-

Consumer awareness for their health and lifestyle is driving the interest towards functional foods, forcing the industry to explore plants and potherbs as valuable ingredients as they provide a plethora of health benefits[1]. Among the vast selection of plants stinging nettle, also known as Urtica dioica L. is a perineal herbaceous plant predominantly growing in temperate regions of Asia, Europe, North Africa, and North America up to an altitude of 1,800 m[2,3]. Urtica is derived from the Latin word 'uro', which means 'to burn', or 'urere', which means 'to sting'[4]. The plants reach approximately 2 m in height covered with stinging hairs with hooked protrusions that are present on the surface of the stinging nettle. When touched these nettles release biochemical mediators like histamine and acetylcholine from the hairs, known for instigating dermatitis[3,4]. Acetylcholine, formic acid, serotonin, and histamine are the active ingredients reportedly present in the stinging nettle trichomes. Stinging nettle leaves are also rich in functional properties due to the presence of bioactive substances such as phenolic compounds, flavonoids, organic acids, vitamins (such as vitamins A, C, and K) and minerals (such as iron, calcium, and magnesium) in addition to these important nutrients like volatile and fatty acids, tannins, polysaccharides, sterols, isolectins, terpenes, and proteins[5−12]. The various bioactive present in the stinging nettle plant including phenols and flavonoids have beneficial properties such as radical scavenging activity[10], reduction of skin irritation and alleviating allergy symptoms, pest management[13], easing the cramps and bloating as well as blood flow during menstruation[14], treatment of cough, cold, with wound healing properties[15].

Stinging nettle is well known for its application in vegetable and animal nutrition, also acts as an immune stimulant and growth regulator and can also be used as a botanical pesticide[10]. The presence of various bioactive compounds in this plant, including polyphenols, carotenoids, organic acids, fatty acids, and amino acids, makes it suitable for incorporation into various food products. The commercialization of the plant is highlighted by Jan et al.[2] as a coloring agent for food and pharmaceutical sectors. In contrast, there are certain functional products made with the infusion of stinging nettle such as pasta[16], nettle cheese[17], and bread[1]. A novel and creative method to combine the health benefits of this plant into a delectable confection is to fortify stinging nettle juice in ice cream[18]. Various products enriched with stinging nettle influence carotenoid and phenolic bio-accessibility during digestion. The products incorporating nettle leaves were found beneficial in maintaining the gut microbiota and the bio-accessibility of bioactive compounds[19,20]. Due to their high nutraceutical value, stinging nettles can be a healthy complement to ice cream. The fortified ice cream has already been prepared from sapota[21], Kunu-Zaki fortified with fruit pulp[22], flaxseed oil microcapsules, fortified ice cream[23], and herbal extracts ice cream[9]. A distinctive and exciting culinary experience can be provided by incorporating this distinct flavour of stinging nettle with ice cream. It gives ice cream lovers a chance to experiment with novel and unusual flavours[24]. Among various dairy food products, the nutritional value of ice cream is high, and due to its acceptability across all age groups not only makes it a valuable product but also aligns with market trends. Furthermore, its functional value can be increased by adding stinging nettle juice, making it a healthier dessert. Therefore, the present study aimed to develop and characterize stinging nettle-fortified ice cream.

-

The ingredients for ice cream include stinging nettle leaves, condensed milk, milk powder, milk cream, and sugar. The stinging nettle leaves were collected from the mountainous region of Solan district Himachal Pradesh, India. The collected leaves were washed with clean water and further blanched for 10 min at 50 °C, Afterwards the leaves were ground to extract the juice, stored at −20 °C. The other ingredients are condensed milk (400 ml Amul), milk powder (Everyday), milk cream (Amul), and sugar purchased from Solan district market, H.P., India.

Process of making ice cream

-

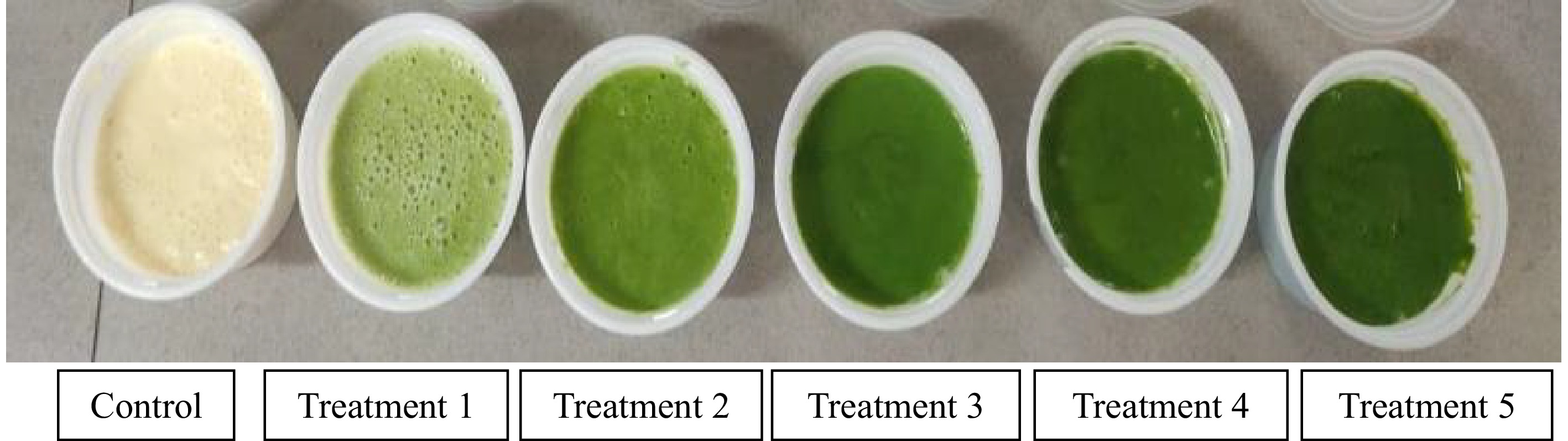

Initially, the condensed milk, milk powder, milk cream, and sugar were added and a homogenized mixture was prepared until all the clumps were removed and air was incorporated into the mixture. In this homogenized mixture, the stinging nettle juice was incorporated in different concentrations of 5%, 10%, 15%, 20%, and 25% as treatments T1, T2, T3, T4, and T5 respectively whereas the control treatment was prepared without incorporation of stinging nettle extract (Table 1). The blends were then poured into the containers and stored at −4 °C. The stored samples were homogenized at one-hour intervals so that air could be incorporated into it. The formulation of ice cream with the incorporation of stinging nettle is explained in Fig. 1 and the obtained results are pictorially presented in Fig. 2.

Table 1. Treatment table for control and stinging nettle extract incorporated ice cream.

Ingredients C T1 T2 T3 T4 T5 Stinging nettle juice (%) 0 5 10 15 20 25 Milk cream (%) 45 40 35 20 25 20 Condensed milk (%) 40 40 40 40 40 40 Milk powder (%) 10 10 10 10 10 10 Sugar (%) 5 5 5 5 5 5 Total (%) 100 100 100 100 100 100 C: Control; T1: Treatment 1; T2: Treatment 2; T3: Treatment 3; T4: Treatment 4; T5: Treatment 5. Sensory evaluation

-

We begin with sensory analysis when all the ice cream treatments were formulated. For sensory analysis, the panel members were from the School of Bio-Engineering and Food Technology, Shoolini University, H.P., India. The panel members were given the formulated ice cream and a Performa on which they gave the rating based on a nine-point Hedonic scale where each number represented a preference as 9: Like Extremely, 8: Like Very Much, 7: Like Moderately, 6: Like Slightly, 5: Neither Like nor Dislike, 4: Dislike Slightly, 3: Dislike Moderately, 2: Dislike Very Much, 1: Dislike Extremely; for the ice cream according to color, texture, flavor, appearance, and overall acceptability. According to the sensory analysis results the best ice cream treatment was selected for further analysis[25].

Proximate analysis

-

The total soluble solids (TSS) of the samples were recorded using hand refractometer represented as ºB [AOAC 2000], similarly the titratable acidity was determined as per (AOAC, 2000) method and pH was monitored using a pH meter (CpH-102, M/s., India)[26]. The crude fat content of ice cream samples was estimated by using the Soxhlet apparatus as described in AOAC (1990)[27]. The protein content of ice cream was determined by using the AOAC (2005) Lowry method respectively and the absorbance is measured at 540 nm using a UV-Spectrophotometer[28], and shelf life[29]. The free radical scavenging activity (RSA) was measured using diphenyl-picrylhydrazyl (DPPH) assay. The absorbance was measured at 515 nm using a UV-Spectrophotometer[8,30]. Folin-Ciocalteau (FC) technique analysis was conducted for the total polyphenolic content (TPC), the absorbance was measured at 725 nm. Gallic acid was used as a standard for the calibration curve. Total phenolic content was expressed as mg gallic acid equivalents per gram of sample (mg/g)[8,30]. Mineral content (Ca, Na, Fe, and Mg) estimation was done using the AACC International (2012) method No.40–70.01 using (ICP-OES)[28]. Texture profile analysis (TPA) of ice creams was analyzed using the TA-XT plus texture analyzer[31]. FTIR measurements were made with an IRSpirit (SHIMADZU) spectrometer and then averaged after undergoing Fourier processing. Thermo Fisher Scientific's Grams/AI 8.0 software was used to process and analyze them[32].

Overrun

-

In ice cream preparation, overrun is created by incorporating air in the mixture to increase the volume. The quality of ice cream is influenced by the amount of air incorporated. It is equivalent to the % of the added air during the whipping–freezing process and that was determined gravimetrically[33] using a typical volume of aged mix and frozen end product (50 mL) as follows:

$ Overrun\; \text{%}=\dfrac{\mathrm{We\mathrm{i}}\mathrm{g}\mathrm{h}\mathrm{t}\; \mathrm{o}\mathrm{f}\mathrm{ }\mathrm{i}\mathrm{c}\mathrm{e}\; \mathrm{c}\mathrm{r}\mathrm{e}\mathrm{a}\mathrm{m}\; \mathrm{m}\mathrm{i}\mathrm{x}\; \left(\mathrm{g}\right)-\mathrm{W}\mathrm{e}\mathrm{i}\mathrm{g}\mathrm{h}\mathrm{t}\; \mathrm{o}\mathrm{f}\; \mathrm{i}\mathrm{c}\mathrm{e}\; \mathrm{c}\mathrm{r}\mathrm{e}\mathrm{a}\mathrm{m}\; \left(\mathrm{g}\right)}{\mathrm{W}\mathrm{e}\mathrm{i}\mathrm{g}\mathrm{h}\mathrm{t}\; \mathrm{o}\mathrm{f}\; \mathrm{i}\mathrm{c}\mathrm{e}\; \mathrm{c}\mathrm{r}\mathrm{e}\mathrm{a}\mathrm{m}\; \left(\mathrm{g}\right)}\times100 $ Melting rate test of ice cream

-

The melting rate at 25 °C was calculated using ice cream samples (50 g) of the same size and form. The ice cream specimen was placed on a mesh screen, and the melting sample was collected in a Petri dish below. As a function of time, the weight of the dripping liquid was measured as it passed through the screen and into the Petri dish. The melting rate was checked by plotting the time (min) against the dripping liquid's weight (g) and using the slope of the major melting event as the reference point[28].

-

The developed stinging nettle enriched ice-cream are presented in Fig. 2. The change in color of the ice cream can be clearly seen upon the increase in concentration of the stinging nettle juice.

Sensory evaluation

-

The sensory attributes of stinging nettle fortified ice cream were evaluated by the panelists based on a nine-point hedonic scale, according to the sensory analysis, the best treatment was selected based on the appealing look, pleasant aroma, well-balanced flavor profile, creamy texture, and an aftertaste that leaves a favorable impression. Treatment 2 (T2) was selected as the best among the five treatments and received the highest overall acceptability rating of 8.44 ± 0.57, its excellent color 8.33 ± 0.00, texture 8.66 ± 0.57, flavor 8.06 ± 0.57, and appearance 8.69 ± 0.57, as compared to the scores for control treatment for different parameters like color 8.10 ± 0.00, texture 8.50 ± 0.00, flavor 8.00 ± 0.00, appearance 8.50 ± 0.00 and overall acceptability 8.20 ± 0.00. Table 2 shows a high score for different sensory attributes for prepared ice-cream thus recognizing that U. dioica can be fortified as an acceptable new ingredient in ice-cream. Similar acceptability based on sensory evaluation has been observed previously for dry fruits enriched nettle cheese ice cream prepared with nettle cheese, almonds, crispy nettle leaves, cherries, and black cherry gel[17]. The acceptability of the product can depend on various factors like color, taste, flavor, appearance, and texture of the sample. The results obtained in Table 2 are also graphically presented in Fig. 3.

Table 2. Sensory evaluation of stinging nettle (U. dioica) extracts incorporated ice cream.

Parameter Control T1 T2 T3 T4 T5 Color 8.10 ± 0.00 9.00 ± 0.57 8.33 ± 0.00 6.00 ± 0.57 5.33 ± 1.54 4.66 ± 1.02 Texture 8.50 ± 0.00 8.00 ± 1.15 8.66 ± 0.57 6.00 ± 1.00 5.66 ± 1.54 5.00 ± 1.00 Flavor 8.00 ± 0.00 8.33 ± 0.57 8.06 ± 0.57 6.66 ± 0.57 5.66 ± 1.02 4.66 ± 0.57 Appearance 8.50 ± 0.00 7.99 ± 1.52 8.69 ± 0.57 6.66 ± 1.52 6.00 ± 1.00 4.66 ± 1.52 Overall acceptability 8.20 ± 0.00 8.28 ± 0.95 8.44 ± 0.57 6.33 ± 1.02 5.91 ± 0.97 4.75 ± 1.00 Proximate and physico-chemical analysis of U. dioica

-

The TSS of stinging nettle leaves was recorded at 8.50 ± 0.06 °B, total phenols 19.09 ± 0.13 mg GAE/g dry leaves, and antioxidant activity 73.03% ± 1.87%. The pH of stinging nettle (U. dioica) leaves was observed at 6.30 ± 0.05 and varied depending on various factors, including soil and environmental factors. Generally, stinging nettle prefers slightly acidic to neutral soil conditions. Leaves of stinging nettle are also a rich source of minerals like calcium 1,193.73 ± 8.462 mg/kg, sodium 1,414.53 ± 8.859 mg/kg, magnesium 76.14 ± 1.260 mg/kg, and iron with a concentration of 0.01 ± 0.002 mg/kg. The physicochemical analysis is represented in Table 3.

Table 3. Physico-chemical characteristics of U. dioica.

Parameters Readings TSS (°Brix) 8.50 ± 0.06 pH 6.30 ± 0.05 Titratable acidity (%) 0.33 ± 0.018 Total phenols (mg GAE/g dry leaves) 19.09 ± 0.13 Antioxidant activity (%) 73.03 ± 1.87 Mineral content Calcium (mg/kg) 1,193.73 ± 8.462 Sodium (mg/kg) 1,414.53 ± 8.859 Iron (mg/kg) 0.01 ± 0.002 Magnesium (mg/kg) 76.14 ± 1.260 Proximate and physico-chemical analysis result

-

The standard ice cream (control) and best-chosen stinging nettle fortified ice cream (Treatment 2, T2) were analyzed for different characteristics and the results are presented in Table 4.

Table 4. Proximate and physico-chemical characteristics of control ice-cream and U. dioica extract incorporated ice-cream.

Parameters Control ice cream U. dioica extract incorporated

into ice creamTSS °B 32.00 ± 1.10 35.00 ± 1.85 pH 5.71 ± 0.24 6.10 ± 0.29 Titratable acidity (%) 0.24 ± 0.02 0.29 ± 0.03 Total phenols (mg GAE/g dry leaves) 14.19 ± 0.66 22.12 ± 2.07 Antioxidant activity (%) 7.25 ± 0.02 38.33 ± 1.35 Protein (μg/mg) 633.33 ± 1.607 781.90 ± 0.615 Fat (%) 2.072 ± 0.003 2.348 ± 0.0335 TSS

-

Generally, the TSS of ice cream ranges from 30% to 40%, although some premium or specialty ice creams may have higher TSS levels. The control sample TSS is 32.00 ± 1.10 °Brix and the TSS of U. dioica extract incorporated ice cream was recorded at 35.00 ± 1.85 °Brix which falls into the range of desirable TSS of ice cream. The results showing the increase in total solid content of about 10% is recorded due to the presence of bioactive compounds and biomolecules in stinging nettle juice. The total solids of the ice cream prepared using ultrasound technology from oleogel extracted from tomato seeds oil were found in the range of 36.48 ± 0.11 to 36.86 ± 0.27[33], and 35.15 to 37.24 in sapota fruit pulp ice cream[21].

pH

-

The pH of ice cream can vary depending on its formulation, flavourings, and other ingredients used. Generally, ice cream falls within a slightly acidic to neutral pH range. However, it's important to note that the variation in the pH depends on factors such as specific recipes, additives, and processing conditions. The control ice cream sample pH was 5.71 ± 0.24 and the U. dioica extract incorporated ice-cream pH was observed 6.10 ± 0.29. The slight increase in pH was due to the higher acidity of stringing nettle juice (ranging from 6.00 to 6.54). The findings were consistent with the pH of the ice cream developed ultrasound technology from oleogel extracted from tomato seeds oil in the almost similar range of 6.37 ± 0.01 to 6.46 ± 0.01[33].

Titratable acidity

-

Many organic acids are identified in U. dioica such as citric, formic, malic, silicic, succinic, oxalic, threono-1,4-lactone, etc. The control ice cream sample acidity was 0.24% ± 0.02% and the U. dioica extract incorporated ice-cream acidity came across 0.29% ± 0.03% and the changes is not very significant. The slight enhancement in titratable acidity could be due to the acidic nature of stinging nettle juice. However titratable acidity in the range of 0.10% ± 0.02% to 0.19% ± 0.02%[34].

Determination of polyphenol content

-

The total amount of phenolic compounds present in the control ice cream was 14.190% and the U. dioica extract incorporated in ice cream shows up to 22.129% in 100 μL of the sample. The increase in TPC suggested a higher concentration of phenols present in the fortified ice cream sample as compared to the control ice cream sample. The result clearly indicating that the addition of stinging nettle juice increased the bioactive compounds like phenolic content in ice cream. Previously in case of rowanberry pulp added ice cream the total phenolic content values of ice cream samples ranged from 89.05 to 127.86 mg GAE/g which corroborates the present findings[34].

Determination of antioxidant activity

-

Antioxidant substances found in stinging nettle include polyphenols: including flavonoids like quercetin, kaempferol, and rutin as well as phenolic acids like caffeic acid and chlorogenic acid. The antioxidant activity of the control ice cream sample was recorded as 38.33% and the U. dioica extract incorporated ice cream sample exhibited antioxidant activity of 49.44%. This value indicated that the particular fortified ice cream sample showed a higher level of antioxidant activity compared to the control. The increase in percentage inhibition is owing to the presence of various bioactive compounds in the stinging nettle juice and this results clearly suggests a greater ability to neutralize free radicals and protect against oxidative damage. The antioxidant activity of the bioactive compound fortified food product often increased owing to the presence of various free radical scavenger in plant-based extract[35]. A similar increase in the antioxidant capacity was observed from 36.92% ± 0.29% to 53.08% ± 0.21% was observed in ice creams with an increase in rowanberry pulp[34].

Determination of protein content

-

Ice cream often contains protein because milk and/or cream are its main ingredients. The casein and whey proteins found in milk and cream are considered excellent protein sources. However, elements like the fat content, milk solids, and extra components like mix-ins or flavourings can have an impact on the protein amount of ice cream. The control ice cream had 633.33 ± 1.607 (μg/mL) of protein in 100 μL sample and U. dioica extract incorporated ice cream contained 781.90 ± 0.615 (μg/mL) of protein with an increase in concentration the protein content also increases in the ice cream sample. However, previously it has been reported that protein content was in the range of 12.31 ± 0.06 to 13.80 ± 0.05 (g/100 g) in ice cream prepared using ultrasound technology from tomato seeds oleogel[32].

Determination of fat content

-

Ice cream must contain a minimum of 10% milk fat by weight to meet the FDA's criterion of identity. Nevertheless, there are other variants of ice cream with lower fat content, such as reduced fat, light, or low-fat. The fat content of the control ice cream sample was recorded as 2.072% ± 0.003% and the fat content of the U. dioica extract incorporated ice-cream sample was recorded as 2.348% ± 0.0335%. These results show that the fat content in the control ice cream sample is lower as compared to U. dioica extract incorporated ice cream sample. The increase in fat % in the fortified sample is because of the incorporation of stinging nettle juice as it contains some fatty groups and as a result slight increment was noticed. Previous studies conducted on ice cream developed by ultrasound technology from tomato seed oleogel were in the range of 10.15 ± 0.09 to 13.80 ± 0.07 (g/100 g)[32].

Determination of mineral content

-

The elemental analysis of the control ice cream sample is rich in compounds like Ca (921.76 mg/kg), Na (138.45 mg/kg), then Mg (170.48 mg/kg), and least Fe (Table 5). The ice cream formulated with the incorporation of stinging nettle is rich in Ca (2,172.71 mg/kg), Na (1,473.18 mg/kg), and it also contains Mg (210.22 mg/kg) but the least is Fe. The increase in mineral content is owing to the presence of minerals in stinging nettle juice which could be beneficial for the uptake of micronutrients from desserts. Similar effects on the elemental composition of ice cream samples, especially an increase in the rates of Ca, K, Mg, and P were observed when flour of peach pulp and peel were incorporated in ice cream[35].

Table 5. Elemental analysis of control ice cream and U. dioica extract incorporated ice cream.

Element Control ice cream U. dioica extract incorporated

into ice creamCa (mg/kg) 921.76 2,172.71 Fe (mg/kg) 0.12 0.10 Na (mg/kg) 138.45 1,473.18 Mg (mg/kg) 170.48 210.22 Texture profile analysis

-

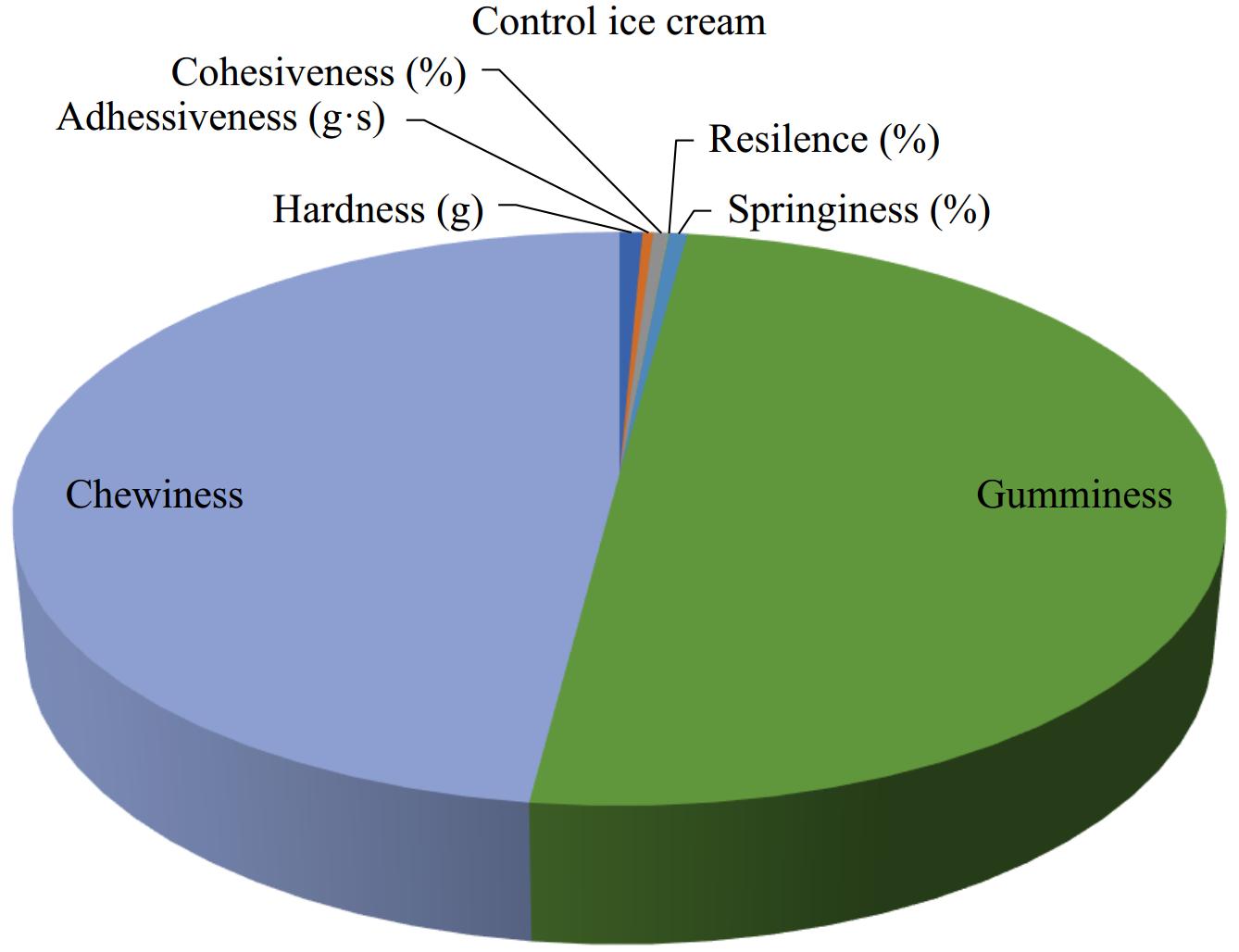

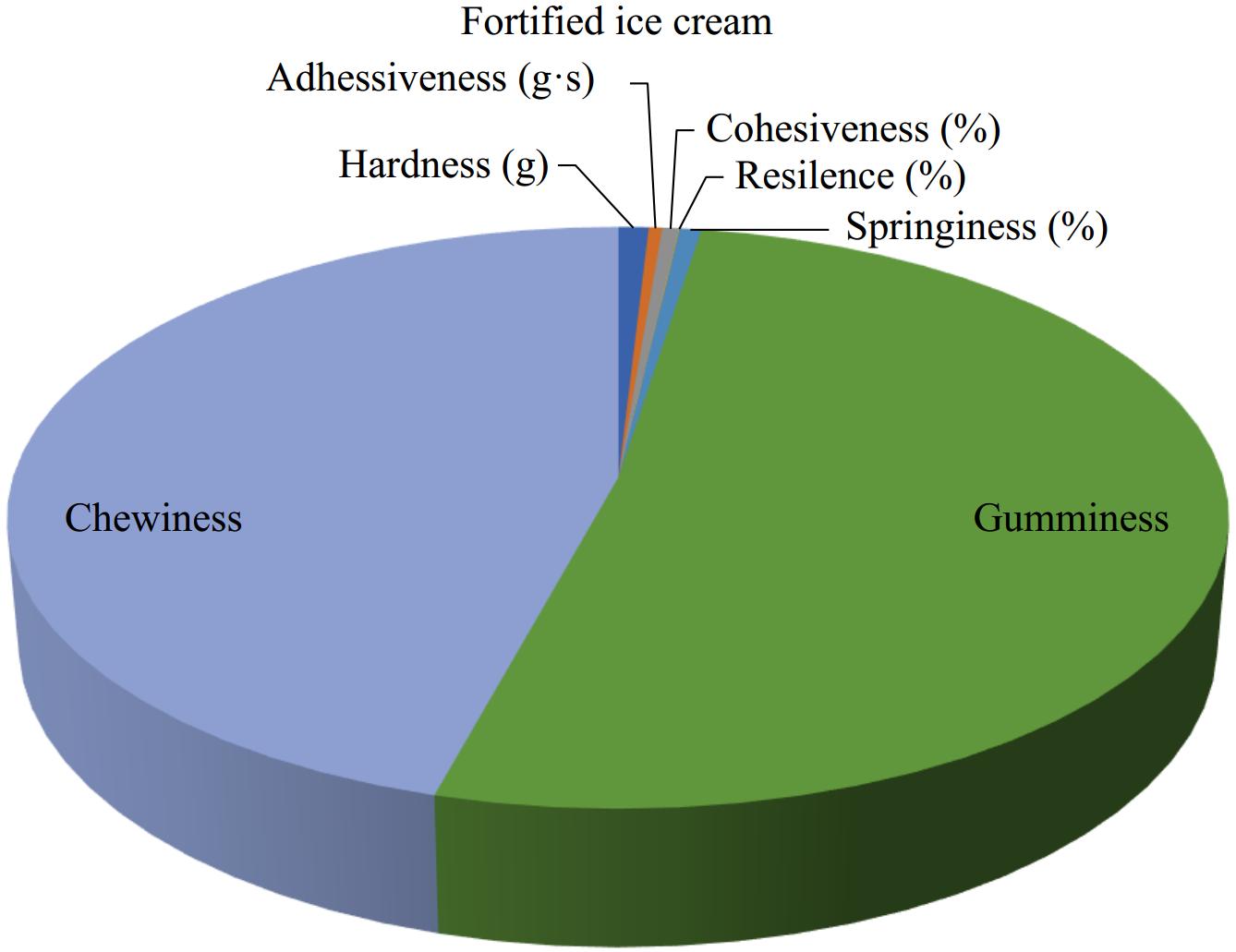

A common technique for assessing the textural qualities of food goods, including ice cream, is texture profile analysis (TPA). TPA entails applying controlled compressive forces on a sample of ice cream and utilizing a texture analyzer to evaluate the reaction. Some of the important textural factors that are frequently assessed in TPA for ice cream include the following: Hardness, cohesiveness, gumminess, springiness, chewiness, adhesiveness, and resilience. These textural parameters are measured during both the compression (first cycle) and relaxation (second cycle) of the sample. The TPA profile of the control and test T2 sample is present in Table 6 and Figs 4 & 5 respectively. The hardness, adhesiveness, and resilience of the ice cream was increased although the changes were not very significant, on the other side the cohesiveness, gumminess, chewiness and springiness of the ice cream sample reduced. The changes in TPA profile could be due to the additives as well as interaction between the biomolecules and bioactive ingredients. In case of rowanberry pulp incorporated ice-cream, the hardness values of the ice cream products varied between 236.80 (g) and 494.50 (g) for control and treatment group, respectively. The increase in hardness values on TPA is similar to the present study[34].

Table 6. Texture profile analysis of control ice cream and U. dioica extract incorporated ice cream.

Sample Control ice cream U. dioica extract

incorporated

into ice-creamHardness (g) 118.01 ± 66.36 124.05 ± 79.64 Adhesiveness (g·s) −58.076 ± 38.25 −55.554 ± 52.20 Cohesiveness (%) 76.433 ± 15.99 68.156 ± 26.84 Resilence (%) 2.172 ± 0.06 2.704 ± 2.13 Springiness (%) 96.4027 ± 1.837 89.253 ± 9.94 Gumminess 8,313.52 ± 2,622.33 7,032.35 ± 1,305.98 Chewiness 7,984.22 ± 2,364.81 6,220.78 ± 946.21 FTIR

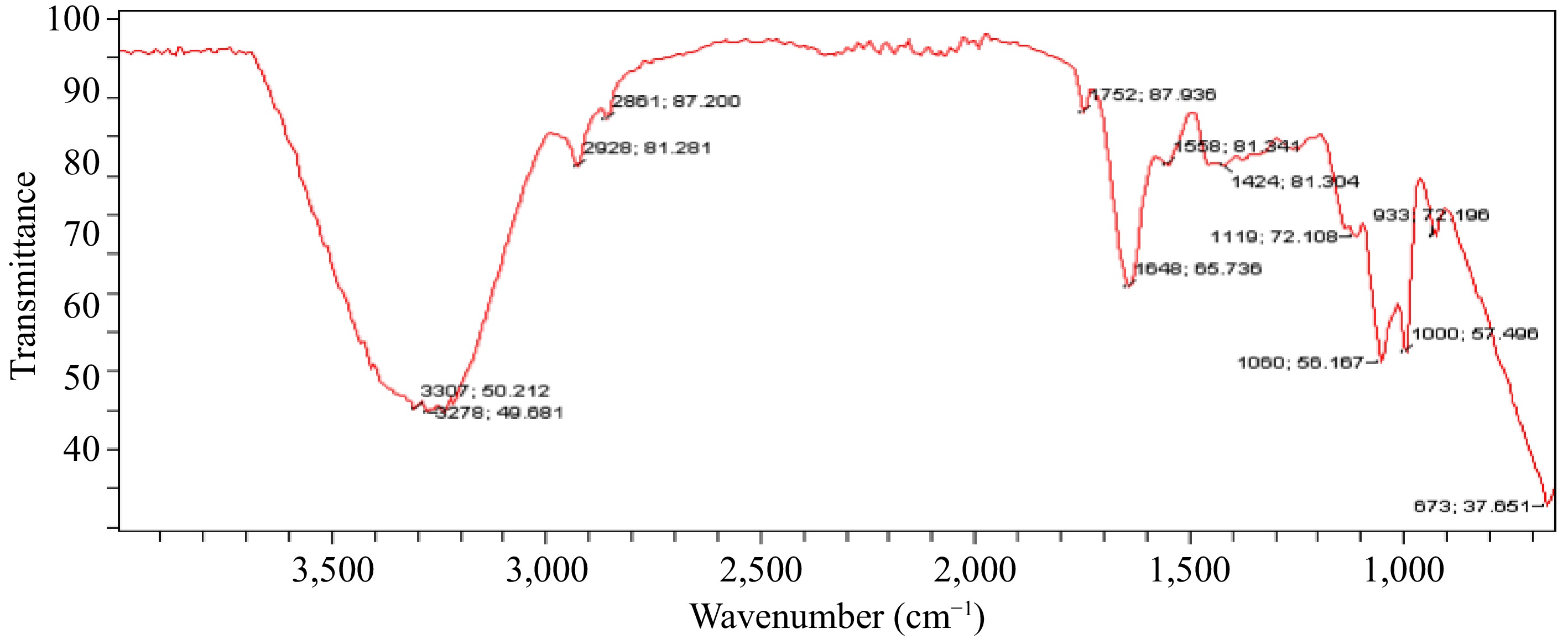

-

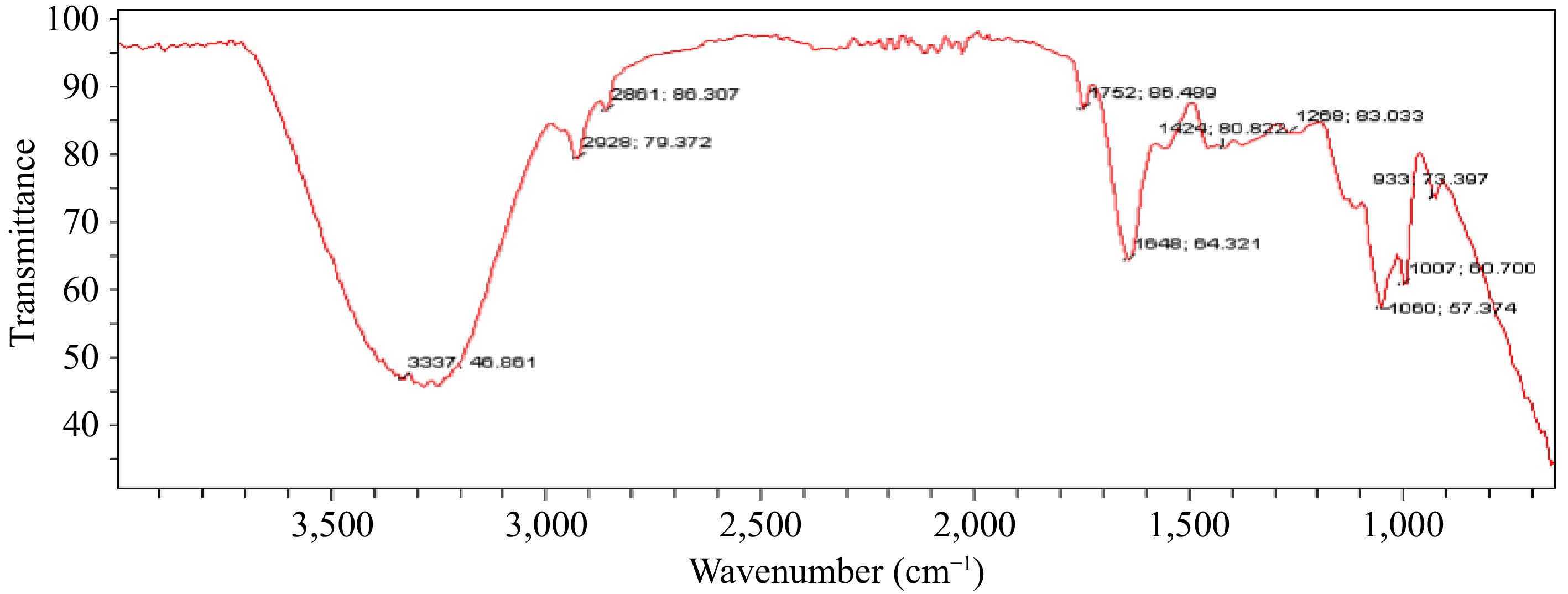

The FTIR analysis of the U. dioica incorporated ice cream was conducted, and spectra in the range of 3,500−1000 cm−1 were observed (Figs 6 & 7). The FTIR spectra had multiple peaks, only the sharpest ones were chosen for further analysis. Asymmetric and symmetric C-H stretching can be seen between the range 2,850 and 2,960 cm−1. The C-H bending, and C-C-H stretching results in bands between 1,400 and 1,477 cm−1, and 900−1,200 cm−1 are caused by C-O-C vibrations. The fingerprint region lies between 1,300–400 cm−1, the C-C region lies between 1,100−1,400 cm−1, the carbonyl group (C=O) stretch region lies between 1,800–1,600 cm−1 and the C-H stretch region lies between 3,200–2,800 cm−1, the alteration between the wavelength of control ice cream sample and U. dioica incorporated sample is less but still because of the stinging nettle incorporation the FTIR peak has been changed slightly. The slight changes in FTIR peak in presence of stinging nettle could be due to the physical interaction between the biomolecules and bioactive compounds[36].

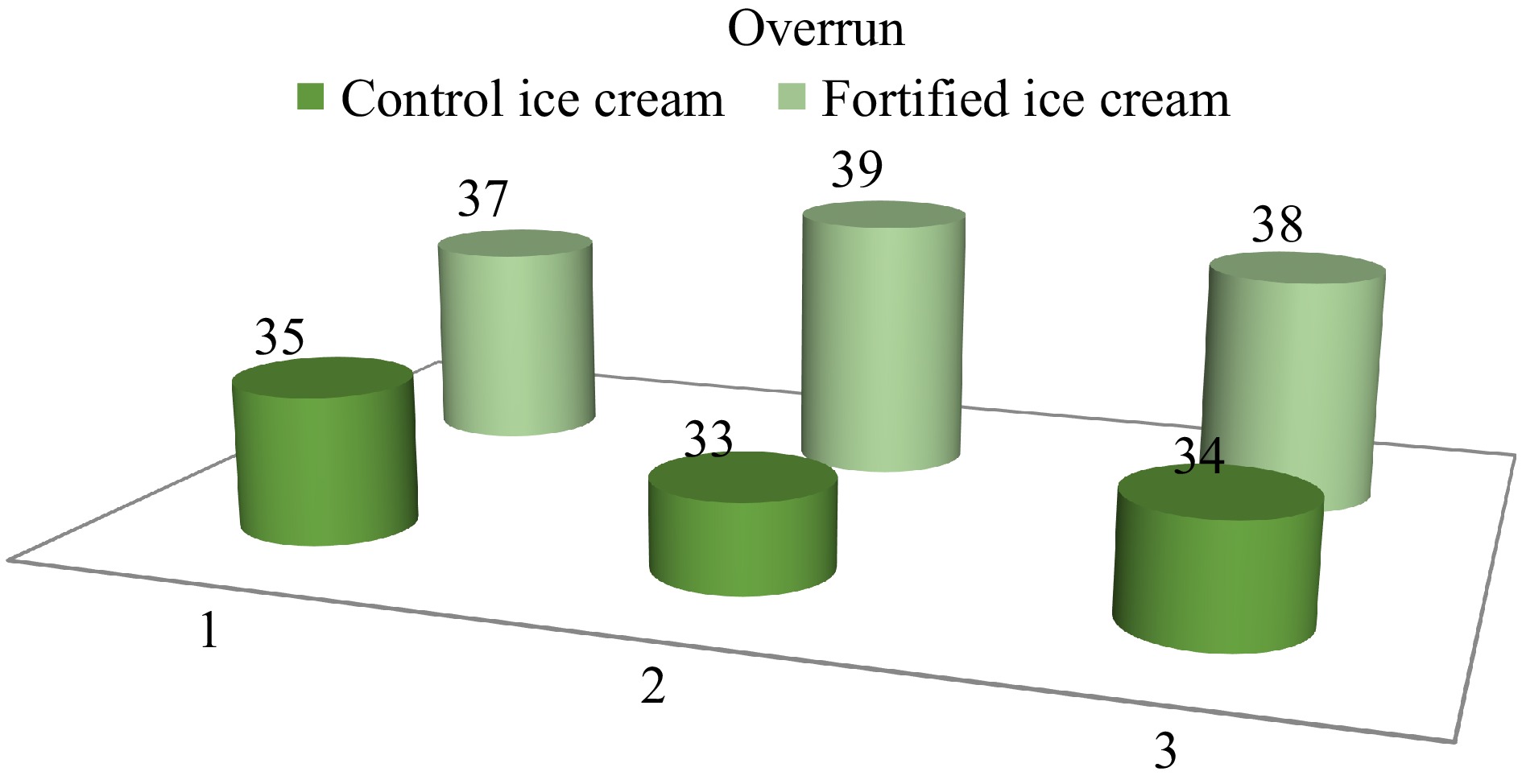

Overrun

-

The mouthfeel, creaminess, and texture of ice cream an important factor determined based on overrun. By comparing the increase of the ice cream mixture volume to the volume of the base mix before freezing, the overrun percentage is determined. Various elements, including the recipe, the components, and the production method, might affect the quantity of overrun. Ice cream is often manufactured with an overrun of 25% to 100%. Lower overrun results in a denser and richer texture, whereas higher overrun typically results in a lighter and softer ice cream (Fig. 8). The ice-cream mixes contents and the production process, together with the extrusion and homogenization phases, were factors in the study by Yangilar[37] that affected the overrun (air inclusion) of ice cream. High-pressure homogenization generated ice cream with a lower overrun than conventional homogenization, according to research[38].

Figure 8.

Overrun of control ice cream and fortified ice cream (T2) at different time gaps to incorporate air and check the weight after freezing.

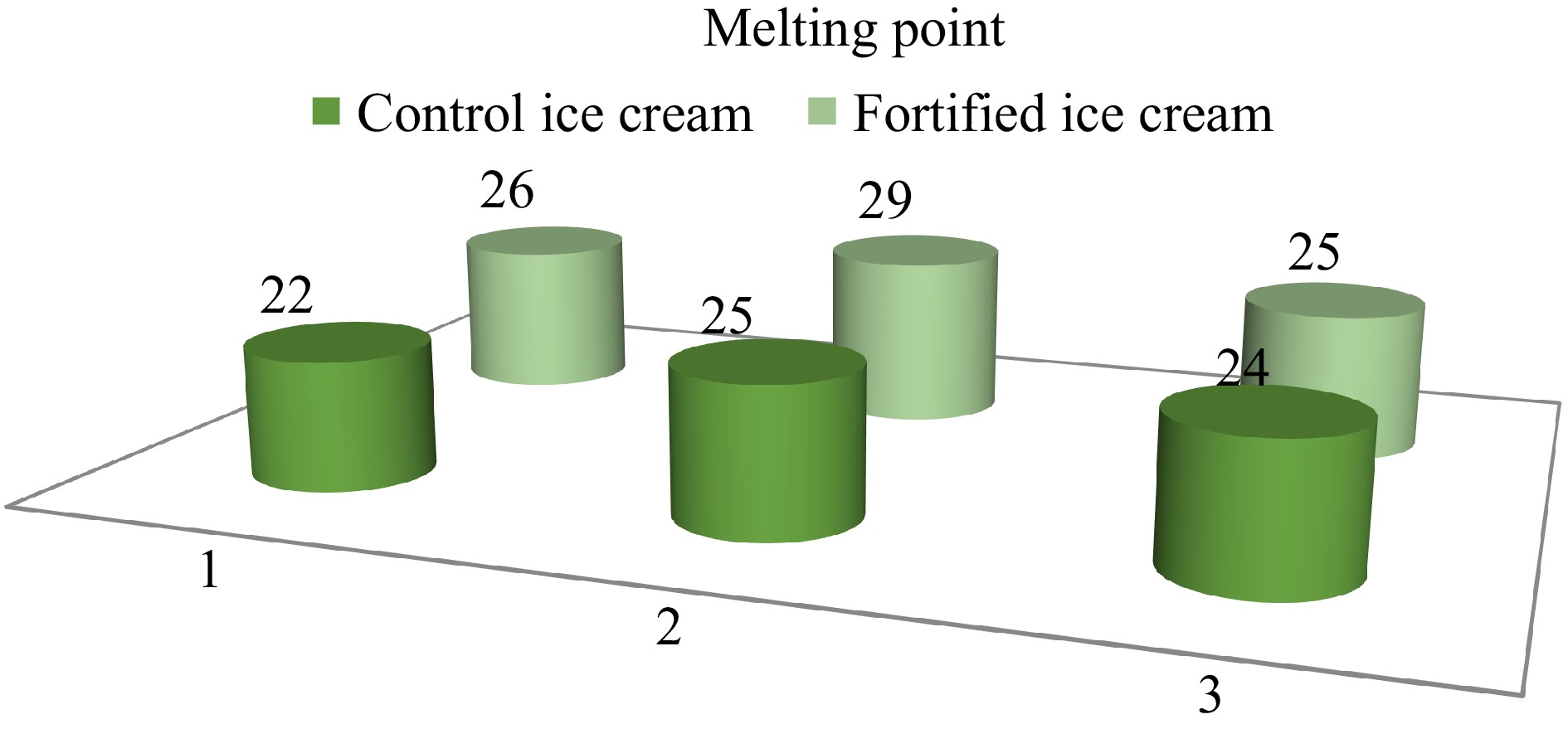

Melting behaviour

-

Ice cream's melting behaviour is a crucial aspect that affects the flavor and quality of the product. As it changes from a solid to a liquid state, ice cream melts. Fats, sugars, and stabilizers are some of the substances in ice cream that most affect how it melts. Due to their capacity to create a stable network and obstruct the flow of water molecules, fats, especially milk fat, can contribute to a smoother ice cream with a slower melting rate. On the other hand, sugars can make ice cream more likely to melt since they reduce the freezing point. Emulsifiers and stabilizers play a part in regulating the composition and stability of ice cream, which impacts how quickly it melts. The control ice cream sample takes around 23.66 ± 2.31 min to melt down completely. In contrast, the fortified ice cream sample takes around 26.66 ± 2.08 min to melt down completely (Fig. 9). Both heat and mass transfer phenomena are involved in the melting of ice cream. The ice crystals melt when heat from outside the ice cream enters the interior. The water that is generated diffuses into the texture of foam and drips[39,40].

-

Fortified ice cream prepared by the inclusion of stinging nettle in ice cream offers the possibility of incorporating its nutritional compounds, vitamins, and potentially beneficial bioactive compounds into a tasty dessert. While stinging nettle itself has a long history of traditional use and shows promise in various areas of health, including anti-inflammatory and antioxidant effects, it is essential to recognize the specific health benefits of stinging nettle ice cream. It can be observed that the ice cream color changed from creamy white to pale green to light green and finally dark green depending on the content of the stinging nettle leaf extract. This ice cream qualifies as functional ice cream because it contains bioactive substances that a typical dairy product does not, such as phenols (22.19%) and antioxidants (38.33%). The ice cream's calcium content, including stinging nettle, is high (2,172.71 mg/kg), as is the sodium content (1,473.18 mg/kg). There is also a small amount of iron and magnesium (0.10 and 210.22 mg/kg, respectively). Ice cream's shelf life can change based on formulation, storage circumstances, and the use of stabilizers or preservatives, among other things. To preserve its quality and reduce the rate of deterioration, ice cream should be refrigerated below freezing, often at a temperature of −18 °C (0 °F). Texture alterations, the development of ice crystals, and quality deterioration might result from frequent temperature changes or extended exposure to higher temperatures. For consumers who enjoy novel and unique ice cream flavours and are interested in exploring the potential benefits of stinging nettle, fortified ice cream with stinging nettle can be a fascinating option. Future studies should concentrate on the long-term impacts on health and the best degrees of fortification to maximize nutritional value while retaining sensory appeal.

-

The authors confirm contribution to the paper as follows: study conception and design: Singh A, Chandel V; experiment performed: Singh A, Amarnath V, Bhtoya R, Lukram M; draft manuscript preparation: Singh A, Chandel V, Roy S; figures preparation: Singh A, Chandel V, Biswas D; manuscript review & editing: Chandel V, Roy S, Biswas D. All authors reviewed the results and approved the final version of the manuscript.

-

All data generated or analyzed during this study are included in this published article.

-

We are grateful to Shoolini University for providing us with all the facilities.

-

The authors declare that they have no conflict of interest.

- Copyright: © 2025 by the author(s). Published by Maximum Academic Press on behalf of Nanjing Agricultural University. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Singh A, Chandel V, Velmurugan A, Bhtoya R, Lukram M, et al. 2025. Development of ice cream nutritionally enriched with Urtica dioica extract. Food Materials Research 5: e003 doi: 10.48130/fmr-0025-0002

Development of ice cream nutritionally enriched with Urtica dioica extract

- Received: 06 November 2024

- Revised: 31 December 2024

- Accepted: 17 February 2025

- Published online: 27 March 2025

Abstract: Stinging nettle (Urtica dioica), a rich source of vital minerals and bioactive components with many health-improving effects, was utilized as an ingredient for the development of popular frozen treat ice cream. The ice cream was prepared by incorporating stinging nettle juice in five treatments at a concentration of 5%, 10%, 15%, 20%, and 25%. Among these treatments, ice cream containing 10% stinging nettle extract was adjudged best based on organoleptic evaluation. The analysis revealed that stinging nettle ice cream was rich in bioactive components like phenols 22.12% and antioxidant activity 49.44%. Among minerals stinging nettle ice cream contains a good amount of calcium (2,172.71 mg/kg) and sodium (1,473.18 mg/kg) and it also contains iron (0.10 mg/kg) and magnesium (210.22 mg/kg) but in less quantities. Stinging nettle fortification offers a chance to improve the nutritional profile of ice cream without jeopardizing its pleasant qualities.

-

Key words:

- Ice cream /

- Fortification /

- Stinging nettle /

- Functional food /

- Nutritional composition /

- Sensory evaluation.