-

Siraitia grosvenorii is a traditional Chinese medicine belonging to the Cucurbitaceae family. The cultivation history of Siraitia grosvenorii can be traced back more than 200 years in Guangxi Province, China[1]. Currently, four main species are distributed in China as listed in Table 1. These species were collected from different locations and have their own characteristics. Siraitia grosvenorii is the most widely known species among the Siraitia genus, which is mainly distributed in China, including Guangxi Province, Guizhou Province, southern Hunan Province, Guangdong, and Jiangxi Province. Yongfu County and Longsheng County of Guangxi Province are the most significant commercial production areas. In recent years, the Geographic Information System for Global Medicinal Plants (GMPGIS) has been used to analyze the global ecological suitability of Siraitia grosvenorii, and the results showed that Brazil and the Democratic Republic of the Congo could be the two greatest potential growth areas, whereas Indonesia, Colombia, Peru, USA, Bolivia, Thailand, and Myanmar also have potential for the cultivation of this plant[2]. However, the commercial cultivation of this plant in these areas needs more time for cultivar introduction, scientific trials, and government and industry engagements.

Subgenus name Species name Distribution Subgen. Siraitia Siraitia grosvenorii

(Swingle) C. Jeffrey ex A. M. Lu & Zhi Y. ZhangGuangxi province, Guizhou province, Southern Hunan province, Guangdong and Jiangxi province Subgen. Siraitia Siraitia siamensis

(Craib) C. Jeffrey ex S. Q. Zhong & D. FangWestern Guangxi province, Southeastern Yunnan province Subgen. Microlagenaria

(C. Jeffery) A.M. Lu et Z.Y. ZhangSiraitia borneensis

(Merr.) C. Jeffrey ex A. M. Lu & Zhi Y. ZhangGuangdong province, Xichou of Yunnan province, Motuo of Xizang Subgen. Microlagenaria

(C. Jeffery) A.M. Lu et Z.Y. ZhangSiraitia taiwaniana

(Hayata) C. Jeffrey ex A. M. Lu & Zhi Y. ZhangTaiwan area Siraitia grosvenorii is famous for its fruit, which is not only a food but also a traditional Chinese medicine, commonly known as Luo Han Kuo (LHK) or monk fruit, and was registered as a medical and edible source by the Chinese Ministry of Health in 2002[3]. The Siraitia grosvenorii fruit has a sweet and refreshing taste and was traditionally used to treat cough, pertussis, chronic tracheitis, laryngitis, and gastrointestinal diseases[4]. The annual yield of LHK can be as high as 1 billion pieces, where China is the largest commercial producer[5]. More than 90% of them were produced in Longsheng County, Lingui County, and Yongfu County of Guilin City in Guangxi Province (Table 2).

Table 2. The annual yield of Siraitia grosvenorii in different counties of Guilin city in 2015−2018[176−179].

Region (county) Yield (10 k pieces) 2015 2016 2017 2018 Yongfu 33569 41458 36407 47024 Lingui 24042 26927 27199 27009 Longsheng 18881 22247 28121 30672 Lingchuan 3993 4213 3967 3927 Gongcheng 3254 3679 3670 3716 Xing'an 3032 3448 3454 3509 Quanzhou 3403 3457 3664 3691 Yangshuo 290 286 − 365 Guanyang 800 809 828 830 Ziyuan 528 753 796 835 Pingle 41 49 54 58 Lipu 222 224 312 314 Such concentrated production of LHK in Guilin City may be attributed to specific soil, climate, and geographic conditions of the production area. Siraitia grosvenorii prefers loose, light, moist brown limestone soil for its cultivation, whereas the mountainous area is their primary cultivation preference[6]. It is also worth noting that potassium fertilizer and other heavy metal elements (such as Cd) need to be supplemented and monitored, respectively, to grow high-quality LHK due to its high potassium absorption efficiency and heavy metal accumulation rate[7,8]. Soil pH could also affect Siraitia grosvenorii development, where the normal range is between 4.0−6.5 and usually at 5.5, which is acidic or slightly acidic[9,10] . Excessively low pH (under 4) could stimulate the accumulation of Cd in Siraitia grosvenorii, then inhibit its growth and enhance the oxidative stress on plant leaves by inhibiting the activity of antioxidant enzymes[11]. Therefore, appropriate soil management methods should be applied to modulate the cultivation area's soil physical and chemical conditions[12]. In addition, Siraitia grosvenorii requires unique cultivation environment conditions, such as being planted on the cool side of the tropical or subtropical mountains with an altitude of 50−800 m, high relative humidity (≥ 75%), relatively warm temperature (15−30 °C), with an annual rainfall of 1,500−2,000 mm and annual illumination 1,100−1,600 h[13]. In the meantime, it should be planted in an area surrounded by bush or bamboo, with short daily sunshine time (6−7 h), and accompanied by a foggy and humid mountain climate[14]. These requirements emphasize the importance of temperature, illumination, and humidity on their growth and high fruit quality.

The LHK fruit has various functional components, including cucurbitane-type triterpenoid glycosides, flavonoids, polysaccharides, and other minorities such as protein, oil, vitamins, and others. All these compounds play an important role in their pharmacological effects and the extraction methods may impact the functional compound composition, as well as the purity. From a commercial perspective, patents are suitable to understand the development of the extraction methods, and the current and future application of Siraitia grosvenorii could also be relevant to the patent registration situation.

The review aims to summarize the functional components of Siraitia grosvenorii, including their structural and bioactive functions. Also, the extraction technology of each component will be discussed in detail with associated patents to demonstrate the current progress of the technology. In addition, the development of Siraitia grosvenorii products will also be discussed to provide a comprehensive understanding of Siraitia grosvenorii current industry status, as well as future directions.

-

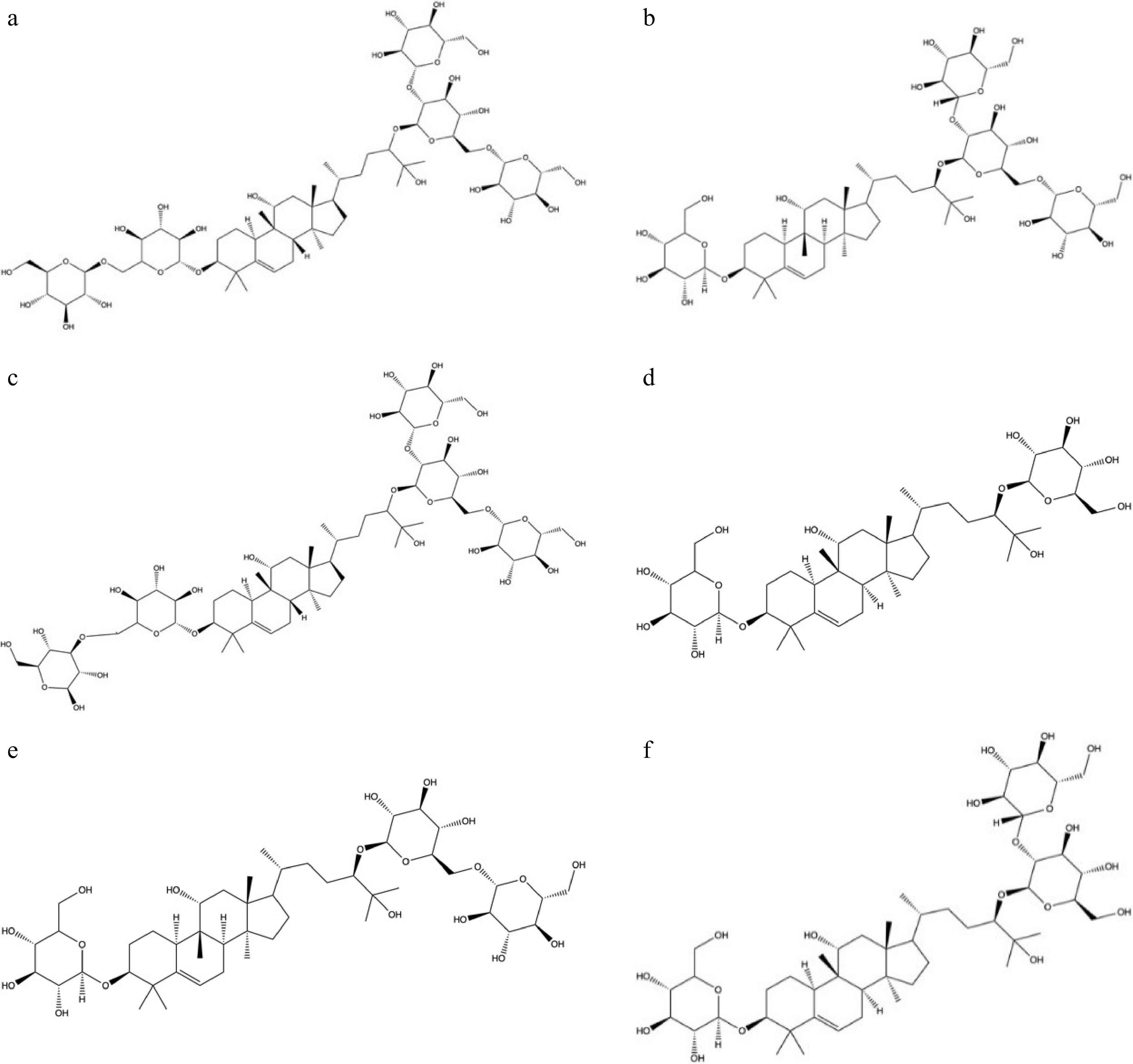

Cucurbitane-type triterpenoid glycosides are the main functional and sweet substances in Siraitia grosvenorii. Lee[15] first reported the chemical structure of the sweet substances in LHK. Thereafter, more individual sweet components were found in the following decades, and mogroside is one of the most studied substances. Most of the cucurbitane-type triterpenoid glycosides share the same mogrol structure, which contains an aglycone with different numbers of glucose units (Fig. 1)[10,16,17]. It has been suggested that more than three glucose units attached to the aglycone could generate a sweet taste[13]. These sweet compounds are non-caloric with no glycemic properties because the glycosidic bonds cannot be digested by the human gastrointestinal system[18]. This property offers it a high commercial value as a natural food sweetener.

Figure 1.

Chemical structures of some important mogrosides. (a) Mogroside V; (b) Siamenoside I; (c) Iso-mogroside V; (d) Mogroside IIE; (e) Mogroside III; (f) Mogroside IIIE) in Siraitia grosvenorii.

Interestingly, compounds with different structures of the cucurbitane-type triterpenoid glycosides may have a sweet taste, tasteless, or even bitter taste. For example, the most studied substance is mogroside V (Fig. 1) in the fruit of Siraitia grosvenorii, which was isolated by Takemoto et al. in 1983, as well as other two compounds of mogroside IV and VI[19−21]. Siamenoside I is another sweet component which is the sweetest in the Siraitia grosvenorii plant. It was isolated by Kasai et al. in 1989[22]. Neomogroside is a trace amount of sweet substance in Siraitia grosvenorii, separated by Si et al. in 1996[23]. Another minor sweet component, iso-mogroside V, was isolated by Jia and Yang in 2009[24]. It is sweeter than mogroside V but less than Siamenoside I. The sweet intensities of mogroside V, iso-mogroside V, and Siamenoside I are 250−425, 500, and 563 times sweeter than sucrose respectively[24,25]. In terms of bitter mogroside, mogroside A was extracted from the fresh fruit of Siraitia grosvenorii in 1992[26]. Its structure was determined to be the same as one of the hydrolysates of mogroside V and mogroside IIE[20]. Mogroside IIE mainly exists in unripe fruit[7]. There are dozens of other substances found with different tastes, including mogroside III and mogroside IIIE being tasteless[25]. It should be noted that the structures of these components are very similar, and the main differences are the units attached to the mogrol aglycon, and different numbers of glucose units have different tastes[27] (Fig. 1). Additionally, Li et al.[7] reported that the composition and concentration of mogrosides change during the ripe process of the fruit, and more mogroside V is formed at the later stage of fruit ripening. The content of cucurbitane-type triterpenoid glycosides comprising over 1% or more (as high as 2.5%) of dried fruit, where mogroside V is the main component, occupies more than 50% of total Cucurbitane-type triterpenoid glycosides (as high as 2%)[28−30].

Additionally, mogroside V has some unique bioactivities. A study reported that mogroside V can potentially protect against respiratory tract inflammation induced by lipopolysaccharides in an acute lung injury model[31]. Moreover, another compound of triterpenoid acid isolated from the roots of Siraitia grosvenorii also has a potential anti-cancer effect[32]. Meanwhile, research showed that mogroside is non-toxic to mice when the maximum oral dose is 15 g/kg[33]. There was no reproductive and genetic toxicity under various doses of mogrosides at 0.25, 0.5, and 1 g/kg, Although there was a slight potential genotoxicity in male mice when the dose of the stomach tube reached 5 g/kg[33], it is merely impossible to achieve this dose for a 70 kg adult (350 g/day). Meanwhile, the FDA approved mogroside V as a new sweetener in 2010, which certified its safety as a food additive. Recently, mogroside V was reported to have potential prebiotic effects as well[34], which would expand the utilization of mogroside in industry.

Flavonoids

-

Flavonoids are the primary health-promoting components in Siraitia grosvenorii, which could be extracted from almost every part of the plant, including fruits, leaves, stems, and flowers. One of the most common sources of the flavonoids is the fruit (both fresh and dry), such as grosvenorine and kaempferol-3,7-α-L-dirhmnopyranoside[35], kaempferol[36] and quercetin[37] . In addition, kaempferol 3,7-di-O-α-L-rhamnopyranoside and kaempferol-7-O-α-L-rhamnopyranoside were isolated from Siraitia grosvenorii fruit as well[35,36,38]. The total flavonoids in the fruit varies according to the size (diameter) and the content ranges 5−10 mg/piece[37]. However, another research reported that the total flavonoids could reach 13.87 mg/g[39], which suggested that Siraitia grosvenorii fruit grown at different years or areas may have different total flavonoid content.

Furthermore, other parts of Siraitia grosvenorii are also rich in flavonoids. The total flavonoids in fresh leaves, stem, and roots are 28, 14.2, and 1.29 mg/g respectively[40,41]. Leaves mainly contain kaempferol-3,7-di-O-α-L-rahmnoside, kaempferol-3-O-α-L-rahmnoside, quercetin-7-O-L-rhamnoside, quercetin-3-O-β-D-glucoside-7-α-O-L-rhamnoside[10,42], kaempferol, and quercetin[43]. In addition, ferulic acid, 4'-O-methyldihydroquercetin, emodin, and aloe-emodin were reported in the leaves[43]. Meanwhile, kaempferol is the main flavonoids in stem[44]. The total kaempferol and flavonoid in the extract of leaves and stem are 180.5 and 326.9 mg/g, respectively[45,46]. Recently, research focused on increasing the extraction rate of flavonoids. Yang[47] reported that the yield of flavonoid in the leave water extract reached 42 mg/g, and the concentration of flavonoids in the water extract was 33.24% which increased sharply to 42.29% after ethanol purification. In the flower of the Siraitia grosvenorii, it contains about 10.71 and 5.06 mg/g of kaempferol in dried whole female and male flowers respectively[48].

As a potential medical ingredient, flavonoids have been reported to possess antioxidant properties, promoting blood circulation, and antibacterial effects[47,49,50]. It was reported that the extract from the leave and stem of Siraitia grosvenorii could scavenge DPPH free radical with similar capacity to butylated hydroxytoluene and citric acid respectively[51,52]. Kaempferol and kaempferol-7-α-L-rhamnopyranoside from the extract of Siraitia grosvenorii flower, have demonstrated strong antioxidant ability in ferric reducing antioxidant potential assay (FRAP), Trolox equivalent antioxidant capacity assay (TEAC) and oxygen radical absorbance capacity (ORAC). Other flavonol glycosides (e.g. 7-methoxyl Kaempferol 3-O-β-D-glucopyranoside, 3-O-α-L-rhamnopyranosyl Kaempferol 7-O-[β-D-glucopyranosyl (1-2)-α-L-rhamnopyranoside]) which have different hydroxyl unit attached to the kaempferol aglycone showed a weaker antioxidant ability due to the lack of 3,7-hydroxyl in its structure, which is the critical group that affects the antioxidant activity. Hydroxyl glycosidation and hydroxyl methylation also reduce its antioxidant activity[53]. Also, flavonoids could significantly reduce the total cholesterol (TC) and triglyceride (TG) contents of hypercholesterolemia mice and increase high-density lipoprotein cholesterol (HDL-C) levels, suggesting the Siraitia grosvenorii flavonoids may have antithrombotic, antiplatelet aggregation, lipid-lowering, and anticoagulant activities[47]. In addition, ethanol extracts from leaves and stems showed the antibacterial activity against Pseudomonas aeruginosa, with the antibacterial efficiency of 90.9% and 76.7% respectively when their concentration was 50.00 mg/mL. The inhibitory rate of stem extract against Escherichia coli was 70.2%. However, the inhibition efficiency of ethanol extracts from Siraitia grosvenorii leaves and stems against Staphylococcus aureus, Micrococcus garcinia, and Candida albicans was less than 50%[54], which indicates its limited antimicrobial ability for these microorganisms.

Polysaccharides

-

Polysaccharides in the Siraitia grosvenorii are simpler than cucurbitane-type triterpenoid glycosides and flavonoids. There are only two types of polysaccharides in the fruits of Siraitia grosvenorii, i.e. SGPS1 and SGPS2, with molecular weight of 470,000 and 790,000 respectively[55]. They have very different structures. SGPS1 consists of D-glucose, D-galactose, D-xylose, L-arabinose, L-rhamnose, and glucuronic acid[56]. The main chain is consisted of (1→4) Glc and (1→3) Gal where (1→4) Glc is the main unit[57]. In contrast, SGPS2 is composed of L-rhamnose and glucuronic acid only, and (1→2,4) Rha and (1→4) Rha are its main chain. The content of polysaccharides varies between 2.88%−7.13% in different fruits and different parts of the fruits, with the order of fruit flesh > peel > seeds[58,59].

The root of Siraitia grosvenorii also contains polysaccharides. It is composed of glucose, arabinose, and xylose in which glucose is the main constitute[60]. The root is composed of more than 30.89% starch, which can be developed to be a rich source of editable starch and has the possibility for large scale production[55].

Some polysaccharides have potential health benefits. Research reported that Siraitia grosvenorii polysaccharides exhibited glucose-lowering and lipid disorder amelioration effects on hyperglycemic rabbits induced by feeding with high fat/high sucrose diets[61]. The hypoglycemic activity of Siraitia grosvenorii polysaccharides could also be achieved by inhibiting the activity of the enzyme[62]. It was also reported that Siraitia grosvenorii polysaccharides could inhibit the activities of α-glucosidase and α-amylase, thus controlling the starch hydrolysis and glucose release and lowering the blood sugar level[63]. In addition, Siraitia grosvenorii polysaccharides have been reported to increase spleen and thymus indexes, improve super oxidase dismutase activity, proliferate B, T cells, enhance immune system, ameliorate spleen tissue damage induced by cyclophosphamide and regulate the level of reactive oxygen species (ROS) in vitro[64,65]. Therefore, Siraitia grosvenorii polysaccharides possess potential immunomodulatory and antioxidant activity. Further research indicated that the polysaccharides from Siraitia grosvenorii roots could eliminate 66.27% hydroxyl radical, 86.53% superoxide anion radical, 75.38% DPPH, and 55.39% ABTS[66]. Interestingly, due to the high content of cellulose, semi-cellulose, and lignin in Siraitia grosvenorii extraction residue, which was left over after mogroside and flavonoids extraction, it has very good dye absorption ability[67], which could be used to prepare novel absorption material for methylene blue dye in spinning and textile printing wastewater treatment.

Minor components

-

Besides glycosides, flavonoids, and polysaccharides, there are other minor components in the Siraitia grosvenorii, including proteins, oils, vitamins, and others[68]. It was reported that the crude protein content of a wild Siraitia grosvenorii fruit is about 9.26%−13.35%, which contains eight essential amino acid (AA) plus ten non-essential amino acids, including Val, Leu, Ile, Phe, Thr, Lys, His, Met, Asp, Glu, Arg, Ala, Gly, Ser, Pro, Tyr, Cys, and γ-aminobutyric acid. The aspartic acid content is the highest (1,125 mg/100 g), followed by glutamate (1,082 mg/100 g), whereas γ- aminobutyric acid is the lowest (26.3 mg/100 g)[69,70]. In another report of the cultivated Siraitia grosvenorii, the crude protein content is a bit lower which is between 8.67%−10.78%[69]. Similar to the wild species, there are 18 AA in cultivated Siraitia grosvenorii (Table 3) and vary by species[71]. However, the content order is different from the wild one. Glutamate content is the highest which is about 1,100 mg/100 g, followed by aspartic acid (939 mg/100 g), and the content of γ-aminobutyric acid is the lowest as well (35.6 mg/100 g)[69,71]. Later, with the development of the amino acid determination method, more AA were determined in Siraitia grosvenorii. Zhou et al.[72] detected cysteine (Cys), glutamine (Gln), glutathione (GSH), asparagine (Asn), alanyl glutamine (Ala Gln), citrulline (Cit), ornithine (Orn), and L-proline (LPro) in the fruit.

Table 3. Comparison of amino acid content of cultivated and wild Siraitia grosvenorii[71].

AA name Content (mg/100 mg) Cultivated Wild Valine (Val) 555 536 Leucine (Leu) 526 486 Isoleucine (Ile) 439 420 Phenylalanine (PHE) 349 365 Threonine (Thr) 309 313 Lysine (Lys) 147 179 Histidine (His) 101 115 Methionine (Met) 62.7 65.2 Asparagine (Asp) 939 1125 Glutamic (Glu) 1110 1082 Arginine (Arg) 478 646 Alanine (Ala) 575 538 Glycine (Gly) 465 446 Serine (Ser) 466 445 Proline (Pro) 402 430 Tyrosine (Tyr) 271 267 Cystine (Cys) 121 106 γ-aminobutyric acid 35.6 25.3 Siraitia grosvenorii oil is mainly extracted from the seeds, and the residue which was left after mogroside production has a high amount of oil. The seed contains 27%−33% oil which is primarily composed of linoleic acid, oleic acid, and palmitic acid[38]. Linoleic acid and oleic acid could prevent atherosclerosis and reduce cholesterol[73]. In addition, high-value oil components had been found in the seed oil and the residue oil. For example, farnesol was detected in Siraitia grosvenorii seed oil, which accounts for 52.14% of the oil[74]. Farnesol is an expensive perfume additive, which has been used to enhance the perfume scent. As the content was measured using the GC-MS peak area normalization method, it has the possibility to be false high[75] and further research is needed. In addition, squalene is another valuable and vast amount component in the seed kernel, and it accounts for 4.4% of total oil content which is much higher than that in olive oil and palm oil (the squalene amount in these two products is about 1.16%)[75]. The content of squalene in Siraitia grosvenorii seed kernel oil was determined to be as high as 12.5% in another study[76]. This phenomenon indicates that the oil content could vary significantly due to its growth year or area. It was noted that 82.56% of the fatty acid in Siraitia grosvenorii oil was unsaturated[77]. Besides seed oil, 0.34% squalene was also found in the residue oil[75]. The yield of squalene was increased to 7.82%−16.81% after supercritical CO2 extraction, plus 30.78% linoleic acid in the extracted oil from Siraitia grosvenorii residue[73,78]. The squalene could be used to enhance physical fitness, anti-fatigue, and treat liver inflammation[79].

The volatile components were distilled and extracted from the water solution using diethyl ether. They are a part of the oil from the fruit, and the composition is different in various Siraitia grosvenorii species. For general Siraitia grosvenorii, the major volatile components include 2-methyl-2-butyl butyrate (30.76%, relative content of volatile oil), 2,4-Diacetoxypentane (11.05%), 2-heptanol (10.58%), butyl acetate (4.93%), 1-hexanol (3.81%), and 2-butanol acetate (3.05%)[80]. For seedless Siraitia grosvenorii fruit, the volatile composition is different, which includes ethanol-2-isopropoxy (27.21%), 1,2-benzenedicarboxylic acid, butyl-2-ethylhexylester (13.51%), 1,2-benzenedicarboxylicacid, bis (2-methylpropyl) ester (10.85%), nonanal (10.22%), E-3-decenoic acid (6.52%), butyl butyrate (4.99%), and 2-ace-toxytridecane (4.86%)[81]. These components offer a unique aroma to Siraitia grosvenorii oil and its product, such as wine[82].

Vitamin C is another crucial component in Siraitia grosvenorii with the amount about 339.68−487.52 mg/100 g in the fruit, which is 10, 16, 97, and 162 times higher than that in orange, mandarin, apple, and pear respectively[83]. The vitamin C content is higher in fruit peels than in fruit flesh, and differs due to growing season, area[84−86], as well as soil conditions[87].

-

Solvent extraction is the most used extraction method to obtain mogroside from Siraitia grosvenorii. Ancient Chinese boiled Siraitia grosvenorii in water for several hours to extract the effective medical components to treat coughing and throat pain[88]. This method of using hot water as the solvent is called decoction, which is simple and easy to operate[89]. However, the disadvantage of this method is the low yield of mogroside. Recently, using solvents combined with column separation or membrane separation has been applied to increase the yield (Table 4). For example, Fan[90] added 6,000 g water with 2,000 g Siraitia grosvenorii, boiled three times, for 3−5 h, and then combined with ultrafiltration membrane separation. This comprehensive method could obtain high mogroside yield of 1.8%. Luo[91] used 12 times of water to the fruit, pasteurized for 2.5 min at 300 kpa three times, and then deployed 18C column for separation resulting in the separated mogroside with a yield of 0.47% and purity of 96.1%. Furthermore, Qi et al.[92] used 70% aqueous ethanol (three times × 2,000 mL) to obtain extract from 500 g Siraitia grosvenorii fresh fruit plus D101 macroporous resin column to purify mogroside. The yield of mogroside extract is 0.5% and the total amount of mogroside V (69.24%), 11-oxo-mogroside V (10.6%), siamenoside V (9.8%), and mogroside IV (4.54%) is 94.18%. Li et al.[93] also applied 60 L distilled water to 20 kg of fruit and heated at 80 °C for 4 h. After three extractions, the extract was purified with macroporous resin column using ethanol as an eluting solvent to prepare crude Siraitia grosvenorii saponin, with the product saponin amount of 280 g and a yield of 1.4%. The total mogroside amount could reach 52.024 g after purification and the purity is 18.58%. There were six novel compounds being separated including iso-mogroside IVe, iso-mogroside IVa, 11-epi-mogroside V, mogroside VIa, 11-oxo-siamenoside I, and 11-oxo-mogroside VI.

Table 4. Various mogroside extraction methods from Siraitia grosvenorii.

No. Method name Material Solvent Solid/liquid ratio Temperature (°C) Time Extraction frequency Other conditions Yield (purity) Ref. 1 Solvent extraction Fresh fruit Water 1:3 Boiled water 3−5 h 3 Membrane separation 1.8% (86%) [90] 2 Solvent extraction Fresh fruit Water 1:12 Ambient 2.5 min 3 300 kPa 0.47% (96.1%) [91] 3 Solvent extraction Fresh fruit 70% ethanol 1:4 80 NA 3 NA 0.5% (94.18%) [92] 4 Solvent extraction Fruit Water 1:3 80 4 h 3 NA 1.4% (18.58%) [93] 5 Microwav e-assisted extraction Fresh fruit Water 1:8 Boiled water 15 min 1 Microwave 750 W 0.73% [95] 6 Microwave-assisted extraction Dried fruit Water 1:30 NA 2 h + 25 min 2 Microwave 638 W 1.31% [96] 7 Microwave-assisted extraction Dried fruit 40% ethanol 1:30 NA 6 min 1 Microwave 495 W 0.8% [57] 8 Ultrasonic-assisted extraction Fruit 20%−40% ethanol 1:25 (1st time);

1:20 (2nd & 3rd time)60,65,75 40, 30, 20 min 3 Ultrasonic 40 kHz, 100 W, 3.6% [98] 9 Ultrasonic-assisted extraction Fruit powder Water 1:20 70 NA 1 Ultrasonic 50 kHz, 80 W 3.42% [99] 10 Ultrasonic-assisted extraction Fruit Water 1:30 50 40 min 1 Ultrasonic 20 kHz 3.97% (91.84%) [103] 11 Flash extraction Dried fruit Water 1:18 40 7 min 1 NA 8.77% [102] 12 Flash extraction Fruit Water 1:25 60 10 min 1 NA 8.6% (> 92%) [100] 13 Flash extraction Fruit Water 1:20 Ambient 4 min 1 6000 r/min 10.06% [104] 14 Supercritical fluid extraction Fruit powder Subcritical water NA 150 10 min 1 11.7 MPa Subcritical water 62.4% (yield rate) [105] NA: Not Applicable. Microwave-assisted extraction

-

Microwave-assisted extraction technology is widely used in the extraction of natural compounds due to its advantages of high heating efficiency and fast extraction process[94] (Table 4). Zhu & He[95] used water as the extraction solvent with the solid/liquid ratio of 1:8, and microwave heated at 750 W for 15 min. Under this condition, the mogroside yield is 7.346 mg/g (0.73%), which was significantly higher than the hot water extraction method (6.029 mg/g) (0.6%).

Li et al.[96] showed that under the microwave treatment of 638 W for 25 min, with 1:30 solid/water ratio, and extract for 25 min twice, the yield of mogroside reached 1.31%. Furthermore, using 40% ethanol as solvent at 1:30 solid/liquid ratio, and treated with 495 W microwave power for 6 min, the yield achieved 0.8%[57].Ultrasonic-assisted extraction

-

Ultrasonic waves are effective in natural component extraction[94], including mogroside extraction. Its working principle is using the cavitation of ultrasonic processing to damage cell tissue to release compounds into the solvent and increase the extraction efficiency[97].

Ma et al.[98] applied 40 kHz, 100 W ultrasonic condition to three-cycle mogroside extraction using aqueous ethanol as a solvent achieving a mogroside yield of 3.6%. Another study showed that ultrasound at higher frequency (50 kHz, 80 W, yield 3.42%) resulted in a higher yield than that at a lower frequency (28 kHz, 200/400 W, yield 2.98%/3.19%) extraction, despite the power was lower[99]. Liu et al.[100] also reported that the yield of mogroside could reach 3.97% and purity of 91.84% under the condition of 20 kHz ultrasound treatment for 40 min at 50 °C and solid/liquid ratio of 1:30.Flash extraction

-

Flash extraction is a novel method in the extraction of traditional Chinese medicine. The principle of flash extraction is that at the presence of an appropriate solvent, the plant cell tissue will be destroyed by a high-speed homogenizer, and the active components make full contact with solvent under the effect of high-speed mechanical shear force and stirring force. Thus, the components dissolve in the solvent and transfer from cell tissue to solvent rapidly. This process achieves internal and external dissolution balance in a very short time[101] (Table 4).

Yang et al.[102] optimized the flash extraction condition, adopting JHBE-50S flash extractor and using 18 times water as the solvent and processed for 7 min at 40 °C, which obtained a high extraction rate of mogroside (8.77%) with a purity of 92% after column chromatography purification. Liu et al.[103] reported a different optimal condition of flash extraction of mogroside using a Herbal Blitzkrieg extractor as the equipment. The solid/liquid ratio was 1:25, processing time of 10 min, and temperature of 60 °C. Under this condition, the mogroside yield reached 8.6%. Meanwhile, flash extraction had been compared with other extraction methods. It was reported that under 1:20 solid/solvent ratio, rotational speed of 6,000 r/min of the homogenizer, and processed for 4 min at ambient temperature, the mogroside extraction yield was 10.06% which was higher than ultrasonic (1:30, 800 W, 30 min, ambient temperature) (yield 5.97%), and microwave (1:30, 750 W, 15 min, 90°C) (yield 9.41%) extraction[104].Supercritical fluid extraction

-

Supercritical fluid extraction technique has the advantages of high extraction efficiency with low waste and non-hazardous material production. Generally, subcritical water and supercritical carbon dioxide are the primary solvents (Table 4). Xia et al.[105] compared these two solvents and reported that subcritical water showed higher efficiency than supercritical CO2 under appropriate conditions. In this study, the condition of subcritical water extraction was the flow rate of 0.7 mL/min, pressure 1.17 MPa, temperature 150 °C, processing for 10 min, whereas the condition of supercritical CO2 processing was the flow rate of 1 mL/min, pressure 20.7 MPa, temperature 60 °C, processing for 30 min with 0.5 mL/min addition flow rate for ethanol as co-solvent. The efficiency of supercritical CO2 was improved by adding ethanol as a modifier, which acts as a co-solvent to mobilizing mogroside molecular in the cell tissue, thus increasing the extraction efficiency[105]. The extraction yield of mogroside by subcritical water treatment was 62.4%, which was higher than that of supercritical CO2 treatment (37%, adjusted by ethanol). Both subcritical water and supercritical CO2 treatment have a higher yield than the Soxhlet extraction method (5.1%)[105,106].

Membrane-assisted isolation

-

Membrane isolation/filtration is a green processing method with low pollution to the environment. It is generally used after crude extraction to purify the compounds. According to the pore size of the membrane, membrane filtration includes microfiltration, ultrafiltration, and nanofiltration. Microfiltration could be used to remove any impurities larger than 0.1 μm, such as suspended solids, bacteria, colloids, and proteins, as well as the protease in the Siraitia grosvenorii, with a mogroside extraction yield of 0.85%[107]. Ultrafiltration could isolate compounds with relative molecular weight between hundreds and millions, whereas nanofiltration intercepts compounds with relative molecular weight higher than 150−200. Membrane purification could not only improve production efficiency but also obtain high-purity products at a low cost[108]. However, the membrane fouling and high replacement costs are the main disadvantages[90].

Extraction of Siraitia grosvenorii flavonoids

-

Flavonoids are another group of important compounds in Siraitia grosvenorii and are the main contributors for potential medical purpose. Their extraction methods are very similar to the extraction of mogroside, including solvent extraction, ultrasonic-assisted extraction, microwave-assisted extraction, enzyme-assisted extraction, supercritical fluid extraction and flash extraction (Table 5).

Table 5. Various flavonoid extraction methods from Siraitia grosvenorii.

No. Method name Material Solvent Solid/liquid ratio

(S/L ratio)Temperature (°C) Time Frequency Other conditions Yield Ref. 1 Solvent extraction Fruit 70% ethanol 1:15 70 2 h 1 NA 0.58% [109] 2 Solvent extraction Leaf Water 1:30 Boiled water 50 min 3 NA 1.32% [110] 3 Solvent extraction Stem and leaf 50% ethanol 1:20 70 3 h 3 NA 1.47% [111] 4 Ultrasonic- assisted extraction Fruit 30% ethanol 1:30 70 45 min 1 Soak in 30% ethanol for 24 h before ultrasonic processing 1.62% [113] 5 Ultrasonic- assisted extraction Fruit 40% ethanol 1:25 70 40 min 2 40% ethanol 1.76% [114] 6 Ultrasonic- assisted extraction Fruit 30% ethanol 1:9 80 40 min 1 Ultrasonic 250 W 2.86% [115] 7 Ultrasonic-assisted Residue Aqueous ethanol 1:34.75 50.65 29.2 min 1 Ultrasonic 200 W 2.25% [116] 8 extraction Microwave- assisted extraction Fruit 50% ethanol 1:30 65 (Heat 15 s

per 5 min)15 min 1 650 W 40 mesh dried fruit powder 1.73% [120] 9 Microwave- assisted extraction Flower 60% ethanol 1:30 NA 20 min 2 350 W 7.6% [121] 10 Enzyme- assisted extraction Fruit powder Ethanol, petroleum ether, ethyl acetate 1:8 (ethanol);

3:1 (petroleum ether);

2:1 (ethyl acetate)65 80 min 1 Enzyme 50 U/ml pH 5.2 6.92% [122] 11 Supercritical fluid extraction Subcritical water 1:30 140 20 min 1 Addition of 15% ethanol 0.7%−1.1% [124] 12 Flash extraction Water 1:25 8.5 3.5 min 1 2.73% [125] Solvent extraction

-

Yang et al.[109] reported that using 70% ethanol solvent, with the solid/liquid ratio of 1:15 and extraction temperature of 70 °C for 2 h, the yield of flavonoids from Siraitia grosvenorii fruit was 0.58%. Liang et al.[110] used water as the solvent and solid/liquid ratio of 1:30 to extract the leaves for 50 min and repeated three times, the content of flavonoids reached 1.32% (13.18 mg/g). Zhong et al.[111] also reported a method using 50% ethanol as extractant to extract kaempferol 3,7-O-L-dirhamnoside from vine and leaves three times, 3 h each time at 1:20 solid/liquid ratio, and the content of kaempferol 3,7-O-L-dirhamnoside was 1.47% (14.71 mg/g). In addition to water and ethanol, other organic solvents are used to extract flavonoids. Yang et al.[112] extracted a mixture containing ten flavonoids from Siraitia grosvenorii by using petroleum ether, chloroform, ethyl acetate, and n-butanol as solvents. These compounds include P-hydroxybenzoic acid, succinic acid, aloe emodin acetate, aloe emodin, palmitic acid, honokiol, coumarin, emodin, kaempferol 3,7-O-α-L-dirhamnoside and rapeseed sterol. It is worth noting that the bioactivity of Siraitia grosvenorii extract may be different due to various extraction solvents, as the antioxidant activity was higher in the flavonoid extract by the solvent of chloroform and methanol than that by petroleum ether and n-butanol solvent[49]. The solvent extraction is a simple, easy-to-operate method. However, due to its long processing time and low efficiency, some assistant methods are commonly applied.

Ultrasonic-assisted extraction

-

Ultrasonic-assisted extraction is another method of flavonoid extraction. Chu & Zhang[113] reported that at 1:30 solid/liquid ratio, the dried Siraitia grosvenorii fruit was soaked in 30% ethanol for 24 h, then treated with 70% power ultrasonic for 45 min at 70 °C, and resulted in 1.62% flavonoid yield. Rong et al.[114] observed that the extraction yield could increase to 1.76% under similar ultrasonic conditions using 40% ethanol and a solid/liquid ratio of 1:25. In addition, the yield of flavonoids extracted from the fruit could achieve 2.86% using 30% ethanol, solid/liquid ratio of 1:9, processing for 40 min at 80 °C combined with 250 W ultrasonic treatment[115]. Siraitia grosvenorii residue after mogroside extraction is another abundant source of flavonoids. With the processing time and temperature of 29.2 min and 50.65 °C respectively, accompanied with ultrasonic treatment at a solid/liquid ratio of 1:34.75, the extraction yield of flavonoids from Siraitia grosvenorii residue was 2.25%[116]. Stem, leaves, and flowers are other important parts to extract flavonoids from Siraitia grosvenorii. Lu et al.[117] and Zhang et al.[118] reported that under the condition of ultrasonic treatment with 80% and 67.55% of ethanol, 104 min and 43.62 min processing time, the solid/liquid ratios of 1:38 and 1:15, the extraction yield of flavonoids in stem/leaves and flowers were 4.01% and 6.54% respectively.

Microwave-assisted and enzyme-assisted extraction

-

Microwave-assisted extraction is an easy-to-operate, high efficiency and energy-saving method[119]. Qin & Liu[120] reported that using 50% ethanol as solvent and solid/liquid ratio of 1:30 and treated the Siraitia grosvenorii fruit powder with 650 W microwave power for 15 min, the flavonoid extraction yield was 1.73%. Besides, Zhang et al.[121] showed that the extraction yield of flavonoid from Siraitia grosvenorii flower reached 7.6% using 60% ethanol as solvent and solid/liquid ratio 1:30, microwave power 350 W, and extracted for two cycles with 20 min each.

Enzyme-assisted extraction is another mature technology to extract flavonoids from plants, which applies the high specificity of enzyme reaction to hydrolyze or degrade the cell wall. Thus, the structure of the cell wall will be broken, and the active compounds will be fully exposed to and dissolved in an extractant which facilitates the extraction[122]. In some cases, the enzyme not only breaks the structure of the cell wall but also increases the solubility of active compounds in solvent[123]. Wang et al.[122] used cellulase with a concentration of 50 U/ml to treat grounded dried Siraitia grosvenorii fruit. The treatment temperature and time were 65 °C and 80 min under pH 5.2 with the solvents of ethanol, petroleum ether, and ethyl acetate respectively, the average yield reached 6.921 g/100 g fruit (6.92%).

Supercritical fluid extraction and flash extraction

-

In Siraitia grosvenorii flavonoid extraction, Xu et al.[124] used subcritical water extraction and the optimal parameters were 15% ethanol and treated at 140 °C for 20 min. The content of total flavonoids in the extract varied between 0.7%−1.1% (7−11 mg/g).

For flash extraction, Liu et al.[125]used a solid/liquid ratio of 1:25, extraction time and temperature of 3.5 min and 8.5 °C and resulted in a flavonoid yield of 2.73% using JHBE-50S flash extractor. This technology is of high efficiency and low cost and is suitable for industrial-scale production.

Extraction of other components

-

In Siraitia grosvenorii, oil and polysaccharides are two other components that could have potential commercial value. For oil extraction, the basic principle is using an organic solvent to extract due to non-oil substances are not or rarely soluble in the solvent. Ethanol and petroleum ether are commonly used. Fan et al.[126] used ethanol as a solvent under the condition of solid/liquid ratio of 1:10, and extract for 120 min at 70 °C, followed by centrifugation and drying to obtain Siraitia grosvenorii seed oil, with an oil extraction yield of 11.11%. Wang et al.[77] also reported that using petroleum ether as an extractant, at the solid/liquid ratio of 1:6 and extracted at 80 °C for 6 h, the extraction rate of Siraitia grosvenorii seed oil was 8.17%, which is mainly constituted with linoleic acid (47.2%) and linolenic acid (24.53%). In addition, application of petroleum ether refluxing in the Soxhlet's extractor under ultrasonic conditions, higher oil yield (11.46%) and higher squalene content were achieved[127]. Wang et al.[73] reported that under the optimal condition of supercritical fluid extraction pressure 26.5 MPa, extraction time 2.33 h, processing temperature 45 °C with flow rate 20 L/h, the oil yield of supercritical CO2 extraction method could reach 6.68% of which 16.81% was squalene. Supercritical CO2 showed higher extraction efficiency on linoleic oil (30.78%) and squalene (16.81%) extraction than subcritical extraction on linoleic oil (13.91%) and squalene (7.82%) from Siraitia grosvenorii residue after mogroside extraction[78].

The polysaccharide extraction method is very similar to that of flavonoids, which uses solvent extraction, enzyme-assisted extraction, and ultrasonic-assisted extraction methods (Table 6). Li et al.[128] reported the optimal condition for extracting polysaccharides at a solid/liquid ratio of 1:30, processing for two cycles and 4 h each time at 50 °C. The oil, monosaccharides, and protein were removed by petroleum ether, 80% ethanol, and Sevag method respectively. The yield of the polysaccharides was 0.66%. Cellulase is another useful extraction tool. Li et al.[129] used 500 U/g cellulase solution to process the grounded LHK fruit. The pH of the solution was 6.0, and the processing time and temperature were 55 min and 50 °C. Under these conditions, the polysaccharide yield was 6.80% which is 10%-22% higher than the conventional solvent-only extraction method. Chen et al.[130] also reported that using ultrasonic-assisted extraction method could increase the yield of polysaccharides to 6.39% under appropriate conditions (solid/liquid ratio 1:30, 70 °C, 300 W, 30 min) vs water extraction (5.56%).

Table 6. Various oil and polysaccharides extraction methods from Siraitia grosvenorii.

No. Components Extraction method Material Solid/

liquid ratioTemperature

(°C)Time Other conditions Yield Ref. 1 Oil Solvent extraction Seed 1:10 70 120 min 95% ethanol 11.11% [126] 2 Oil Solvent extraction Seed 1:6 80 6 h Petroleum ether 8.17% [77] 3 Oil Supercritical fluid extraction Residue NA 45 2.33 h 26.5 MPa Flow rate 20 L/h 6.68% [73] 4 Polysaccharides Solvent extraction Dried fruit 1:30 50 4 h Water as extractant 0.59% [128] 5 Polysaccharides Enzyme- assisted extraction Fruit 1:50 50 55 min 500 U/g pH 6 6.8% [129] 6 Polysaccharides Ultrasonic- assisted extraction Fruit 1:30 70 30 min 300 W 6.39% [130] Siraitia grosvenorii functional component extraction patent status

-

Many patents have been registered for Siraitia grosvenorii functional component extraction, including mogroside, polysaccharides, proteins, and others, in which most of the patents are about pure mogroside extraction or complex extract. Patent US20190133166A1[131] published a method to extract mogroside V from Siraitia grosvenorii fruit(LHK). The technology includes pre-treatment, continuous countercurrent water extraction, centrifugation, enzymolysis, ultrafiltration, nanofiltration, decolorisation, concentration, and microwave drying. It uses 0.01%−0.03% enzyme (a complex liquid enzyme of cellulase, pectinase, and protease mixture from Novozymes) assisted water extraction treats the fruit at 30−50 °C, pH 3−6 for 2−4 h, and then membrane separation is applied to isolate and purify mogroside. In the ultrafiltration and nanofiltration processing, the molecular weight cut-off of the membranes is 80,000−100,000 and 600−5,000, respectively. The following step uses a resin column to decolorise the mogroside. This method demonstrates some advantages. First, the countercurrent water extraction reduces water consumption and extraction time, and saves energy. Second, nanofiltration also saves water and reduces sewage. Third, the membrane separation/purification avoids using organic solvents, which is environmentally friendly. The continuous large-scale production is applicable in practical industrial processing.

A Chinese patent CN110669095A[132] also published an extraction method of high purity mogroside V. Its processing flow includes post-freezing high-temperature pre-treatment, ambient ultrahigh pressure extraction, clarification, purification, concentration, and drying. This patent uses a clarifying agent of ZTC-II to clarify the extract (remove polysaccharides and proteins) and aa C18 column to purify the product, with 25%−35% acetonitrile-water solution as the purification solvent. The advantages of the patent include high efficiency, high purity, and time and energy saving. The clarifying agent of ZTC-II shows higher efficiency on polysaccharide and protein removement compared with Ca(OH)2 hence resulting in higher mogroside yield and purity. The acetonitrile-water system reduces organic solvent usage and is environmentally friendly.

Another Chinese patent CN110105458A[133] published a method to extract polysaccharides and D-mannitol from Siraitia grosvenorii liquid waste after mogroside extraction. The processing steps include ultrafiltration and decolorisation, gel column chromatography, alcohol settlement, and crystallization. The purity and yield of the polysaccharides could reach 95% and 92% respectively, whereas the purity and yield of D-mannitol could reach 98% and 92%. The advantages of the method are that it is easy to operate, short processing time, low cost with less effluent, and is suitable for large-scale production.

In addition to directly extracting sweet compounds from Siraitia grosvenorii, using an enzyme to catalyze the transfer of bitter compounds to sweet compound mogroside has also been registered as a patent. The patent CN110669809A[134] uses UDP glucosyltransferase UGT032 enzyme to catalyze mogroside IIE and III and transfer to mogroside IV and V. This technology can enhance the sweet taste of the Siraitia grosvenorii extract. The processing condition is mild with easy to control and fewer by-products and is suitable for industrial-scale production.

Furthermore, waste obtained from centrifugation extraction of Siraitia grosvenorii can be used for amino acid production via multi-pH-condition enzyme treatment and dual-phase membrane separation[135], where other components of starch[136] and proteins[137] can also be extracted from Siraitia grosvenorii via various methods including enzyme treatment or microwave assistance. The registration of these patents suggests the wide interest in Siraitia grosvenorii industry about the functional component extraction and potential application.

-

The fruit of Siraitia grosvenorii is a traditional Chinese medicine in treating throat and pulmonary diseases. In recent years, due to its intense sweetness, more studies focus on its mogroside extraction and commercialization as a natural sweetener[138], healthy products[139], and new food products containing Siraitia grosvenorii extract[140].

Siraitia grosvenorii food-related product development

-

Considering mogroside as a food additive (sweetener) started in 1995, but it didn't receive GRAS certification from FDA until 2010[141,142]. China launched a national standard to regulate mogroside additive in 2016[143] and Australia approved monk fruit extract as a food additive in 2018[144]. The development of mogroside-related food additives also attracted great attention. Lin et al.[145] developed a natural sweetener composed of mogroside, stevia, citric acid, sodium chloride, and glycine at different ratios. The sweetener has a high sweet intensity (400 times than sucrose) with low-calorie characteristics. Parker et al.[146] conducted a sensory evaluation to measure consumers' acceptance of the natural sweetener. The research revealed that a protein beverage with sugar-reduced formula (25% stevia / 25% monk fruit / 50% fructose) and all-natural sweetener formula (25% stevia / 75% monk fruit) showed the highest acceptance. This research also confirmed that consumers prefer the beverage with all-natural sweetener labeling. Another study reported that the Siraitia grosvenorii extract could be distinguished from other sweeteners by its yellowness color, honey-like flavour, and licorice flavor[147]. The bitterness and acridness were not significantly different to sucrose, and the extract exhibited a delayed peak sweet intensity with sustained sweet aftertaste[147]. Research also confirmed that combining mogroside, with Rebaudisides M (a type of stevia) and sucralose as a complex sweetener in yogurt, could obtain a similar taste to the yogurt containing sucrose only as the sweetener[148].

In addition to use as food additives, mogroside is used as a cigarette additive[149] and liquor flavoring substance[150] to adjust cigarette and liquor sensations. Besides mogrosides, the Siraitia grosvenorii's flower extract could enhance the preservative capability of applefruit[151]. LHK had also been applied in many food products due to its sweetness and throat-relieving sensation. Zhang et al.[152] developed a compound beverage containing no synthetic additives, which was mainly the water extract of several dried plant materials including dried Siraitia grosvenorii fruit, lemon, and kumquat, whereas Siraitia grosvenorii acted as a sweetener and flavor enhancer. Teng[153] combined Siraitia grosvenorii juice with cured palm by-product (salted liquid for palm curing) to develop a Siraitia grosvenorii vinegar using honey as the favorable sugar. The cured palm by-product had been used by Chinese in southern China to treat throat and oral cavity disease and Siraitia grosvenorii could relieve cough and reducing sputum. The new product of Siraitia grosvenorii vinegar could enhance these benefits and have a broader application.

Interestingly, a traditional Chinese medicine (TCM) developed from LHK has been made into candy-like products. Liu et al.[154] developed a chewable tablet according to a traditional Chinese medicine recipe Ganjietang. Based on licorice and platycodon grandiflorum, the polygonatum odoratum, fructus mume, and Siraitia grosvenorii were introduced into the recipe to obtain TCM thick extract paste via decoction, filtration, and concentration. The extract was mixed with microcrystalline cellulose, mannitol, and magnesium stearate on the ratio of TCM extract : microcrystalline cellulose : mannitol = 1:2:3, with 0.1% magnesium stearate. An integral, glossy, compact chewable tablet with uniform color and well chewiness was produced under this condition (Table 7).

Table 7. Some selected Siraitia grosvenorii (LHK) food products.

No. Product type Product name LHK role Key ingredients Sensory characteristics Ref. 1 Compound beverage Sour carambola & LHK compound beverage Major ingredient Sour carambola juice 9%, LHK extract 4%, aspartame 0.03%, table salt 0.05% Light yellow liquid, uniform and stable colour & body, no impurities and precipitation, no off-taste, possess unique sour carambola flavour, moderately sweet & sour taste [180] 2 Anti-haze Qingfei Drink Minor ingredient Astragalus membranaceus 9%, LHK 2%, pear 50% & xanthan gum 0.1% Uniform & translucent body, possess pear fruit & medicinal aroma, appropriate sour & sweet taste with proper mouth perception; Significant improvement on haze mice's pathological lung damage after mice test were proved. [181] 3 Purple Sweet potato residue functional beverage Major ingredient Purple sweet potato residue anthocyanins extract 70 mL, LHK extract 30 mL, sucrose 6 g/100 mL Bright purple liquid with unique flavour and aroma of purple sweet potato & LHK, liquid exhibit uniform & stable state, no phase separation or precipitation, no impurities and suspended matter, sour & sweet taste with palatability, no off-odour. Anthocyanin [182] 4 Wine Sweet glycosides-free fruit wine Major ingredient Sweet glycosides-free LHK juice (residue after glycosides extraction), diluted at 1:60 ratio, fermentation temperature 28 °C with 7% Golden yellow wine, clear, translucent, and shiny wine body, slightly darker than LHK juice. The wine taste is fresh and soft, with obvious LHK fruity aroma & new [183] 5 LHK tea fermented wine Major ingredient LHK tea extract : bean sprout juice = 6:1, yeast 5% (v/v), inoculation time 12 h, fermentation time 6 d at 30 °C The wine has a yellowish-brown colour, transparent and shiny body, with mellow and soft sensation. The wine possesses slight sweet taste with harmonious fruity & wine aroma, where LHK flavour is obvious. The alcohol content 6.5% vol [184] 6 Tea beverage Hawthorn leaf tea beverage with LHK flavour Flavour ingredient Hawthorn leaf extract 80 ml/100 ml, LHK concentration 6 g/100 ml, Vc 0.08 g/100 ml Moderate sweet & sour taste, soft sensation with intense aroma, low-calorie [185] 7 Sugar-free LHK & Chrysanthemum tea beverage Major ingredient LHK extract : chrysanthemum extract = 5:5, citric acid 0.02%, stevioside 0.003%, xanthan gum 0.15% Bright reddish-brown liquid with uniform and clear body, no impurities visible to the naked eye; with LHK & chrysanthemum unique scents and flavours; The beverage possess sweet and sour taste, with harmonious scent and without peculiar smell, as well as cool & refreshing sensation [186] 8 Fermented beverage Sweet glycoside-free LHK vinegar Major ingredient Sweet glycoside-free dilution at 1:40 ratio using water, fermented at 30°C where the kombucha culture is 15% addition The acid content could reach 17.04 g/kg after 11 d fermentation, which the highest content [187] 9 Low-sugar fermented beverage with rose residue Minor residue Rose residue extract : LHK extract = 1:2, LAB ferment powder (culture) 3%, ferment time 12 h, xanthan gum 0.04%, CMC-Na 0.03%, glucose 2.4 g/100 g Light-red liquid with delicate fragrance of rose and LHK. Appropriate stickiness and fluidity, proper sweet & sour taste, no peculiar smell, and impurities. Sugar content less than 5 g/100 ml which is low-sugar beverage [188] 10 Solid beverage LHK solid beverage Major ingredient LHK Solid/liquid ratio 1:20 (kg/L), extract temperature 80 °C, extract time 30 min Dark-brown powder or granules, reddish-brown liquid after resolution. Transparent liquid body with the unique flavour and smell of LHK, combined with appropriate sweet taste [189] 11 Fufangqingfei Effervescent tablets Major ingredient Dry extraction powder (DEP) : dried tangerine peel, Lonicera japonica, LHK, Lily, Semen Cassiae, the materials were soaked for 30 min using 50% ethanol twice, 80 min each time. The solid/liquid ratio is 1:14 (w/w); Sour material : Citric acid 19.78%, DEP 17.5%, lactose 15%, proper 1% PEG6000 ethyl absolute solution; Alkaline source : sodium bicarbonate 15.22%, DEP 17.5%, lactose 15%, proper 1% PEG6000 ethyl absolute solution, then mix acid and alkaline source Short disintegration time (189 s), high CO2 release amount (1,091 mg/tablet) [190] 12 Dairy product LHK yoghurt Major ingredient Applying microwave-assisted and 70 °C hot water dual-extraction method to obtain LHK extract, where the ratio of bacillus and cocci of the culture is 1:4. Applying normal yoghurt fermentation technology, where the LHK extract were added before and after fermentation Light-brown liquid, rich taste, with intense LHK and fruit fragrance. The liquid has suitable viscosity & fluidity, where no instable situation occurred, such as stratification or precipitation when placed for 90 d at 5°C. The milk solid is 7%−8%, protein 2.0%−2.5%, and acidity is 65−70°T [191] 13 Food LHK chewable tablet Major ingredient LHK extract 15%, starch 33%, microcrystalline cellulose 25%, mannitol 20%, citric acid 0.5%, magnesium stearate 1.5% The tablet has smooth surface, uniform color with LHK unique aroma and sweet & sour taste. The tablet has a certain effect on gram-positive bacteria, of which the most effective object is to against Staphylococcus aureus. It has no antibacterial activity on Pseudomonas aeruginosa [192] 14 Passion fruit soft candy Flavour ingredient Passion fruit juice 20 g, LHK extract 7 g, compound gel 6 g (gelatin : agar powder = 3:1, m/m) Soft candy has pure color, moderate hardness, unique flavor & taste with best sensation. The water content of the candy is 16%−25% [193] 15 Ginkgo nutritional powder Flavour ingredient Ginkgo powder 2 g, almond powder 1 g, LHK powder 1 g, sugar 1.5 g The nutritional powder's color is uniform and light brown, and the solution is brown and uniform liquid. The liquid has smooth taste, with unique ginkgo, almond and sweet LHK flavour [194] Some other main applications of Siraitia grosvenorii in food industry are summarized in Table 7, which indicates that the Siraitia grosvenorii have been applied in compound beverages, wine, tea beverages, fermented beverages, solid beverages, dairy, and other food products. It should be noted that only a few food products (LHK nutrition powder)[155] emphasized its health effects, including hypoglycemic index and non-caloric properties[156]. Therefore, more attention should be paid to the development of potential health food products of Siraitia grosvenorii to meet different consumer demands.

Additionally, the safety of mogroside (monk fruit extract) needs to be considered. Dan et al.[157] tested the potential toxicity of mogroside. The mice test proved that mogroside has no damage to the autonomic activity and climbing pole ability of mice in the dose range of 0.075−0.3 g/kg (dose 5.25−21 g/d for a 70 kg adult). The blood pressure and electrocardiogram of the tested rats are stable vs the control group (feeding distilled water instead of mogroside). The heart rate of another test mice group (dose 0.0625−0.25 g/kg for rats, equals dose 4.375−17.5 g/d for a 70 kg adult) has no significant difference with control group (feeding with distilled water instead of mogroside). These results indicate that mogroside has no adverse effect on mice's neural systems and rats' cardiovascular systems. In addition, the EFSA panels on food additives and flavorings evaluated the safety of monk fruit extract as a new food additive[158]. The result showed that the mogroside has a negative effect on bacterial reverse mutation assay and does not induce structural and numerical chromosomal damage, which does not influence the reproductive and developmental function of rats. In addition, no maternal and developmental toxicity was observed. However, due to the limited toxicity database, the panel believes it is insufficient to conclude monk fruit extract as a safe additive, at this stage.

Siraitia grosvenorii medical-related product development

-

The Chinese traditional medicine normally uses dried plants as raw materials and their water or ethanol extracts as the medicine. In contrast, healthy or functional foods are believed to have some specific health functions or intended to supplement vitamins and minerals, that are suitable to a particular group of people to promote immunity or regulating health, and have no acute, subacute, or chronic harm to the human[159]. Siraitia grosvenorii has been developed for various medication forms such as pharyngeal tablets which possess anti-inflammatory and analgesic effects[10,160], and syrup which possess anti-tussive, anti-inflammatory, and immunological effect[10,161,162]. It should be noted that pharmacological tests and clinical tests should be performed to validify the claimed health effects.

Siraitia grosvenorii product-related patents

-

The patents related to Siraitia grosvenorii products are mainly about food additive products. Usually, the combination of different materials is the primary concept. Patent US9609887B2[163] developed a sweetener composition containing monk fruit extract (Siraitia grosvenorii extract) and Rebaudiside A and B, which could be used to enhance the pleasant taste compared with other non-caloric sweeteners. Many patents have highlighted multiple usages, such as dry mixes, baked products, beverages, dietetic products, and veterinary products, even tobacco or cigarette products[164−167].

Some Chinese patents published methods using Siraitia grosvenorii as major or minor ingredients to produce multi types of food with various recipes (Table 8), such as noodle or mousse cake[168,169]. Besides, some patents applied Siraitia grosvenorii beyond the food or food additive field (Table 8), which was used in cigarette paper oil[170] or the cosmetic field[171]. These wide applications revealed the potential of Siraitia grosvenorii to be used in food and other relevant industries, including healthcare, medical, cigarette and alcohol, and the cosmetic industry (Table 8).

Table 8. Selected patents of application of Siraitia grosvenorii (LHK) in different products.

No. Product type Product name Patent formula and specialty Tracking no. & published year 1 Food LHK stirred noodle Recipe (serving): flour 400−500, soybean flour 50−60, corn flour 20−30, water 180−220, salt 4−6, sugar 2−4, butter 50−60, LHK 60−80. Features: mellow & smooth sensation with high nutritional value & medicinal value. The product has a clearing effect and beneficial to the throat, intestine and blood circulation. There is also a beauty effect. CN108713753A, 2018[169] 2 LHK mousse cake Recipe (serving): cream 260−340, gel 3−5, konjac powder 5−7, milk 60−80, LHK 20−40, yolk 40−60, sugar 45−55, lemon juice 3−7. Feature: LHK juice is sweet which could reduce sugar amount, which fits children to consume to avoid the risk of dental caries. CN09105424A, 2019[168] 3 Ganoderma & LHK jelly Recipe (serving): fresh Osmanthus 20−40, fresh LHK 40−100, Ganoderma 10−30, licorice 5−15, xylitol 30−70, water-retaining agent 30−80, gelling agent 10−30, sucralose 0.1−0.3. Feature: the jelly contains CN111011784A, 2020[195] 4 Food ingredient Protein-free pure LHK concentration Technology: The LHK fresh fruit were compressed, and the residue was extracted by ice water, then adjust pH to alkaline. Then add protease to hydrolyze, then heated and centrifuged. Followed by cationic and anion exchange resin column purification. Feature: protein content < 0.1%, and the mogroside content is 4.53%, the yield could reach 98%; The concentration is a light-yellow, transparent, and thick liquid. The aroma of the liquid is refreshing and pleasant, the taste is intense sweet without peculiar taste. The sweetness is similar to sucrose. This technology is operable, safe, environmental and no-pollution occurred, which is applicable in industry. CN109247467A, 2018[196] 5 Natural LHK syrup Processing: LHK producing residue were refined, decoloured, decided, and the pesticide residue and heavy were removed from the residue. Then concentrated to obtain products. Feature: There no other components except LHK and water. No additives which can be applied in multiple products. The preparation method is simple and operable, and the product is valuable, and the waste is sustainable which does not need further treatment. This is a comprehensive utilization of the LHK producing residue, which possesses high economic value and suitable for industry application CN110527750A, 2019[197] 6 Food additive Mogroside flavour and taste compound Processing: the LHK were roasted, then the volatile oil was collected, extracted and refined. Then the extract was filtrated and clarified using ceramic membrane. Then separated and concentrated using membrane as well. Following by resin discolouration, deodourization, and the pesticide residue and heavy metal were removed. Active carbons were applied in the next step to remove peculiar smell, then clarified again using ceramic membrane and vacuum concentration. Feature: There is no bitter components in the compound, which possesses LHK flavour and nutritional components, which has intense fruity and burnt flavour and aroma. The compound has refreshing sweet taste which similar to sucrose, with short last time period, but the sweet taste has high saturation. The preparation technology

is simple with low cost.CN110521993A, 2019[198] 7 Dairy product LHK goat milk formula powder Recipe (serving): raw goat milk 5,000−6,000, desalt whey powder 200−300, concentrated whey powder 30−50, lactose 50−60, mixed canola oil 65−75, nutritional enhancer 10−15, colostrum powder 0.2−0.5, LHK powder 0.5−1, combined AB bacterial 0.2−0.4. Feature: LHK could reduce goat milks unpleasant flavour and improve the sensation and taste. The dry and wet process technology could guarantee the nutritional activity of each group. The milk powder has good uniformity. CN110999985A, 2020[199] 8 Tea beverage LHK fruit tea Recipe (serving): LHK fruit flesh 10−30, other fresh fruit 3−10. Feature: using 85−100 °C water to brew the tea, and the tea is a light-yellow colour and transparent liquid, with unique aroma and sweet & sour taste. The tea preserves the refreshing sensation and the taste of LHK and other fruits, without sugar addition. CN108740195A, 2018[200] 9 Imperatae rhizome

health-promoting teaRecipe (serving): Imperatae rhizome 30, taraxaci herba 10, chrysanthemum 10, LHK 4. Feature: clearing heat, resolving phlegm, relive cough, moist throat, promote excretion and fits all kinds of consumer CN111903817A, 2020[201] 10 Compound beverage Red physalis LHK qingyanrunhou beverage Recipe (serving): red physalis juice 50%−60%, loquat juice 8%−12%, Tremella fuciformis 12%−18%, pear juice 8%−12%, LHK juice 1%−3%, Lonicera japonica extract 2%−5%, mint extract 1%−3%, citri reticulatae pericarpium extract 0.5%−1.5%, Schisandeae chinensis fructus extract 0.5%−1.5%, phragmitis rhizome extract 1%−3%. Feature: using red physalis juice as main material, which has anti-microbial effect and enhance the stability of beverage. The product has good social and financial benefits. CN110301567A, 2019[202] 11 Solid beverage LHK compound effervescent tablets Recipe (serving): LHK compound beverage (LHK : Dried lemon : dried kumquat = 4:1.5:1.5), drying agent 125%, acid source and alkaline source 35% (acid : alkaline = 0.5:0.5), filling agent 10%. Processing: material selection, pre-treatment, extract, filtration, spray drying, mixing, tablet formation. Feature: dissolved rapidly, and the beverage obtained has unique flavour with sweet & sour taste. The tablet is easy to carry and fits the need of consumer. This product is also applicable to obesity and diabetic patients. CN111053178A, 2020[203] 12 Medicine A traditional chinese medicine composition for the treatment of mycoplasma synovial sac disease in chicken Recipe (serving): inula flower 20−30, aurantii fructus immaturus 10−20, bupleuri radix 5−10, paeoniae radixs alba 10−20, licorice 10−20, astragali radix 10−20, mori cortex 10−20, descurainiae semen lepidii semen 5−10, Fructus trichosanthis 10−20, poria 10−20, atractylodis macrocephalae rhizoma 10−20, codonopsis radix 10−20, angelicae sinensis radix 10−20, LHK 10−20, notopterygii rhizoma et radix 5−10, angelicae pubescentis radix 5−10, chaenomelis fructus 10−20, stephaniae tetrandrae radix 10−20. Feature: the treatment of the whole prescription is clear with reasonable compatibility. The prescription has synergistic effect of various herbs which could relive depression, promote body circulation, benefit to liver, spleen, and lung, and improve metabolite excretion. CN110403991A, 2019[204] 13 A traditional chinese medicine compounds to treat chronic pharyngitis Recipe (serving): LHK 10−20, mume fructus 10−20, platycodonis radix 8−15, licorice 5−12, taraxaci herba 5−12, sterculiae lychnophorae semen 5−10, chrysanthemi flos 5−10, gardeniae fructus 5−10, phyllanthi fructus 2−7, canarii fructus 2−7. Feature: The compositions are all composed of edible and medical source plant, with high safety and wide application range. The product can effectively treat chronic pharyngitis, and can obviously eliminate or relieve the pharyngeal discomfort caused by chronic pharyngitis, such as foreign body sensation, itching sensation, burning sensation, dryness and/or irritation sensation, as well as mild pharyngeal pain, pharyngeal cough, accompanying nausea, thickening of pharyngeal mucosa, sticky or sticky secretions, and other symptoms. CN110548077A, 2019[205] 14 LHK capsule Recipe: LHK compound extract 23%−27%, persimmon powder 5%−10%, corn starch 30%−35%, maltosedextrin 25−30, microcrystalline cellulose 5%−10%. LHK compound extract: using LHK extract as solvent to extract dried tea leaves, dry aloe leaves, dry hibiscus, dry basil, at a weight ratio 2:(0.5−2):(1−1.5):(0.1−1). Feature: this capsule has the effect of antioxygen, antimicrobial and immune improvement. CN104886594A, 2015[206] 15 Health care product A fungus substitute tea product which can relieve cough and moistening

lungRecipe: tremella 20%−30%, Pleurotus tuber-regium 20%−30%, ganoderma 20%−30%, LHK 10-20%, rhodiolae crenulatae radix et rhizoma 5%−15%. Feature: the brewed liquid has the effect to relieve cough and moistening lung, and no side effect observed after drinking, which makes it easy to produce and application. CN110279019A, 2019[207] 16

LHK health- promoting pulpRecipe (serving) : LHK 60−70, rice 30−40, honey 4−7, maltose 3−5, citric acid 2−3, chrysanthemi flos 10−20, mori folium 7−12, phragmitis rhizoma 5−9, platycodonis radix 6−10, schisandrae chinensis fructus 7−13, pectinase 5−9. Feature: the product has uniform yellow colour with good clarity, stability and appropriate sweet & sour taste, and possesses intense natural LHK aroma. CN110800898A, 2020[208] 17 Respiratory health- caring tea Recipe (serving): pear peel 10−80, houttuyniae herba 1−30, taraxaci herba 1−25, poria 1−20, platycodonis radix 1−20, LHK 1−25, citri reticulatae pericarpium 1−12, licorice 1−10. Feature: Products is suitable for people with diabetes, where there is no toxic side effects with high safety. It can inhibit airway inflammation, embellish lung phlegm, clear pharynx and larynx, detoxicating, and benefit to spleen. It has significant therapeutic effect on upper respiratory tract symptoms and respiratory diseases such as cough phlegm, caused by pathogenic microorganism, stay up late, overtime and excessive alcohol, tobacco, or environmental pollution. CN107616277A, 2018[209] 18 Alcohol Flavoured compound alcohol Processing: mix three solutions to prepare product. Solution A is composed of the zymolyte of LHK juice, stevia rebaudiana extract, Malus hupehensis extract; solution B is a reactant that obtained from reaction of LHK juice, stevia rebaudiana extract, Malus hupehensis extract and maltodextrin which was catalyzed by cyclodextrin glycosyltransferase. Then combine solution A, solution B and base liquor together and clarify to obtain compound alcohol. Feature: there are many functional components of the extracts, and the product could antioxidation and reduce body weight. CN110468015A, 2019[210] 19 Other applications A compound contains probiotic Recipe (serving): probiotics 10, lycii fructus juice 0.5−10, LHK extract 0.1−10, nutritional substrate 70−89.85. Feature: The compound could regulate the intestinal flora of animals and then treat diarrhea of animals. Compound can also be used in the field of fermentation to obtain feed; The compound can also be used to prepare biological products from the intracellular and extracellular separation of probiotics. CN110760463A, 2020[211] 20 LHK extract for cigarette Processing: LHK was enzyme hydrolyzed after mashing, then heated to deactivate enzyme. Following by ethanol extract twice, extract precipitation, vacuum filtration, and decompressed concentration. Feature: the product could provide soft and delicate smoke, increase sweetness, reduce irritation, and improve throat comfort. CN111466609A, 2020[212] 21 LHK flavonoids cigarette paper Process: LHK flavonoid material separation, purification, light oil of LHK flavonoids cigarette paper preparation, LHK flavonoids cigarette paper preparation, LHK paper crimping, drying, cutting and sealed preservation. Recipe (serving): acrylic resin 13−17, nitrocellulose 6−7, polyketone resin 6−7, ethyl ester 18−22, isopropyl ester 4−5, LHK flavonoids 1. Feature: The process of the product is simple. LHK flavonoids can improve the aroma, cover up the impurity gas, improve the smoothness and softness of the flue gas and increase the sweetness of the flue gas. CN111764194A, 2020[170] -

Siraitia grosvenorii is well-known as Huo Han Kuo and is mainly cultivated in the Guangxi Province of China and southeast Asian. It has various functional components in which the most important compounds are a group of cucurbitane-type triterpenoid glycosides and mogroside V is the representative. The high sweet intensity and non-caloric properties makes it a novel natural sweetener. Mogroside V could be used to treat diabetes, respiratory tract inflammation, and lung diseases. Flavonoids are another important group of compounds in Siraitia grosvenorii, with potential health benefits of antioxidant and antibacterial effect, and promoting blood circulation. Furthermore, polysaccharides, proteins, and oils are also functional components in Siraitia grosvenorii.

Water or organic solvent extraction are the most common methods in the extraction of mogroside, flavonoids, and other components from Siraitia grosvenorii, and microwave and ultrasonic are always combined to enhance the extraction efficiency. Flash extraction and supercritical fluid extraction are also used, whereas flash extraction possesses better industry application potential. The most used separation and purification method includes membrane separation/purification and macroporous adsorption resin column separation/purification.

Siraitia grosvenorii especially its fruit has been used in variable product development including food additives, food, and medical products. The natural but no caloric sweetener of mogroside makes it widely applicable. In addition, the application of other components from Siraitia grosvenorii such as flavonoids and oil, and the incorporation of these components in new product development also have great potential in industry.

This work was supported by Guilin Hengliyuan Biotechnology Co. Ltd., Guangxi, China.

-

The authors confirm contribution to the paper as follows: study conception and design, analysis and interpretation of results, draft manuscript preparation: Fang Z, Ma S; data collection: Ma S; supervision, project management: Fang Z. All authors reviewed the results and approved the final version of the manuscript.

-

All data generated or analyzed during this study are included in this published article.

-

The authors declare that they have no conflict of interest.

- Copyright: © 2024 by the author(s). Published by Maximum Academic Press on behalf of Nanjing Agricultural University. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Ma S, Fang Z. 2024. Extraction of Siraitia grosvenorii functional components and product development: a review. Food Materials Research 4: e034 doi: 10.48130/fmr-0024-0019

Extraction of Siraitia grosvenorii functional components and product development: a review

- Received: 26 July 2024

- Revised: 14 September 2024

- Accepted: 03 October 2024

- Published online: 26 December 2024

Abstract: Siraitia grosvenorii is a traditional Chinese medicine with four main species in China. Its special botanical properties and cultivation requirement make it most suitable to be grown in the Guangxi Province of China. Siraitia grosvenorii's functional components include cucurbitane-type triterpenoid glycosides, flavonoids, polysaccharides, and others. Among these, the widely utilized component is mogroside, which is a sweet agent with the characteristics of high sweetness and low calories. Although traditional methods have been used to extract these components, advanced technologies are needed to improve extraction efficiency. In recent years, the commercialization of Siraitia grosvenorii extract or utilization of mogroside have attracted industrial attention, evidenced by the increasing number of new products and patent registration. This review summarizes the functional components of Siraitia grosvenorii with their extraction methods, as well as the most recent Siraitia grosvenorii product development and patent registration status. The future potential application of Siraitia grosvenorii was also proposed.

-

Key words:

- Siraitia grosvenorii /

- Mogroside /

- Extraction /

- Flavonoid /

- Food application