000}{\varepsilon\ \mathrm{\times}\mathrm{\ }\mathrm{l}} $ $\begin{split}&\rm TA\;monomer\; (mg\; delphinidine{\text-}3{\text-}glucoside/kg\; dried\; noodles)\\=\;&\rm TA\;(mg/L)\;\dfrac{2\; mL}{ x\; g}\,\times\, \rm\dfrac{1\; L}{ 1,000\; mL}\,\times\, \dfrac{1,000\; g}{1\; kg}\end{split} $ where, x = the weight of dried noodles.

2,2-Diphenyl-1-picrylhydrazyl free radical scavenging activity

-

DPPH analysis was measured based on the methods of Shirazi et al.[39] and Widyawati et al.[40]. Briefly, 10 μL of the extract was added to a 10 mL test tube containing 3 mL of DPPH solution (4 mg DPPH in 100 mL methanol) and incubated for 15 min in a dark room. The solution was centrifuged at 5,000 rpm for 5 min, and the absorbance of samples was measured at λ517 nm (Spectrophotometer UV-Vis 1800, Shimadzu, Japan). The antioxidant activity of the samples was stated as an inhibition capacity with gallic acid as the standard reference (y = 0.1405x + 2.4741, R2 = 0.9974) and expressed as mg GAE (Gallic Acid Equivalent) per kg of dried noodles. The percentage of DPPH free radical scavenging activity was calculated using the equation:

Inhibition of DPPH free radical scavenging activity

$\rm y \;({\text{%}}) = \dfrac{A0 - As}{A0}\,\times\, 100{\text{%}}$ where, A0 = absorbance of the control and As = absorbance of the samples.

$\begin{split}&\rm DPPH\; free\; radical\; scavenging\; activity \;(mg\; GAE/kg\; dried\; noodles)=\\&\rm\dfrac{y-2.4741}{0.1405}\,\times\, \dfrac{2\;mL}{x\;g}\,\times\,\dfrac{1\;L}{1000\;mL}\,\times\, \dfrac{1000\;g}{1\;kg}\end{split}$ where, x = the weight of dried noodles.

Ferric reducing antioxidant power

-

FRAP analysis was performed using the modified method of Al-Temimi & Choundhary[41]. Approximately 50 μL of the extract in a test tube was added with 2.5 mL of phosphate buffer solution at pH 6.6 and 2.5 mL of 1% potassium ferric cyanide, shaken and incubated for 20 min at 50 °C. After incubation, the solution was added with 2.5 ml of 10% mono-chloroacetic acid and shaken until homogenized. Then, 2.5 mL of the supernatant was taken and added with 2.5 mL of bi-distilled water and 2.5 mL of 0.1% ferric chloride and incubated for 10 min. After incubation, samples were measured with absorbance at λ700 nm (Spectrophotometer UV-Vis 1800, Shimadzu, Japan). Gallic acid was used as the standard reference (y = 2.2025x − 0.0144, R2 = 0.9983), and the results were expressed in mg GAE (Gallic Acid Equivalent) per kg of dried noodles. The reducing power of samples was calculated using the formula:

The reducing power (RP) (%) = [(As − A0)/As] × 100%

Where, A0 = absorbance of the control and As = absorbance of the samples.

$\begin{split}&\rm FRAP \;(mg\; GAE/kg\; dried\; noodles)\ =\\ &\rm \dfrac{RP+0.0144}{2.2025}\,\times\, \dfrac{2\;mL}{x\;g}\,\times\,\dfrac{1\;L}{1000\;mL}\,\times \, \dfrac{1000\;g}{1\;kg}\end{split}$ where, x = the weight of dried noodles.

Sensory evaluation

-

The sensory properties of cooked wet noodles were analyzed based on the methods of Nugroho et al.[42] with modifications. The assessment used hedonic scale scoring with the parameters including color, aroma, taste, and texture attributes with 15 level, score 1 was stated as very much dislike, and 15 was very much like. This sensory analysis was performed by 100 untrained panelists between 17 and 25 years old who had previously gained knowledge of the measurement procedure. Each panelist was presented with 12 samples to be tested and given a questionnaire containing testing instructions and asked to give a score to each sample according to their level of liking. The hedonic scale used is a value of 1−15 given by panelists according to their level of liking for the product. A score of 1−3 indicates very much dislike, a score of 4−6 does not like, a score of 7−9 is neutral, a score of 10−12 likes it, and a score of 13−15 is very much like it. The best treatment was determined by the index effectiveness test[43]. The best determination was based on sensory assay which included preferences for color, aroma, taste, and texture. The principle of testing was to give a weight of 0−1 on each parameter based on the level of importance of each parameter. The higher the weight value given means the parameter was increasingly prioritized. The treatment that has the highest value was determined as the best treatment. Procedure to determin the best treatment for wet noodles included:

(a) Calculation of the average of the weight parameters based on the results filled in by panelists

(b) Calculation of normal weight (BN)

BN = Variable weight/Total weight

(c) Calculation of effectiveness value (NE)

NE = Treatment value − worst value/Best value − worst value

(d) Calculation of yield value (NH)

NH = NE × normal weight

(d) Calculation of the total productivity value of all parameters

Total NH = NH of color + NH of texture + NH of taste + NH of aroma

(e) Determining the best treatment by choosing the appropriate treatment had the largest total NH

Design of experiment and statistical analysis

-

The design of the experiment used was a randomized block design (RBD) with two factors, i.e., the four ratios of the composite flour (wheat flour, stink lily flour, and κ-carrageenan) including 80:20:0 (K0); 80:19:1 (K1); 80:18:2 (K2), and 80:17:3 (K3) (% w/w), and the three-butterfly pea flower powder extracts, including 0 (T0), 15 (T1), 30 (T3) (% w/v). The experiment was performed in triplicate. The homogenous triplicate data were expressed as the mean ± SD. One-way analysis of variance (ANOVA) was carried out, and Duncan's New multiple range test (DMRT) was used to determine the differences between means (p ≤ 0.05) using the statistical analysis applied SPSS 23.0 software (SPSS Inc., Chicago, IL, USA).

-

The quality results of the wet noodles, including moisture content, water activity, tensile strength, swelling index, cooking loss, and color, are shown in Tables 2−5, and Fig. 1. Moisture content and water activity (Aw) of raw wet noodles were only significantly influenced by the various ratios of composite flour (p ≤ 0.05) (Table 3). However, the interaction of the two factors, the ratios of composite flour and the concentrations of butterfly pea extract, or the concentrations of butterfly pea extract itself did not give any significant effects on the water content and Aw of wet noodles (p ≤ 0.05) (Table 2). The K3 sample had the highest water content (70% wet base) compared to K0 (68% wet base), K1 (68% wet base), and K2 (69% wet base) because the sample had the highest ratio of κ-carrageenan. An increase of κ-carrageenan proportion influenced the amount of free and bound water in the wet noodle samples, which also increased the water content of the wet noodles. Water content resembles the amount of free and weakly bound water in the samples' pores, intermolecular, and intercellular space[7,20]. Protein networking between gliadin and glutelin forms a three-dimensional networking structure of gluten involving water molecules[44]. The glucomannan of stinky lily flour can form a secondary structure with sulfhydryl groups of the gluten network to stabilize it, increasing water binding capacity and retarding the migration of water molecules[45]. κ-carrageenan can bind water molecules around 25−40 times[46]. κ-carrageenan can cause a structure change in gluten protein through electrostatic interactions and hydrogen bonding[47]. The interaction among the major proteins of wheat flour (gliadin and glutelin), glucomannan of stinky lily flour, and κ-carrageenan also changed the conformation of the three-dimensional network structure formation involving electrostatic forces, hydrogen bonds, and intra-and inter-molecular disulfide bonds that can establish water mobility in the dough of the wet noodles. The interaction of all components in the composite flour significantly influenced the amount of free water (p ≤ 0.05) (Table 3). The addition of κ-carrageenan between 1%−3% in the wet noodle formulation reduced the Aw by about 0.005−0.006. The capability of κ-carrageenan to absorb water molecules reduces the water mobility in the wet noodles due to the involvement of hydroxyl, carbonyl, and ester sulfate groups of them to form complex structures[48]. The complexity of the reaction among components in the wet noodles to form a three-dimensional network influenced the amount of free water molecules that determined water activity values. The strength of the bonding among the components between wet noodles and water molecules also contributed to the value of the water activity.

Table 2. Quality properties of wet noodles at various ratios of composite flour and concentrations of butterfly pea flower extract.

Samples Moisture content (% w/w) Water activity Swelling index (%) Cooking loss (%) Tensile strength (g) K0T0 67.94 ± 0.11 0.975 ± 0.008 126.39 ± 2.06 18.91 ± 0.03 0.102 ± 0.008 K0T15 68.31 ± 0.07 0.976 ± 0.005 126.84 ± 1.69 19.02 ± 0.10 0.094 ± 0.003 K0T30 67.86 ± 0.66 0.978 ± 0.008 131.85 ± 2.97 19.76 ± 0.75 0.095 ± 0.003 K1T0 67.64 ± 0.27 0.971 ± 0.009 127.45 ± 7.15 18.71 ± 0.13 0.108 ± 0.007 K1T15 68.34 ± 0.44 0.973 ± 0.004 131.46 ± 0.93 18.77 ± 0.11 0.116 ± 0.011 K1T30 68.63 ± 1.08 0.969 ± 0.005 141.83 ± 8.15 19.32 ± 0.29 0.108 ± 0.008 K2T0 68.64 ± 0.52 0.974 ± 0.008 132.81 ± 3.77 18.26 ± 0.12 0.140 ± 0.002 K2T15 69.57 ± 0.59 0.973 ± 0.004 138.12 ± 1.18 18.43 ± 0.06 0.138 ± 0.006 K2T30 68.46 ± 0.68 0.962 ± 0.002 141.92 ± 8.23 18.76 ± 0.06 0.138 ± 0.013 K3T0 69.71 ± 0.95 0.969 ± 0.008 155.00 ± 4.16 17.54 ± 0.27 0.183 ± 0.002 K3T15 69.08 ± 0.38 0.973 ± 0.005 158.67 ± 7.28 18.03 ± 0.28 0.170 ± 0.011 K3T30 69.76 ± 0.80 0.970 ± 0.005 163.66 ± 7.52 18.33 ± 0.03 0.161 ± 0.002 No significant effect of interaction between composite flour and butterfly pea extract on quality properties of wet noodles. The results were presented as SD of means that were achieved in triplicate. All of the data showed that no interaction of the two parameters influenced the quality properties of wet noodles at p ≤ 0.05. Table 3. Effect of composite flour proportions on quality properties of wet noodles.

Samples Moisture content (% w/w) Water activity Swelling index (%) Cooking loss (%) Tensile strength (g) K0 68.04 ± 0.40a 0.976 ± 0.01b 128.36 ± 3.30a 19.23 ± 0.55d 0.097 ± 0.097a K1 68.20 ± 0.74a 0.971 ± 0.01a 133.58 ± 8.42b 18.93 ± 0.34c 0.112 ± 0.111b K2 68.89 ± 0.73b 0.970 ± 0.01a 137.62 ± 6.05b 18.48 ± 0.23b 0.141 ± 0.139c K3 69.52 ± 0.73c 0.971 ± 0.01a 159.11 ± 6.77c 17.96 ± 0.40a 0.173 ± 0.171d All of the data showed that there was a significant effect of composite flour on the quality properties of wet noodles at p ≤ 0.05. The results were presented as SD of means that were achieved in triplicate. Means with different superscript letters in the same column are significantly different, p ≤ 0.05. Table 4. Effect of butterfly pea extract concentration on quality properties of wet noodles.

Samples Moisture content (% w/w) Water activity Swelling index (%) Cooking loss (%) Tensile strength (g) T0 68.48 ± 0.96 0.970 ± 0.010 135.41 ± 12.72a 18.35 ± 0.57a 0.134 ± 0.034b T15 68.67 ± 0.66 0.974 ± 0.000 138.77 ± 13.12a 18.56 ± 0.41a 0.130 ± 0.030ab T30 68.83 ± 1.00 0.970 ± 0.010 144.82 ± 13.55b 19.04 ± 0.67b 0.129 ± 0.028a All of the data showed that there was a significant effect of butterfly pea extract concentration on the quality properties of wet noodles at p ≤ 0.05. The results were presented as SD of means that were achieved in triplicate. Means with different superscript letters in the same column are significantly different, p ≤ 0.05. Table 5. Effect of interaction between composite flour and butterfly pea extract on wet noodle color.

Samples L* a* b* C oh K0T0 66.10 ± 0.30f 0.90 ± 0.10f 15.70 ± 0.10f 15.70 ± 0.10f 86.60 ± 0.20a K0T15 48.70 ± 0.20c −11.40 ± 0.30bc −3.50 ± 0.20c 12.00 ± 0.30c 197.00 ± 0.70c K0T30 44.00 ± 0.60a −12.80 ± 0.20a −6.50 ± 0.30a 14.40 ± 0.20e 206.90 ± 1.00d K1T0 67.10 ± 0.40f 0.90 ± 0.20f 15.80 ± 0.60f 15.80 ± 0.60f 86.60 ± 0.50a K1T15 51.50 ± 1.80d −10.80 ± 0.40cd −3.00 ± 0.20cd 11.30 ± 0.40bc 195.60 ± 0.60c K1T30 45.50 ± 0.20b −11.80 ± 0.80b −6.30 ± 0.30a 13.40 ± 0.70d 208.40 ± 2.30d K2T0 67.10 ± 0.20f 1.00 ± 0.10f 16.30 ± 0.10fg 16.30 ± 0.10fg 86.40 ± 0.10a K2T15 53.40 ± 0.30e −10.30 ± 0.80de −2.80 ± 0.10d 10.70 ± 0.80b 195.50 ± 1.30c K2T30 46.00 ± 0.40b −10.40 ± 0.20de −6.10 ± 0.40a 12.10 ± 0.40c 210.60 ± 1.30e K3T0 67.40 ± 0.30f 1.20 ± 0.10f 16.80 ± 0.70g 16.90 ± 0.70g 85.90 ± 0.20a K3T15 53.80 ± 1.30e −9.80 ± 0.70e −1.20 ± 0.20e 9.90 ± 0.70a 187.50 ± 1.10b K3T30 47.90 ± 0.70c −10.10 ± 0.40de −5.50 ± 0.30b 11.60 ± 0.20bc 208.40 ± 2.30d All of the data showed that there was a significant effect of interaction between composite flour and butterfly pea extract on the quality properties of wet noodles at p ≤ 0.05. The results were presented as SD of means that were achieved in triplicate. Means with different superscript letters in the same column are significantly different, p ≤ 0.05.

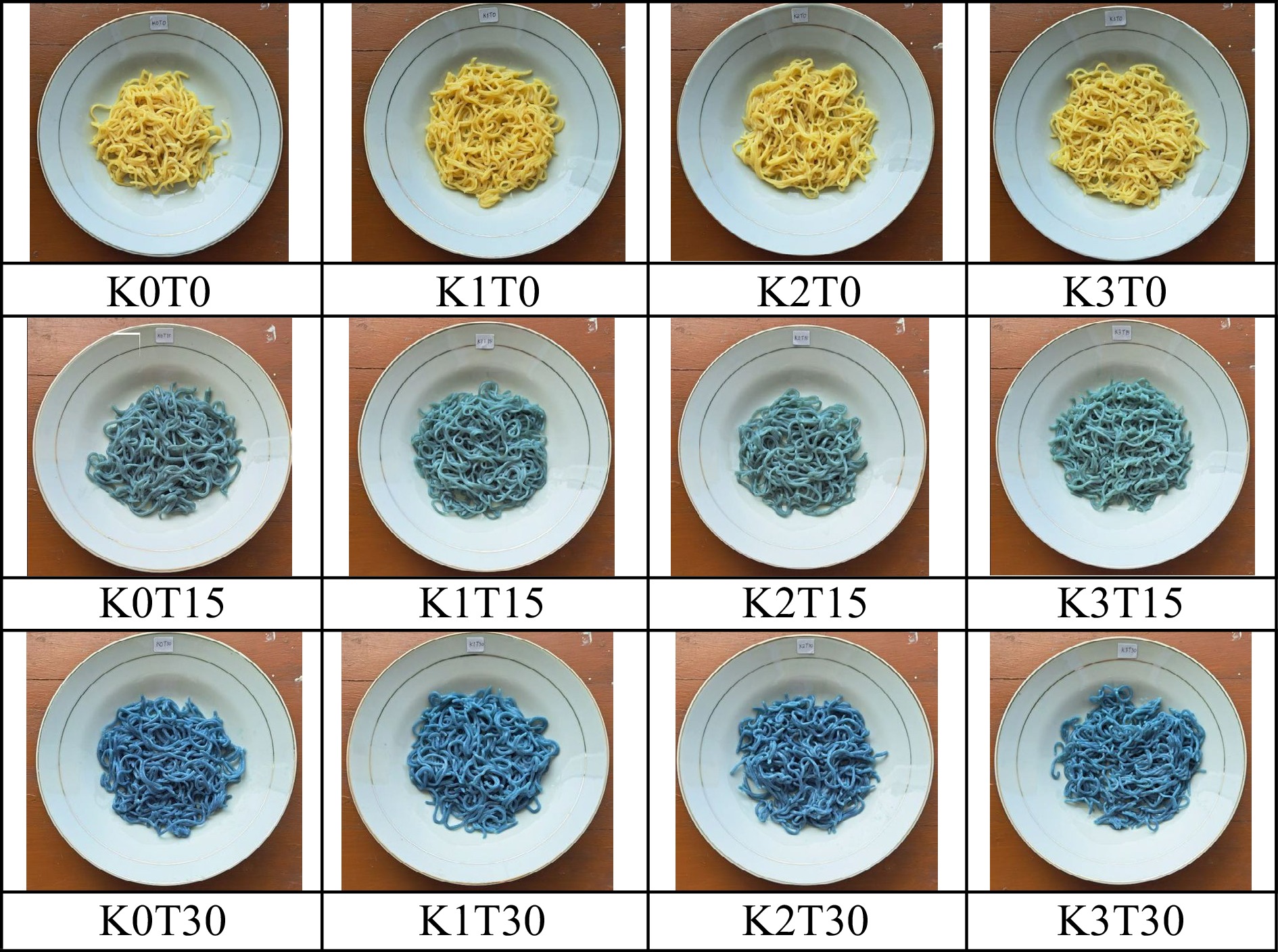

Figure 1.

Color of wet noodles with various proportions of composite flour and concentrations of butterfly pea flower extract.

Tensile strength, swelling index, and cooking loss of cooked wet noodles were significantly influenced by each factor of the ratios of composite flour or the concentrations of butterfly pea flower extract (p ≤ 0.05) (Tables 3 & 4). However, the interaction between the two factors was not seen to influence the tensile strength, swelling index, and cooking loss of wet noodles (p ≤ 0.05) (Table 2). An increase in the ratio of κ-carrageenan in the composite flour increased the tensile strength and swelling index and decreased the cooking loss of wet noodles. On the other hand, the increasing butterfly pea extract concentration decreased the tensile strength and increased the swelling index and cooking loss of wet noodles. Different ratios of the composite flour affected the tensile strength, which ranged between 0.197 and 0.171 g. At the same time, incorporating butterfly pea extract caused the tensile strength of wet noodles (T15 and T30) to significantly decrease from around 0.003 to 0.008 than control (K1). The highest and lowest swelling index values were owned by K3 and K0 samples, respectively. The swelling index values of wet noodles ranged from 128% to 159%. The effect of the composite flour proportion of wet noodles showed that the K0 sample had the highest cooking loss, and the K3 sample possessed the lowest cooking loss. In contrast, the effect of the concentrations of butterfly pea extract resulted in the lowest cooking loss values of the T0 sample and the highest cooking loss values of the T30 sample. The cooking loss values of wet noodles ranged from 18% to 19%.

Tensile strength, cooking loss, and swelling index of wet noodles were significantly influenced by the interaction of components in dough formation, namely glutelin, gliadin, glucomannan, κ-carrageenan, and polyphenolic compounds, which resulted in a three-dimensional network structure that determined the capability of the noodle strands being resistant to breakage and gel formation. κ-carrageenan is a high molecular weight hydrophilic polysaccharide composed of a hydrophobic 3,6-anhydrous-D-galactose group and hydrophilic sulfate ester group linked by α-(1,3) and β-(1,4) glycosidic linkages[49] that can bind water molecules to form a gel. Glucomannan is a soluble fiber with the β-1,4 linkage main chain of D-glucose and D-mannose that can absorb water molecules around 200 times[50] to form a strong gel that increases the viscosity and swelling index of the dough[51]. Park & Baik[52] stated that the gluten network formation affects the tensile strength of noodles. Huang et al.[48] also reported that κ-carrageenan can increase the firmness and viscosity of samples because of this hydrocolloid's strong water-binding capacity. Cui et al.[45] claimed that konjac glucomannan not only stabilizes the structure of gluten network but also reacts with free water molecules to form a more stable three-dimensional networking structure, thus maintaining dough's rheological and tensile properties.

The increased swelling index of dough is caused by the capability of glucomannan to reduce the pore size and increase the pore numbers with uniform size[53]. The synergistic interaction between these hydrocolloids and gluten protein results in a stronger, more elastic, and stable gel because of the association and lining up of the mannan molecules into the junction zones of helices[54]. The cross-linking and polymerization involving functional groups of gluten protein, κ-carrageenan, and glucomannan determined binding forces with each other. The stronger attraction between molecules composed of cross-linking reduces the particles or molecules' loss during cooking[54,55]. The stability of the network dimensional structure of the protein was influenced by the interaction of protein wheat, glucomannan, κ-carrageenan, and polyphenol compounds in the wet noodle dough that determined tensile strength, swelling index, and cooking loss of wet noodles. Schefer et al.[19] & Widyawati et al.[7] explained that phenolic compounds can disturb the interaction between the protein of wheat flour (glutelin and gliadin) and carbohydrate (amylose) to form a complex structure through many interactions, including hydrophobic, electrostatic, and Van der Waals interactions, hydrogen bonding, and π-π stacking. The phenolic compounds of butterfly pea extract interacted with κ-carrageenan, glucomannan, protein, or polysaccharide and influenced complex network structure. The phenolic compounds can disrupt the three-dimensional networking of interaction among gluten protein, κ-carrageenan, and glucomannan through aggregates or chemical breakdown of covalent and noncovalent bonds, and disruption of disulfide bridges to form thiols radicals[55]. These compounds can form complexes with protein and hydrocolloids, leading to structural and functional changes and influencing gel formation through aggregation formation and disulfide bridge breakdown[19,20,56].

The color of wet noodles (Table 5 & Fig. 1) was significantly influenced by the interaction between the composite flour and butterfly pea extract (p ≤ 0.05). The L*, a*, b*, C, and oh increased with increasing the composite flour ratio and the concentration of butterfly pea extract. Most of the color parameter values were lower than the control samples (K0T0, K1T0, K2T0, K3T0), except yellowness and chroma values of K2T0 and K3T0, whereas an increased amount of butterfly pea extract changed all color parameters. The L*, a*, b*, C, and oh ranges were about 44 to 67, −13 to 1, −7 to 17, 10 to 16, and 86 to 211, respectively. Lightness, redness, and yellowness of wet noodles intensified with a higher κ-carrageenan proportion and diminished with increasing butterfly pea flower extract. The chroma and hue of wet noodles decreased with increasing κ-carrageenan proportion from T0 until T15 and then increased at T30. K2T30 treatment had the strongest blue color compared with the other treatments (p ≤ 0.05). The presence of κ-carrageenan in composite flour also supported the water-holding capacity of wet noodles that influenced color. κ-carrageenan was synergized with glucomannan to produce a strong stable network that involved sulfhydryl groups. Tako & Konishi[57] reported that κ-carrageenan can associate polymer structure that involves intra-and intern molecular interaction, such as ionic bonding and electrostatic forces. The mechanism of making a three-dimensional network structure that implicated all components of composite flour was exceptionally complicated due to the involved polar and non-polar functional groups and many kinds of interaction between them. These influenced the water content and water activity of the wet noodles, which impacted the wet noodle color. Another possible cause that affects wet noodles' color profile is anthocyanin pigment from the butterfly pea extract. Vidana Gamage et al.[58] reported that the anthocyanin pigment of butterfly pea is delphinidin-3-glucoside and has a blue color. Increasing butterfly pea extract concentration lowered the lightness, redness, yellowness, and chroma and also changed the hue color from yellow to green-blue color.

The effect of composite flour and butterfly pea extract on color was observed in chroma and hue values. Glucomannan proportion of stinky lily flour intensified redness and yellowness, but butterfly pea extract reduced the two parameters. Thanh et al.[59] also found similarities in their research. Anthocyanin pigment of butterfly pea extract can interact with the color of stinky lily and κ-carrageenan, impacting the color change of wet noodles. Thus, the sample T0 was yellow, T15 was green, and T30 was blue. Color intensity showed as chroma values of yellow values increased along with the higher proportion of κ-carrageenan at the same concentration of butterfly pea extract. However, the higher concentration of butterfly pea extract lessened the green and blue colors of wet noodles made using the same proportion of composite flour. Wet noodle color is also estimated to be influenced by the phenolic compound content, which underwent polymerization or degradation during the heating process. Widyawati et al.[20] reported that the bioactive compounds in pluchea extract could change the wet noodle color because of the discoloration of pigment during cooking. K2T30 was wet noodles exhibiting the strongest blue color due to different interactions between anthocyanin and hydrocolloid compounds, especially κ-carrageenan, that could reduce the intensity of blue color or chroma values.

Phenolic (TPC), total flavonoid (TFC), and total anthocyanin (TAC) content of wet noodles

-

The results of TPC, TFC, and TAC are shown in Table 6. The TPC and TFC of wet noodles were significantly influenced by the interaction between two parameters: the ratio of composite flour and the concentration of butterfly pea extracts (p ≤ 0.05). The highest proportion of κ-carrageenan and butterfly pea extract resulted in the highest TPC and TFC. The K2T30 had the highest TPC and TFC of about ~207 mg GAE/kg dried noodles and ~57 mg CE/kg dried noodles, respectively. The TAC of wet noodles was only influenced by the concentration of butterfly pea extract, and the increase in extract addition led to an increase in TAC. The extract addition in T30 possessed a TAC of about 3.92 ± 0.18 mg delfidine-3-glucoside/kg dried noodles. In addition, based on Pearson correlation assessment, there was a strong, positive correlation between the TPC of wet noodles and the TFC at T0 (r = 0.955), T15 (r = 0.946), and T30 treatments (r = 0.765). In contrast, a weak, positive correlation was observed between the TPC of samples and the TAC at T0 (r = 0.153) and T30 treatments (r = 0.067), except the T15 treatment, which had a correlation coefficient of −0.092 (Table 7). The bioactive compounds of wet noodles were correlated with their quality properties and antioxidant activity (AOA). The dominant anthocyanin pigment from butterfly pea extract is delphinidin[60], around 2.41 mg/g samples[61] that has more free acyl groups and aglycone structure[62] that can be used as a natural pigment. The addition of butterfly pea extract influenced the color of wet noodles. Anthocyanin is a potential antioxidant agent through the free-radical scavenging pathway, cyclooxygenase pathway, nitrogen-activated protein kinase pathway, and inflammatory cytokines signaling[63]. Nevertheless, butterfly pea extract is also composed of tannins, phenolics, flavonoids, phlobatannins, saponins, essential oils, triterpenoids, anthraquinones, phytosterols (campesterol, stigmasterol, β-sitosterol, and sitostanol), alkaloids, and flavonol glycosides (kaempferol, quercetin, myricetin, 6-malonylastragalin, phenylalanine, coumaroyl sucrose, tryptophan, and coumaroyl glucose)[12,13], chlorogenic, gallic, p-coumaric caffeic, ferulic, protocatechuic, p-hydroxy benzoic, vanillic, and syringic acids[62], ternatin anthocyanins, fatty acids, tocols, mome inositol, pentanal, cyclohexene, 1-methyl-4(1-methylethylideme), and hirsutene[64], that contribute to the antioxidant activity[10,64]. Clitoria ternatea exhibits antioxidant activity based on the antioxidant assays, such as 2,2-diphenyl-1-picrylhydrazyl radical (DPPH) radical scavenging, ferric reducing antioxidant power (FRAP), hydroxyl radical scavenging activity (HRSA), hydrogen peroxide scavenging, oxygen radical absorbance capacity (ORAC), superoxide radical scavenging activity (SRSA), ferrous ion chelating power, 2,2'-azino-bis(3-ethylbenzthiazoline-6-sulphonic acid) (ABTS) radical scavenging, and Cu2+ reducing power assays[64]. The TPC and TFC of wet noodles increased along with the higher proportion of glucomannan in the composite flour and the higher concentration of butterfly pea extract. Zhou et al.[65] claimed that glucomannan contained in stinky lily has hydroxyl groups that can react with Folin Ciocalteus's phenol reagent. Devaraj et al.[66] reported that 3,5-acetyltalbulin is a flavonoid compound in glucomannan that can form a complex with AlCl3.

Table 6. Effect of interaction between composite flour and butterfly pea extract on wet noodle's bioactive compounds and antioxidant activity.

Samples TPC (mg GAE/kg

dried noodles)TFC (mg CE/kg

dried noodles)TAC (mg define-3-glucoside/kg

dried noodles)DPPH (mg GAE/kg

dried noodlesFRAP (mg GAE/kg

dried noodles)K0T0 126.07 ± 0.90a 16.74 ± 6.26a 0.00 ± 0.00a 2.99 ± 0.16a 0.009 ± 0.001a K0T15 172.57 ± 2.14e 36.66 ± 2.84d 2.67 ± 0.21b 21.54 ± 1.71d 0.023 ± 0.002c K0T30 178.07 ± 2.54f 48.36 ± 3.29f 3.94 ± 0.28c 39.23 ± 0.91f 0.027 ± 0.002e K1T0 137.07 ± 1.32b 21.66 ± 3.67b 0.00 ± 0.00a 3.13 ± 0.19a 0.011 ± 0.001a K1T15 178.48 ± 0.95f 36.95 ± 3.05d 2.74 ± 0.21b 21.94 ± 0.68d 0.023 ± 0.001cd K1T30 183.65 ± 1.67g 52.28 ± 3.08g 3.84 ± 0.19c 41.42 ± 1.30g 0.029 ± 0.001f K2T0 150.40 ± 0.52d 27.49 ± 5.39c 0.00 ± 0.00a 7.45 ± 0.69c 0.014 ± 0.001b K2T15 202.48 ± 0.63j 48.28 ± 2.41f 2.95 ± 0.57b 24.70 ± 0.90e 0.025 ± 0.001d K2T30 206.90 ± 2.43i 56.99 ± 7.45h 3.93 ± 0.42c 47.55 ± 1.31i 0.034 ± 0.002g K3T0 141.15 ± 1.28c 25.37 ± 3.46c 0.00 ± 0.00a 5.45 ± 0.49b 0.013 ± 0.001b K3T15 186.32 ± 1.15h 43.57 ± 2.28e 2.66 ± 0.21b 22.45 ± 0.48d 0.024 ± 0.001cd K3T30 189.90 ± 0.63k 54.95 ± 3.72gh 3.98 ± 0.37c 44.93 ± 1.28h 0.031 ± 0.001f All of the data showed that there was a significant effect of interaction between composite flour and butterfly pea extract to bioactive compounds and antioxidant activity of wet noodles at p ≤ 0.05. The results were presented as SD of means that were achieved in triplicate. Means with different superscript letters in the same column are significantly different, p ≤ 0.05. Table 7. Pearson correlation coefficients between bioactive contents (TPC, TFC, and TAC) and antioxidant activity (DPPH and FRAP).

Parameter TPC TFC TAC DPPH T0 T15 T30 T0 T15 T30 T0 T15 T30 T0 T15 T30 TPC 1 1 1 TFC 0.955 0.946 0.765 1 1 1 TAC 0.153 −0.092 0.067 0.028 −0.239 −0.020 1 1 1 DPPH 0.893 0.815 0.883 0.883 0.739 0.753 0.123 0.127 0.194 1 1 1 FRAP 0.884 0.425 0.859 0.902 0.464 0.742 0.056 −0.122 −0.131 0.881 0.321 0.847 Correlation significant at the 0.05 level (2-tailed). Antioxidant activity of wet noodles

-

The antioxidant activity (AOA) of wet noodles was determined using DPPH radical scavenging activity (DPPH) and ferric reducing antioxidant power (FRAP), as shown in Table 6. The proportion of composite flour and the concentration of butterfly pea extracts significantly affected the DPPH results (p ≤ 0.05). The noodles exhibited DPPH values ranging from 3 to 48 mg GAE/kg dried noodles. Several wet noodle samples, including the composite flour of K0 and K1 and without butterfly pea extracts (K0T0 and K1T0), had the lowest DPPH, while the samples containing composite flour K2 with butterfly pea extracts 30% (K2T30) had the highest DPPH. Pearson correlation showed that the TPC and TFC were strongly and positively correlated with the DPPH (Table 7). The correlated coefficient values (r) between TPC and AOA at T0, T15, and T30 treatments were 0.893, 0.815, and 0.883, respectively. Meanwhile, the r values between TFC and DPPH at T0, T15, and T30 treatments were 0.883, 0.739, and 0.753, respectively. However, the correlation coefficient values between TAC and AOA at T0, T15, and T30 treatments were 0.123, 0.127, and 0.194, respectively. The interaction among glucomannan, phenolic compounds, amylose, gliadin, and glutelin in the dough of wet noodles determined the number and position of free hydroxyl groups that influenced the TPC, TFC, and DPPH. Widyawati et al.[40] stated that free radical inhibition activity and chelating agent of phenolic compounds depends on the position of hydroxyl groups and the conjugated double bond of phenolic structures. The values of TPC, TFC, and DPPH significantly increased with higher levels of stinky lily flour and κ-carrageenan proportion and butterfly pea extract for up to 18% and 2% (w/w) of stinky lily flour and κ-carrageenan and 15% (w/w) of extract. However, the use of 17% and 3% (w/w) of stinky lily flour and κ-carrageenan and 30% (w/w) of the extract showed a significant decrease. The results show that the use of stinky lily flour and k-carrageenan with a ratio of 17%:3% (w/w) was able to reduce free hydroxyl groups, which had the potential as electron or hydrogen donors in testing TPC, TFC, and DPPH.

FRAP of wet noodles was significantly influenced by the interaction of two parameters of the proportion of composite flour and the concentration of butterfly pea extracts (p ≤ 0.05). FRAP was used to measure the capability of antioxidant compounds to reduce Fe3+ ions to Fe2+ ions. The FRAP capability of wet noodles was lower than DPPH, which ranged from 0.01 to 0.03 mg GAE/kg dried noodles. The noodles without κ-carrageenan and butterfly pea extracts (K0T0) had the lowest FRAP, while the samples containing composite flour K2 with 30% of butterfly pea extract (K2T30) had the highest FRAP. The Pearson correlation values showed that TPC and TFC at T0 and T30 treatments had strong and positive correlations to FRAP activity, but T15 treatment possessed a weak and positive correlation (Table 7). The correlation coefficient (r) values of TAC at the 0 treatment was weak with a positive correlation to FRAP samples, but the r values at T15 and T30 treatments showed weak negative correlations (Table 7). The obtained correlation between DPPH and FRAP activities elucidates that the DPPH method was highly correlated with the FRAP method at the T0 and T30 treatments and weakly correlated at the T15 treatment (Table 7). The DPPH and FRAP methods showed the capability of wet noodles to scavenge free radicals was higher than their ability to reduce ferric ion. It proved that the bioactive compounds of wet noodles have more potential as free radical scavengers or hydrogen donors than as electron donors. Compounds that have reducing power can act as primary and secondary antioxidants[67]. Poli et al.[68] stated that bioactive compounds with DPPH free radical scavenging activity are grouped as a primary antioxidant. Nevertheless, Suhendy et al.[69] claimed that a secondary antioxidant is a natural antioxidant that can reduce ferric ion (FRAP). Based on AOA assay results, phenolic compounds indicated a strong and positive correlation with flavonoid compounds, as flavonoids are the major phenolic compounds potential as antioxidant agents through their ability to scavenge various free radicals. The effectivity of flavonoid compounds in inhibiting free radicals and chelating agents is influenced by the number and position of hydrogen groups and conjugated diene at A, B, and C rings[70]. Previous studies have proven that TPC and TFC significantly contribute to scavenge free radicals[71]. However, TAC showed a weak correlation with TFC, TPC, or AOA, although Choi et al.[71] stated that TPC and anthocyanins have a significant and positive correlation with AOA, but anthocyanins insignificantly correlate with AOA. Different structure of anthocyanins in samples determines AOA. Moreover, the polymerization or complexion of anthocyanins with other molecules also determines their capability as electron or hydrogen donors. Martin et al.[72] informed that anthocyanins are the major groups of phenolic pigments where their antioxidant activity greatly depends on the steric hindrance of their chemical structure, such as the number and position of hydroxyl groups and the conjugated doubles bonds, as well as the presence of electrons in the structural ring. However, TPC and TFC at T0 and T30 treatments were highly and positively correlated with FRAP assay due to the role of phenolic compounds as reducing power agents that contributed to donating electrons. Paddayappa et al.[67] reported that the phenolic compounds are capable of embroiling redox activities with an action as hydrogen donor and reducing agent. The weak relationship between TPC, TFC, or DPPH, and FRAP in the T15 treatment suggested that there was an interaction between the functional groups in the benzene ring in phenolic and flavonoid compounds and the functional groups in components in composite flour, thereby reducing the ability of phenolic and flavonoid compounds to donate electrons.

Sensory evaluation

-

Sensory properties of wet noodles based on the hedonic test results showed that composite flour and butterfly pea extract addition significantly influenced color, aroma, taste, and texture preferences (p ≤ 0.05) (Table 8). The preference values of color, aroma, taste, and texture attributes of wet noodles ranged from 5 to 6, 6 to 7, 6 to 7, and 5 to 7, respectively. Incorporating butterfly pea extracts decreased preference values of color, aroma, taste, and texture attributes of wet noodles. Anthocyanin of butterfly pea extract gave different intensities of wet noodle color that resulted in color degradation from yellow, green, to blue color, impacting the color preference of wet noodles. Nugroho et al.[42]also reported that the addition of butterfly pea extracts elevated the preference of panelists for dried noodles. The aroma of wet noodles was also affected by two parameters of treatments, where the results showed that the higher proportion of stinky lily caused the wet noodles to have a stronger, musty smell. Utami et al.[73] claimed that oxalic acid in stinky lily flour contributes to the odor of rice paper. Therefore, a high proportion of k-carrageenan could reduce the proportion of stink lily flour, thereby increasing the panelists' preference for wet noodle aroma. Sumartini & Putri[74] noted that panelists preferred noodles substituted with a higher κ-carrageenan. Widyawati et al.[7] also proved that κ-carrageenan is an odorless material that does not affect the aroma of wet noodles. Neda et al.[63] added that volatile compounds of butterfly pea extract can mask the musty smell of stinky lily flour, such as pentanal and mome inositol. In addition, Padmawati et al.[75] revealed that butterfly pea extract could give a sweet and sharp aroma. The panelists' taste preference for wet noodles without butterfly pea extract addition was caused by alkaloid compounds, i.e., conisin[76], due to Maillard reaction during stinky lily flour processing. Nevertheless, using butterfly pea extract at a higher concentration in wet noodles increased the bitter taste, which is contributed by tannin compounds in this flower, as has been found by Handayani & Kumalasari[77]. The effect of composite flour proportion and butterfly pea extract addition also appeared to affect the texture preference of wet noodles. Panelists preferred wet noodles that did not break up easily, which was the K3T0 sample, as the treatment resulted in chewy and elastic wet noodles. The results were also affected by the tensile strength of wet noodles because of the different concentrations of butterfly pea extract added to the wet noodles. The addition of butterfly pea extract at a higher concentration resulted in sticky, easy-to-break, and less chewy wet noodles[18,19,77] due to the competition among phenolic compounds, glutelin, gliadin, amylose, glucomannan, κ-carrageenan to interact with water molecules to form gel[78]. Based on the index effectiveness test, the noodles made with composite flour of K3 and butterfly pea extract of 30% (K3T30) were the best treatment, with a total score of 1.0504.

Table 8. Effect of interaction between composite flour and butterfly pea extract to sensory properties of wet noodles and the best treatment of wet noodles based on index effectiveness test.

Samples Color Aroma Taste Texture Index effectiveness test K0T0 8.69 ± 3.31a 7.41 ± 3.80a 8.71 ± 3.16a 10.78 ± 2.86abcde 0.1597 K0T15 8.96 ± 3.38b 7.75 ± 3.89b 9.35 ± 3.36cde 11.19 ± 3.10abcd 0.6219 K0T30 8.93 ± 3.50bc 7.71 ± 3.76c 9.26 ± 3.17bcd 11.13 ± 3.09a 0.6691 K1T0 8.74 ± 3.62a 8.13 ± 3.56ab 9.58 ± 3.13ab 11.33 ± 3.12de 0.4339 K1T15 9.98 ± 3.06bc 8.40 ± 3.28c 10.16 ± 2.59def 10.61 ± 2.82ab 0.7086 K1T30 10.08 ± 3.28bc 9.10 ± 3.08c 10.44 ± 2.32bcd 10.36 ± 2.81ab 0.7389 K2T0 10.41 ± 3.01a 9.39 ± 3.27ab 11.04 ± 2.44ab 10.55 ± 2.60cde 0.3969 K2T15 10.8 ± 2.85bc 9.26 ± 3.10c 10.11 ± 2.76f 10.89 ± 2.65abcd 0.9219 K2T30 10.73 ± 3.02c 9.10 ± 3.46c 9.85 ± 2.99def 10.16 ± 2.74abc 0.9112 K3T0 10.73 ± 3.42a 9.19 ± 3.38b 9.93 ± 2.50bc 10.34 ± 2.84e 0.5249 K3T15 10.91 ± 3.23bc 9.48 ± 3.56c 10.45 ± 2.82cde 10.49 ± 2.68bcde 0.9235 K3T30 10.88 ± 3.14c 9.49 ± 3.59c 10.81 ± 2.74ef 10.86 ± 2.60bcde 1.0504 All of the data showed that there was a significant effect of interaction between composite flour and butterfly pea extract on the sensory properties of wet noodles at p ≤ 0.05. The results were presented as SD of means that were achieved in triplicate. Means with different superscript letters in the same column are significantly different, p ≤ 0.05. -

Using composite flour containing wheat flour, stinky lily flour, and κ-carrageenan and butterfly pea extract in wet noodle influenced wet noodles' quality, bioactive compounds, antioxidant activity, and sensory properties. Interaction among glutelin, gliadin, amylose, glucomannan, κ-carrageenan, and phenolic compounds affected the three-dimensional network structure that impacted moisture content, water activity, tensile strength, color, cooking loss, swelling index, bioactive content, antioxidant activity, and sensory properties of wet noodles. The higher concentration of hydrocolloid addition caused increased water content and swelling index and decreased water activity and cooking loss. In addition, incorporating butterfly pea extract improved color, bioactive content, and antioxidant activity and enhanced panelists preference for wet noodles. Glucomannan of stinky lily flour and bioactive compounds of butterfly pea extract increased the functional value of the resulting wet noodles.

-

The authors confirm contribution to the paper as follows: study conception and design, literature search, methodologies of the lab analyses design: Widyawati PS, Suseno TIP; Fieldwork implementation, data collection, analysis and interpretation of results: Widyawati PS, Ivana F, Natania E;draft manuscript preparation: Widyawati PS; Manuscript revision:Wangtueai S. All authors reviewed the results and approved the final version of the manuscript.

-

Data reported in this study are contained within the article. The underlying raw data are available on request from the corresponding author.

-

The authors would like to thank the Food Nutrition Research Center, Research institutions and community service, Widya Mandala Surabaya Catholic University for the research grant (7554/WM01/N/2022).

-

The authors declare that they have no conflict of interest.

- Copyright: © 2024 by the author(s). Published by Maximum Academic Press, Fayetteville, GA. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Widyawati PS, Suseno TIP, Ivana F, Natania E, Wangtueai S. 2024. Effect of butterfly pea (Clitoria ternatea) flower extract on qualities, sensory properties, and antioxidant activity of wet noodles with various composite flour proportions. Beverage Plant Research 4: e022 doi: 10.48130/bpr-0024-0011

Effect of butterfly pea (Clitoria ternatea) flower extract on qualities, sensory properties, and antioxidant activity of wet noodles with various composite flour proportions

- Received: 24 September 2023

- Revised: 14 January 2024

- Accepted: 29 January 2024

- Published online: 19 June 2024

Abstract: Improvement of wet noodles' qualities, sensory, and functional properties was carried out using a composite flour base with the butterfly pea flower extract added. The composite flour consisted of wheat flour and stink lily flour, and κ-carrageenan at ratios of 80:20:0 (K0), 80:19:1 (K1), 80:18:2 (K2), and 80:17:3 (K3) (% w/w) was used with concentrations of butterfly pea extract of 0 (T1), 15 (T15), and 30 (T30) (% w/v). The research employed a randomized block design with two factors, namely the composite flour and the concentration of butterfly pea flower extract, and resulted in 12 treatment combinations (K0T0, K0T15, K0T30, K1T0, K1T15, K1T30, K2T0, K2T15, K2T30, K3T0, K3T15, K3T30). The interaction of the composite flour and butterfly pea flower extract significantly affected the color profile, sensory properties, bioactive compounds, and antioxidant activities of wet noodles. However, each factor also significantly influenced the physical properties of wet noodles, such as moisture content, water activity, tensile strength, swelling index, and cooking loss. The use of κ-carrageenan up to 3% (w/w) in the mixture increased moisture content, swelling index, and tensile strength but reduced water activity and cooking loss. K3T30 treatment with composite flour of wheat flour-stink lily flour-κ-carrageenan at a ratio of 80:17:3 (% w/w) had the highest consumer acceptance based on hedonic sensory score.

-

Key words:

- Composite flour /

- Butterfly pea flower /

- Quality /

- Sensory /

- Wet noodles