-

There are many kinds of fermented meat products, which are mainly divided into two categories: one is fermented ham products, such as Jinhua ham and Xuanwei ham; the other is fermented sausage products, such as Cantonese sausage, Szechuan sausage, salami, and so on, which are popular with consumers. Fermented sausage refers to a kind of instant meat product made by microbial fermentation or enzymes under certain conditions with livestock and poultry meat as raw materials, and the finished product has a unique flavor[1]. Meat myofibrillar protein accounts for 60%−70% of the protein content and has good gel properties. The formation of protein gel structure is an important index affecting the texture and sensory properties of meat products[2].

Gel is the main tissue form of meat in fermented sausages and is formed by the denaturation of collagen in the muscles. During fermentation, lactic acid and other metabolites produced by lactic acid bacteria can affect the denaturation process of collagen, making the gel more stable and strong. At the same time, lactic acid bacteria can also produce some metabolites with adhesive properties, which help to enhance the gel structure. Due to the differences in natural environment, diet and culture, there are great differences in the production process of fermented sausages in different countries or regions of the world, such as Chinese fermented sausages usually cut lean meat into small dices and fatty meat into minced meat when preparing, while Western fermented sausages are cut into minced meat with lean meat and fatty meat. The size of the raw particles can affect the combination tightness and uniformity of distribution between the fat and lean meat particles, resulting in differences in moisture, gel properties and microorganisms between the two sausages[3].

At present, the research on the gel properties of muscle protein and the gel properties of meat paste is quite comprehensive home and abroad, while the research on the influencing factors of the gel properties of fermented sausage still needs to be further explored.

Fermented sausage is a typical representative of fermented meat products. In this paper, we will focus on the formation mechanism of fermented sausage gel, the influencing factors of fermented sausage gel characteristics (including exogenous microorganisms, temperature, etc.), and the analysis method of fermented sausage gel characteristics. The aim is to provide an effective strategy for improving the gel properties of fermented sausages and provide a theoretical basis for further improving the quality of gel fermented sausages.

-

Fermented sausage is a kind of meat product made by crushing meat and fat, mixing with various auxiliary materials, pouring into casing, fermentation, drying, and ripening[4]. The typical flavor substances of fermented sausage include volatile (alcohol, ketones, aldehydes, and furans) and non-volatile compounds (amino acids, peptides, sugars, and nucleotides)[5]. Microorganisms produce proteases and lipases during the fermentation and maturation stages of fermented sausages, lipase-catalyzed lipolysis can promote the release of flavor compounds such as aldehydes and ketones, and free amino acids produced by proteolysis can directly or indirectly affect the formation of flavor substances as precursors of flavor substances[6]. Because the ambient humidity in the fermentation process is lower than the internal value of the sausage, the Aw value of the sausage decreases and the shear force increases, and at the same time, the lactic acid bacteria ferment carbohydrates to form lactic acid, which reduces the pH value of the sausage and inhibits the growth of spoilage bacteria[7,8]. The lower pH denatures the salt-soluble proteins in the meat, favoring the formation of a gel structure.

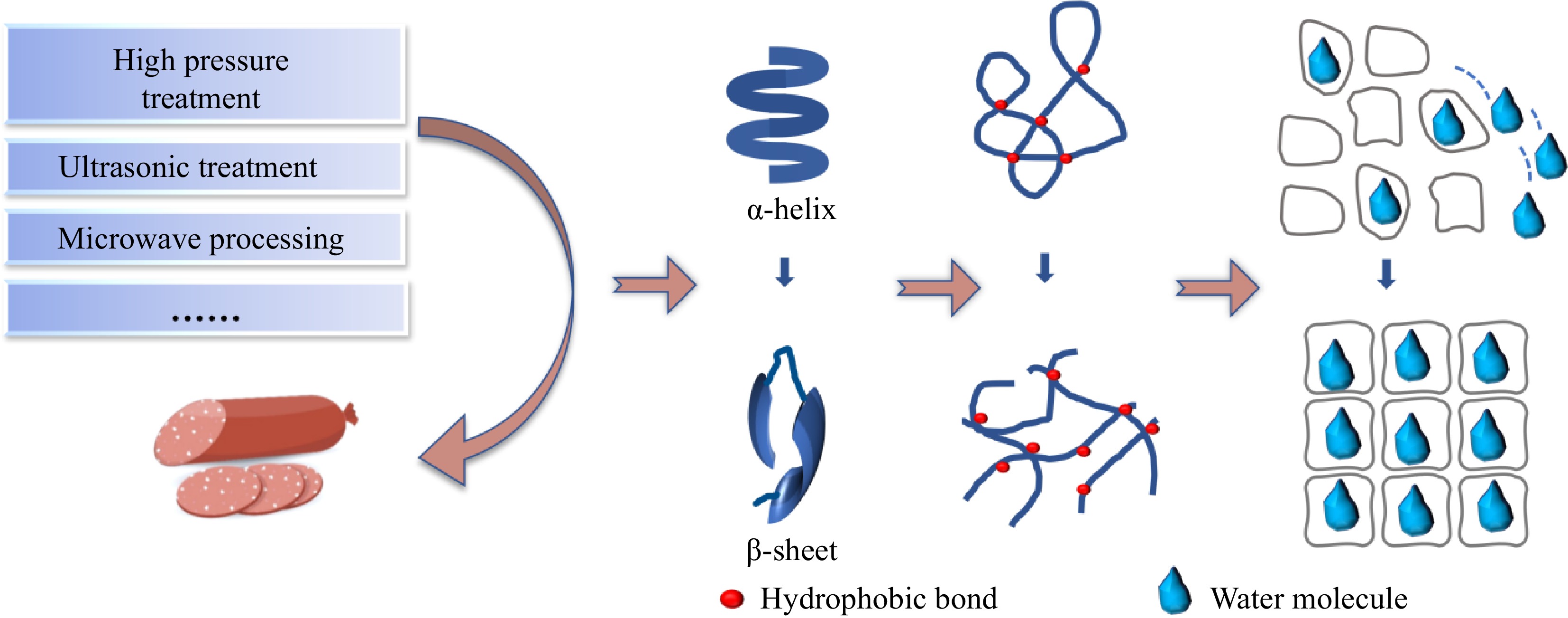

The formation mechanism of the gel structure of fermented sausage is shown in Fig. 1. During the chopping process of sausage, muscle cells are broken, myofibrillar protein, sarcoplasmic protein, etc. are released, and fat is broken into smaller fat particles, which are evenly dispersed in the protein matrix, in which myosin plays an important role in the formation of gel. There are three steps for myosin to form the gel matrix: (1) Denaturation: Firstly, myosin unfolds, exposing active binding sites such as hydrophobic residues and thiol groups. (2) Aggregation: After the hydrophobic residues are exposed, myosin aggregates through hydrophobic interactions due to unstable intermolecular forces. (3) Gel network formation: Myosin molecules fix fat particles in meat protein gels through disulfide bonds, hydrogen bonds, and covalent interactions to form an interface film. This layer of protein membrane can not only form a spatial barrier to prevent the flocculation and aggregation of fat particles, but also prevent free radicals from penetrating into lipids[9,10], which is crucial to the gel properties of sausages. When the protein film is unstable, it will lead to the precipitation of water and oil during the processing, which will have a negative impact on the texture and gel properties of fermented sausages and make their taste worse[11].

In the process of fermented sausages, lactic acid bacteria glycolyze carbohydrates to produce lactic acid, resulting in a rapid decrease in pH, promoting the interaction between muscle proteins (such as myosin and actin), and the protease in acid bacteria cells can be responsible for the hydrolysis of myofibrillar proteins, promoting the formation of sausage gel properties, and improving the elasticity, tenderness and juiciness of meat products[12].

-

The exogenous microorganisms in sausages include bacteria, molds, and yeasts. Mold generally grows on the surface of sausages and can change the color of sausages. On the surface of fermented sausages in Argentina, Penicillium Nessleri is generally dominant[13]. The organic acids produced during the growth and metabolism of yeast can lower the pH value of sausages. Debaryomyces hansenii strains grow on the surface of sausages, which can regulate the release of water during the maturation process, increase the Aw value of sausages, and reduce their hardness and chewiness[14]. Yeast can promote the formation of volatile compounds in fermented sausage, but it has no obvious effect on the sensory quality of sausage, such as taste and tenderness[15]. At present, the most commonly used bacterial starter in fermented sausage is lactic acid bacteria. Studies have shown that lactic acid bacteria can promote the gel properties of fermented sausage, Organic acids are produced during the metabolism of lactic acid bacteria. Organic acids are dissociated to produce hydrogen ions, which enhances the ionic strength in the product and increases the solubility of myofibrillar proteins. At the same time, a large number of organic acids will also reduce the pH value of the product, making the protein molecules further aggregated.

The polysaccharides and enzymes produced by the metabolism of lactic acid bacteria can promote the cross linking of proteins, and the antioxidant effect of lactic acid bacteria can also prevent the negative effects of excessive protein aggregation on the gel[16]. Therefore, the effects of lactic acid bacteria on the gel properties of fermented sausages are mainly introduced below.

Effect of lactic acid bacteria metabolites organic acids on gel properties

-

Organic acids produced during the growth and metabolism of lactic acid bacteria include lactic acid, phenyllactic acid, oxalic acid, tartaric acid, etc. During the fermentation process, the organic acid is partially dissociated to form hydrogen ions, which increases the ionic strength. Ionic strength is one of the important factors affecting the formation of the gel network. Different organic acids will affect the rheological properties of the gel due to their different ionic strength and dissociation constant. The ionic strength and dissociation constant of formic acid and lactic acid are larger than those of glacial acetic acid, Paker et al. found that formic acid and lactic acid can increase the ion concentration in the solution more quickly, dissolve myofibrillar protein and induce it to form actomyosin[17]. At the same time, the hydrogen ion produced by the dissociation of organic acids can reduce the pH value of fermented sausage. When the pH value of the environment of the protein changes, the hydrophobic groups in the protein molecules are exposed, and the protein molecules are bound to each other through disulfide bonds[18], myofibrillar protein aggregates to form a gel[19]. It can be seen that changes in pH value during the processing have a significant impact on the quality of meat products.

Mi et al. studied the effects of organic acids (organic acids corresponding to four organic salts: sodium citrate, sodium succinate, sodium lactate, and sodium acetate) and heat induction on the quality of Peruvian squid sausage, the results showed that the organic acid-induced sausage was significantly higher than the heat-induced sausage in terms of gel strength, water holding capacity, hardness, resilience, and chewiness[20]. Myofibrillar protein molecules can form a denser and more ordered network structure under acidic conditions, Omura et al. reported that acid induction can increase the hydrophobicity of protein surface and the content of disulfide bonds, and enhance the mechanical properties of minced meat gel[21].

Effect of antioxidant effect of lactic acid bacteria on gel properties

-

Shen et al.[22] formed a hydroxyl radical generating system composed of ascorbic acid solution and H2O2 to oxidize myofibrillar protein. Studies have shown that 0−0.2 mM H2O2 can not only increase the salt solubility of myofibrillar proteins, but also change the protein structure and expose hydrophobic groups. Proteins are cross linked by hydrophobic interactions and disulfide bonds, increasing the hardness and water holding capacity of the gel[22]. The free radicals produced by fat oxidation can induce the oxidation reaction of protein, thereby reducing calpain activity and affecting the tenderness of meat[23,24]. With the extension of storage time, the degree of oxidation of protein and fat in fermented sausage will further increase, and excessive oxidation will destroy the gel structure of the product, therefore, it is necessary to add antioxidant in fermented sausage to prevent excessive oxidation.

Lactic acid bacteria are natural antioxidants that primarily exert antioxidant effects by clearing free radicals, chelating metal ions, inhibiting lipid oxidation, and enhancing antioxidant enzyme activity[25]. Li et al. verified the antioxidant activity of Lactobacillus helveticus TR13 in vitro and in vivo, and found that lactic acid bacteria could significantly increase the activity of glutathione peroxidase and superoxide dismutase in tissues[26]. The antioxidant activity of lactic acid bacteria can inhibit the oxidation of lipids and proteins in sausages, maintain the stability of the natural structure of proteins in sausages, and improve the quality of sausages[27]. The extracellular polysaccharides produced by lactic acid bacteria metabolism can also enhance the activity of intracellular antioxidant enzyme system and inhibit the excessive oxidation of lipids. The composite film prepared by Li et al. using two high-yielding extracellular polysaccharide lactic acid bacteria has high antioxidant activity, which can effectively delay the decay, deterioration and browning of food[28]. The antioxidant properties of lactic acid bacteria were applied to fermented sausage, which could regulate the oxidation degree of protein and prevent the deterioration of gel structure caused by excessive oxidation of protein.

Effect of lactic acid bacteria adhesion on gel properties

-

Lactic acid bacteria (such as Pediococcus pentosaceus, Lactiplantibacillus plantarum, etc. ) can produce exopolysaccharides (EPS) during the metabolic process. EPS has good stability and thickening, and plays an important role in the quality of fermented dairy products. Recently, it has also been used to improve the gel properties of meat products and other products[29]. The production of EPS is related to the fermentation conditions, and temperature is one of the decisive factors, Khanal & Lucey found that different Streptococcus salivarius subsp. Thermophilus were cultured at 33, 39, 45 °C. The results showed that the acidification rate was the fastest at 45 °C, but the yield of EPS was lower[30]. Dertli et al. observed that the hardness and chewiness of fermented sausages inoculated with lactic acid bacteria was higher than those of fermented sausages without lactic acid bacteria at 14 and 16 °C, but the observation results at 18 °C were different. EPS produced by lactic acid bacteria can form a network structure in meat, which increases the hardness and reduces the viscosity of sausage[31]. Cai et al. applied EPS extract of Lactiplantibacillus plantarum to fermented milk and found that the degree of protein crosslinking increased with the increase of EPS content. At the same time, the formation of gel structure can promote the formation of aldehydes, acids, and lipid flavor substances in yogurt[32]. Yang et al. found that the hardness of gel induced by fermentation of Lactobacillus acidophilus, Lactiplantibacillus plantarum and Lactobacillus casei was significantly higher than that of other groups by studying the characteristics of lactic acid bacteria on soy protein isolate gel, which may be because EPS improved the aggregation and structural changes of protein, forming a high molecular polymer[33].

Effect of lactic acid bacteria metabolite enzymes on gel properties

-

Enzymes produced by lactic acid bacteria during metabolism have positive or negative effects on the formation of gel structure, such as glutamine transaminase, which helps to improve the degree of protein cross linking[34]. Glutamine transglutaminase can catalyze the acyl transfer of proteins, reduce the content of protein α-helix, increase the content of β-sheet, and promote the formation of non-disulfide covalent bonds, which leads to the formation of high molecular weight polymers in the heavy chain of myofibrillar proteins and improves the structure of the gel[35,36]. Rotease hydrolyzes myofibrillar protein into small particles and produces soluble peptides, which can promote the formation of flavor substances[37]. IIkonic et al. found that the degree of protein hydrolysis, hardness and chewiness of fermented sausage added with fermentation starter were higher than those of traditional fermented sausage[38]. Inoculation of Lactiplantibacillus plantarum and Lactobacillus xylose increased the degree of acidic protein hydrolysis of fermented sausages and improved the sensory properties of sausages[39]. Wang et al. found that the protease produced by Staphylococcus carnosus can promote the degradation of meat protein and improve the tenderness of meat, but the excessive degradation of protein will destroy the chemical bond between myofibrillar proteins, weaken their aggregation ability, and cause the quality of gel products to deteriorate[40].

Effect of temperature on gel properties of fermented sausages

-

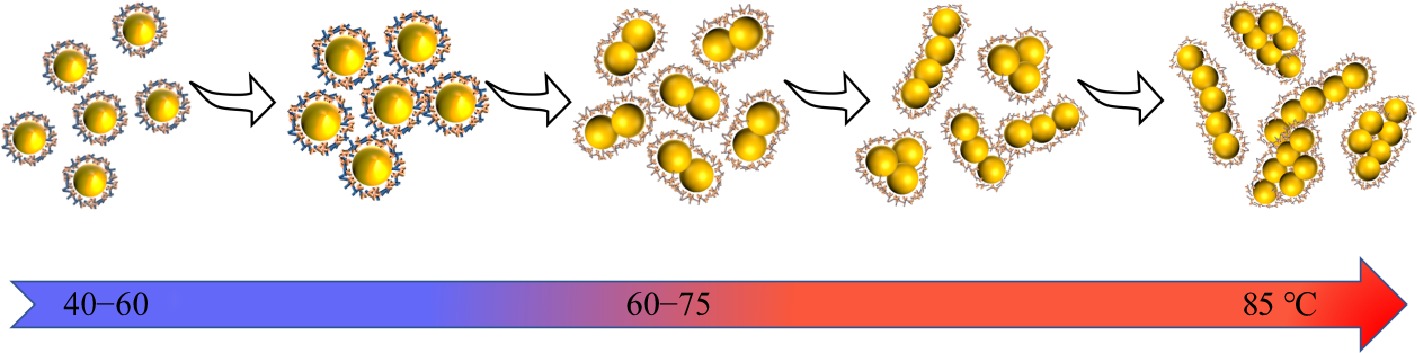

Temperature is one of the important factors that causes protein aggregation, research shows that heat treatment of fermented sausage can increase the hardness and safety of the product, accelerate the drying process of fermented sausage, and shorten the production cycle[41], which may affect the gel properties of fermented sausage. The gel mechanism of myofibrillar protein at different processing temperatures is shown in Fig. 2. With the increase of temperature, proteins unfold and intermolecular forces change, causing protein aggregation, affecting the formation of the gel structure of meat products and the distribution of water and fat. Myofibrillar proteins form the strongest gel at 60−75 °C[42], When the temperature exceeds 85 °C, more proteins aggregate, and the aggregate inserts functional groups of the protein into the interior, reducing the non-covalent cross-linking that maintains the gel structure, resulting in the instability of the gel network structure[43]. Wang et al. studied the effects of different heating temperatures on the structure and gel properties of myofibrillar protein, and found that 70 °C was the best temperature for the formation of protein gel. At this time, the β-sheet content of myofibrillar protein increased, the hydrophobic amino acid residues were exposed, the hydrophobicity of the protein surface was enhanced, and the protein formed a dense and uniform three-dimensional network structure[44].

Figure 2.

Schematic diagram of the gelation mechanism of MP at the different processed temperatures[35].

Effect of processing methods on gel properties of fermented sausage

-

High pressure treatment and addition of fermentation starter can inhibit the growth of Lactobacillus monocytogenes and Lactobacillus typhimurium in fermented sausage, and increase the safety of the product[45]. Stollewerk et al. found that high pressure treatment can reduce the number of Lactobacillus monocytogenes, Enterococcus, and Coliforms in sausages, without affecting the physical and chemical properties and sensory quality, and is more popular with consumers[46]. No Enterobacter was detected in sausages treated with ultra hydrostatic pressure, and the safety was improved[47]. Different processing methods will affect the gel properties of fermented sausage, thus affecting its taste and quality. As shown in Fig. 3, high pressure treatment, ultrasonic treatment, and other processing methods are helpful to improve the gel properties of meat products. As myofibrillar protein denatures at 400 MPa, the spatial structure of the protein will change after processing, myosin α-helix will open, forming a β-sheet with spatial stability, exposing the hydrophobic groups inside the protein, and strengthening the hydrophobic bond between the protein and water molecules. More water molecules are bound to myofibrillar protein to form a more dense gel network structure and improve the tenderness of meat[48].

Yang et al.[49] found that under DC magnetic fields of different intensities (3.5, 3.8, 9.5, 10.4 mT), pork myofibrillar protein had different water retention capacity. The suitable magnetic field environment is beneficial to increase the content of protein β-sheet, expose more tyrosine and aliphatic groups in the protein, and induce the orderly rearrangement of charged protein molecules. However, a magnetic field intensity higher than 10.4 mT will lead to excessive aggregation of proteins, forming a smooth gel network structure, reducing the contact area with water, and weakening the stability of the gel[49]. Shi et al. reported that ultrasonic treatment combined with potassium alginate solution curing can improve the tenderness and water holding capacity of chicken breast meat. Ultrasonic treatment can change the structure of the protein, increase the content of sulfhydryl groups, transform more α-helix into β-sheet structure, reduce the formation of aggregates, and improve the three-dimensional network structure of the gel. In addition, due to the high pH value of the meat, it may affect the electrostatic repulsion of myofibrillar proteins. After being pickled with potassium alginate solution, calcium ions in the muscle act as salt bridges to crosslink with negatively charged sodium alginate, resulting in stronger electrostatic repulsion, the myofibrillar protein changed from 'egg-box' to 'divergent', which reduced the dense aggregation of proteins and formed a good three-dimensional gel network structure[50].

-

Scanning electron microscope (SEM) is one of the most powerful imaging and analytical instruments for the characterization of microstructure morphology and chemical composition. It uses a focused electron beam to scan and image the sample surface point by point[51]. Pereira et al. used SEM to study the effect of coconut fiber on the function and microstructure of myofibrillar protein gel. The results showed that after adding coconut fiber, the water holding capacity and texture of myofibrillar protein were improved, and the stability of gel structure was promoted[52]. Chen et al. studied the effect of different temperature induced myofibrillar protein gels by SEM. The results showed that appropriate temperature could improve the gel properties of myofibrillar proteins, and higher temperatures would make the pores of the gel rough and uneven[53]. Confocal laser scanning optical microscopy (CLSM) achieves three-dimensional imaging of the observed sample area through point by layer scanning and can remove interference from defocused fluorescence. It is a non-destructive optical imaging technology. Tong et al.[54] used confocal laser scanning microscopy to study the effect of konjac glucomannan on pork myofibrillar protein. The results showed that the localization of konjac glucomannan and myofibrillar protein was consistent in the composite system. This phenomenon further indicates that there is good compatibility between myofibrillar protein and konjac glucomannan, forming a three-dimensional gel network structure[54]. Tong et al. studied the effect of konjac glucomannan on pork myofibrillar protein by confocal laser scanning microscopy, the results showed that the localization of konjac glucomannan and myofibrillar protein was consistent in the composite system. This phenomenon further indicated that there was good compatibility between myofibrillar protein and konjac glucomannan, forming a denser three-dimensional gel network structure[55]. At present, SEM has been widely used in the study of the gel structure of meat products, and has achieved good results. The gel structure of fermented sausage is similar to that of meat products, therefore, SEM can also be used to study the gel properties of fermented sausage.

Infrared spectroscopy

-

Fourier Transform Infrared Spectrometer (FTIR) is a technique that can determine molecular structure and is also a tool for studying protein changes[56]. It has a characteristic absorption pattern for proteins, in which the amide I region (1,600−1,700 cm−1) can clearly reflect the information of a proteins secondary structure[57]. Ma et al. used FTIR to study the effect of different concentrations of gelatin on the gel properties of oyster protein. The results showed that with the increase in gelatin concentration, the peak value moved from 1,657.00 to 1,647.29 cm−1. The composite gel formed more β-sheet structures, formed chemical bonds such as hydrogen bonds and ionic bonds, increased the water holding capacity of the gel, and improved the texture of the gel[58]. Xu et al. found that the addition of egg yolk modified starch complex and salt could promote the shape of chicken gel structure by studying the amide I region spectrum of chicken gel, and egg yolk modified starch could make more fat particles interact with protein[59]. These methods are also applicable to fermented sausages, and near-infrared spectroscopy technology is very sensitive to changes in chemical composition during the drying process of fermented sausages. It can predict changes in surface water activity and moisture content of fermented sausages, monitor the drying and maturation process of sausages, and avoid the formation of crust on the surface[60].

Raman spectroscopy

-

Raman spectroscopy is a kind of molecular vibration spectroscopy technique, The structure of the protein can be analyzed by Raman spectroscopy to determine the gel properties, preservation, and other aspects. Yan et al. used Raman spectroscopy to analyze the gelation mechanism of microwave heated surimi and fish oil composite gel, and found that mild oxidation is also one of the main ways to improve the gel properties. Compared with traditional water bath heating, fish oil oxidized after microwave heating, the protein cross linking degree increased, and the microstructure of the gel became denser[61]. Li et al. analyzed the effect of nano starch and micron-starch addition on the gel properties of myofibrillar egg by Raman spectroscopy and further confirmed that β-sheet dominated the formation of gel, and the addition of nano-starch and micron-starch did not interfere with myofibrillar degeneration[62]. Applying Raman spectroscopy to fermented sausages can monitor the relationship between protein structure changes and gel properties of fermented sausages during processing and storage, and better reveal the formation mechanism of gel properties of fermented sausages.

Nuclear magnetic resonance

-

Nuclear magnetic resonance (NMR) is a phenomenon in which a nucleus absorbs resonant radio frequency energy in a static magnetic field to form a spectrum[63]. Low field NMR is a tool for the rapid detection of water holding capacity and water-protein interaction. It is non-destructive during heating and can be used to determine various indicators of meat products. The main components of sausage are protein, lipids, and water. Protein is used to form a dense gel network structure. The fluidity of water and fat can be studied by low field NMR. Pajuelo et al. first used 1H NMR spectroscopy to analyze the distribution of fatty acids and triacylglycerol hydrolysates in Iberian ham[64]. Miklos et al. used the 1H NMR relaxation method to study the effects of diacylglycerol, pig back fat and sunflower seed oil on the moisture and fat fluidity of fermented sausage. It was found that the mobility of diacylglycerol in sausage was the largest, and the mobility of pig back fat was the smallest, indicating that there was a difference in the distribution of fat[65].

NMR imaging is a fast and accurate food analysis tool. It can not only determine the amount of water in food, but also visualize the distribution of water molecules in gel through proton density imaging. Liu et al. studied the effect of ozone water washing on the microstructure and protein-water interaction of grass carp surimi gel. It was found that when the concentration of ozone water increased to 7 mg/L, more hydrogen protons appeared in the surimi gel, and the protein was oxidized. Fixed water and free water were closely combined with the gel, and oxidation promoted the crosslinking of myofibrillar proteins, however, after treatment with 10 mg/L ozone water, the protein was overoxidized, the water content of the surimi gel decreased, and the gel structure deteriorated[66]. Nuclear magnetic resonance can better explain the relationship between moisture and gel properties of fermented sausages during sausage processing, reveal the relationship between protein structure changes and moisture status, and the effect of moisture migration on gel structure.

-

In summary, the ability of lactic acid bacteria to produce acid, enzyme, extracellular polysaccharide, and antioxidant properties play an important role in the formation of fermented sausage gel properties. In addition, the gel properties of fermented sausages are also closely related to various factors such as temperature and processing methods. At present, there are many reports on the gel properties of proteins, but the mechanism of the gel properties of lactic acid bacteria and fermented sausages is not thorough enough. The mechanism of gel formation and the mechanism of intermolecular interaction remain to be discussed. Therefore, in order to further clarify the mechanism of the formation of fermented sausage gel, it is necessary to use precision instruments such as Fourier transform infrared spectroscopy, Raman spectroscopy, and nuclear magnetic resonance in future studies to interpret the gel properties of fermented sausages from different perspectives. Analyze the relationship between protein structure and gel properties of meat products during lactic acid bacteria fermentation, and lay a good theoretical foundation for expanding its application in food.

Microbial fermentation can decompose the protein in meat into aromatic small molecules such as amino acids, which can not only improve the flavor and nutritional value of meat products, but also increase the added value of products so that the fermented sausage has good gel properties and taste. Therefore, the use of microbial fermentation technology to produce healthy and delicious gel type meat products is a new development trend in the meat industry and a new direction for achieving healthy life.

-

The authors confirm contribution to the paper as follows: study conception and design: Hao S, Tian J, Qian M, Wang Y; draft manuscript preparation: Hao S, Qian M; Writing-re-review and editing: Hao S, Tian J, Qian M, Wang Y; resources, funding acquisition: Tian J, Zhang K, Wang X; project administration: Tian J, Zhang K, Wang X. All authors reviewed the results and approved the final version of the manuscript.

-

Data availability is not applicable to this article as no new data were created or analyzed in this study.

This study was supported by The Regional project of the National Natural Science Foundation of China (Grant Nos 31960514 and 32160589); The central government guides local science and technology development fund projects (Grant No. 2022ZY0133); Science and Technology Projects of Inner Mongolia Autonomous Region (Grant Nos 2019GG239 and 2022YFDZ0020); Inner Mongolia Natural Science Foundation Project, (Grant No. 2021MS03090); Transformation project of scientific and technological achievements in Inner Mongolia Autonomous Region (Grant No. 2019CG066); The key project of Bayannur National Agricultural High-tech Industry Demonstration Zone is the key project of the 'Science and Technology Revitalizing Mongolia' action (Grant No. NMKJXM202205); The Science and Technology Project of Inner Mongolia Agricultural University (Grant No. SPKJ202003).

-

The authors declare that they have no conflict of interest.

-

# Authors contributed equally: Shiqin Hao, Min Qian

- Copyright: © 2024 by the author(s). Published by Maximum Academic Press on behalf of Nanjing Agricultural University. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Hao S, Qian M, Wang Y, Zhang K, Tian J, et al. 2024. Research progress on the gel properties of fermented sausage. Food Materials Research 4: e007 doi: 10.48130/fmr-0023-0042

Research progress on the gel properties of fermented sausage

- Received: 26 September 2023

- Revised: 16 November 2023

- Accepted: 07 December 2023

- Published online: 01 February 2024

Abstract: Fermented sausage is a fermented meat product favored by a large number of of consumers. In fermented sausages, the formation of gel is one of the key steps, and its composition mainly includes meat protein and fat, among which myofibrillar protein is essential for the gel properties of fermented sausages. During the processing of fermented sausages, the myofibrillar protein and myosin in the meat are deformed, losing their original solubility and becoming a gel substance, while the metabolites and enzymes of microorganisms in the fermented sausage can interact with the protein and fat in the meat to promote the formation of gel, thereby helping to improve the texture, water retention and taste of the fermented sausage. In this paper, the formation mechanism of gel properties of fermented sausage was comprehensively discussed, the effects of lactic acid bacteria, temperature, and other factors on the gel properties of fermented sausage were analyzed, and the research methods of gel properties were introduced. The aim was to provide a basis for the control of process parameters in the processing of fermented sausage and to provide a reference for further improving the gel quality of fermented sausage.

-

Key words:

- Fermented meat products /

- Gel properties /

- Myofibrillar protein /

- Lactic acid bacteria