-

With the improvement of residents' living standards, cold chain meat has become the mainstream of people's daily consumption due to its unique taste, rich nutrition, high food safety and other advantages[1]. However, there are some problems in the function of processing, storage, logistics and sale of meat, such as the contamination of spoilage microorganisms and food borne pathogens, which is at present, the biggest risk faced by cold chain meat products[2]. Temperature is the most critical factor affecting the spoilage of meat in the cold chain[3]. At present, the low temperature of the cold chain system can inhibit the growth and reproduction of microorganisms[4], effectively delaying their spoilage and ensuring the safety of consumers[5]. There are some problems in the process of cold chain transportation in China, such as complex environments and lack of supervision[6]. This will cause problems such as frequent temperature fluctuations during transportation and difficulty in effective supervision[7]. Eventually, it will lead to cross-contamination of products in the process of logistics and sales. Temperature fluctuations can accelerate the growth and reproduction of microorganisms, speeding up the process of meat spoilage and seriously threatening the economic income of meat enterprises and consumer health[8]. Therefore, how to monitor the freshness and retain shelf life of cold chain meat real time is one of the key issues that needs to be solved.

For information systems for cold chain meat supervision, the main focus is traceability system research, such as the study by Eskil Forås et al. based on EPCIS and RFID technology to supervise the real-time temperature information of cold chain meat in the process of supply chain and improved the traceability of cold chain meat[9]; He et al. developed a whole-chain food safety supervision cloud platform based on QoS technology, which enables food safety to form a whole-chain closed loop from the source to the end, realizing process tracking, risk warning and traceability of the whole food chain[10]; Tang et al. built a cold chain food quality and safety supervision platform based on blockchain technology to effectively supervise and trace abnormal monitoring indicators and products[11]. Most information systems focus on the post-facto traceability of abnormal products, which is not timely and lagging behind. Compared to the post-facto traceability of abnormal products, it is more important to monitor and warn the products in real time, which is still lacking, and is not conducive to real-time monitoring of products by enterprises, consumers and regulatory authorities. In terms of predictive model database construction and expert systems, there are already some mature three-tier predictive microbial model expert systems at home and abroad, such as the Pathogen Modeling Program (PMP) developed by the US Department of Agriculture[12]; Food Micromodel (FM) developed by the UK Ministry of Agriculture, Fisheries and Food[13]; ComBase Predict developed by the UK Institute of Food Research, the US Department of Agriculture Research Centre, etc. ComBase Predictor (CP), developed jointly by the UK Food Research Institute and the US Department of Agriculture[14]. However, in terms of industrial food applications, there is an urgent need to solve the problem of how to make better use of expert systems and microbial prediction model databases to achieve practical industrial and intelligent regulatory applications.

In view of the above problems, this paper developed an intelligent monitoring system for cold chain meat freshness which is effectively combined with industrial application. The system is developed with B/S architecture and divided into five core functional modules, which are multi-role login module, big data visualization display and analysis module, product information management module, product quality real-time supervision module and system user management module. The system is designed to monitor the freshness of cold chain meat in the whole industrial chain in real time, to achieve real-time monitoring of product quality by managers, business users and consumers, and to ensure the safety of cold chain products.

-

Cold chain meat in the storage, processing, logistics and sales process, due to the implementation of cold chain system standards are not in place, the production and circulation and sales process of the cold chain logistics system is not sound, and the transport environment is complex, involving a wide range of unexpected circumstances and difficult to control, often leading to its cold chain meat spoilage. On the other hand, the freshness and quality of cold chain meat during the logistics and sales process is difficult to obtain directly, resulting in a delay in handling abnormal information, causing waste and even affecting the health of consumers.

Therefore, it is possible to provide business users with accurate, real-time product quality analysis by developing a cold chain meat wisdom supervision system that predicts cold chain meat freshness indicators through dynamic collection of product-related environmental information and displays freshness and shelf life in real time in the form of statistical charts, to quickly deal with abnormalities, reduce business costs and ensure food safety.

System development module analysis

-

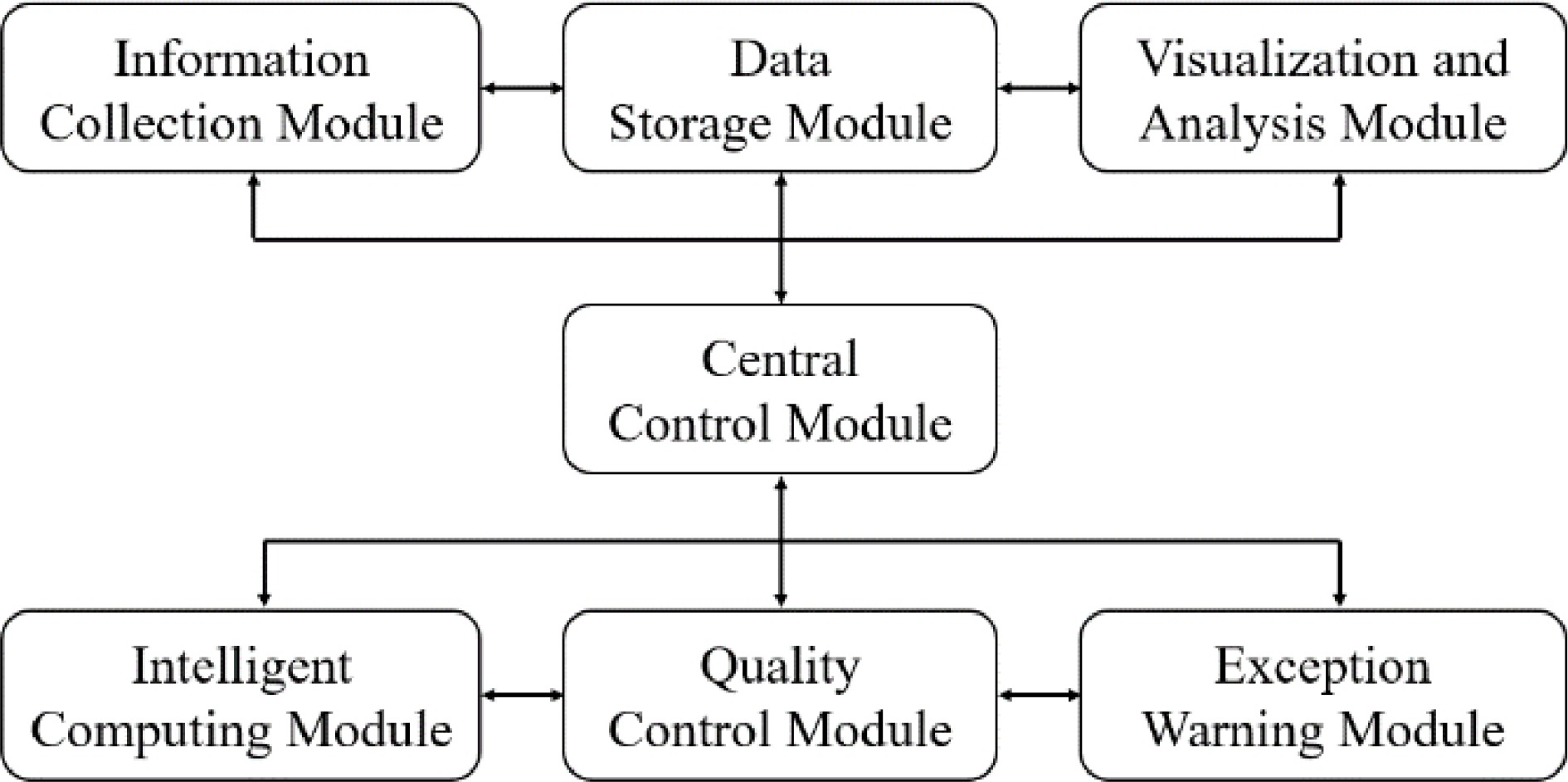

The overall system development module is divided into seven parts, namely the central control module, information collection module, data storage module, visualization and analysis module, intelligent computing module, quality supervision module and abnormality warning module. The system module diagram is shown in Fig. 1.

1) The central control module is the core module of the system, sending automatic operation instructions to the system data acquisition, transmission, computing and other modules, completing different tasks by calling different modules, coordinating the various collaborative functions between modules, and at the same time allowing module expansion of the system, leaving the application expansion interface for system perfection.

2) The information collection module is the data base module of the system, through multi-functional environmental sensors to collect the environmental information of the whole industrial chain of cold chain meat, real-time data transmission, to provide data support for system computing and big data analysis.

3) The data storage module is an important module of the system, which stores real-time monitoring information from environmental sensors and is called by other computing and supervision modules to complete the functions of cold chain meat wisdom supervision. At the same time, it integrates the multi-source heterogeneous data generated by various links in the whole industry chain to solve the problem of data silos generated by multiple systems. The data storage module stores the cold chain meat quality supervision information generated in the system operation to provide data support for the next big data analysis and wisdom warning.

4) The visualization and analysis module is the display module of the system, which displays and interacts with the key information collected by the system, the quality information obtained through computing and the abnormal warning information in the form of a visualization user interface, and provides the usual interactive functions of the system, integrating the functions of the underlying data storage and calling and intelligent computing, and finally displaying and interacting with them in the form of statistical charts.

5) The intelligent computing module is the signal interaction module of the system. Through the design of the computing logic between the system modules, the interaction relationship between different modules is clarified, and the intelligent signal interaction function is completed for the interaction flow of different data streams, so that the system modules can interact efficiently and complete the command computing function within the system.

6) The quality control module is the core business module of the system. Through information collection, data processing and arithmetic, the system can obtain the input parameters required for quality control in real time, and the input parameters are encapsulated by the underlying arithmetic functions in the quality control module to output quality control indicators, such as cold chain meat freshness level and shelf life information, which provide the basis for user decision making.

7) Abnormal warning module is the main function module of the system, through where quality supervision can obtain cold chain meat various real-time indicators, through the setting of abnormal warning indicators and thresholds, the quality supervision output parameters can be monitored in real time, monitoring indicators exceed the set threshold, then through a variety of forms of abnormal alarms, assist managers with timely intervention, reduce food safety risks and enterprise losses.

System design

The design of multi-tier system architecture for application requirements

-

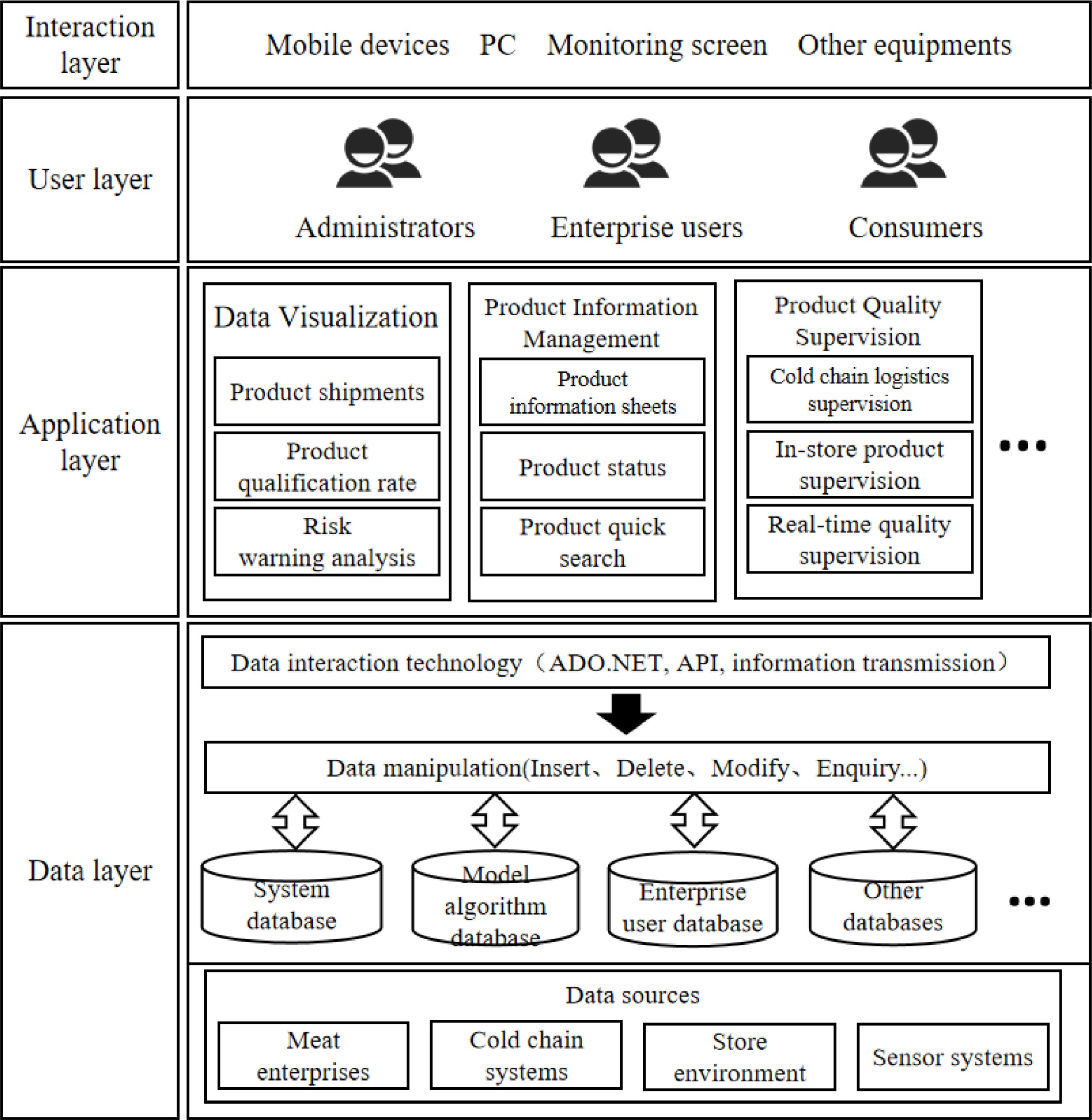

Through the demand analysis of this system, from the perspective of real-time supervision of cold chain meat quality, this system is developed using B/S structure (Brower/Server, browser/server mode)[15]. The system is divided into a four-layer structure from the perspective of the development technology architecture, which are the interaction layer, user layer, application layer and data layer. The overall system architecture is shown in Fig. 2.

1) The interaction layer, i.e. the development of the GUI (Graphical User Interface), is the bridge between the application layer and the user layer. Through the B/S structure combined with the visualization of the web front-end, the user logs in to the system from the browser side and carries out the corresponding big data viewing, product information query, product quality monitoring, warning information acceptance and abnormal situation handling operations in the system, and after the front-end interaction page obtains the corresponding form data, it is transmitted to the server for processing and adds, deletes, changes and checks the underlying database, and then outputs the operation results to the front-end page in the form of visualization. The operation results are then output to the front-end page in visual form to complete the interactive function.

2) The user level is the actual user of the system. Through the analysis of the system requirements, it is determined that the users of the system are divided into three roles, namely administrator, business user and consumer. Different roles have different requirements for the use of the system, where the administrator can view all users of the system, edit the use rights of each role, set the relevant parameters of the system, and is the highest level user of the system. Enterprise users can view the big data statistics of their products in the system, product information and product quality dynamics monitoring, etc. Consumers can log in to the system and scan the QR code of purchased products to view the current quality and shelf life of the products, assisting consumers in their product purchases.

3) The application layer is the core layer of the system, which can realize the overall business logic of the cold chain meat wisdom supervision system and achieve the overall operation of the required functions of the system, including big data statistics, real-time freshness status calculation, product shelf life calculation and user interaction logic during operation, and is the core layer of the system operation, with multi-functional interfaces, multi-source heterogeneous data processing and other important functions.

4) The data layer provides data services for the application layer, and the back-end database technology uses MySQL database management system for data management. The data layer uses ADO.NET, data API information bi-directional transmission technology for data addition, deletion and checking operations, and the database for operations is divided into system database, model algorithm database, enterprise user database and other required databases. This data layer data source is multi-source heterogeneous data, the main data come from sources such as meat enterprises, cold chain systems, shop environments and sensor systems. The multi-level data sources help the system to obtain comprehensive and accurate information.

System core business process design

-

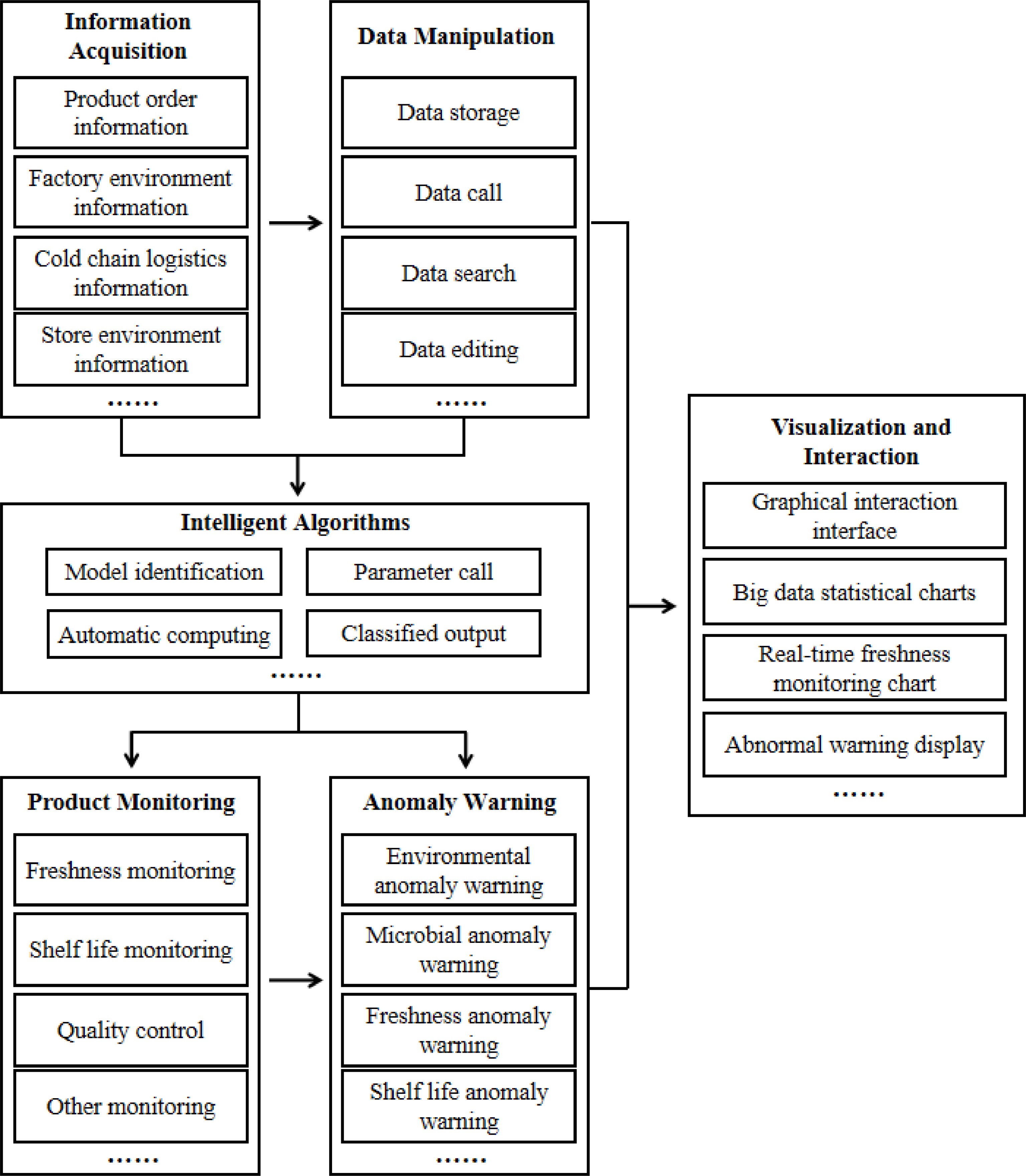

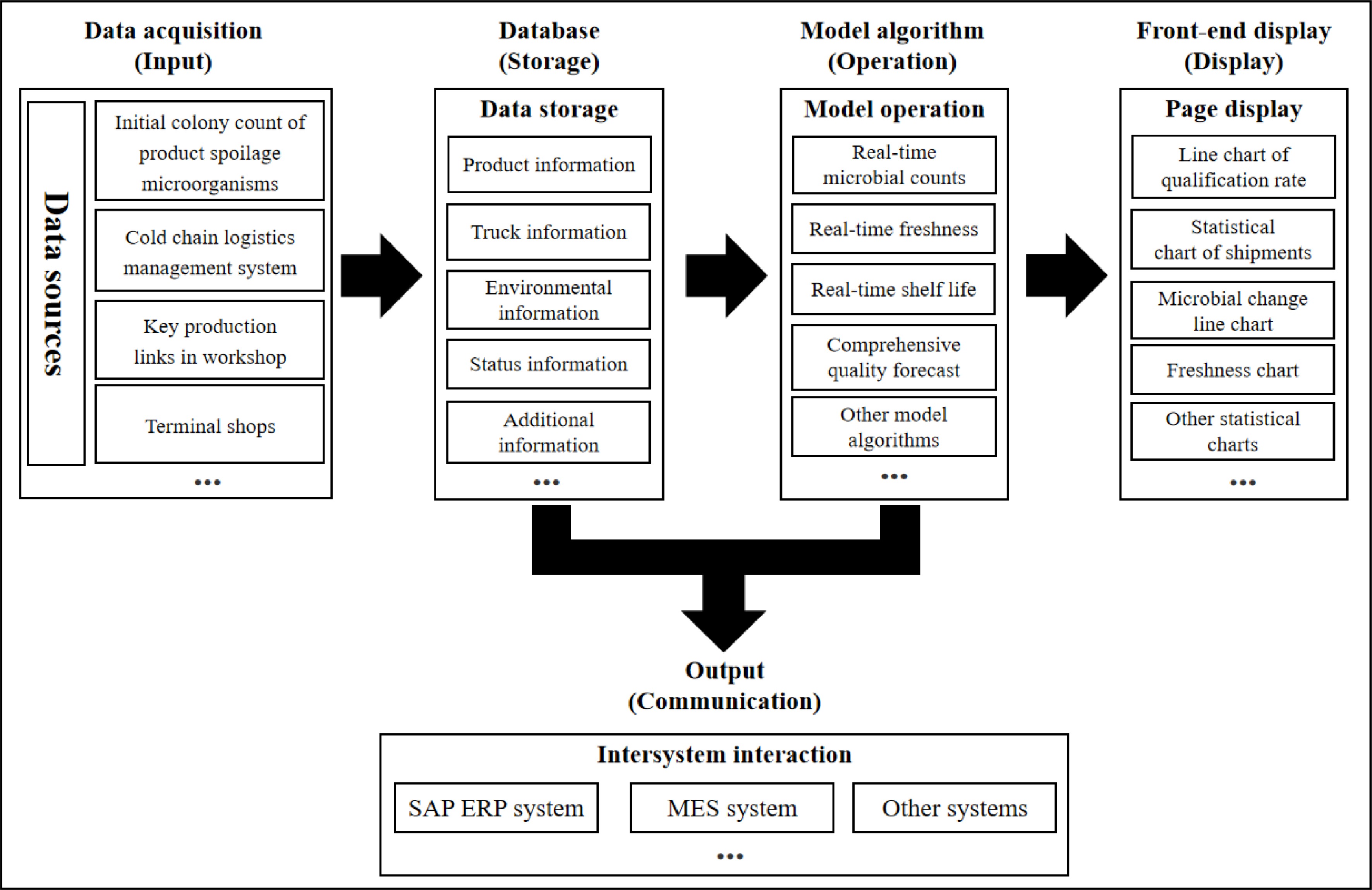

The core business process of the system is designed so that the system can complete the intelligent supervision function of cold chain meat. The system firstly goes through information collection, collecting multiple sources of heterogeneous data such as order information, factory environment information, cold chain logistics information and shop environment information. The collected data is categorized and stored in a database and awaits operations such as retrieval, recall and editing. The intelligent algorithm automatically acquires the real-time collected data, selects different models for different products, inputs the corresponding parameters for automatic operation and outputs the results in a classified manner. After the output results are passed through the product monitoring module, the current product quality situation is resolved and the real-time supervision function is completed. The abnormal warning module monitors the product quality in real time and provides an abnormal warning if the monitoring threshold is exceeded. Ultimately, the information and data analysis statistics are displayed and interacted with on the visualization interface, making it easy for managers to operate the system. The core business process of the system is shown in Fig. 3.

System database design

-

The system database is designed according to the SQL (Structured Query Language) standard based on the overall business process and the data flow generated by the system. The development process includes defining the relational schema, creating data tables, and adding, querying, modifying, and deleting data tables, etc. The database should have efficient and flexible data manipulation functions. In the database design, in order to facilitate the use of functional modifications, there is also a need for good secondary development and extension functions.

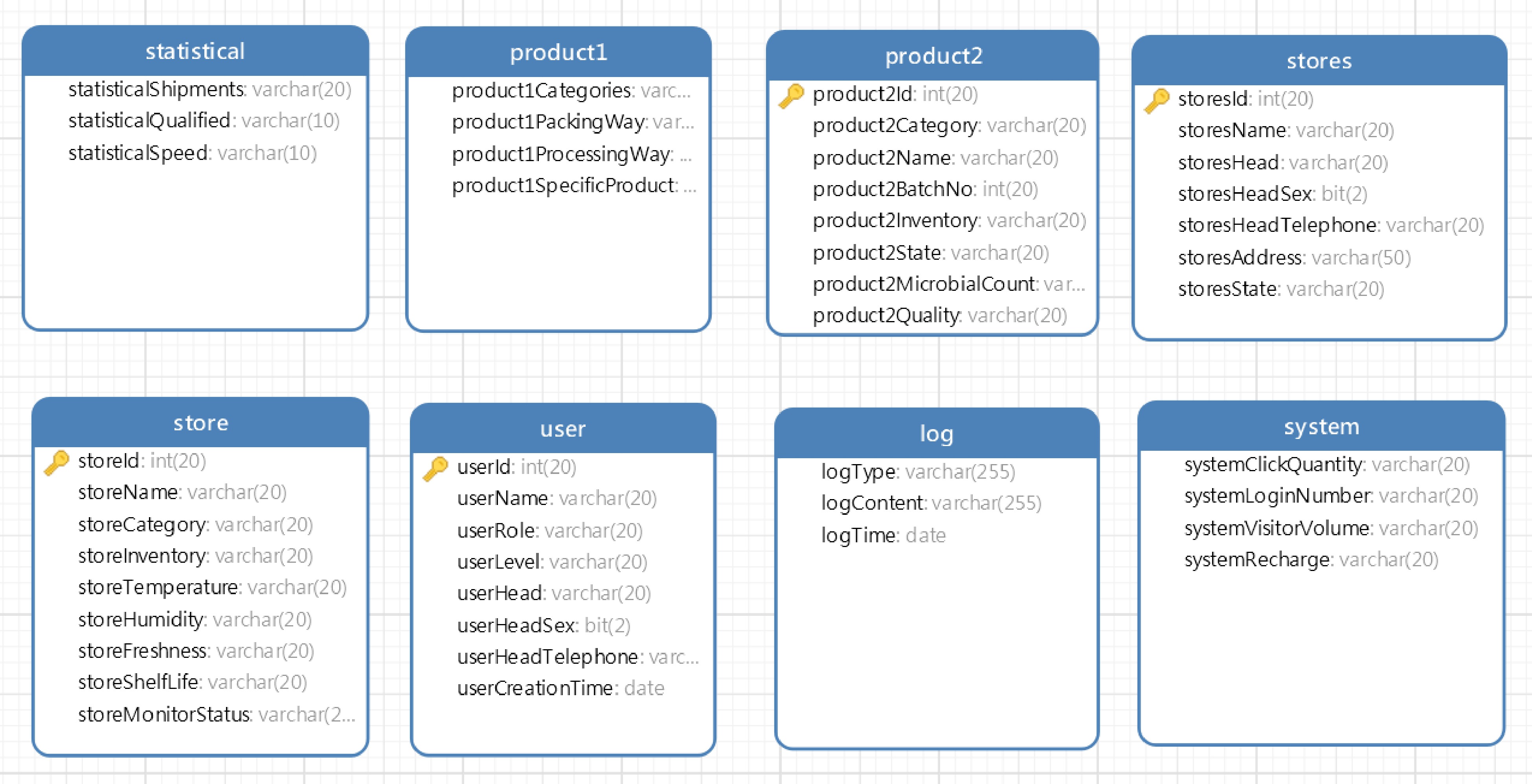

Based on the actual needs of this system, the core data tables created are: big data statistics table, product category table, product information table, shop information table, shop product monitoring table, user table, system operation log table, and system general data table. These core data tables complete the standardization of heterogeneous data from multiple sources for this system's products, storing detailed information on product freshness and remaining shelf life during storage, processing, logistics and sales.

System function design

-

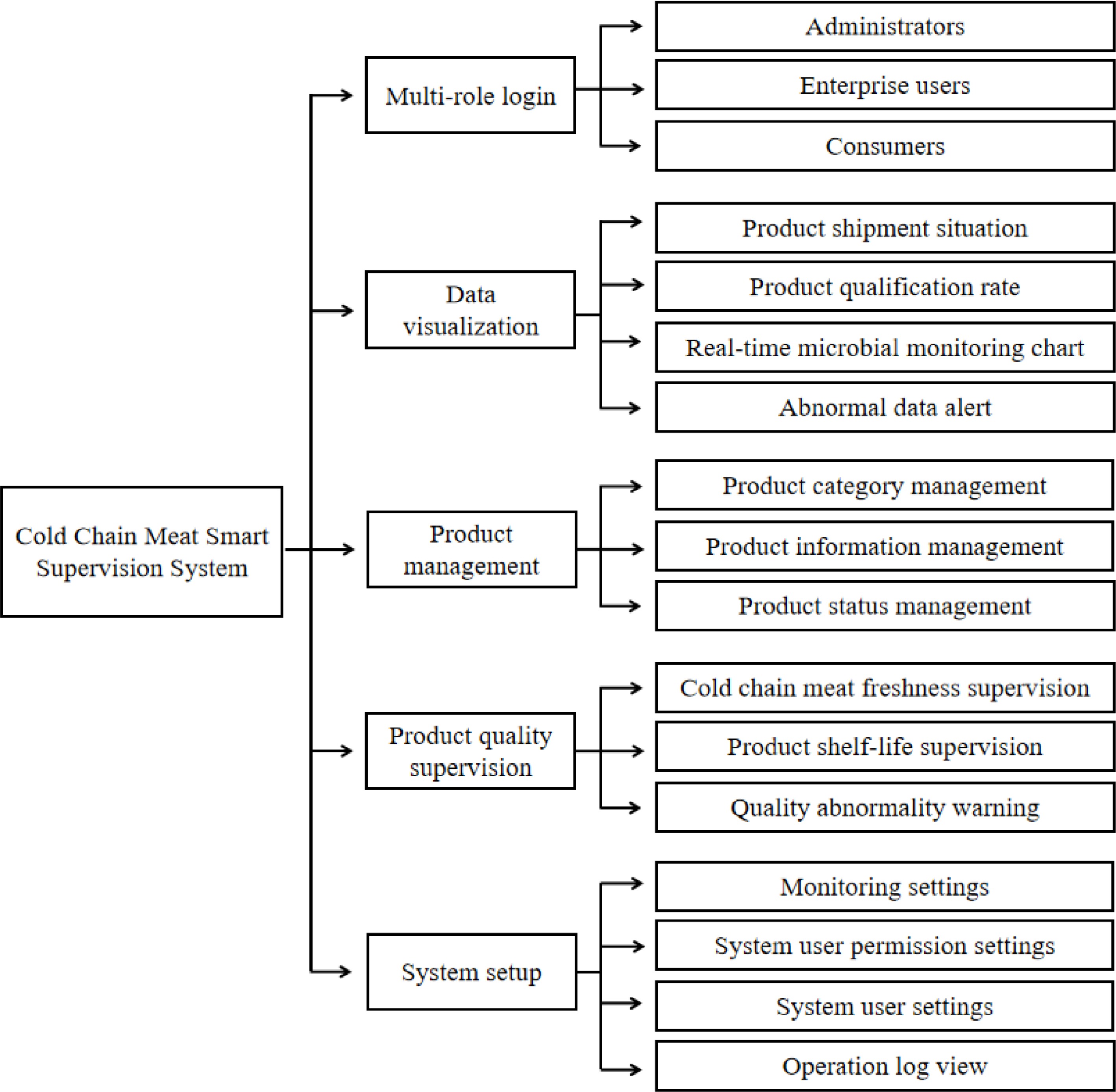

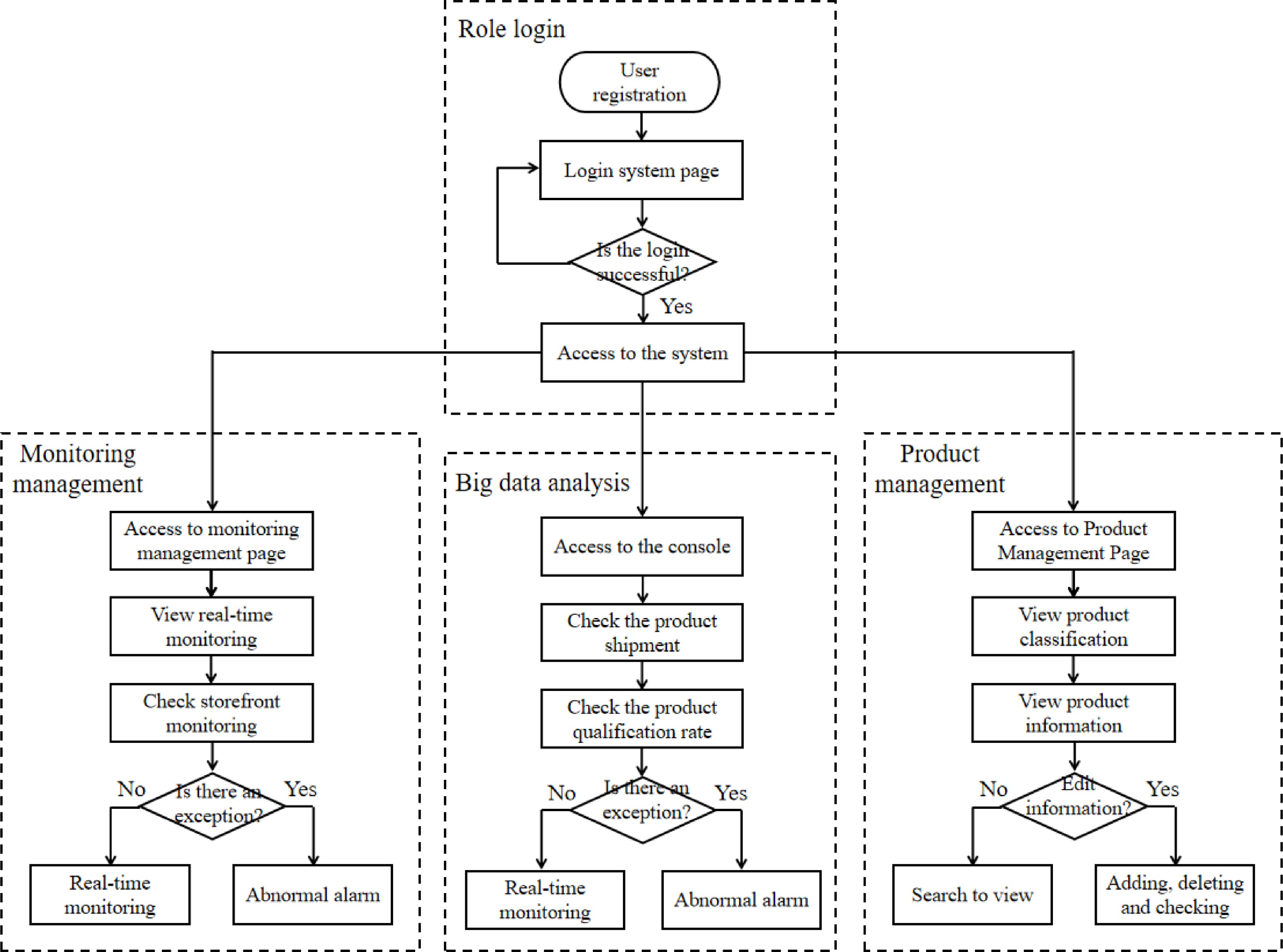

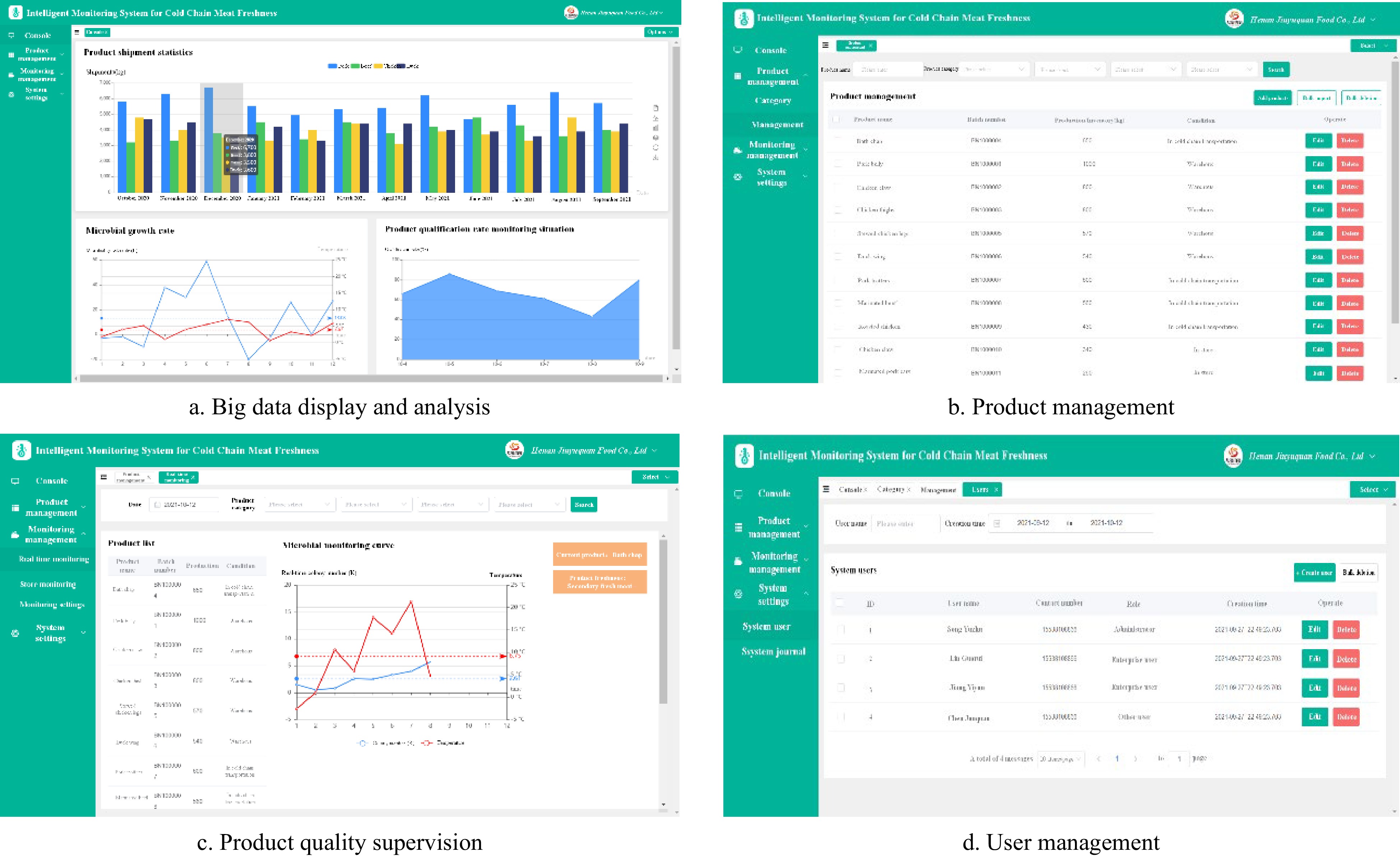

According to the system requirements, the core application functions of the system are set up in five modules, namely: multi-role login module, data visualization module, product management module, product quality supervision module and system setting module, and the system function design diagram is shown in Fig. 4.

1) Multi-role login module. There are three roles: Administrator, Enterprise User and Consumer. Each role has different requirements for the use of the system, different setting permissions and different interaction pages. The Administrator role is the highest level role in the system. This role allows you to view all registered users of the current system, view information and permission settings for each enterprise user, set global settings for common functions of the system, and update and maintain the system. Enterprise users can view the product information and real-time status of all cold chain meat products of their enterprises. By viewing the real-time monitoring information of products, we can handle abnormalities and reduce losses in time. The consumer role can scan the product QR code information to view the quality history of the product and provide scientific advice on purchasing behavior.

2) Data visualization module. It is divided into product shipment, product qualification rate, microbial real-time monitoring chart, abnormal data warning and other functions, the most concerned product data for enterprise users to carry out data statistics, and presented in bar graphs, line graphs, pie charts and other visual statistical charts, so that enterprise managers can understand the product situation of this enterprise in a timely manner, to assist enterprises in decision-making and abnormal situation emergency and processing.

3) Product management module. It was divided into product category management, product production information management, product status management and other functions. It can complete the batch import of enterprise products, product category editing operation, product information retrieval and management, cold chain logistics product freshness quality monitoring, product status real-time view and other functions, so that the enterprise management personnel of this enterprise product specific information for unified management.

4) Product quality monitoring module. By collecting information on the environment in which the cold chain meat products are stored, processed, logistically and sold, we can obtain key environmental information. After analyzing the environmental information, real-time spoilage microbial logarithm values are calculated by freshness and remaining shelf life algorithms. The calculated results are compared with the freshness threshold to derive real-time product freshness and remaining shelf life. It also provides alarms for abnormal situations in the monitoring process, so that enterprise managers can deal with abnormal situations in a timely manner.

5) System settings module. This is divided into monitoring settings, system user rights settings, system user settings and operation log viewing. Monitoring settings can adjust the monitoring indicators in the system to make it more in line with the application requirements. The system user rights setting can set up different functions for different roles of the system, so that the system functions can meet the needs of different roles. The system user settings function allows you to view the information of all current system users and system usage, and to improve and upgrade the system functions according to the system suggestions submitted by users.

System implementation

System database development

System basic database development

-

This system is developed by using the relational database management system MySQL 5.7.31. MySQL is one of the best RDBMS (Relational Database Management System) applications for web applications[16]. By storing data in different tables and linking tables to each other, the speed of data storage and recall can be increased and the flexibility of the database greatly improved[17]. The development process was carried out in conjunction with Navicat for MySQL 15.0.22 visualization software, a fully featured graphical database development software that provides a powerful graphical interface for MySQL database management, development and maintenance.

Using MySQL to create a cold chain meat system database, as the general database of the cold chain meat wisdom supervision system, according to the system requirements, through the E-R diagram (entity-relationship diagram), to build the data relationship of different tables in the database, the cold chain meat wisdom supervision system database to build 8 data tables, respectively, are big data statistics table, product type table, product information table, shop information table, shop product monitoring table, user table, system operation log table, system general data table, the above data tables store all the interaction data of the system for transmission through the data transmission interface API, so that the system computing module and the front-end visualization page can quickly call and edit the data. The database structure is shown in Fig. 5.

Database development of prediction model for freshness and shelf life of cold chain meat

-

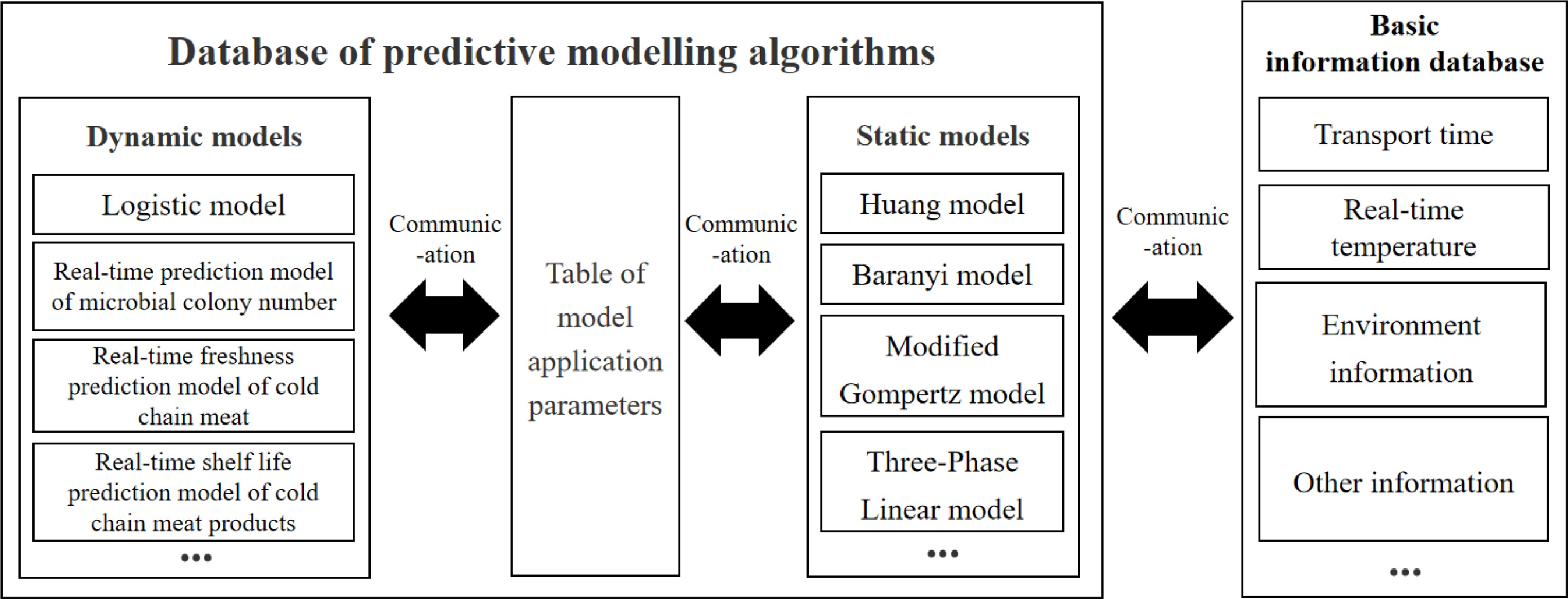

The prediction model database is an important part of the system, providing data and algorithm support for the inter-system model operation, and the intelligent operation module of the system.

The prediction model database should contain two main functions. Firstly, it needs to contain a wide range of realistic operational models required for cold chain meat quality prediction and contain the growth parameters of different cold chain meat spoilage microorganisms for the algorithm to call. Secondly, model parameters for other cold chain meat spoilage microorganisms can be uploaded at a later stage to continuously expand the product envelope included in the database for different cold chain meat industry informatics applications. The structure of the predictive model algorithm database is shown in Fig. 6.

Front end page development

-

The front-end visual interaction page of the system is developed using the B/S structure (Browser/Server mode). The B/S structure uses the working mode of browser request and server response. Users can quickly request and visit the distributed servers on the network through the browser[18]. The browser receives the request, which is processed by the server and transmitted to the front-end page for visualization.

The front-end development technology is developed using ASP.NET and combined with Vue.js 2.6 MVVM bi-directional data binding framework to achieve front-end page development[19], the statistical charts in the page are designed and developed using open source ECharts line charts, bar charts, pie charts and so on[20]. The front-end pages are divided into system introduction page, login page, console page, product management page, monitoring management page and system settings page.

Multi-system integration interface development

-

In order to better integrate this system with practical industrial applications, it is necessary to develop multi-system integration interfaces, and data communication between different systems to collect the required data for real-time supervision of the freshness and shelf life of cold chain meat products.

The system is interfaced with the cold chain logistics management system of 'Henan Jiuyuquan Food Co., Ltd', a sauce and marinated meat products company, with the initial colony count of spoilage microorganisms, real-time temperature and humidity of logistics trucks and other environmental information, key workshop points and terminal shop environmental information as data sources input and stored in the system database, different functional modules for data call.

As shown in Fig. 7, the data sources of the system are the initial colony count of product spoilage microorganisms, cold chain logistics management system, key production link points in the workshop and environmental information of the terminal shops, etc. The system collects data from the data sources and stores them in the system base database, the model database matches different products according to different product types, calls the relevant dynamic data in the base database, predicts the freshness and shelf life of the products in real time, and this is displayed on the front-end page of the B/S system to facilitate timely and effective management by the management staff. The output results and related data can also be exported to different systems through the data interface for statistical analysis.

-

The system tested the model algorithm using a shelf-life prediction model algorithm constructed by Sun for vacuum-packed raw beef, which identified Lactobacillus and Pseudomonas as specific spoilage bacteria for vacuum-packed raw beef products and constructed a specific spoilage bacteria growth model and a residual shelf-life model[21].

$ Y\left( t \right) = {Y_0} + \left( {{Y_{\max }} - {Y_0}} \right)exp\left\{ { - exp\left[ {\frac{{{\mu _{\max }}e}}{{{Y_{\max }} - {Y_0}}}\left( {\lambda - t} \right) + 1} \right]} \right\} $ (1) Eq. (1) is a modified Gompertz model, the first level of the microbial prediction model, used to describe the process of change in spoilage microorganisms over time, and is the basis of the freshness and shelf-life prediction model.

$ \sqrt {{\mu _{\max }}} = b\left( {T - {T_{\min }}} \right) $ (2) $ \sqrt {\frac{1}{\lambda }} = {b_\lambda }\left( {T - {T_{\min }}} \right) $ (3) Eq. (2) and Eq. (3) are square root models, which are secondary models of the microbial prediction model, used to describe the effect of temperature on the primary model and to determine the parameter values for specific growth rate and lag time in the primary model.

$ SL = \lambda - \frac{{{N_{\max }} - {N_0}}}{{{\mu _{\max }}e}}\left\{ {\ln \left[ { - \ln \left( {\frac{{{N_s} - {N_0}}}{{{N_{\max }} - {N_s}}}} \right)} \right] - 1} \right\} $ (4) Eq. (4) is a shelf-life prediction model, constructed based on a growth model of specific spoilage bacteria, which predicts the shelf-life of a product by calculating the time from initial colony count (N0) to minimum spoilage (Ns) of a specific spoilage bacteria.

$ MSE = \frac{{RSS}}{{n - p}} $ (5) $ RMSE = \sqrt {\frac{{RSS}}{{n - p}}} $ (6) $ AIC = n\ln \left( {\frac{{RSS}}{n}} \right) + 2\left( {m + 1} \right) + \frac{{2\left( {m + 1} \right)\left( {m + 2} \right)}}{{n - m - 2}}$ (7) Eqs (5), (6) and (7) are the assessed values of the model fit effect, where MSE is the mean square error, RMSE is the root mean square error and AIC is the Akaike information criterion. The above three equations are used to assess the prediction model non-linear fit effect.

The system was tested under the conditions shown in Table 1.

Table 1. System test conditions.

Test category Test condition Software Environment Net Framework4.6.2 + IIS7.5 + MySQL 5.7.31 Hardware environment CPU: 2×Intel Xoen quad-core X5530 2.40GHz or more RAM 8GB (4G*2) DDR3-1333 with fault-tolerant repair Hard Disk SAS10K 320GB × 4 (RAID5) Network Card 10/100/1000 MB Ethernet port × 2 A flow chart of the system in use is shown in Fig. 8.

Through system testing, the development of intelligent supervision system for cold chain meat was finally realized. The functional modules of the system run well and meet the trial needs of different roles, part of the system running effect diagram is shown in Fig. 9.

The system has been tested and used, you can login to the system through different roles. Display and analyze big data on the console page. Unified management and retrieval of enterprise products through tables to view product information. In the product quality supervision module, real-time supervision of cold chain meat freshness quality information and abnormal warning using different colors. In the user management module, you can view all user information of the current system and set user rights. After testing, the overall system works well and can complete the design functions of the intelligent supervision system for cold chain meat.

-

The proposed system combines technologies such as Web Internet and visualization, so that different users can use this system smoothly to complete the required functions. By constructing a cold chain meat freshness prediction model database to monitor the real-time freshness of cold chain meat in the whole industry chain process in real time. It also combines technologies such as Web Internet and visualization, so that different users can use this system smoothly to complete the required functions. The system enables different business users to monitor the quality of their products in real time without contact, and provide real-time warning of abnormalities, to assist business managers in making decisions, and to greatly reduce the losses caused by failure to obtain cold chain meat quality information in a timely manner. Consumers can also use the system to scan QR codes to obtain information on the quality of the cold chain meat products they buy and provide scientific buying advice.

This research was financially supported by the Major science and technology projects in Henan province (221100110500), the Science Foundation for Outstanding Youth of Henan Province (212300410008),and the Science and Technology Innovation Team of Henan Universities (22IRTSTHN021).

-

The authors declare that they have no conflict of interest.

- Copyright: © 2023 by the author(s). Published by Maximum Academic Press on behalf of Nanjing Agricultural University. This article is an open access article distributed under Creative Commons Attribution License (CC BY 4.0), visit https://creativecommons.org/licenses/by/4.0/.

-

About this article

Cite this article

Niu Z, Yang J, Zhu Y, Xu L, Yang S, et al. 2023. Development and design of an intelligent monitoring system for cold chain meat freshness. Food Materials Research 3:2 doi: 10.48130/FMR-2023-0002

Development and design of an intelligent monitoring system for cold chain meat freshness

- Received: 14 December 2022

- Accepted: 31 January 2023

- Published online: 28 February 2023

Abstract: Cold chain meat has become the main force of meat consumption in China due to its unique taste and rich nutrition. However, there are serious regulatory blind spots throughout the cold chain process, making it difficult to monitor the freshness quality and shelf life of cold chain meat in real time. Therefore, in this study, the dominant spoilage microorganism prediction model for cold chain meat was parsed to predict the logarithmic value of the dominant spoilage microorganism in real time based on temperature information, which was compared with the freshness quality threshold to derive real-time quality information. This paper proposes to develop the system with ASP.NET three-tier architecture as the development framework and .NET Framework 4.6.2 as the development environment. Combining MySQL 5.7.31 application database, Vue 2.6 and Apache ECharts front-end technology development a intelligent monitoring system for cold chain meat freshness. The system has five core application modules: multi-role login module, big data visualization and analysis module, product information management module, product freshness quality and shelf life real-time monitoring and warning module, and system setting module, to monitor the freshness quality and shelf life of cold chain meat products at all stages, real time. The development of this system can realize the real-time supervision of the quality of cold chain meat products in the whole industrial chain of processing, storage, transportation and sales, timely detect product abnormalities, provide technical support for food enterprises, and provide food safety assurance for consumers.

-

Key words:

- Cold chain meat /

- Quality prediction /

- Freshness /

- Intelligent supervision /

- System development